Ngenxa yobume bayo obuntsonkothileyo kunye neempawu ezizodwa,ukuveliswa kweebhodi ze-rigid-flex kufuna iinkqubo ezikhethekileyo zokuvelisa. Kule post yebhlog, siza kuphonononga amanyathelo ahlukeneyo abandakanyekayo ekwenzeni ezi bhodi zePCB eziguquguqukayo eziphambili kwaye sibonise imiba ethile ekufuneka ithathelwe ingqalelo.

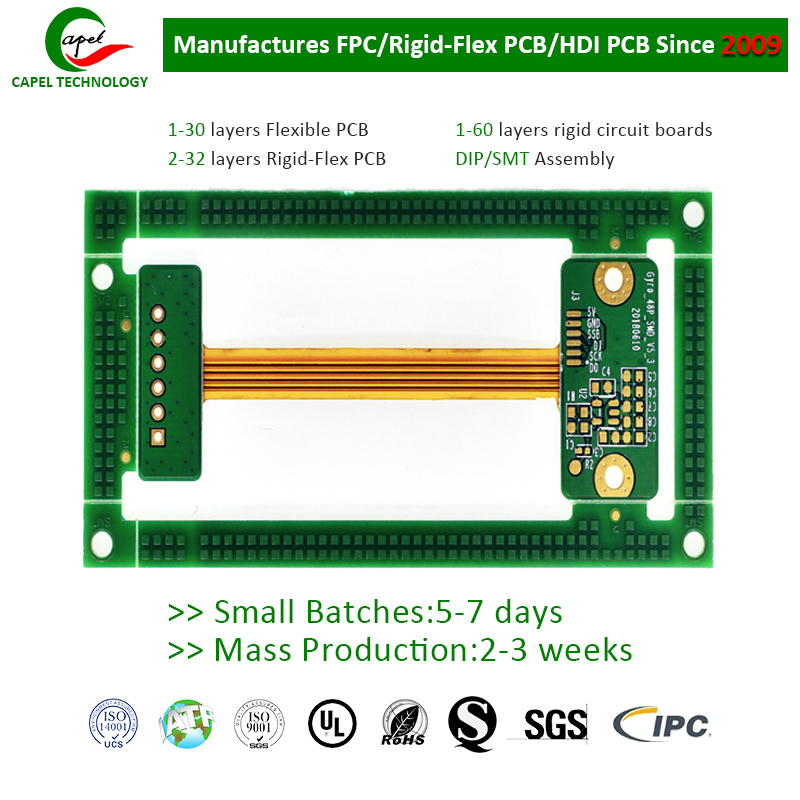

Iibhodi zesekethe eziprintiweyo (PCBs) ziyintsika ye-electronics yanamhlanje. Zisisiseko sezinto ezidityanisiweyo ze-elektroniki, zibenza babe yinxalenye ebalulekileyo yezixhobo ezininzi esizisebenzisa yonke imihla. Njengoko itekhnoloji ihambela phambili, ngokunjalo nesidingo sezisombululo ezibhetyebhetye nezihlangeneyo. Oku kuye kwakhokelela ekuphuhlisweni kwe-PCB eqinile-elula, enika indibaniselwano ekhethekileyo yokuqina kunye nokuguquguquka kwibhodi enye.

Yila ibhodi eqinileyo-eguquguqukayo

Isinyathelo sokuqala kunye nesona sibalulekileyo kwinkqubo yokuvelisa i-rigid-flex kuyilo. Ukuyila ibhodi engqongqo-eguqukayo ifuna ukuqwalaselwa ngononophelo koyilo lwebhodi yesekethe ngokubanzi kunye nokubekwa kwecandelo. Iindawo ze-Flex, i-bend radii kunye neendawo ezigobileyo kufuneka zichazwe ngexesha lesigaba soyilo ukuqinisekisa ukusebenza okufanelekileyo kwebhodi egqityiweyo.

Izinto ezisetyenziswa kwii-PCB eziguquguqukayo kufuneka zikhethwe ngononophelo ukuhlangabezana neemfuno ezithile zesicelo. Ukudityaniswa kwamacandelo aqinileyo kunye neziguquguqukayo kufuna ukuba izinto ezikhethiweyo zibe nenhlanganisela ekhethekileyo yokuguquguquka kunye nokuqina. Ngokuqhelekileyo ii-substrates eziguquguqukayo ezifana ne-polyimide kunye ne-FR4 encinci zisetyenziswa, kunye nezinto eziqinileyo ezifana ne-FR4 okanye isinyithi.

