Iibhodi zeSekethe ezinaMacala amabini uMvelisi wePcb

Ubuchule beNkqubo yePCB

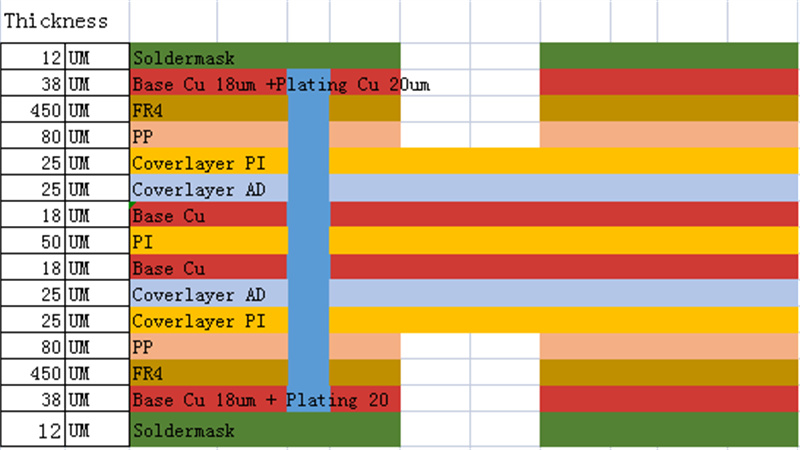

| Hayi. | Iprojekthi | Iimpawu zobugcisa |

| 1 | Umaleko | 1-60(umaleko) |

| 2 | Eyona ndawo yokusetyenzwa | 545 x 622 mm |

| 3 | Ubuncinci bokutyeba | 4(umaleko)0.40mm |

| 6(umaleko) 0.60mm | ||

| 8(umaleko) 0.8mm | ||

| 10(umaleko)1.0mm | ||

| 4 | Ubuncinci bobubanzi bomgca | 0.0762mm |

| 5 | Ubuncinci bezithuba | 0.0762mm |

| 6 | Ubuncinci bokungena koomatshini | 0.15mm |

| 7 | Umngxuma udonga lobhedu ubukhulu | 0.015mm |

| 8 | Metallized aperture tolerance | ±0.05mm |

| 9 | Unyamezelo lwembobo engenametali | ±0.025mm |

| 10 | Ukunyamezela komngxuma | ±0.05mm |

| 11 | Ukunyamezela komgangatho | ±0.076mm |

| 12 | Ubuncinci ibhulorho ye-solder | 0.08mm |

| 13 | Ukumelana ne-insulation | 1E+12Ω(eqhelekileyo) |

| 14 | Umlinganiselo wokutyeba kwepleyiti | 1:10 |

| 15 | Umothuko wobushushu | 288 ℃ (amaxesha ama-4 kwimizuzwana eyi-10) |

| 16 | Igqwethiwe kwaye igobile | ≤0.7% |

| 17 | Amandla okuchasana nombane | >1.3KV/mm |

| 18 | Amandla okuchasa ukuhluba | 1.4N/mm |

| 19 | I-Solder imelana nobunzima | ≥6H |

| 20 | Ukusilela komlilo | 94V-0 |

| 21 | Ulawulo lwe-impedance | ±5% |

Senza iPrototyping yeeBhodi zeSekethe ngamava angama-15 eminyaka ngobungcali bethu

