Iibhodi zesekethe eziprintiweyo eziguquguqukayo (PCBs), ezaziwa ngokuba ziiPCB eziguqukayo, ziye zanda kakhulu kwiminyaka yakutshanje ngenxa yokugoba kwazo okukodwa kunye nokujija. Ezi bhodi zesekethe ziguquguqukayo ziguquguquka kakhulu kwaye zifumana izicelo kumashishini amaninzi, kubandakanya iimoto, i-elektroniki yabathengi, ukhathalelo lwezempilo kunye nonxibelelwano. Xa uodola ii-PCB eziguquguqukayo, kubalulekile ukuqonda izinto ezichaphazela amaxabiso azo ukuze kuphunyezwe ukusebenza kakuhle kweendleko kunye nokusebenza kakuhle.Kweli nqaku, siza kuphonononga kwizinto eziphambili eziphembelela ikhowuti yePCB eguqukayo, ekwenza ukwazi ukwenza izigqibo ezizizo xa ubeka iiodolo. Ngokufumana ulwazi kwezi zinto, ungalongeza ibhajethi yakho kwaye uqinisekise ukuba iimfuno zakho zePCB zihambelana neemfuno zakho kunye nemigangatho yoshishino.

1.Uyilo oluntsonkothileyo: Enye yezinto eziphambili ezichaphazela iikowuteshini zePCB ezibhetyebhetye kuyilo oluntsonkothileyo.

Uyilo oluntsonkothileyo ludlala indima ebalulekileyo ekumiseleni iindleko zokwenziwa kwee-PCB eziguqukayo. Uyilo oluntsonkothileyo luhlala lubandakanya ukujikeleza okuntsonkothileyo, ukusebenza okuphezulu, kunye neemfuno ezizodwa ezifuna izixhobo ezikhethekileyo kunye neenkqubo. Ezi mfuno zongezelelweyo zandisa ixesha lokuvelisa kunye nomgudu, okukhokelela kwiindleko eziphezulu zokuvelisa.

Enye inkalo yoyilo oluntsonkothileyo kukusetyenziswa kwezandi zepitch entle. Amacandelo e-fine-pitch anemivalo yokukhokela emxinwa, efuna ukuchaneka okuphezulu kwinkqubo yokuvelisa. Oku kufuna izixhobo ezikhethekileyo kunye neenkqubo zokuqinisekisa ukufaneleka okuchanekileyo. Amanyathelo awongezelelweyo kunye nezilumkiso ezifunekayo kumacandelo e-fine-pitch yongeza kubunzima bokuvelisa kunye neendleko.

I-radii encinci ye-bend yenye into echaphazela ukuntsokotha koyilo. Iibhodi zesekethe eziprintiweyo eziguquguqukayo ziyaziwa ngokukwazi ukugoba kunye nokujija, kodwa xa i-bend radii incinci kakhulu, oku kudala imiqobo kwinkqubo yokuvelisa. Ukufezekisa i-radii ye-bend encinci kufuna ukukhethwa kwezinto eziphathekayo kunye neendlela ezichanekileyo zokugoba ukuphepha umonakalo wesiphaluka okanye ukuguqulwa. Ezi ngqwalasela zongezelelweyo zandisa ubunzima bokwenza kunye neendleko.

Ukongeza, ukuhanjiswa kwesekethe entsonkothileyo yenye inkalo echaphazela ukuyila ubunzima. Uyilo oluphucukileyo luhlala lufuna ukuhanjiswa kwemiqondiso entsonkothileyo, ukuhanjiswa kwamandla, kunye neenqwelomoya zomhlaba. Ukufezekisa umzila ochanekileyo kwii-PCB eziguquguqukayo kunokuba ngumngeni kwaye kunokufuna amanyathelo ongezelelweyo afana neendlela ezikhethekileyo zokucwenga ubhedu okanye ukusetyenziswa kwee-vias ezingaboniyo kunye nokungcwatywa. Ezi mfuno zongezelelweyo zandisa ubunzima bokwenza kunye neendleko.

2.Ukukhethwa kwezinto:Enye into ephambili ekumiseleni iikowuteshini zePCB eziguquguqukayo kukukhethwa kwezinto.

