UJiko olukhawulezayo lwe-PCB Prototyping 6 Umaleko oPhezulu woXinano oluNxinaniso lweeBhodi ezininzi eziguquguqukayo zeZithuthi

Inkcazo

| Udidi | Inkqubo Yamandla | Udidi | Inkqubo Yamandla |

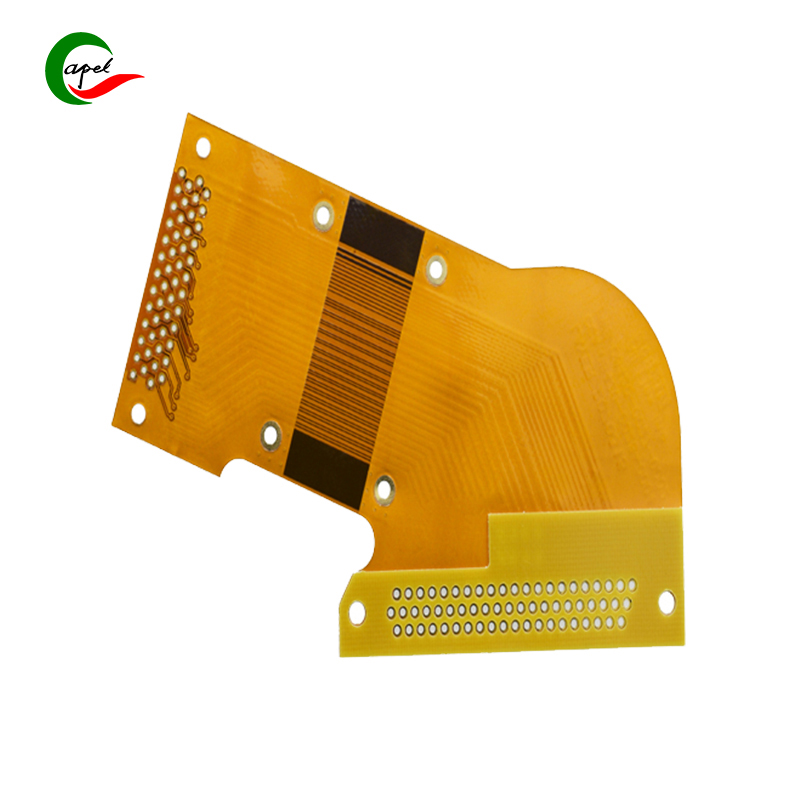

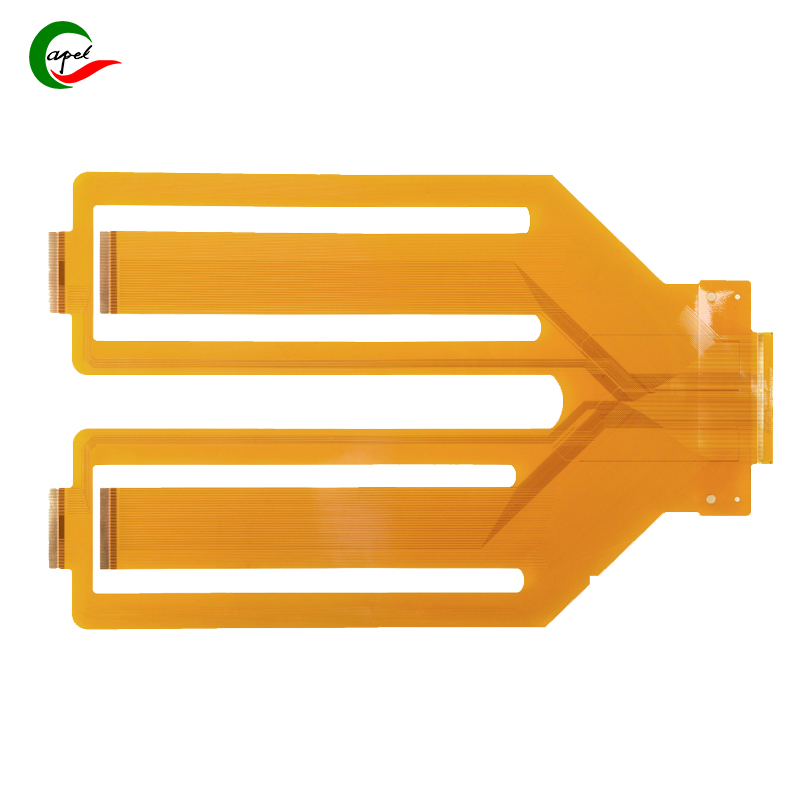

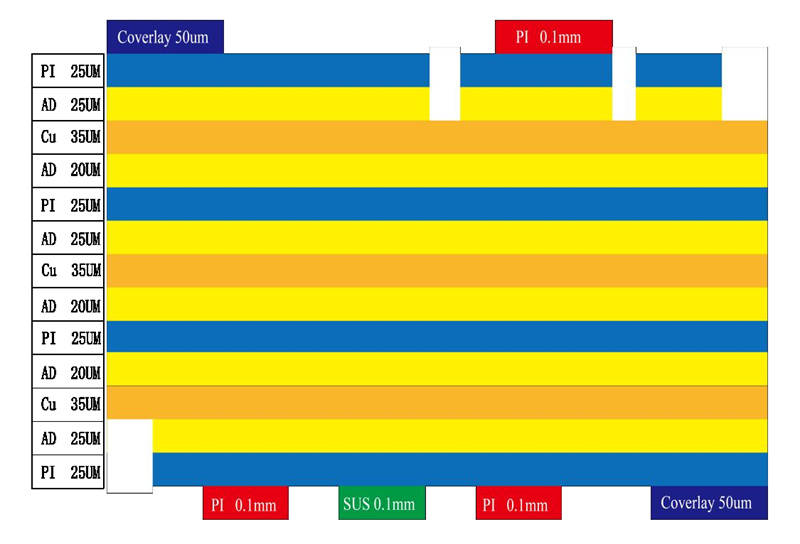

| Uhlobo lweMveliso | Umaleko omnye FPC / Umaleko ophindwe kabini FPC Ii-FPC ezininzi / iiPCB zeAluminiyam I-Rigid-Flex PCBs | ILayers Number | 1-16 umaleko FPC 2-16 umaleko Rigid-FlexPCB Iibhodi zeSekethe eziprintiweyo zeHDI |

| Ubungakanani obukhulu bokuVeliswa | Umaleko omnye FPC 4000mm Doulbe umaleko FPC 1200mm Imigangatho emininzi yeFPC 750mm I-Rigid-Flex PCB 750mm | I-Insulating Layer Ukutyeba | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um / 150um |

| Ukutyeba kweBhodi | I-FPC 0.06mm - 0.4mm I-Rigid-Flex PCB 0.25 - 6.0mm | Ukunyamezela kwe-PTH Ubungakanani | ±0.075mm |

