Yazisa:

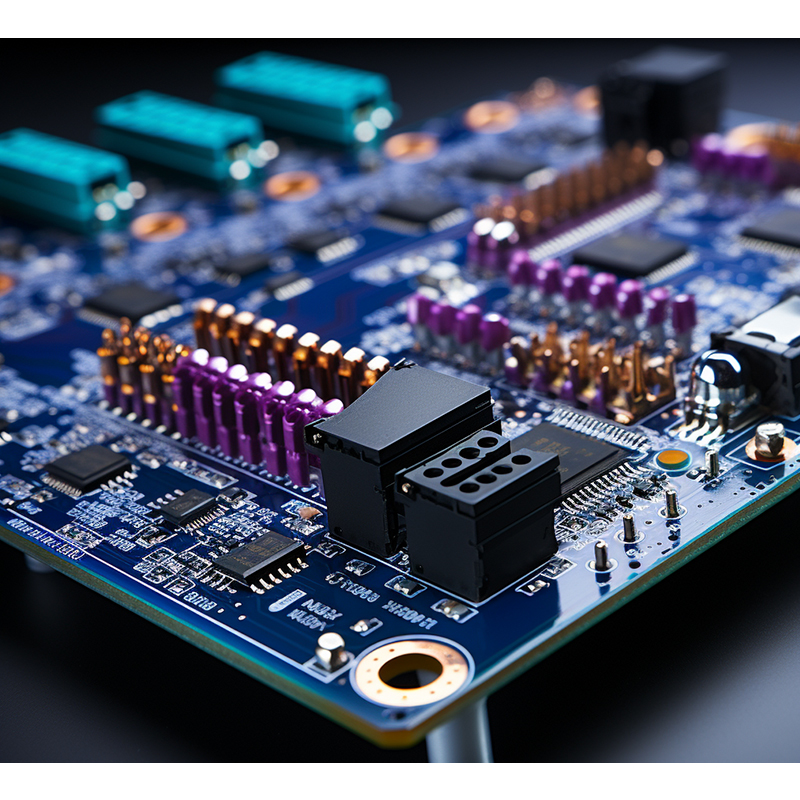

Kule post yebhlog, siza kuphonononga kwiinkcukacha zendlela iileya ezikwibhodi yesekethe eqinile-eguqukayo ibotshelelwa ngayo, sijonga iindlela ezahlukeneyo ezisetyenziswa kwinkqubo.

Iibhodi zesekethe eziguquguqukayo ziyaziwa kumashishini ahlukeneyo kubandakanya i-aerospace, ezonyango, kunye ne-elektroniki yabathengi.Ezi bhodi ziyingqayizivele kuba zidibanisa ukujikeleza okuguquguqukayo kunye namacandelo aqinile, ukubonelela ngokuzinzileyo kunye nokuguquguquka.Enye yezona zinto zibalulekileyo eziqinisekisa ukusebenza kunye nokuthembeka kweebhodi ezilukhuni-flex iteknoloji yokudibanisa esetyenziselwa ukudibanisa iindidi ezahlukeneyo.

1. Itekhnoloji yokudibanisa:

Itekhnoloji ye-Adhesive bonding isetyenziswa ngokubanzi kwi-rigid-flex circuit board board.Kubandakanya ukusetyenziswa kwe-adhesive ekhethekileyo equlethe i-agent yokushisa ukushisa.Ezi zincamathelisi zisetyenziselwa ukudibanisa iileya eziguquguqukayo kwiindawo eziqinileyo zeebhodi zesekethe.I-adhesive ayiboneleli kuphela ngenkxaso yesakhiwo kodwa iqinisekisa ukudibanisa kombane phakathi kweengqimba.