Iibhodi ezi-4 zeFlex-Rigid

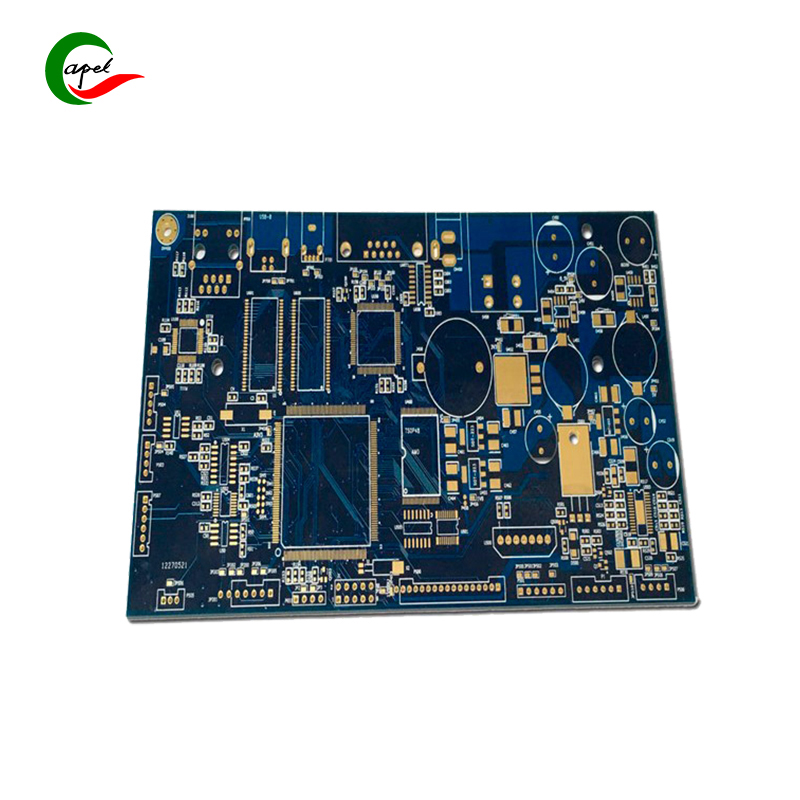

8 umaleko Rigid-Flex PCBs

8 layer HDI Iibhodi zeSekethe eziprintiweyo

Uvavanyo kunye nezixhobo zokuHlola

Uvavanyo lweMicroscope

Ukuhlolwa kwe-AOI

Uvavanyo lwe-2D

Uvavanyo lwe-Impedans

Uvavanyo lweRoHS

Flying Probe

Umvavanyi othe tye

Ukugoba iTeste

Iibhodi zethu zeSekethe yeNkonzo yokuFanekisa

.Ukubonelela ngenkxaso yobugcisa Ukuthengiswa kwangaphambili kunye nasemva kokuthengisa;

.Ngokwesiko ukuya kuthi ga kwi-40 imigangatho, i-1-2days Ukujika ngokukhawuleza iprototyping ethembekileyo, ukuthengwa kwecandelo, iNdibano ye-SMT;

.Ibonelela kuzo zombini izixhobo zoNyango, uLawulo lwezoShishino, iZithuthi, iAviation, i-Consumer Electronics, i-IOT, i-UAV, uNxibelelwano njl.

.Amaqela ethu eenjineli kunye nabaphandi bazinikele ekufezekiseni iimfuno zakho ngokuchanekileyo nangobuchule.

Ukwenziwa njani iibhodi zeSekethe eziMacala-mbini ezikumgangatho ophezulu?

1. Yila ibhodi: Sebenzisa isoftware yoyilo oluncediswa yikhompyutha (CAD) ukuyila uyilo lwebhodi.Qinisekisa ukuba uyilo luyahlangabezana nazo zonke iimfuno zombane nezoomatshini, kubandakanywa ububanzi bomkhondo, isithuba, kunye nokubekwa kwecandelo.Qwalasela izinto ezifana nokuthembeka komqondiso, ukuhanjiswa kwamandla, kunye nolawulo lwe-thermal.

2. Iprototyping kunye nokuvavanya: Ngaphambi kokuveliswa kobuninzi, kubalulekile ukwenza ibhodi yeprototype ukuqinisekisa ukuyila kunye nenkqubo yokuvelisa.Vavanya ngokucokisekileyo iiprototypes zokusebenza, ukusebenza kombane, kunye nokuhambelana koomatshini ukuchonga nayiphi na imiba enokubakho okanye uphuculo.

3. Ukukhetha izinto eziphathekayo: Khetha imathiriyeli ekumgangatho ophezulu ehambelana neemfuno zakho zebhodi.Izinto eziqhelekileyo ezikhethiweyo zibandakanya i-FR-4 okanye i-high-temperature FR-4 ye-substrate, ubhedu lweendlela zokuqhuba, kunye ne-solder mask ukukhusela amacandelo.

4. Yenza umaleko wangaphakathi: Kuqala lungisa umaleko wangaphakathi webhodi, obandakanya amanyathelo aliqela:

a.Coca kwaye urhabaxa i-laminate ye-copper clad.

b.Faka ifilimu eyomileyo yefotosensitive kwindawo yobhedu.

c.Ifilimu ibonakaliswe kukukhanya kwe-ultraviolet (UV) ngesixhobo sokufota esinepateni yesekethe efunwayo.

d.Ifilimu iphuhliswa ukususa iindawo ezingabonakaliyo, ishiya iphethini yesiphaluka.

e.I-Etch eveziweyo yobhedu ukususa imathiriyeli engaphezulu ushiya umkhondo ofunekayo kunye neepads kuphela.