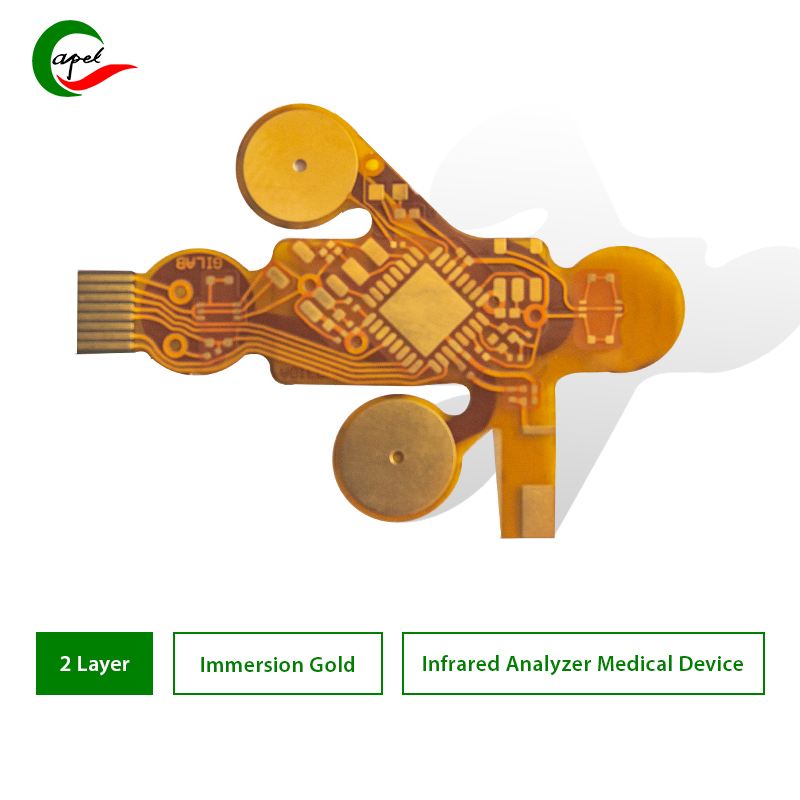

| Umphezulu Gqiba | Ukuntywiliselwa kweGolide / ukuntywiliselwa ISilver/iGold Plat/I-Tin Plat ing/OSP | Stiffener | FR4 / PI / PET / SUS / PSA / Alu |

| Ubungakanani beSemicircle Orifice | Ubuncinci 0.4mm | Min Line Isithuba/ ububanzi | 0.045mm/0.045mm |

| Ukutyeba Ukunyamezela | ±0.03mm | Impedance | 50Ω-120Ω |

| Ukutyeba kweFoil yobhedu | 9um/12um/18um/35um/70um/100um | Impedance Iyalawulwa Ukunyamezelana | ±10% |

| Ukunyamezela kwe-NPTH Ubungakanani | ±0.05mm | Ububanzi beMin Flush | 0.80mm |

| Min Via Hole | 0.1mm | Phumeza Umgangatho | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Senza iibhodi ezininzi eziguquguqukayo ezinamava angama-15 eminyaka ngobungcali bethu

