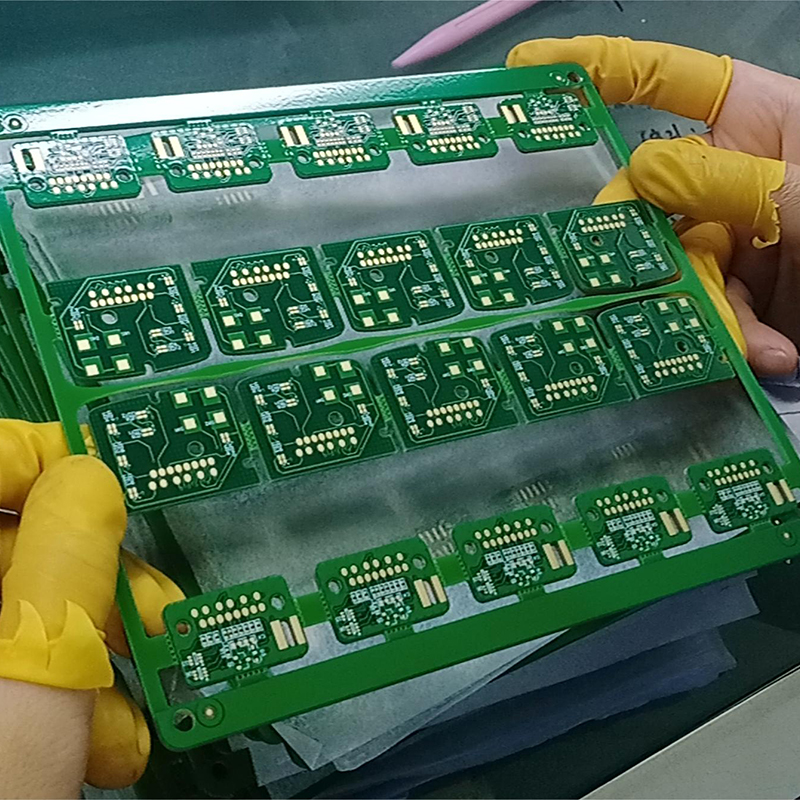

Uphuhliso olukhawulezayo lweshishini lombane lukhokelele ekusetyenzisweni okubanzi kwebhodi ye-rigid-flex. Nangona kunjalo, ngenxa yokungafani kwamandla, iteknoloji, amava, inkqubo yokuvelisa, ubuchule benkqubo kunye nokucwangciswa kwezixhobo zabavelisi abahlukeneyo, iingxaki zomgangatho weebhodi ezilukhuni-flex kwinkqubo yokuvelisa ubuninzi nazo zihluke.I-Capel elandelayo iya kuchaza ngokubanzi iingxaki ezimbini eziqhelekileyo kunye nezisombululo eziza kwenzeka kwimveliso yobuninzi beebhodi eziguquguqukayo eziqinileyo.

Kwinkqubo yokuvelisa ngobuninzi beebhodi eziguquguqukayo eziqinileyo, ukucolwa kwetoni okungalunganga kuyingxaki eqhelekileyo. Ukungacoceki kakuhle kwetoti kunokukhokelela ekungazinzini

i-solder joints kwaye ichaphazela ukuthembeka kwemveliso.

Nazi ezinye izinto ezinokubangela ukuba kubekho iitoni ezingalunganga:

1. Ingxaki yokucoca:Ukuba umphezulu webhodi yesekethe awucocwanga ngokucokisekileyo phambi kokutshiza, oko kunokukhokelela kwi-solder engalunganga;

2. Ubushushu be-solder alifanelekanga:ukuba ubushushu be-soldering buphezulu kakhulu okanye buphantsi kakhulu, bunokukhokelela ekuthini ukugonywa;

3. Iingxaki zomgangatho wokuncamathelisa kwi-Solder:intlama ye-solder ekumgangatho ophantsi inokukhokelela kwi-tinning engalunganga;

4. Iingxaki zomgangatho wamacandelo e-SMD:Ukuba umgangatho we-pad wamacandelo e-SMD awufanelekanga, kuya kukhokelela kwi-tinning embi;

5. Ukusebenza kwe-welding engafanelekanga:Ukungachaneki kwe-welding kusenokukhokelela ekuthini ukutonwa kakuhle.

Ukuze uthintele ngcono okanye uzisombulule ezi ngxaki zingalunganga zokuthengisela, nceda uqaphele la manqaku alandelayo:

1. Qinisekisa ukuba umphezulu webhodi ucocwe ngokucokisekileyo ukuze kususwe ioli, uthuli kunye nobunye ukungcola phambi kokutshiza;

