Ehlabathini leebhodi zeesekethe eziprintiweyo (PCBs), ukukhethwa kwezinto kunye neenkqubo zokuvelisa kunokuchaphazela kakhulu umgangatho kunye nokusebenza kwezixhobo zombane. Olunye uhlobo olunjalo yiPCB eshinyeneyo yegolide, ebonelela ngeenzuzo ezizodwa kwiiPCB eziqhelekileyo.Apha sijonge ukubonelela ngokuqondwa okubanzi kwe-PCB eshinyeneyo yegolide, sichaza ukubunjwa kwayo, iingenelo, kunye nomahluko kwiiPCB zemveli.

1.Ukuqonda Thick Gold PCB

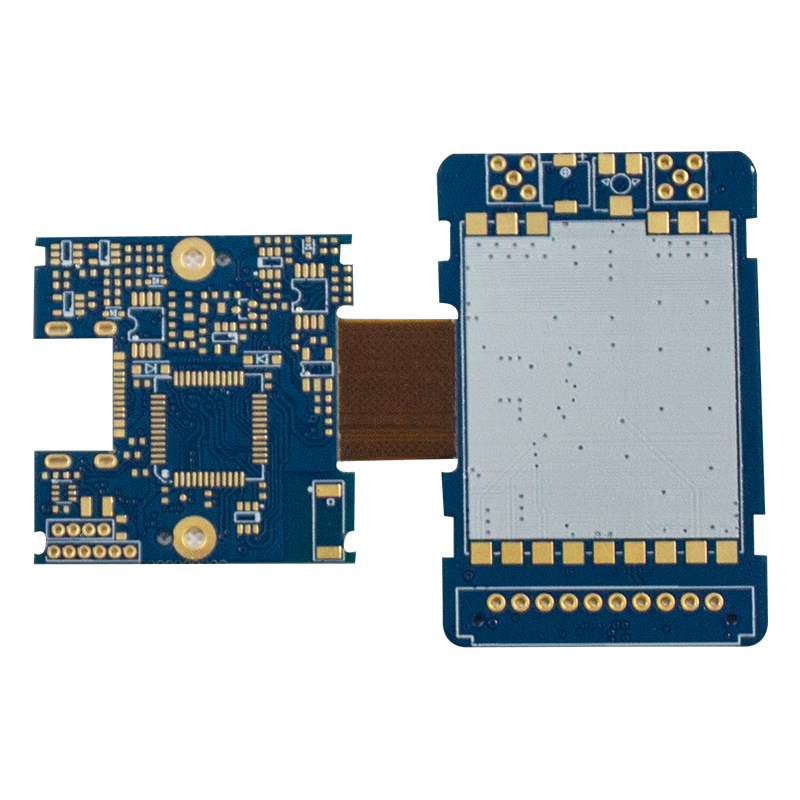

I-PCB yegolide eshinyeneyo luhlobo olukhethekileyo lwebhodi yesekethe eprintiweyo enomaleko wegolide ongqindilili kumphezulu wayo.Ziqulunqwe ngamanqwanqwa amaninzi obhedu kunye nezixhobo ze-dielectric ezinomgangatho wegolide wongezwe phezulu. Ezi PCBs zenziwa ngenkqubo electroplating eqinisekisa umaleko igolide nkqu kwaye ngokuqinileyo bonded.Ngokwahlukileyo PCBs eqhelekileyo, PCBs eshinyeneyo zegolide unomaleko oshinyeneyo ngokutyabeka igolide kumphezulu wokugqibela. Ubungqingqwa begolide kwi-PCB eqhelekileyo buqhelekile malunga ne-1-2 intshi okanye i-0.025-0.05 microns. Xa kuthelekiswa, iiPCB zegolide ezishinyeneyo zihlala zinobukhulu obuyi-30-120 microns okanye i-0.75-3 microns.

2.Izinto eziluncedo zePCB eshinyeneyo yegolide

IiPCB zegolide ezishinyeneyo zibonelela ngeenzuzo ezininzi kwiinketho eziqhelekileyo, kubandakanya ukuqina okongeziweyo, ukuhanjiswa okuphuculweyo kunye nokusebenza okuphezulu.

Ukuqina:

Enye yeenzuzo eziphambili zeePCB zegolide ezishinyeneyo kukuqina kwazo okukhethekileyo. Ezi bhodi zenzelwe ngokukodwa ukumelana neendawo ezinzima, ezizenza zibe zilungele izicelo ezihlala zibonakaliswe kumaqondo okushisa aphezulu okanye iimeko ezinzima. Ubukhulu be-plating yegolide bunika umaleko wokukhusela ekungcoleni, kwi-oxidation kunye nezinye iindlela zomonakalo, ukuqinisekisa ubomi obude be-PCB.