Ukukhetha izinto eziphathekayo kukuqwalasela okuphambili ekumiseleni iindleko zePCB eguquguqukayo. Ii-substrates ezahlukeneyo zibonelela ngamanqanaba ahlukeneyo okusebenza kunye nefuthe leendleko. Ukukhethwa kwezinto eziphathekayo kuxhomekeke kwiimfuno ezithile zesicelo.

I-Polyimide (PI) iyaziwa ngeempawu zayo eziphezulu zokusebenza, kubandakanywa ukuzinza okuhle kakhulu kwe-thermal kunye nokuguquguquka. Inokumelana namaqondo obushushu aphezulu kwaye ifanelekile kwizicelo ezinobushushu obuphezulu bokusebenza. Nangona kunjalo, ukusebenza okuphezulu kwe-polyimide kuza ngexabiso eliphezulu xa kuthelekiswa nezinye izinto. Oku kungenxa yenkqubo yokwenziwa entsonkothileyo kwaye enexabiso eliphezulu yemathiriyeli ekrwada ye-polyimide.

I-Polyester (PET) yenye i-substrate eqhelekileyo yee-PCB eziguquguqukayo. Ixabiso eliphantsi kune-polyimide kwaye inokuguquguquka okuhle. Polyester-based flex PCBs zifanelekile kwizicelo ezineemfuno ezisezantsi zobushushu. Nangona kunjalo, ukuzinza kwe-thermal ye-polyester akulunganga njenge-polyimide, kwaye ukusebenza kwayo jikelele kunokuba ngaphantsi. Ukusetyenziswa kweendleko eziphantsi kweemeko zokusebenza eziphantsi, iipolyester zikhetho olusebenzayo kunye neendleko.

I-PEEK (i-polyetheretherketone) yinto ephezulu yokusebenza esetyenziswa ngokubanzi kwizicelo ezifunwayo. Inomsebenzi ogqwesileyo womatshini kunye ne-thermal kwaye ifanelekile kwiimeko ezinzima. Nangona kunjalo, i-PEEK ibiza kakhulu kune-polyimide kunye ne-polyester. Ihlala ikhethwa kwizicelo apho umsebenzi ophezulu ufuneka kwaye ixabiso eliphezulu lezinto eziphathekayo linokuthetheleleka.

Ukongeza kwi-substrate material, ezinye izinto ezisetyenziselwa inkqubo yokuvelisa, ezifana ne-laminates, iifilimu zokugubungela kunye nezinto zokubambelela, nazo zichaphazela iindleko ezipheleleyo. Iindleko zezi zinto ezongezelelweyo zinokuhluka ngokuxhomekeka kumgangatho wabo kunye neempawu zokusebenza. Ngokomzekelo, i-laminates ekumgangatho ophezulu kunye neempawu zombane eziphuculweyo okanye iifilimu ezikhethekileyo zokugubungela kunye nokukhusela okongeziweyo kwizinto zokusingqongileyo kunokongeza kwiindleko ezipheleleyo ze-PCB eguquguqukayo.

3.Ubungakanani kunye nephazili:Ubungakanani bePCB ebhetyebhetye efunekayo budlala indima ebalulekileyo ekumiseleni ikowuteshini.

Ubungakanani obufunekayo ngumba ophambili xa amaxabiso e-PCBs aguqukayo. Abavelisi bakholisa ukwenza amaxabiso asekelwe kubungakanani, nto leyo ethetha ukuba xa uphezulu umyinge, ixabiso leyunithi lisezantsi. Oku kungenxa yokuba iiodolo ezinkulu zivumela uqoqosho olungcono lwesikali kwaye ngaloo ndlela zithobe iindleko zemveliso