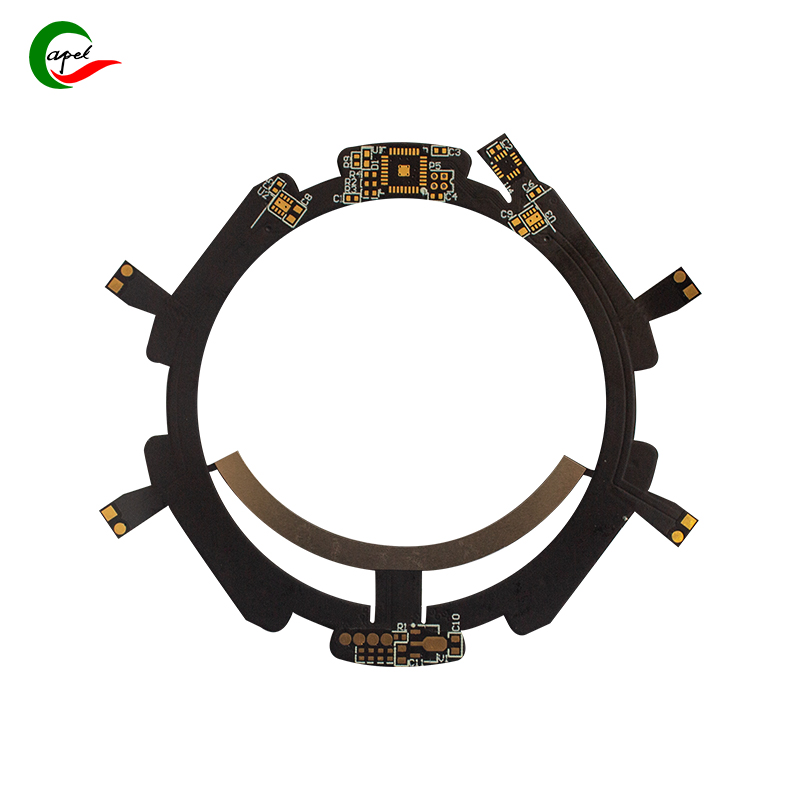

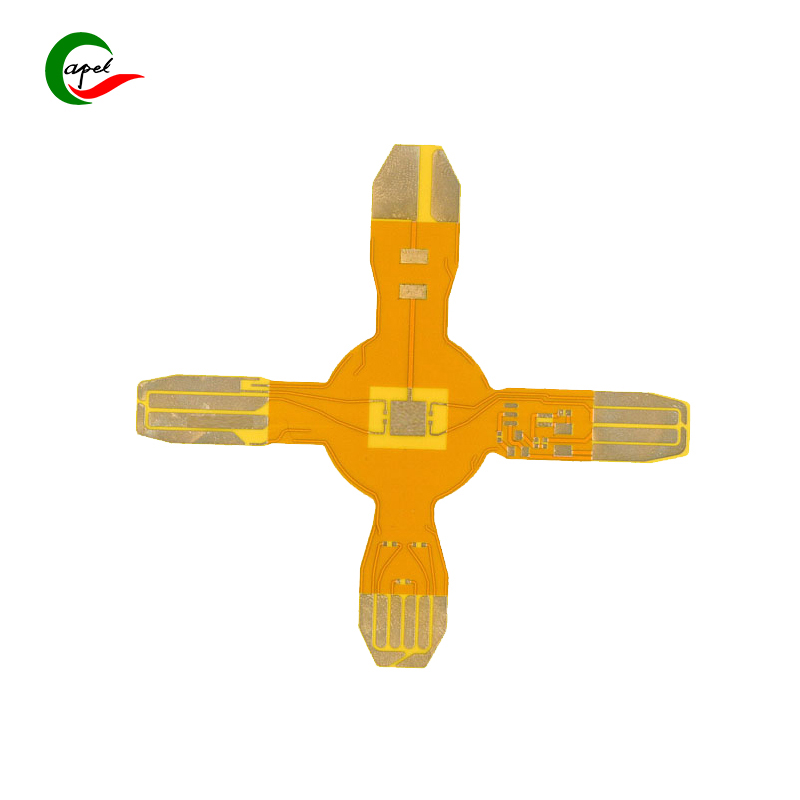

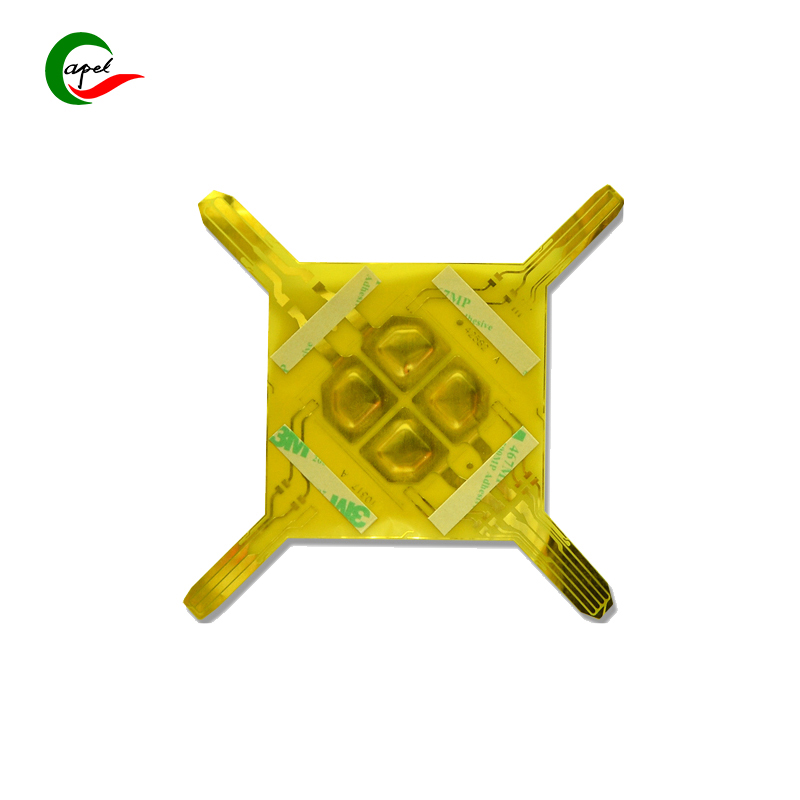

3 umaleko Flex PCBs

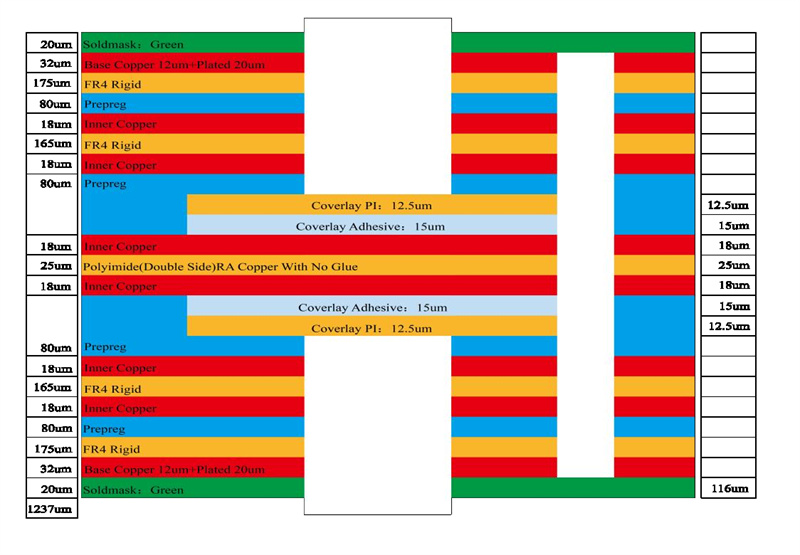

8 umaleko Rigid-Flex PCBs

8 layer HDI Iibhodi zeSekethe eziprintiweyo

Uvavanyo kunye nezixhobo zokuHlola

Uvavanyo lweMicroscope

Ukuhlolwa kwe-AOI

Uvavanyo lwe-2D

Uvavanyo lwe-Impedans

Uvavanyo lweRoHS

Flying Probe

Umvavanyi othe tye

Ukugoba iTeste

Iibhodi zethu ezininzi eziguquguqukayo zeNkonzo

.Ukubonelela ngenkxaso yobugcisa Ukuthengiswa kwangaphambili kunye nasemva kokuthengisa;

.Ngokwesiko ukuya kuthi ga kwi-40 imigangatho, i-1-2days Ukujika ngokukhawuleza iprototyping ethembekileyo, ukuthengwa kwecandelo, iNdibano ye-SMT;

.Ibonelela kuzo zombini izixhobo zoNyango, uLawulo lwezoShishino, iZithuthi, iAviation, i-Consumer Electronics, i-IOT, i-UAV, uNxibelelwano njl.

.Amaqela ethu eenjineli kunye nabaphandi bazinikele ekufezekiseni iimfuno zakho ngokuchanekileyo nangobuchule.

Zeziphi iimfuno zobugcisa zePCBs zeemoto zeebhodi ezininzi eziguquguqukayo?

1. Ukuqina: IiPCB eziziThuthi kufuneka zikwazi ukumelana neemeko ezinzima zokusebenza kwesithuthi, kubandakanywa nokuguquguquka kobushushu, ukungcangcazela, kunye nokufuma.Bathembisa ubomi obude benkonzo kunye nozinzo olubalaseleyo lomatshini.