F. Jonga umaleko wangaphakathi ukuze ubone naziphi na iziphene okanye ukutenxa kuyilo.

5. Laminates: Iileyile zangaphakathi zidityaniswe kunye ne-prepreg kumatshini wokushicilela.Ukushisa kunye noxinzelelo lusetyenziselwa ukudibanisa iileyile kunye nokwenza ipaneli eyomeleleyo.Qinisekisa ukuba iileyile zangaphakathi zilungelelaniswe ngokufanelekileyo kwaye zibhalisiwe ukukhusela nayiphi na impazamo.

6. Ukugrumba: Sebenzisa umatshini wokugaya ngokuchanekileyo ukugrumba imingxuma yokufakwa kwecandelo kunye nokudibanisa.Ubukhulu obahlukeneyo bokomba basetyenziswa ngokweemfuno ezithile.Qinisekisa ukuchaneka kwendawo yomngxuma kunye nobubanzi.

Ukwenziwa njani iibhodi zeSekethe eziMacala-mbini ezikumgangatho ophezulu?

7. I-Electroless Copper Plating: Faka umaleko obhityileyo wobhedu kuzo zonke iindawo zangaphakathi eziveziweyo.Eli nyathelo liqinisekisa ukuqhuba okufanelekileyo kwaye liququzelele inkqubo yokubeka kumanyathelo alandelayo.

8. Imifanekiso yomaleko wangaphandle: Ngokufana nenkqubo yomaleko wangaphakathi, ifilimu eyomileyo enefotosensitive igqunywe kumaleko obhedu angaphandle.

Yiveze kwisibane se-UV ngesixhobo sefoto ephezulu kwaye uphuhlise ifilimu ukuveza ipateni yesekethe.

9. Ukuhombisa umaleko wangaphandle: Cofa ubhedu olungeyomfuneko kumaleko angaphandle, ushiye imikhondo efunekayo kunye neepads.

Jonga umaleko wangaphandle ukuba kukho naziphi na iziphene okanye ukutenxa.

10. IMask yeSolder kunye neLegend Printing: Faka i-solder mask imaski ukukhusela imikhondo yobhedu kunye neepads ngelixa ushiya indawo yokufakwa kwecandelo.Shicilela iintsomi kunye neziphawuli kumaleya aphezulu nasezantsi ukubonisa indawo yecandelo, ipolarity, kunye nolunye ulwazi.

11. Ukulungiswa komphezulu: Ukulungiswa komphezulu kusetyenziswa ukukhusela ubuso obubhengeziweyo bebhedu kwi-oxidation kunye nokubonelela nge-solderable surface.Ukhetho lubandakanya ukulinganisa umoya oshushu (HASL), igolide ye-nickel yokuntywiliselwa nge-electroless (ENIG), okanye ezinye izinto eziphambili.

12. Umzila kunye noKuqulunqa: Iiphaneli zePCB zisikwa kwiibhodi ezizimeleyo zisebenzisa umatshini womzila okanye inkqubo ye-V-scribing.

Qinisekisa ukuba imiphetho icocekile kwaye imilinganiselo ichanekile.

13. Uvavanyo loMbane: Yenza uvavanyo lombane njengovavanyo oluqhubekayo, imilinganiselo yokuchasana, kunye nokuhlolwa kwedwa ukuze kuqinisekiswe ukusebenza kunye nokuthembeka kweebhodi ezenziweyo.

14. Ulawulo noHlolo loMgangatho: Iibhodi ezigqityiweyo zihlolwa ngokucokisekileyo ukuze zibone naziphi na iziphene zokuvelisa ezifana neebhulukhwe ezimfutshane, ezivulekileyo, ezingalungelelanisiyo, okanye iziphene ezingaphezulu.Ukuphumeza iinkqubo zokulawula umgangatho ukuqinisekisa ukuthotyelwa kweekhowudi kunye nemigangatho.

15. Ukupakisha kunye nokuThunyelwa: Emva kokuba ibhodi idlulise ukuhlolwa komgangatho, ifakwe ngokukhuselekileyo ukukhusela umonakalo ngexesha lokuthunyelwa.

Qinisekisa iilebhile ezifanelekileyo kunye namaxwebhu okulandelela ngokuchanekileyo kunye nokuchonga iibhodi.