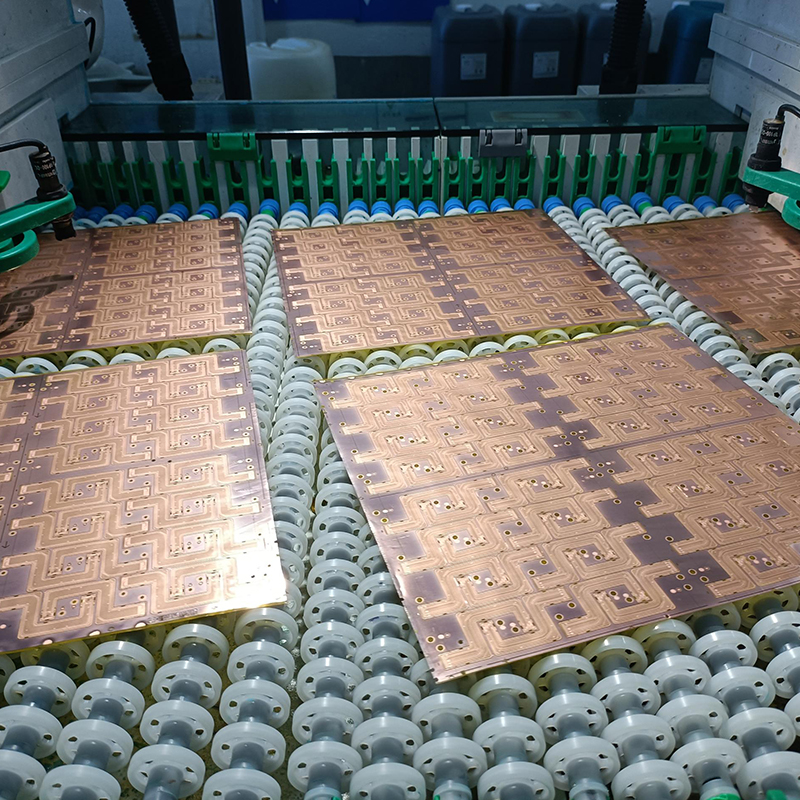

Enye indlela yokwandisa ukusetyenziswa kwezinto kunye nokusebenza kakuhle kokwenziwa kweepaneli. Iphaneli ibandakanya ukudibanisa iiPCB ezincinci ezininzi kwiphaneli enkulu. Ngokucwangcisa ngobuchule uyilo kwiipaneli, abavelisi banokunciphisa inkunkuma kwaye bakhulise imveliso ngexesha lenkqubo yokuvelisa.

Iphaneli ineenzuzo ezininzi. Okokuqala, kunciphisa inkunkuma yezinto eziphathekayo ngokusetyenziswa ngokufanelekileyo kwendawo ekhoyo kwipaneli. Endaweni yokuvelisa ii-PCBs ezahlukeneyo ezinemida yazo kunye nesithuba, abavelisi banokubeka uyilo oluninzi kwiphaneli enye, besenza eyona ndawo ingasetyenziswanga phakathi. Oku kubangela ukongiwa kwezinto ezibalulekileyo kunye nokunciphisa iindleko.

Ukongeza, i-panelization yenza lula inkqubo yokuvelisa. Ivumela inkqubo yokuvelisa ezenzekelayo nesebenzayo njengoko ii-PCB ezininzi zinokusetyenzwa ngaxeshanye. Oku kwandisa imveliso kwaye kunciphisa ixesha lokuvelisa, okukhokelela kwixesha elifutshane lokukhokela kunye neendleko eziphantsi. Iphaneli esebenzayo ifuna ukucwangciswa ngononophelo kunye nokuqwalaselwa kwezinto ezifana nobungakanani bePCB, iimfuno zoyilo, kunye nobuchule bokwenza. Abavelisi banokusebenzisa izixhobo zesoftware ezikhethekileyo ukuncedisa kwinkqubo yepaneli, ukuqinisekisa ulungelelwaniso olufanelekileyo kunye nokusetyenziswa ngokufanelekileyo kwezinto.

Ngaphezu koko, uyilo lwepaneli kulula ukuphatha kunye nokuthutha. Emva kokuba inkqubo yokuvelisa igqityiwe, iiphaneli zinokwahlulwa zibe yiPCB nganye. Oku kwenza ukupakishwa kube lula kwaye kunciphisa umngcipheko womonakalo ngexesha lokuthunyelwa kwenqanawa, okugcina konga imali.

4. Ukuphela komhlaba kunye nobunzima beCopper: Ukugqitywa komphezulu kunye nobunzima bobhedu zizinto eziphambili zokuqwalaselwainkqubo yokwenziwa kwe-PCB eguquguqukayo.

Ukugqitywa komphezulu ngumba obalulekileyo wokwenziwa kwePCB njengoko kuchaphazela ngokuthe ngqo ukuthengiswa kunye nokuqina kwebhodi. Unyango oluphezulu lubumba uluhlu olukhuselayo phezu kweendlela zobhedu eziveziweyo, ukuthintela i-oxidation kunye nokuqinisekisa ukuba i-solder joints ethembekileyo. Unyango lomphezulu olwahlukileyo luneendleko ezahlukeneyo kunye neenzuzo.

