Yazisa:

Kule mihla yedijithali, inkqubela phambili yetekhnoloji iguqula ngokukhawuleza amashishini kwihlabathi jikelele. Ngokungeniswa kokwenziwa kobuchule kunye neenkqubo zolawulo lwedatha, iinkqubo zokuvelisa ziye zatshintsha utshintsho. Ushishino lwebhodi yesekethe eprintiweyo (PCB) nalo lwenze utshintsho olukhulu ngenxa yenkqubela phambili yetekhnoloji.Kule post blog, siya kuphonononga ukuba ngaba iCapel inokubonelela ngobuchule bokuvelisa kunye nolawulo lwedatha kwiibhodi zeesekethe zePCB.

1. Qonda iibhodi zesekethe zePCB:

Phambi kokungena ekudibaneni kwebhodi yesekethe yePCB yokwenziwa ngobuchule kunye nolawulo lwedatha, kubalulekile ukuba ubambe ingqikelelo yePCB ngokwayo. IiPCB zingumqolo wezixhobo zombane zala maxesha, ezibonelela ngeqonga lokuqhagamshelanisa amacandelo awohlukeneyo e-elektroniki. IiPCBs zikhule ngokuntsonkotha kule minyaka idlulileyo, ifuna iinkqubo ezisebenzayo zokwenziwa kunye nolawulo lwedatha olungenasiphako.

2. Ukwenziwa ngobukrelekrele kushishino lwePCB:

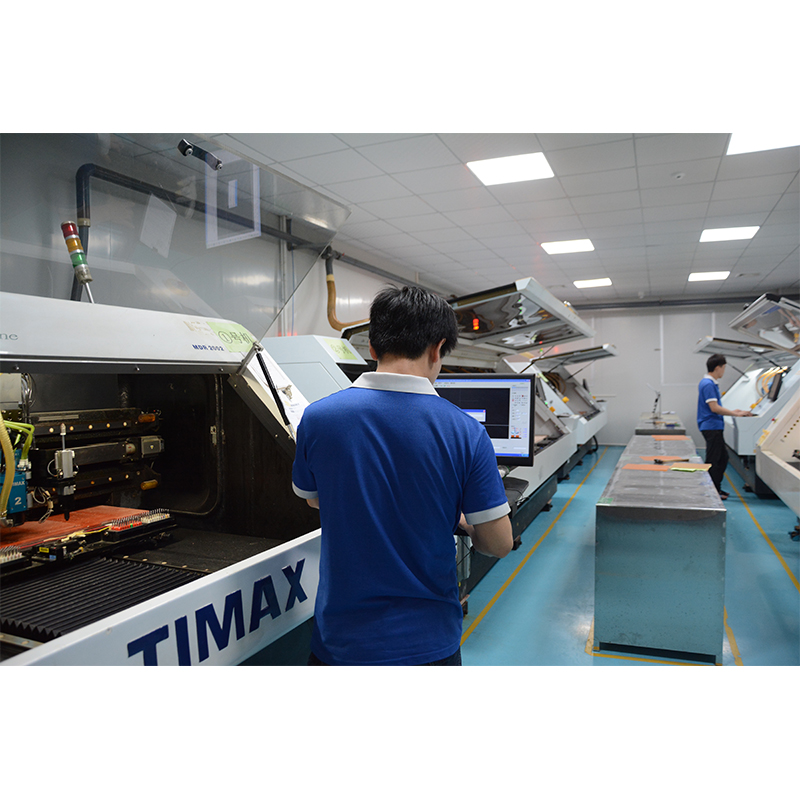

Imveliso ehlakaniphile iphakamisa itekhnoloji ephezulu efana nobukrelekrele bokwenziwa (AI), i-Intanethi yeZinto (IoT), iirobhothi, kunye ne-automation ukuhambisa iinkqubo zemveliso, ukunciphisa iimpazamo, kunye nokwandisa ukusebenza kakuhle. Njengoko ii-PCB ziba nzima ngakumbi nangakumbi, uCapel, njengomqambi omtsha kule ntsimi, uye waqaphela ukubaluleka kokuvelisa ngobuchule kwimveliso yePCB.

2.1 Ukuzitshintsha kwerobhothi:

I-Capel idibanisa i-automation ye-robotic kwiinkqubo zokuvelisa ukwandisa ukuchaneka nokuchaneka. Iirobhothi ziyakwazi ukuphatha amacandelo e-PCB eethe-ethe, ziqinisekisa ukuba iimpazamo ezenziwa ngabantu ziyacinywa. Ukongeza, iirobhothi ezinikwe amandla e-AI zinokwandisa imigca yemveliso ngokuchonga imiqobo kunye nokuhambisa ukuhamba komsebenzi.