Ukuphucula ukuhanjiswa kombane:

IiPCB zegolide ezishinyeneyo zinokuhanjiswa kombane okugqwesileyo, nto leyo ezenza zibe lukhetho lokuqala lwezicelo ezifuna ukuhanjiswa komqondiso okusebenzayo. Ukutyeba okwandisiweyo kweplating yegolide kunciphisa ukuxhathisa kwaye konyusa ukusebenza kombane, kuqinisekisa ukuhanjiswa komqondiso ongenamthungo kwibhodi yonke. Oku kubaluleke ngakumbi kumashishini afana nonxibelelwano, i-aerospace kunye nezixhobo zonyango, apho ukuhanjiswa kwedatha ngokuchanekileyo nokuthembekileyo kubaluleke kakhulu.

Phucula i-solderability:

Enye inzuzo yeePCB zegolide ezishinyeneyo kukuphuculwa kokuthengiswa kwazo. Ukunyuswa kobunzima begolide beplating kuvumela ukuhamba kakuhle kwe-solder kunye nokumanzisa, ukunciphisa ukubakho kwemiba yokuphinda kufakwe i-solder ngexesha lokuvelisa. Oku kuqinisekisa ukuba i-solder joints eqinile kwaye inokuthenjwa, ukuphelisa iziphene ezinokuthi zibe khona kunye nokuphucula umgangatho wemveliso jikelele.

Ubomi boqhagamshelwano:

Uqhagamshelwano lombane kwiiPCB ezishinyeneyo zegolide zihlala ixesha elide ngenxa yokwanda kobunzima begolide. Oku kwandisa ukuthembeka koqhagamshelwano kwaye kunciphisa umngcipheko wokuthotywa kwesignali okanye uqhagamshelo oluphakathi ekuhambeni kwexesha. Ngoko ke, ezi PCB zisetyenziswa ngokubanzi kwizicelo ezinemijikelezo ephezulu yokufaka / yokukhupha, njengezixhumi zekhadi okanye iimodyuli zememori, ezifuna ukusebenza koqhagamshelwano oluhlala ixesha elide.

Phucula ukuxhathisa ukunxiba:

IiPCB zegolide ezishinyeneyo zisebenza kakuhle kwizicelo ezifuna ukunxitywa nokukrazuka okuphindaphindiweyo. Ukunyuka kobunzima begolide yegolide kunika umqobo okhuselayo onceda ukujamelana nokuxubha kunye nemiphumo yokusetyenziswa ngokuphindaphindiweyo. Oku kubenza balungele iziqhagamshelo, iipads zokuchukumisa, amaqhosha kunye namanye amacandelo athambekele ekudibaneni rhoqo ngokomzimba, ukuqinisekisa ubomi obude kunye nokusebenza okungaguqukiyo.

Nciphisa ilahleko yesignali:

Ukulahlekelwa ngumqondiso yingxaki eqhelekileyo kwizicelo eziphezulu zefrikhwensi. Nangona kunjalo, iiPCB zegolide ezishinyeneyo zibonelela ngesisombululo esisebenzayo esinokunciphisa ilahleko yomqondiso ngenxa yokwenziwa kwazo okuphuculweyo. Ezi PCB zibonisa ukuchasana okuphantsi ukuze kuqinisekiswe imfezeko yophawu olufanelekileyo, ukunciphisa ilahleko yokuhanjiswa kwedatha kunye nokwandisa ukusebenza kakuhle kwenkqubo. Ke ngoko, zisetyenziswa kakhulu kumashishini anjengonxibelelwano lomnxeba, izixhobo ezingenazingcingo, kunye nezixhobo ezisebenza rhoqo.

3.Ukubaluleka kokwandisa ubukhulu begolide yeePCB zegolide:

Ukutyeba okwandisiweyo kokutyalwa kwegolide kwiiPCB zegolide ezishinyeneyo kusebenzela iinjongo ezibalulekileyo.Okokuqala, inika ukhuseleko olongezelelweyo kwi-oxidation kunye ne-corrosion, iqinisekisa ukuthembeka kwexesha elide kunye nokuzinza nakwiindawo ezinzima. Ucweyo lwegolide olungqindilili lusebenza njengesithintelo, luthintela nakuphi na ukuhlangana kweekhemikhali phakathi kwemithana yobhedu engaphantsi kunye ne-atmosfera yangaphandle, ngakumbi xa ivezwe kukufuma, ukufuma, okanye ungcoliseko lwemizi-mveliso.