Ukugqitywa okuqhelekileyo yi-HASL (i-Hot Air Solder Leveling), ebandakanya ukusebenzisa umaleko we-solder kwiindlela zobhedu kwaye emva koko usebenzisa umoya oshushu ukulinganisa. I-HASL inexabiso eliphantsi kwaye ibonelela ngokuthengiswa kakuhle, kodwa isenokungafanelanga i-fine-pitch okanye i-fine-pitch components ngenxa yomgangatho ongalinganiyo ovelisayo.

I-ENIG (Electroless Nickel Immersion Gold) lolunye unyango lwangaphezulu olusetyenziswa ngokubanzi. Kubandakanya ukubeka umaleko obhityileyo wenikeli phezu kweetrayisi zobhedu, kulandele umaleko wegolide. Ukuthengiswa okugqwesileyo kwe-ENIG, umphezulu othe tyaba, kunye nokumelana nomhlwa kuyenza ifaneleke kwizinto ezinomgangatho ophantsi kunye noyilo oluxinana kakhulu. Nangona kunjalo, i-ENIG ineendleko eziphezulu xa kuthelekiswa nolunye unyango olungaphezulu.

I-OSP (i-Organic Solderability Preservative) lunyango lomphezulu olubandakanya ukusetyenziswa komgangatho obhityileyo wezinto eziphilayo ukukhusela imikhondo yobhedu. I-OSP ibonelela ngokuthengiswa kakuhle, ukucwangciswa kunye nokusebenza kakuhle kweendleko. Nangona kunjalo, ayihlali ixesha elide njengezinye iziqendu kwaye inokufuna ukuphathwa ngononophelo ngexesha lokuhlanganisa.

Ubunzima (kwii-ounces) zobhedu kwi-PCB bumisela ukuhanjiswa kunye nokusebenza kwebhodi. Iileya ezityebileyo zobhedu zibonelela ngokuxhathisa okuphantsi kwaye ziyakwazi ukuphatha imisinga ephezulu, zizenze zilungele ukusetyenziswa kwamandla. Nangona kunjalo, iileya zobhedu ezishinyeneyo zifuna izinto ezininzi kunye neendlela zokwenza izinto ezinobunkunkqele, ngaloo ndlela zinyusa iindleko zizonke zePCB. Ngokwahlukileyo, iileya zobhedu ezincinci zifanelekile kwizicelo zamandla aphantsi okanye izicelo apho kukho imiqobo yendawo. Zifuna izinto ezincinci kwaye zineendleko eziphezulu. Ukukhethwa kobunzima bobhedu kuxhomekeke kwiimfuno ezithile zoyilo lwePCB kunye nomsebenzi ojoliswe kuwo.

5.ITekhnoloji yokuVelisakunye noMold:Ubuchule bokwenza kunye nezixhobo ezisetyenziselwa ukuvelisa iiPCB eziguquguqukayo nazo zichaphazela amaxabiso.