2.2 Udibaniso lwe-Intanethi yeZinto (IoT):

I-Capel idibanisa amandla e-IoT ukudibanisa oomatshini kunye nezixhobo zayo, ivumela ukuqokelela idatha yexesha langempela kunye nohlalutyo. Olu qhagamshelo luvumela ukubekwa esweni okuqhubekayo kwenkqubo yokuvelisa, ukuqinisekisa ukufunyanwa kwangethuba kwaso nakuphi na ukungahambi kakuhle okanye ukusilela kwezixhobo. Ngokusebenzisa i-IoT, iCapel iqinisekisa ukuhamba komsebenzi okwenziwa ngokukhawuleza kunye nokuphendulayo.

3. Ulawulo lwedatha kushishino lwePCB:

Ulawulo lwedatha lugubungela umbutho ocwangcisiweyo, ukugcinwa kunye nohlalutyo lwedatha kuwo wonke umjikelo wemveliso wePCB. Ulawulo lwedatha olusebenzayo lubalulekile ekulandeleni umgangatho wemveliso, ukuchonga iindawo zokuphucula, kunye nokuqinisekisa ukuthotyelwa kwemithetho. Indlela kaCapel yokulawula idatha ibenza bahluke kubakhiqizi bendabuko.

3.1 Uhlalutyo lwexesha langempela:

I-Capel iphumeze inkqubo yohlalutyo lwedatha ephezulu ekwazi ukucubungula amanani amakhulu edatha yokuvelisa ngexesha langempela. Olu hlaziyo luvumela amaqela ukuba akhuphe ulwazi oluxabisekileyo ukwenza izigqibo ezikhawulezayo kunye nokusombulula imiba ngokuqhubekayo. Ngokuchonga iipateni kunye neendlela, iCapel inokuqhubeka nokwandisa umgangatho wemveliso kunye nokusebenza kakuhle.

3.2 Ukuqinisekiswa koMgangatho kunye nokulandelelwa:

I-Capel ibeka phambili ukuqinisekiswa komgangatho ngokufaka idatha kwinyathelo ngalinye lenkqubo yokuvelisa. Oku kuqinisekisa ukulandeleka okupheleleyo kwemveliso, okuvumela inkqubo esebenzayo yokukhumbula ukuba iyafuneka. Ngokugcina iirekhodi ezicacileyo zedatha yokuvelisa, iCapel iqinisekisa abathengi bolawulo oluluqilima lomgangatho kunye nokukwazi ukulungisa ngokukhawuleza nayiphi na imiba enokubakho.

4. Izinto eziluncedo zeCapel:

I-Capel idibanisa imveliso ehlakaniphile kunye nolawulo lwedatha ukubonelela ngeenzuzo ezininzi kwimveliso yebhodi yesekethe yePCB.

4.1 Ukuphucula ukusebenza kakuhle nokuchaneka:

Ngokusebenzisa i-robotic automation kunye ne-artificial intelligence-driven systems, iCapel inciphisa impazamo yabantu kwaye yandisa imveliso. Ukuhamba komsebenzi okulungelelanisiweyo okwenziwa luhlalutyo lwedatha lwexesha langempela lwenza kube lula ukwabiwa kwezixhobo kunye nokunciphisa amaxesha okujikeleza.

4.2 Ukuphucula ulawulo lomgangatho:

Inkqubo yolawulo lwedatha yeCapel iqinisekisa ukulandeleka okupheleleyo kunye nolawulo lomgangatho, ukuqinisekisa ukuba abathengi bafumana iiPCB ezikumgangatho ophezulu rhoqo. Uhlalutyo lwexesha langempela lunokuchonga imiba esemgangathweni enokubakho kwinkqubo yokuvelisa, ukuvumela ukuba kuthathwe amanyathelo okulungisa ngexesha elifanelekileyo.

4.3 Ukuphucula ukuguquguquka kunye nokusabela:

Indlela ye-Capel yokwenza i-smart production iqhutywa kukudityaniswa kwe-IoT, inika ukuguquguquka okungenakulinganiswa. Ngedatha yexesha langempela, imigca yokuvelisa iyakwazi ukulungelelanisa iimfuno eziguqukayo, ukuqinisekisa ukuhamba komsebenzi okuphendulayo. Olu buchule lwenza ukuba iCapel ikwazi ukuhlangabezana neemfuno ezahlukeneyo zabathengi ngelixa igcina amaxesha afanelekileyo okuhanjiswa.

Ukuququmbela:

Ukuzibophelela kukaCapel ekuveliseni ngobuchule kunye nolawulo lwedatha kuguqule ishishini lePCB. Badibanisa i-robotics, i-IoT, kunye ne-real-time analytics yedatha ukuqhuba ukuveliswa kweebhodi ze-PCB eziphezulu. Ngokunciphisa iimpazamo, ukwandisa ukusebenza kakuhle kunye nokuphucula ulawulo lomgangatho, iCapel ibeka imigangatho emitsha kwimveliso. Njengoko iteknoloji iqhubeka nokuqhubela phambili, iCapel iqinisekisa isikhundla sayo njengenkokeli kwibhodi yesekethe yePCB yokuvelisa ngobuchule kunye nolawulo lwedatha.

Ixesha lokuposa: Nov-03-2023

Emva