2. Lawula amaqondo obushushu kunye nexesha lokuthambisa: Kwinkqubo yokuthambisa, kubaluleke kakhulu ukulawula ubushushu kunye nexesha lokuthambisa. Qinisekisa ukuba usebenzisa iqondo lokushisa elichanekileyo le-soldering kwaye wenze uhlengahlengiso olufanelekileyo ngokwezinto ezithengiswayo kunye neemfuno. Ukushisa okugqithisileyo kunye nexesha elide kakhulu Ixesha linokubangela ukuba i-solder idibanise okanye inyibilike, kwaye ibangele umonakalo kwibhodi eqinile-flex. Ngokuphambene noko, ukushisa okuphantsi kakhulu kunye nexesha kunokubangela ukuba izinto eziphathekayo zingakwazi ukumanzisa ngokupheleleyo kwaye zisasazeke kwi-joint solder, ngaloo ndlela zenze i-solder ebuthakathaka;

3. Khetha izinto ezifanelekileyo ze-soldering: khetha umthengisi othembekileyo we-solder paste, uqinisekise ukuba uhambelana nezinto zebhodi e-rigid-flex, kwaye uqinisekise ukuba iimeko zokugcina kunye nokusetyenziswa kwe-solder paste zilungile.

Khetha izinto ezikumgangatho ophezulu zokuthengisela ukuqinisekisa ukuba izinto zokuthambisa zinokumanzisa kakuhle kunye nendawo efanelekileyo yokunyibilika, ukwenzela ukuba zisasazwe ngokulinganayo kwaye zenze izidibanisi ze-solder ezizinzileyo ngexesha le-tinning;

4. Qinisekisa ukuba usebenzisa amacandelo e-patch asemgangathweni, kwaye ukhangele ukunyameka kunye nokugquma kwephedi;

5. Uqeqesho kunye nokuphucula izakhono zokusebenza kwe-welding ukuqinisekisa indlela echanekileyo yokudibanisa kunye nexesha;

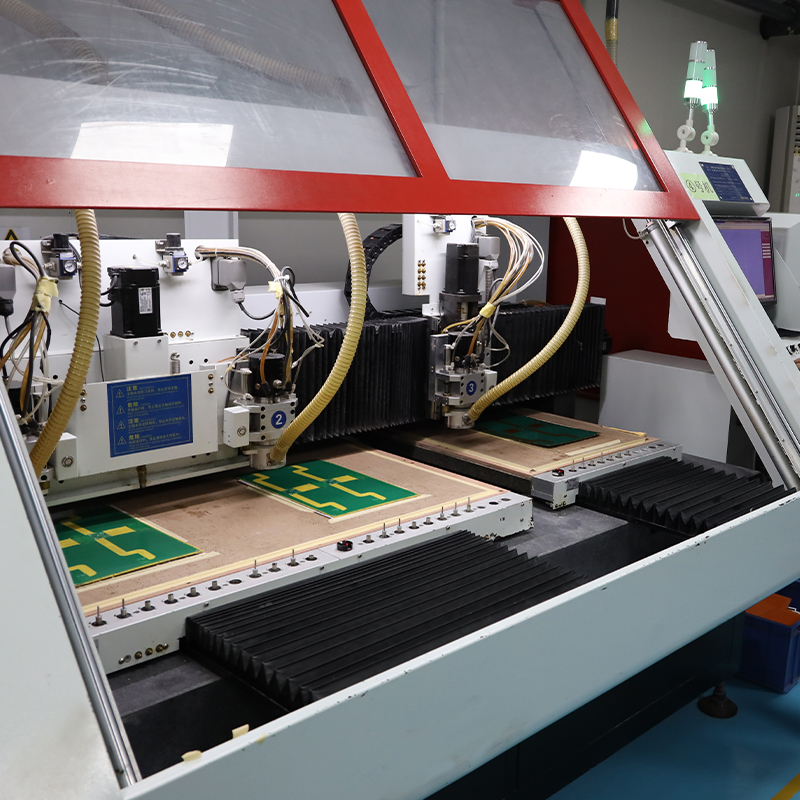

6. Lawula ubukhulu kunye nokufana kwe-tin: qinisekisa ukuba i-tin isasazwe ngokulinganayo kwindawo yokubethela ukuphepha ukugxila kwendawo kunye nokungalingani. Izixhobo ezifanelekileyo kunye nobuchule, obufana noomatshini bokutota okanye izixhobo zokutofa ezizenzekelayo, zingasetyenziswa ukuqinisekisa ukusasazwa nokutyeba okufanelekileyo kwemathiriyeli yokuthambisa;

7. Ukuhlolwa rhoqo kunye novavanyo: Ukuhlolwa rhoqo kunye novavanyo lwenziwa ukuze kuqinisekiswe umgangatho we-solder joints of rigid-flex board. Umgangatho kunye nokuthembeka kwamalungu e-solder kunokuvavanywa ngokusebenzisa ukuhlolwa okubonakalayo, ukutsala uvavanyo, njl.