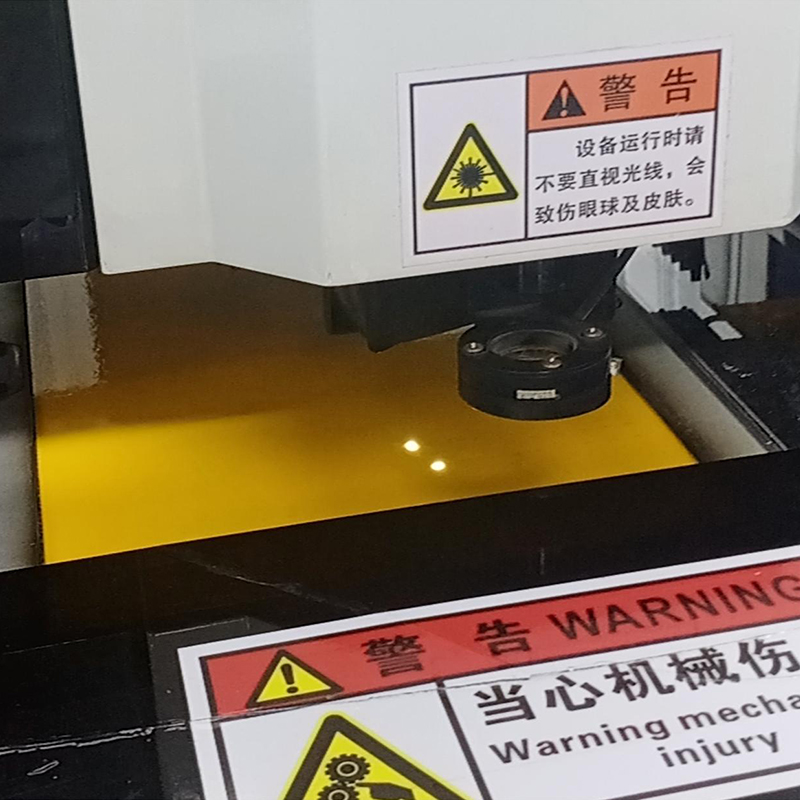

Itekhnoloji yokuvelisa idlala indima ebalulekileyo ekuvelisweni kweePCB eziguquguqukayo kwaye inefuthe elikhulu kumaxabiso. Ubuchwephesha obuphezulu, obufana ne-laser drilling kunye ne-sequential build-up (SBU), inokudala uyilo olunzima kunye noluchanekileyo, kodwa ezi ndlela zihlala ziza neendleko eziphezulu zemveliso. Ukugrumba ngeLaser kunokwenza ii-vias ezintle kunye nemingxuma emincinci, ivumela iisekethe ezinoxinano oluphezulu kwiiPCB eziguqukayo. Nangona kunjalo, ukusetyenziswa kweteknoloji yelaser kunye nokuchaneka okufunekayo kwinkqubo kwandisa iindleko zokuvelisa.

Ulwakhiwo olulandelelanayo (i-SBU) yenye indlela yokuvelisa ephucukileyo ebandakanya ukwahlulahlula iisekethe ezininzi eziguqukayo ukwenza uyilo oluntsonkothileyo. Le teknoloji yandisa ukuguquguquka koyilo kwaye yenza ukuhlanganiswa kwemisebenzi eyahlukeneyo kwi-PCB enye ebhetyebhetye. Nangona kunjalo, ubunzima obongezelelweyo kwinkqubo yokuvelisa kwandisa iindleko zemveliso.

Ukongeza kubuchule bokuvelisa, iinkqubo ezithile ezibandakanyekayo ekuveliseni ii-PCB eziguquguqukayo nazo zinokuchaphazela amaxabiso. Iinkqubo ezifana nokucwenga, ukuqhotyoshwa, kunye ne-lamination ngamanyathelo abalulekileyo ekwenziweni kwe-PCB esebenza ngokupheleleyo nethembekileyo. Umgangatho wale mveliso, kubandakanywa izinto ezisetyenzisiweyo kunye nenqanaba lokuchaneka okufunekayo, lichaphazela ixabiso elipheleleyo

Izixhobo ezizenzekelayo kunye nezixhobo ezintsha zinceda ukwandisa imveliso kunye nokusebenza kakuhle kwinkqubo yokuvelisa. Oomatshini abazenzekelayo, iirobhothi, kunye neenkqubo zokuvelisa ezincediswa yikhompyutha (CAM) zinokwenza lula imveliso, zinciphise iimpazamo zabantu, kwaye zikhawulezise inkqubo yokuvelisa. Nangona kunjalo, ukuphumeza oko kuzenzekelayo kunokufuna iindleko ezongezelelweyo, kubandakanywa utyalo-mali kwangaphambili kwizixhobo kunye nokuqeqeshwa kwabasebenzi.

Ukongeza, ukusetyenziswa kwezixhobo ezintsha kunye nobuchwepheshe, njengesoftware yoyilo lwePCB ephucukileyo kunye nezixhobo zokuhlola, kunokunceda ukunyusa amaxabiso. Ezi zixhobo zihlala zifuna ubuchule obukhethekileyo, ukugcinwa kunye nohlaziyo, zonke ezo zongeza kwiindleko zizonke. Abavelisi kufuneka baqwalasele ngononophelo ukulingana phakathi kobugcisa bokuvelisa, iinkqubo, ukuzenzekelayo kunye nezixhobo ezintsha zokuphumeza iindleko kunye nomgangatho wokulinganisela ofunekayo kwimveliso ye-PCB eguquguqukayo. Ngokuhlalutya iimfuno ezithile zeprojekthi kunye nokusebenza nabathengi, abavelisi banokumisela iteknoloji efanelekileyo kunye neenkqubo ngelixa benciphisa iindleko kunye nokuqinisekisa iziphumo ezingcono kakhulu zokuvelisa.