Okwesibini, umaleko wegolide otyebileyo wonyusa umgangatho wokuqhuba kunye nesakhono sokuhambisa umqondiso wePCB.Igolide yeyona conductor igqwesileyo yombane, ingcono nangaphezu kobhedu oluqhele ukusetyenziswa kwiitrayiti zokuqhuba kwiiPCB eziqhelekileyo. Ngokwandisa umxholo wegolide kumphezulu, ii-PCB zegolide ezishinyeneyo zinokufikelela kwi-resistance esezantsi, ukunciphisa ilahleko yomqondiso kunye nokuqinisekisa ukusebenza okungcono, ngakumbi kwizicelo ezisebenza ngokuphindaphindiweyo okanye ezo zibandakanya imiqondiso ekumgangatho ophantsi.

Ukongeza, iileya zegolide ezishinyeneyo zibonelela ngokuthengiswa ngcono kunye nendawo eyomeleleyo yokunyuka komphezulu.Igolide ine-solderability egqwesileyo, evumela ukuba kuhlanganiswe i-solder ethembekileyo ngexesha lokuhlanganisana. Lo mba ubalulekile kuba ukuba i-solder joints ibuthathaka okanye ayiqhelekanga, inokubangela ukusilela okuphakathi okanye okupheleleyo kwesekethe. Ukonyuka kobunzima begolide kukwaphucula ukuqina koomatshini, kwenza iiPCB zegolide ezishinyeneyo ukuba zingabi lula ukunxitywa nokukrazuka kwaye zixhathise ngakumbi kuxinzelelo lomatshini kunye nokungcangcazela.

Kubalulekile ukuqaphela ukuba ukwanda kobunzima bomaleko wegolide kwiiPCB zegolide ezishinyeneyo kuzisa iindleko eziphezulu xa kuthelekiswa neePCB eziqhelekileyo.Inkqubo ebanzi yokuhombisa igolide ifuna ixesha elongezelelweyo, izixhobo kunye nobuchule, okukhokelela ekunyukeni kweendleko zokwenziwa kwemveliso. Nangona kunjalo, kwizicelo ezifuna umgangatho ophezulu, ukuthembeka kunye nokuphila ixesha elide, utyalo-mali kwiiPCB zegolide ezishinyeneyo zihlala zigqithisa iingozi ezinokubakho kunye neendleko ezinxulumene nokusebenzisa iiPCB eziqhelekileyo.

4.Umahluko phakathi kwe-PCB eshinyeneyo yegolide kunye ne-PCB eqhelekileyo:

IiPCB eziqhelekileyo zidla ngokwenziwa ngezinto ze-epoxy ezinomaleko wobhedu kwelinye okanye kumacala omabini ebhodi. Ezi zingqimba zobhedu zifakwe ngexesha lenkqubo yokuvelisa ukudala ukujikeleza okuyimfuneko. Ubunzima bomaleko wobhedu bungahluka ngokuxhomekeke kwisicelo, kodwa ngokuqhelekileyo kuluhlu lwe-1-4 oz.

I-PCB yegolide eshinyeneyo, njengoko negama libonisa, inomaleko wegolide otyebileyo xa kuthelekiswa ne-PCB eqhelekileyo. IiPCBs eziqhelekileyo zinobukhulu begolide obuyi-20-30 i-intshi ezincinci (0.5-0.75 microns), ngelixa iiPCB zegolide ezishinyeneyo zinegolide yobukhulu be-intshi ezingama-50-100 (1.25-2.5 microns).

Owona mahluko uphambili phakathi kweePCB zegolide ezishinyeneyo kunye neePCB ezisemgangathweni bubunzima bomaleko wegolide, ukuntsokotha kokwenziwa kwemveliso, ixabiso, iindawo zosetyenziso, kunye nokusebenza okulinganiselweyo kwiindawo ezinobushushu obuphezulu.

Ubukhulu bomaleko wegolide:

Umahluko ophambili phakathi kwe-PCB eshinyeneyo yegolide kunye ne-PCB eqhelekileyo bubunzima bomaleko wegolide. I-PCB yegolide eshinyeneyo inomaleko ongqindilili wegolide weplating kune-PCB eqhelekileyo. Olu ngqingqwa olongezelelweyo lunceda ukuphucula ukuqina kwePCB kunye nokusebenza kombane. Umaleko oshinyeneyo wegolide ubonelela ngengubo ekhuselayo eyongeza ukuxhathisa kwePCB ekudlekeni, kwi-oxidation kunye nokunxiba. Oku kwenza i-PCB yomelele ngakumbi kwiindawo ezibuhlungu, iqinisekisa ukusebenza okuthembekileyo kwexesha elide. Iplating yegolide etyebileyo ikwavumela ukuhanjiswa kombane okungcono, okuvumela ukuhanjiswa komqondiso okusebenzayo. Oku kunenzuzo ngakumbi kwizicelo ezifuna ukuhanjiswa komqondiso we-frequency ephezulu okanye isantya esiphezulu, esifana nonxibelelwano, izixhobo zonyango, kunye ne-aerospace systems.