Umngxuma ongonelanga ubukhulu bobhedu kunye nokungalingani komngxuma wokutyatyekwa kobhedu nazo ziingxaki ezinokuthi zenzeke kwimveliso yobuninzi.

iibhodi eziqinileyo-flex. Ukwenzeka kwezi ngxaki kunokuchaphazela umgangatho wemveliso. Oku kulandelayo kuhlalutya izizathu kunye

izisombululo ezinokubangela le ngxaki:

Isizathu:

1. Ingxaki yonyango lwangaphambili:Ngaphambi kwe-electroplating, ukulungiswa kwangaphambili kwodonga lomngxuma kubaluleke kakhulu. Ukuba kukho iingxaki ezinjenge-corrosion, ukungcola okanye ukungalingani kwindonga yomngxuma, kuya kuchaphazela ukufana kunye nokunamathela kwenkqubo yokubeka. Qinisekisa ukuba iindonga zomngxunya zihlanjululwe ngokucokisekileyo ukuze zisuse nayiphi na into engcolileyo kunye ne-oxide layers.

2. Ingxaki yokuqulunqwa kwesisombululo:Ukwenziwa kwesisombululo esingalunganga sokwenza iiplating nako kunokukhokelela ekungalinganini kweeplating. Ukubunjwa kunye nokugxininiswa kwesisombululo se-plating kufuneka kulawulwe ngokungqongqo kwaye kulungiswe ukuqinisekisa ukufana kunye nokuzinza ngexesha lenkqubo yokubeka.

3. Ingxaki yeeparamitha ze-electroplating:iiparamitha ze-electroplating zibandakanya ukuxinana kwangoku, ixesha le-electroplating kunye nobushushu, njl. Qinisekisa ukuba iiparamitha ezichanekileyo zeplating zisetwa ngokweemfuno zemveliso kwaye wenze uhlengahlengiso oluyimfuneko kunye nokubeka iliso.

4. Imiba yenkqubo:Amanyathelo enkqubo kunye nokusebenza kwinkqubo ye-electroplating iya kuchaphazela ukufana kunye nomgangatho we-electroplating. Qinisekisa ukuba abaqhubi balandela ngokungqongqo ukuhamba kwenkqubo kwaye basebenzise izixhobo ezifanelekileyo kunye nezixhobo.

Isisombululo:

1. Lungiselela inkqubo yonyango lwangaphambili ukuze uqinisekise ukucoceka kunye nokunyuka kodonga lomngxuma.

2. Jonga rhoqo kwaye ulungelelanise ukuqulunqwa kwesisombululo se-electroplating ukuqinisekisa ukuzinza kwayo kunye nokufana.

3. Seta iiparamitha ezichanekileyo zokubeka ngokweemfuno zemveliso, kwaye ubeke iliso kwaye ulungelelanise ngokusondeleyo.

4. Ukuqhuba uqeqesho lwabasebenzi ukuphucula izakhono zokusebenza kwenkqubo kunye nokwazisa.

5. Qalisa inkqubo yolawulo lomgangatho ukuqinisekisa ukuba ikhonkco ngalinye liphantsi kolawulo olungqongqo novavanyo.

6. Ukomeleza ulawulo lwedatha kunye nokurekhoda: ukuseka ulawulo lwedatha epheleleyo kunye nenkqubo yokurekhoda ukurekhoda iziphumo zovavanyo lobunzima bobhedu lomngxuma kunye nokufana kweplating. Ngokusebenzisa izibalo kunye nokuhlalutya kwedatha, imeko engaqhelekanga yobunzima bobhedu lomngxuma kunye ne-electroplating uniformity inokufumaneka ngexesha, kwaye amanyathelo ahambelanayo kufuneka athathwe ukulungisa nokuphucula.

Ezi zilapha ngasentla zezona ngxaki zimbini zokungacoci kakuhle, ukutyeba okungonelanga komngxunya wobhedu, kunye nomngxuma wobhedu ongalinganiyo webhodi ehlala isenzeka kwibhodi eguquguqukayo.Ndiyathemba ukuba uhlalutyo kunye neendlela ezinikezelwe nguCapel ziya kuba luncedo kuwo wonke umntu. Ukufumana eminye imibuzo eprintiweyo yebhodi yesekethe, nceda uqhagamshelane neqela leengcali zaseCapel, iminyaka eyi-15 yebhodi yesekethe yobuchwephesha kunye namava obugcisa aya kukhapha iprojekthi yakho.

Ixesha lokuposa: Aug-21-2023

Emva