6.Ixesha lokuhambisa kunye nokuthunyelwa:Ixesha elifunekayo lokukhokela yinto ebalulekileyo echaphazela ikhowuti yePCB eguquguqukayo.

Xa kufikwa kwixesha le-PCB eliguquguqukayo, ixesha lokukhokela lidlala indima ebalulekileyo. Ixesha lokukhokela lixesha elithathayo ukuze umenzi agqibezele imveliso kwaye alungele ukuthunyelwa kweodolo. Amaxesha okukhokela achatshazelwa zizinto ezininzi, kuquka ukuntsonkotha koyilo, inani leePCB eziodolweyo, nomthwalo okhoyo ngoku womenzi.

Iiodolo ezingxamisekileyo okanye iishedyuli eziqinileyo zihlala zifuna ukuba abavelisi babeke phambili imveliso kwaye babele izixhobo ezongezelelweyo ukuhlangabezana nemihla ebekiweyo. Kwiimeko ezinjalo, imveliso inokufuna ukukhawuleziswa, nto leyo enokubangela iindleko eziphezulu. Abavelisi banokubiza imirhumo ekhawulezileyo okanye baphumeze iinkqubo zokuphatha ezizodwa ukuqinisekisa ukuba ii-PCB eziguquguqukayo ziyenziwa kwaye zihanjiswe ngexesha elibekiweyo.

Iindleko zokuthumela nazo zichaphazela ixabiso elipheleleyo le-flex PCB. Iindleko zokuthumela ngenqanawa zimiselwa yimiba emininzi. Okokuqala, indawo yokuhambisa idlala indima ebalulekileyo kwiindleko zokuthumela. Ukuthumela ngenqanawa kwiindawo ezikude okanye ezikude kunokubandakanya iindleko eziphezulu ngenxa yokunyuka kweentlawulo zokuthumela ngenqanawa. Ukongeza, ukungxamiseka kokuhanjiswa kuya kuchaphazela neendleko zokuthumela. Ukuba umthengi ufuna ukuthunyelwa ngokukhawuleza okanye ubusuku bonke, iindleko zokuthumela ziya kuba phezulu xa kuthelekiswa neendlela eziqhelekileyo zokuthumela ngenqanawa.

Ixabiso le-odolo likwachaphazela iindleko zokuthumela ngenqanawa. Abanye abavelisi banokunikezela ngenqanawa yasimahla okanye ethotyiweyo kwiiodolo ezinkulu njengenkuthazo kubathengi ukuba bafake iiodolo ezininzi. Ngakolunye uhlangothi, kwii-odolo ezincinci, iintlawulo zokuthumela ngenqanawa zinokuba phezulu ukuhlawula iindleko ezibandakanyekayo ekupakisheni nasekuphatheni.

Ukuqinisekisa ukuthunyelwa ngokufanelekileyo kunye nokunciphisa iindleko, abavelisi banokusebenzisana ngokusondeleyo nababoneleli bezothutho ukuze banqume eyona ndlela ingabizi kakhulu yokuthumela. Oku kunokubandakanya ukukhetha umntu ophethe inqanawa ofanelekileyo, uthethathethwano ngamaxabiso afanelekileyo othutho, kunye nokuphucula ukupakishwa ukunciphisa ubunzima kunye nobukhulu.