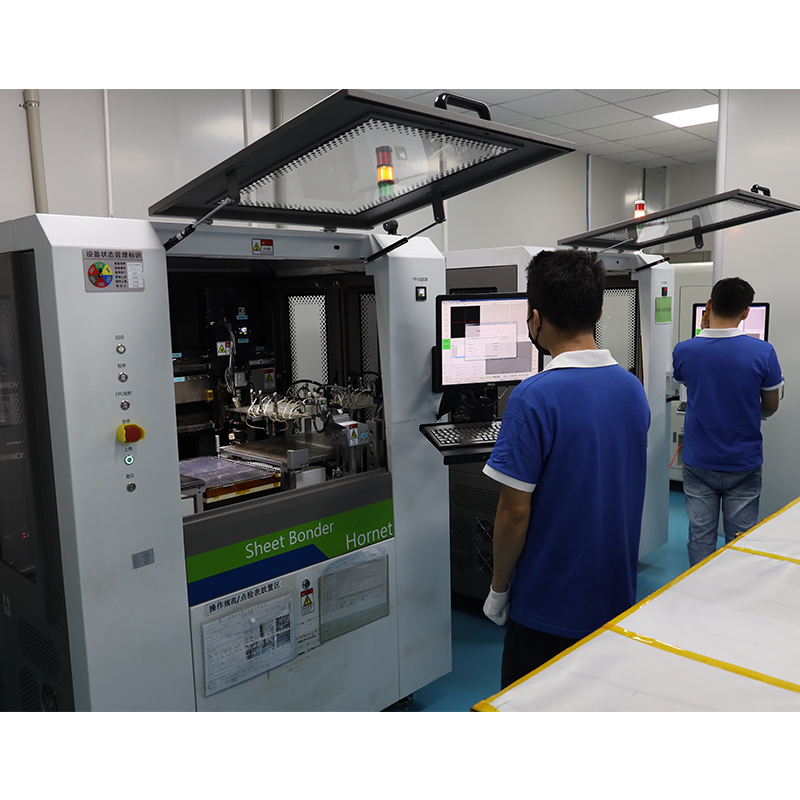

Ukupakishwa koMaleko kunye nokuLungisa i-Substrate yokwenziwa kwe-pcb eguquguqukayo eqinile

Nje ukuba uyilo lugqityiwe, inkqubo yokupakisha iqala. Iibhodi zesekethe eziprintiweyo ezingqongqo zibandakanya iileyile ezininzi eziqinileyo neziguquguqukayo ezidityanisiweyo zisebenzisa i-adhesives ekhethekileyo. Oku kudibanisa kuqinisekisa ukuba iileya zihlala zilungile naphantsi kweemeko ezinzima ezifana nokungcangcazela, ukugoba kunye nokutshintsha kweqondo lokushisa.

Isinyathelo esilandelayo kwinkqubo yokuvelisa kukulungiselela i-substrate. Oku kubandakanya ukucoca kunye nokunyanga umphezulu wokuqinisekisa ukunamathela ngokufanelekileyo. Inkqubo yokucoca isusa nayiphi na into engcolileyo enokuthi ithintele inkqubo yokudibanisa, ngelixa unyango olungaphezulu luphakamisa ukunamathela phakathi kweengqimba ezahlukeneyo. Ubuchwephesha obunjengonyango lweplasma okanye ukufakwa kweekhemikhali zihlala zisetyenziselwa ukufezekisa iipropathi ezinqwenelekayo zomhlaba.

Iipateni zobhedu kunye nokwakheka kwangaphakathi kweebhodi zesekethe eziguquguqukayo eziqinileyo

Emva kokulungiselela i-substrate, qhubela phambili kwinkqubo yokwenza ipateni yethusi. Oku kubandakanya ukubeka ungqimba oluncinci lobhedu kwi-substrate kwaye emva koko wenze inkqubo ye-photolithography ukudala iphethini yesekethe efunekayo. Ngokungafaniyo nee-PCB zemveli, ii-PCB eziguquguqukayo ezilukhuni zifuna ukuqwalaselwa ngononophelo kwenxalenye ebhetyebhetye ngexesha lenkqubo yokwenza ipateni. Ukunyamekela ngokukhethekileyo kufuneka kuthathwe ukuphepha uxinzelelo olungadingekile okanye umonakalo kwiindawo eziguquguqukayo zebhodi yesiphaluka.

Nje ukuba ipateni yobhedu igqitywe, ukwakheka kwangaphakathi kuyaqala. Kule nyathelo, iileyile eziqinileyo kunye neziguquguqukayo zihambelana kwaye uxhulumaniso phakathi kwabo lusekiwe. Oku kudla ngokufezekiswa ngokusetyenziswa kwe-vias, ebonelela ngoqhagamshelo lombane phakathi kweeleya ezahlukeneyo. Ii-Vias kufuneka ziyilwe ngononophelo ukulungiselela ukuguquguquka kwebhodi, kuqinisekiswe ukuba aziphazamisi ukusebenza ngokubanzi.