Ngethuba lenkqubo yokuvelisa, i-adhesive isetyenziswe ngendlela elawulwayo kwaye iileyile zilungelelaniswa ngokuchanekileyo ngaphambi kokuba i-laminated kunye phantsi kobushushu kunye noxinzelelo.Oku kuqinisekisa ibhondi eyomeleleyo phakathi kwamaleko, okubangela ukuba ibhodi yesekethe engqongqo-flex eneempawu ezibalaseleyo zoomatshini kunye nombane.

2. Itekhnoloji yokunyuswa komphezulu (SMT):

Enye indlela edumileyo yokudibanisa iileya zebhodi yesekethe ye-rigid-flex isebenzisa iteknoloji ye-surface Mount (SMT).I-SMT ibandakanya ukubeka izixhobo zokuxhoma umphezulu ngokuthe ngqo kwindawo eqinileyo yebhodi yesekethe kwaye emva koko uthengise la malungu kwiipadi.Le teknoloji ibonelela ngendlela ethembekileyo nesebenzayo yokudibanisa iileyile ngelixa uqinisekisa ukudibanisa kombane phakathi kwabo.

Kwi-SMT, iileya eziqinileyo kunye neziguquguqukayo ziyilwe ngokuhambelana ne-vias kunye neepads ukuququzelela inkqubo ye-soldering.Faka i-solder paste kwindawo ye-pad kwaye ubeke icandelo ngokuchanekileyo.Ibhodi yesekethe emva koko ifakwe kwinkqubo ye-reflow soldering, apho i-solder paste iyanyibilika kwaye idibanise iileya kunye, ukudala ibhondi eqinile.

3. Ngokwalekwa komngxuma:

Ukufezekisa amandla omatshini aphuculweyo kunye noqhagamshelo lombane, iibhodi zesekethe eziqinileyo zihlala zisebenzisa i-plating ye-hole.Ubuchwephesha bubandakanya ukugrumba imingxuma kwiileya kunye nokusebenzisa izinto zokuqhuba ngaphakathi kwaloo mingxuma.Izinto eziphathekayo (ngokuqhelekileyo ubhedu) zifakwe kwi-electroplated kwiindonga zomngxuma, ziqinisekisa ibhondi eyomeleleyo kunye nokudibanisa kombane phakathi kweeleyile.

I-Pinging-hole plating ibonelela ngenkxaso eyongezelelweyo kwiibhodi eziguquguqukayo kunye nokunciphisa umngcipheko we-delamination okanye ukusilela kwiindawo ezinoxinzelelo oluphezulu.Ukufumana iziphumo ezingcono, imingxuma yokubhola kufuneka ibekwe ngononophelo ukuze ihambelane ne-vias kunye neepads kumaleko ahlukeneyo ukufezekisa uqhagamshelwano olukhuselekileyo.

Ukuququmbela:

Itekhnoloji ye-adhesive esetyenziswa kwiibhodi zeesekethe eziqinileyo zidlala indima ebalulekileyo ekuqinisekiseni ukunyaniseka kwesakhiwo kunye nokusebenza kombane.Ukubambelela, itekhnoloji yokunyuka komphezulu kunye nokufakwa komngxuma kumngxuma zisetyenziswa ngokubanzi iindlela zokudibanisa ngaphandle komthungo umaleko ohlukeneyo.Itekhnoloji nganye ineenzuzo zayo kwaye ikhethwa ngokusekelwe kwiimfuno ezithile zoyilo lwePCB kunye nokusetyenziswa kwayo.

Ngokuqonda iindlela zokudibanisa ezisetyenziswa kwiibhodi zesekethe eziqinileyo, abavelisi kunye nabaqulunqi banokudala iindibano ze-elektroniki ezinamandla nezithembekileyo.Ezi bhodi zesekethe eziphambili zihlangabezana neemfuno ezikhulayo zobuchwepheshe bale mihla, zivumela ukuphunyezwa kwe-electronic flexible kunye nesigxina kumashishini ahlukeneyo.

Ixesha lokuposa: Sep-18-2023

Emva