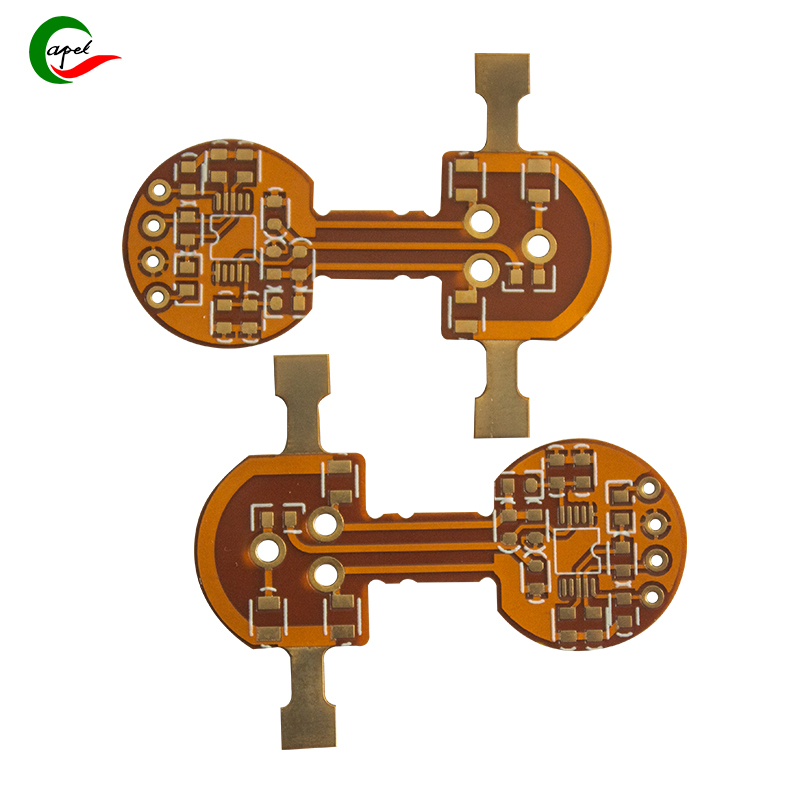

Ukushwankathela,kukho izinto ezininzi ezichaphazela ucaphulo lwePCB ebhetyebhetye. Abathengi abanokuqonda okucacileyo kwezi zinto banokwenza izigqibo ezinolwazi kwaye baphucule iinkqubo zabo zokuvelisa.Ubunzima boyilo, ukukhethwa kwezinto kunye nobuninzi zizinto eziphambili ezichaphazela iindleko zePCB eguquguqukayo.Uyilo oluntsonkothileyo, kokukhona ixabiso liphezulu. Ukukhetha izinto eziphathekayo, njengokukhetha i-substrate esemgangathweni ophezulu okanye ukugqiba umgangatho, kunokuchaphazela ixabiso. Kwakhona, ukuodola izixa ezikhulu kudla ngokukhokelela kwizaphulelo ezininzi. Ezinye izinto, ezifana nepaneli, ubunzima bobhedu, ubuchule bokwenza kunye nezixhobo zokusebenza, nazo zidlala indima ekunqumeni iindleko. Ipaneli ivumela ukusetyenziswa ngokufanelekileyo kwezinto kunye nokunciphisa iindleko. Ubunzima bobhedu buchaphazela inani lobhedu olusetyenzisiweyo, oluchaphazela iindleko kunye nokusebenza kwe-PCB ye-flex. Ubuchule bokuvelisa kunye nezixhobo, ezifana nokusetyenziswa kobuchwepheshe obuphezulu okanye izixhobo ezikhethekileyo, zinokuchaphazela amaxabiso. Ekugqibeleni, ixesha lokuhamba kunye nokuthunyelwa kweenqanawa kubalulekile. Iintlawulo ezongezelelweyo zinokufaka isicelo kwii-odolo ezikhawulezayo okanye imveliso ekhawulezileyo, kwaye iindleko zokuthumela ngenqanawa zixhomekeke kwizinto ezifana nendawo, ukungxamiseka, kunye nexabiso lokuodola. Ngokuphonononga ngocoselelo le miba kunye nokusebenza nomenzi we-PCB onamava kunye nothembekileyo, iinkampani zinokwenza i-PCB enexabiso eliphezulu nekumgangatho ophezulu ehlangabezana neemfuno zabo ezithile.I-Shenzhen Capel Technology Co., Ltd. iye yenza iibhodi zesekethe eziguquguqukayo eziprintiweyo (PCBs) ukususela ngo-2009.Okwangoku, siyakwazi ukubonelela ngokwesiko 1-30 umaleko oguquguqukayo weebhodi zesekethe eziprintiweyo. I-HDI yethu (i-High Density Interconnect) iteknoloji yokuvelisa i-PCB ikhulile kakhulu. Kule minyaka ili-15 idlulileyo, siye sayila itekhnoloji ngokuqhubekayo kwaye saqokelela amava atyebileyo ekusombululeni iingxaki ezinxulumene neprojekthi kubathengi.

Ixesha lokuposa: Aug-31-2023

Emva