Ixabiso:

Xa kuthelekiswa ne-PCB eqhelekileyo, ixabiso lemveliso ye-PCB eshinyeneyo yegolide idla ngokuba phezulu. Ezi ndleko ziphezulu ziphuma kwinkqubo yokucwenga efuna imathiriyeli yegolide eyongezelelweyo ukufezekisa ubukhulu obufunekayo. Nangona kunjalo, ukuthembeka okukhulu kunye nokusebenza kweePCB zegolide ezishinyeneyo zithethelela iindleko ezongezelelweyo, ngakumbi kwizicelo apho iimfuno ezibango kufuneka kuhlangatyezwane nazo.

Iindawo zesicelo:

IiPCB eziqhelekileyo zisetyenziswa kakhulu kumashishini ahlukeneyo, kubandakanywa i-electronics yabathengi, iisistim zeemoto kunye nezixhobo zoshishino. Zifanelekile kwizicelo apho ukuthembeka okuphezulu akuyona into ephambili. IiPCB zegolide ezishinyeneyo, kwelinye icala, zisetyenziswa ikakhulu kwiinkalo zobungcali ezifuna ukuthembeka nokusebenza okuphezulu. Imizekelo yale mimandla yezicelo ibandakanya ishishini le-aerospace, izixhobo zonyango, izixhobo zomkhosi, kunye neenkqubo zonxibelelwano. Kwezi ndawo, imisebenzi ebalulekileyo ixhomekeke kwizinto ezithembekileyo nezikumgangatho ophezulu we-elektroniki, ngoko ke iiPCB zegolide ezishinyeneyo lukhetho lokuqala.

Ukuntsonkotha koveliso:

Xa kuthelekiswa neePCB eziqhelekileyo, inkqubo yokwenziwa kweePCB ezishinyeneyo zegolide inzima kakhulu kwaye idla ixesha. Inkqubo ye-electroplating kufuneka ilawulwe ngononophelo ukufezekisa ubungqingqwa begolide obunqwenelekayo. Oku kwandisa ubunzima kunye nexesha elifunekayo kwinkqubo yemveliso. Ulawulo oluchanekileyo lwenkqubo yokucwenga lubalulekile kuba ukwahluka kobunzima bomaleko wegolide kunokuchaphazela ukusebenza kwePCB kunye nokuthembeka. Le nkqubo yokwenziwa ngobunono inegalelo kumgangatho ophezulu kunye nokusebenza kweePCB zegolide ezishinyeneyo.

Ukufaneleka okulinganiselweyo kwimo engqongileyo yobushushu obuphezulu:

Ngelixa iiPCB zegolide ezishinyeneyo zisebenza kakuhle kwiindawo ezininzi, zisenokungabi lolona khetho lufanelekileyo kwizicelo zobushushu obuphezulu. Phantsi kweemeko zobushushu obuphezulu obugqithisileyo, iileya zegolide ezishinyeneyo zinokuthomalalisa okanye zinciphise, zichaphazela ukusebenza ngokubanzi kwePCB.

Kule meko, unyango olulolunye olufana ne-tin yokuntywila (ISn) okanye isilivere yokuntywila (IAg) lunokukhethwa. Olu nyango lubonelela ngokhuseleko olwaneleyo kwimiphumo yobushushu obuphezulu ngaphandle kokuchaphazela ukusebenza kwePCB.

Ukukhethwa kwezinto zePCB kunokuchaphazela kakhulu umgangatho kunye nokusebenza kwezixhobo zombane. IiPCB zegolide ezishinyeneyo zibonelela ngeengenelo ezizodwa ezinjengokuqina okongeziweyo, ukuphuculwa kokuthengiswa, ukuhanjiswa kombane okugqwesileyo, ukuthembeka okuphezulu kokunxibelelana, kunye nobomi obandisiweyo beshelufu.Izibonelelo zabo zithethelela iindleko eziphezulu zemveliso kwaye zibenza bafaneleke ngokukodwa kumashishini akhethekileyo abeka phambili ukuthembeka, okufana ne-aerospace, izixhobo zonyango, izixhobo zomkhosi, kunye neenkqubo zonxibelelwano. Ukuqonda ukwakheka, iingenelo, kunye nomahluko phakathi kweePCB zegolide ezishinyeneyo kunye neePCB eziqhelekileyo kubalulekile kwiinjineli, abayili, kunye nabavelisi abafuna ukwandisa ukusebenza kunye nobomi obude bezixhobo zabo zombane. Ngokusebenzisa iimpawu ezizodwa zeePCB zegolide ezishinyeneyo, banokuqinisekisa iimveliso ezithembekileyo nezikumgangatho ophezulu kubathengi babo.

Ixesha lokuposa: Sep-13-2023

Emva