2. Uxinaniso oluPhezulu: I-PCB eguquguqukayo ye-Multi-layer ivumela ukudityaniswa kombane kunye namacandelo ukuba ahlanganiswe kwindawo edibeneyo.Uyilo olunoxinaniso oluphezulu lwenza umzila osebenzayo kwaye unciphise ubungakanani bePCB, ukonga indawo exabisekileyo kwisithuthi.

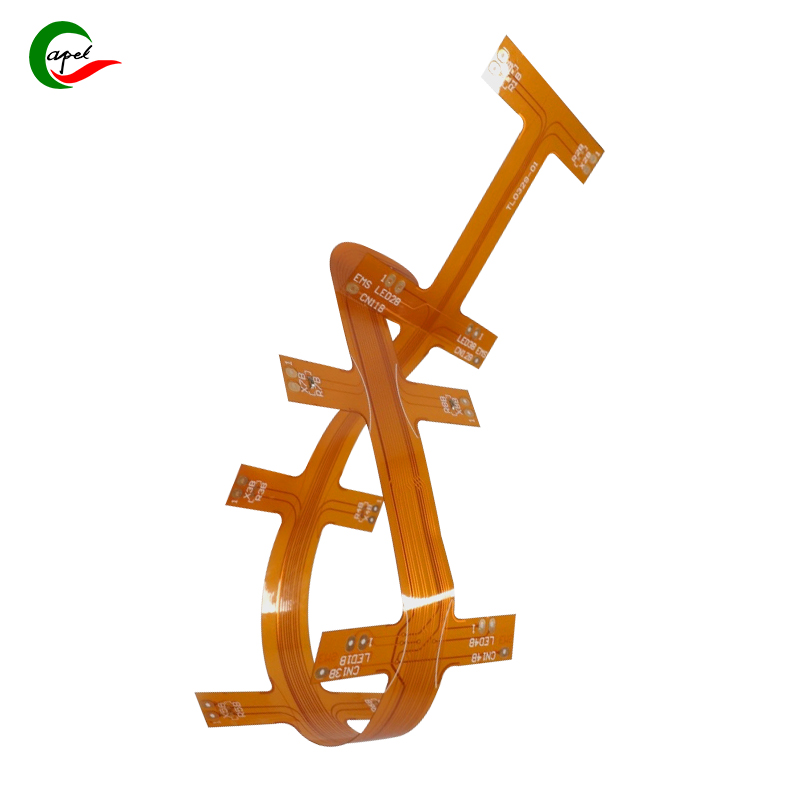

3. Ukuguquguquka nokugoba: IiPCB eziguquguqukayo zinokugotywa ngokulula, zijijelwe okanye zigotywe ukuze zilingane neendawo ezixineneyo okanye zihambelane nokumila kwemoto.Bafanele bagcine ingqibelelo yabo yombane kunye noomatshini ngexesha lokugoba ngokuphindaphindiweyo kunye nokuguquguquka.

4. Ingqibelelo yomqondiso: Kufuneka kubekho ilahleko encinci yomqondiso okanye ukuphazamiseka kwengxolo kwi-PCB ukuqinisekisa unxibelelwano oluthembekileyo phakathi kwamacandelo ahlukeneyo e-elektroniki.Sebenzisa ubuchule obunjengolawulo lwe-impedance kunye nokubekwa komhlaba okufanelekileyo ukugcina imfezeko yomqondiso.

5. Ulawulo lwe-Thermal: Iibhodi zeesekethe zeemoto kufuneka zichithe ngokufanelekileyo ukushisa okwenziwa ngexesha lokusebenza.Ubuchule bokulawula ubushushu obusebenzayo, njengokusebenzisa iiplani zobhedu ezifanelekileyo kunye ne-thermal vias, ziyimfuneko ukukhusela ukushisa nokuqinisekisa ukusebenza okuzinzile.

6. Ukukhusela i-EMI / RFI: Ukuthintela ukuphazamiseka kwe-electromagnetic (EMI) kunye nokuphazamiseka kwerediyo yerediyo (RFI), iiPCB zeemoto zifuna iindlela ezifanelekileyo zokukhusela.Oku kubandakanya ukusebenzisa izikhuselo okanye iinqwelomoya eziphantsi komhlaba ukunciphisa iziphumo zemiqondiso yangaphandle yombane.

