Kwiibhodi eziprintiweyo eziqinileyo, ngenxa yokunganyaniseki kakuhle kwengubo eludongeni lomngxuma (ifilimu ecocekileyo yerabha kunye neshiti lokudibanisa), kulula ukubangela ukuba i-coating ihlukane nodonga lomngxuma xa iphantsi kokutshatyalaliswa kwe-thermal., Kwakhona kufuna ikhefu malunga ne-20 μm, ukwenzela ukuba umsesane wobhedu wangaphakathi kunye nobhedu lwe-electroplated lunonxibelelwano oluthembekileyo olunamanqaku amathathu, oluphucula kakhulu ukuxhathisa ukothuka kwe-thermal ye-metalized hole.Le Capel ilandelayo iza kuthetha ngayo ngokweenkcukacha kuwe.Amanyathelo amathathu okucoca umngxuma emva kokugrumba ibhodi e-rigid-flex.

Ulwazi lokucoca ngaphakathi komngxuma emva kokugrumba iisekethe eziguquguqukayo eziqinileyo:

Ekubeni i-polyimide ingaxhathisi kwi-alkali eyomeleleyo, i-alkaline eyomeleleyo ye-alkaline ye-potassium permanganate desmear ayifanelekanga kwiibhodi eziprintiweyo eziguquguqukayo neziqinileyo.Ngokubanzi, ukungcola kokumba kwibhodi ethambileyo kunye nelukhuni kufuneka icocwe yinkqubo yokucoca iplasma, eyahlulahlulwe yangamanyathelo amathathu:

(1) Emva kokuba umgodi wesixhobo ufikelele kwinqanaba elithile le-vacuum, i-nitrogen ecocekileyo kunye ne-oksijini ecocekileyo ifakwe kuyo ngokulinganayo, umsebenzi oyintloko kukucoca udonga lomngxuma, ukutshisa ibhodi eprintiweyo, kunye nokwenza izinto zepolymer. ube nomsebenzi othile, oluncedo Ukuqhubekeka okulandelayo.Ngokuqhelekileyo, yi-80 degrees Celsius kwaye ixesha yimizuzu eli-10.

(2) I-CF4, i-O2 kunye ne-Nz zisabela nge-resin njengerhasi yokuqala ukufezekisa injongo yokucoca kunye ne-etch back, ngokubanzi kuma-85 degrees Celsius kunye nemizuzu engama-35.

(3) I-O2 isetyenziswe njengerhasi yokuqala ukususa intsalela okanye "uthuli" olwenziwe ngexesha lamanyathelo amabini okuqala onyango;coca udonga lomngxuma.

Kodwa kubalulekile ukuqaphela ukuba xa iplasma isetyenziselwa ukususa ubumdaka bokomba kwimingxunya yeebhodi eziprintiweyo ezininzi eziguquguqukayo neziqinileyo, isantya sokuqhafaza sezinto ezahlukeneyo sahlukile, kunye nomyalelo ukusuka kwinkulu ukuya kwencinci yile: ifilimu ye-acrylic. , i-epoxy resin, i-polyimide, i-fiberglass kunye nobhedu.Iintloko zefiber zeglasi eziphumayo kunye nezangqa zobhedu zinokubonwa ngokucacileyo kudonga lomngxuma olusuka kwimicroscope.

Ukuze kuqinisekiswe ukuba isisombululo se-electroless copper plating sinokuqhagamshelana ngokupheleleyo nodonga lomngxuma, ukwenzela ukuba umaleko wobhedu ungavelisi i-voids kunye ne-voids, intsalela ye-plasma reaction, i-fiber yeglasi ephumayo kunye nefilimu ye-polyimide eludongeni lomngxuma kufuneka ibe. isusiwe.Indlela yonyango ibandakanya iindlela zemichiza kunye neendlela zoomatshini okanye ukudibanisa kwezi zibini.Indlela yeekhemikhali kukucwina ibhodi eprintiweyo ngesisombululo se-ammonium hydrogen fluoride, kwaye emva koko usebenzise i-ionic surfactant (isisombululo se-KOH) ukulungelelanisa ukuhlawulwa kodonga lomngxuma.

Iindlela zoomatshini ziquka ukuqhunyiswa kwesanti emanzi ngoxinzelelo oluphezulu kunye nokuhlamba kwamanzi ngoxinzelelo oluphezulu.Ukudibaniswa kweekhemikhali kunye neendlela zoomatshini kunempembelelo engcono kakhulu.Ingxelo ye-metallographic ibonisa ukuba imeko yodonga lwe-metallised emngxunyeni emva kokutshatyalaliswa kweplasma kuyanelisa.

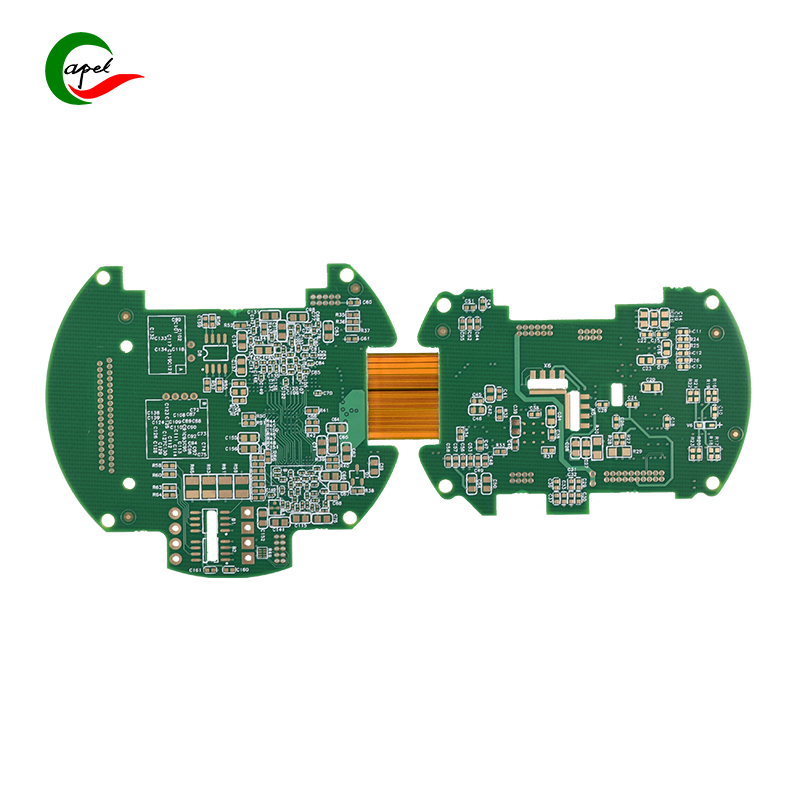

Oku ngasentla ngamanyathelo amathathu okucoca ngaphakathi komngxuma emva kokugaya iibhodi eziprintiweyo ezilukhuni-flex ezicwangciswe ngokucophelela yiCapel.I-Capel igxininise kwibhodi yesekethe eprintiweyo eguquguqukayo, ibhodi ethambileyo, ibhodi enzima kunye nendibano ye-SMT iminyaka eyi-15, kwaye iqokelele ubutyebi bolwazi lobugcisa kwishishini lebhodi yesekethe.Ndiyathemba ukuba olu kwabelana luluncedo kumntu wonke.Ukuba uneminye imibuzo yebhodi yesekethe, nceda uqhagamshelane neqela lethu lobugcisa be-makeup yeCapel ngqo ukubonelela ngenkxaso yobuchwephesha kwiprojekthi yakho.

Ixesha lokuposa: Aug-21-2023

Emva