Ukwanyisa kunye nokwakheka umaleko yangaphandle for engqongqo-flex yokuvelisa pcb

Emva kokuba uluhlu lwangaphakathi lwenziwe, inkqubo ye-lamination iqala. Oku kubandakanya ukupakisha iileya ezizimeleyo kwaye ziphantsi kobushushu kunye noxinzelelo. Ukushisa kunye noxinzelelo kusebenze i-adhesive kwaye ikhuthaze ukudibanisa kwemigangatho, ukudala isakhiwo esinamandla kunye nesigxina.

Emva kwe-lamination, inkqubo yokwakheka komgangatho wangaphandle iqala. Oku kubandakanya ukubeka ungqimba oluncinci lobhedu kumphezulu wangaphandle webhodi yesiphaluka, elandelwa yinkqubo ye-photolithography ukudala iphethini yokugqibela yesiphaluka. Ukuqulunqwa komgangatho wangaphandle kufuna ukuchaneka kunye nokuchaneka ukuze kuqinisekiswe ukulungelelaniswa ngokuchanekileyo kwepateni yesiphaluka kunye nomgangatho wangaphakathi.

Ukugrumba, iplating kunye nonyango umphezulu engqongqo bhetyebhetye pcb iibhodi imveliso

Isinyathelo esilandelayo kwinkqubo yokuvelisa i-drilling. Oku kubandakanya imingxuma yokugrumba kwi-PCB ukuvumela amalungu ukuba afakwe kunye noqhagamshelwano lombane lwenziwe. I-Rigid-flex PCB yokomba ifuna izixhobo ezikhethekileyo ezinokuthatha ubukhulu obuhlukeneyo kunye neebhodi zesekethe eziguquguqukayo.

Emva kokugrumba, i-electroplating iyenziwa ukunyusa umgangatho wePCB. Oku kubandakanya ukubeka umaleko obhityileyo wesinyithi (ngokuqhelekileyo ubhedu) kwiindonga zomngxuma ogrunjiweyo. Imingxuma eplathiweyo inika indlela ethembekileyo yokuseka ukudityaniswa kombane phakathi kwemigangatho eyahlukeneyo.

Ekugqibeleni, ukugqitywa komphezulu kwenziwa. Oku kubandakanya ukufaka isambatho esikhuselayo kwimiphezulu yobhedu eveziweyo ukuthintela ukubola, ukomeleza ukubola, kunye nokuphucula ukusebenza kwebhodi kukonke. Ngokuxhomekeke kwiimfuno ezithile zesicelo, unyango oluphezulu oluhlukeneyo luyafumaneka, njenge-HASL, ENIG okanye i-OSP.

Ulawulo lomgangatho kunye novavanyo lokwenziwa kwebhodi yesekethe eqinileyo eprintiweyo

Kuyo yonke inkqubo yokuvelisa, amanyathelo okulawula umgangatho aphunyezwa ukuze kuqinisekiswe imigangatho ephezulu yokuthembeka nokusebenza. Sebenzisa iindlela zokuvavanya eziphambili ezifana nokuhlolwa kwe-automated optical inspection (AOI), ukuhlolwa kwe-X-ray kunye novavanyo lombane ukuchonga naziphi na iziphene okanye imiba kwibhodi yesekethe egqityiweyo. Ukongeza, uvavanyo olungqongqo lwendalo esingqongileyo kunye nokuthembeka luyenziwa ukuze kuqinisekiswe ukuba ii-PCB eziguquguqukayo zinokumelana neemeko ezinzima.

Ukushwankathela

Ukuveliswa kweebhodi ze-rigid-flex zifuna iinkqubo ezikhethekileyo zokuvelisa. Isakhiwo esiyinkimbinkimbi kunye neempawu ezizodwa zezi bhodi zeesekethe eziphambili zifuna ukuqwalaselwa ngononophelo, ukhetho oluchanekileyo lwezinto eziphathekayo kunye namanyathelo okuvelisa ngokwezifiso. Ngokulandela ezi nkqubo zokwenziwa zikhethekileyo, abavelisi bezinto zombane banokusebenzisa amandla apheleleyo eePCBs eziguquguqukayo kwaye bazise amathuba amatsha okuvelisa izinto ezintsha, eziguquguqukayo kunye nezixhobo zombane ezihlangeneyo.

Ixesha lokuposa: Sep-18-2023

Emva