7. Uvavanyo lwe-Intanethi: Uyilo lwePCB kufuneka luququzelele uvavanyo kunye nokuhlolwa kwe-PCB edibeneyo.Ukufikeleleka okufanelekileyo kumanqaku ovavanyo kunye neeprobes zokuvavanya kuya kubonelelwa ukuze kuqinisekiswe uvavanyo oluchanekileyo nolusebenzayo ngexesha lokwenziwa nokugcinwa.

8. Ukuthotyelwa kwemigangatho yeemoto: Uyilo kunye nokuveliswa kwee-PCB zeemoto kufuneka zilandele imigangatho yoshishino lweemoto, njenge-AEC-Q100 kunye ne-ISO/TS 16949. Ukuthotyelwa kwale migangatho kuqinisekisa ukuthembeka, ukhuseleko kunye nomgangatho weePCB.

Kutheni ufuna iPrototyping yePCB yokuJika ngokukhawuleza?

1. Isantya: Iprototyping ekhawulezayo yePCB ikhawulezisa imijikelo yophuhliso lwemveliso.Inceda ukunciphisa ixesha elifunekayo lokuphindaphinda, ukuvavanya, kunye nokuphucula uyilo lwe-PCB, ivumela iinjineli ukuba zihlangabezane nexesha elibekiweyo leprojekthi okanye ziphendule ngokukhawuleza kwiimfuno zentengiso.

2. UQinisekiso loYilo: I-PCB Prototyping ivumela iinjineli ukuba ziqinisekise ukusebenza, ukusebenza kunye nokwenziwa koyilo lwePCB yazo phambi kokuba ziye kwimveliso yobuninzi.Inceda ukuchonga kunye nokujongana naziphi na iimpazamo zoyilo okanye amathuba okuphucula, ukonga ixesha kunye nemali ekuhambeni kwexesha.

3. Umngcipheko ocuthiweyo: Ukuchwetheza okukhawulezileyo kwe-PCB kunceda ukunciphisa iingozi ezinxulumene nokuveliswa kwe-PCB eninzi.Ngokuvavanya kunye nokuqinisekiswa koyilo kwiibhetshi ezincinci, naziphi na iimpazamo okanye imiba enokuthi ibanjwe kwangethuba, ukuthintela iimpazamo ezibiza kakhulu kunye nokusebenza kwakhona ngexesha lokuvelisa ngokupheleleyo.

4. Ukongiwa kweendleko: Iprototyping ekhawulezayo yePCB inokusebenzisa ngokufanelekileyo izibonelelo kunye nemathiriyeli.Ngokubamba imiba yoyilo kwangethuba kunye nokwenza uhlengahlengiso oluyimfuneko, iinjineli zinokonga izinto ezilahliweyo kunye noyilo olubiza imali eninzi.

5. Ukuphendula kwimarike: Kwishishini elikhawulezayo, ukukwazi ukuphuhlisa ngokukhawuleza kunye nokuqalisa iimveliso ezintsha kunokunika inkampani inzuzo yokukhuphisana.Iprototyping yePCB ekhawulezileyo yenza ukuba iinkampani ziphendule ngokukhawuleza kwiimfuno zentengiso, ukutshintsha iindlela okanye amathuba amatsha, ukuqinisekisa ukukhutshwa kwemveliso kwangexesha.

6. Ukwenziwa ngokwezifiso kunye nokutsha: I-Prototyping iququzelela ukwenza ngokwezifiso kunye nokutsha.Iinjineli zinokuphonononga iikhonsepthi ezintsha zoyilo, zivavanye iimpawu ezahlukeneyo, kwaye zilinge iitekhnoloji eziphambili.Ibenza bakwazi ukutyhala imida kwaye baphuhlise iimveliso ezibukhali.