Kwixesha lanamhlanje lophuhliso olukhawulezayo lwetekhnoloji, izixhobo zombane ziye zaba yinxalenye yobomi bethu bemihla ngemihla. Ukusuka kwii-smartphones ukuya kwizixhobo zonyango, iibhodi zeesekethe eziprintiweyo (PCBs) zidlala indima ebalulekileyo ekunikeni amandla ngokufanelekileyo ezi zixhobo. Iteknoloji ye-PCB ye-teknoloji ye-High Density Interconnect (HDI) ibe yinguqu yomdlalo, inikezela ngoxinaniso lwesekethe ephezulu, ukusebenza okuphuculweyo kunye nokuthembeka okuphuculweyo.Kodwa ngaba ukhe wazibuza ukuba zenziwa njani ezi PCBs ze-HDI? Kweli nqaku, siza kuntywila kwiingxaki zenkqubo yokuvelisa kwaye sicacise amanyathelo abandakanyekayo.

1. Intshayelelo emfutshane ye-PCB yobuchwephesha be-HDI:

HDI technology PCBs zithandwa ukukwazi kwabo ukuhlalisa inani elikhulu lamacandelo kuyilo compact, ukunciphisa ubungakanani ngokubanzi izixhobo zombane.Ezi bhodi zibonisa iileya ezininzi, ii-vias ezincinci, kunye nemigca emincinci yoxinzelelo olukhulu lwendlela. Ukongeza, banikezela ukusebenza kombane okuphuculweyo, ulawulo lwe-impedance, kunye nokuthembeka komqondiso, okubenza ukuba balungele ukusetyenziswa kwesantya esiphezulu kunye nesantya esiphezulu.

2. uyilo loyilo:

Uhambo lokuvelisa lwe-HDI Technology PCB luqala ukusuka kwinqanaba loyilo.Iinjineli ezinezakhono kunye nabaqulunqi basebenza kunye ukukhulisa uyilo lwesekethe ngelixa beqinisekisa ukuba imithetho yoyilo kunye nemiqobo iyahlangatyezwa. Sebenzisa izixhobo zesoftware ephucukileyo ukwenza uyilo oluchanekileyo, uchaze i-stackups, ukubekwa kwecandelo kunye neendlela. Uyilo lukwathathela ingqalelo izinto ezifana nokuthembeka komqondiso, ulawulo lwe-thermal, kunye nokuzinza koomatshini.

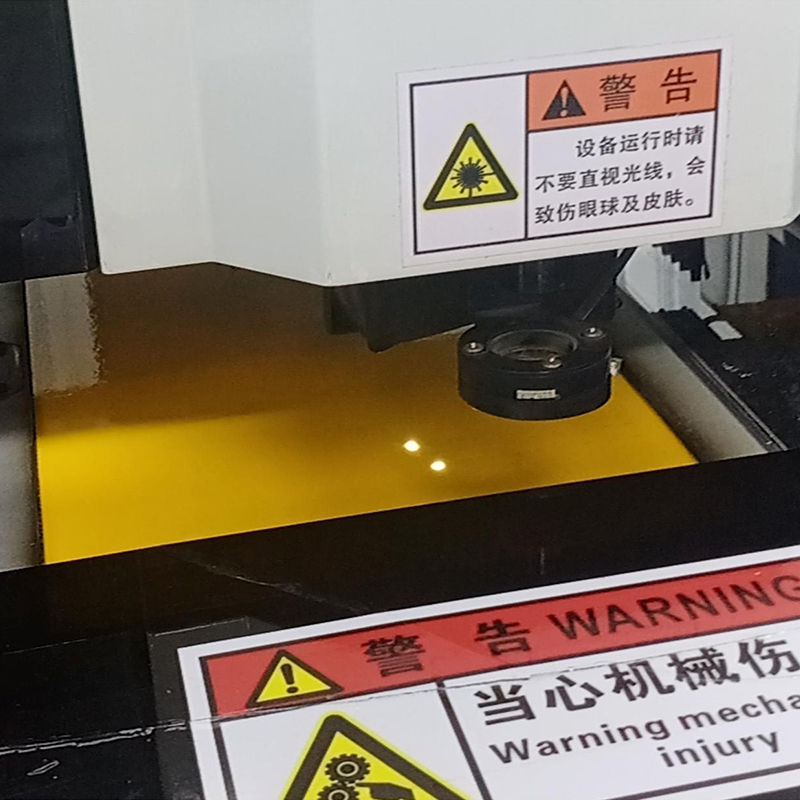

3. Ukwemba iLaser:

Elinye lamanyathelo aphambili kwi-HDI iteknoloji yokwenziwa kwePCB kukugrumba ngelaser.Itekhnoloji yeLaser inokudala i-vias encinci, echanekileyo ngakumbi, ebaluleke kakhulu ekufezekiseni ukuxinana kwesekethe ephezulu. Oomatshini bokugaya i-Laser basebenzisa i-light-energy beam yokukhanya ukususa izinto ezivela kwi-substrate kunye nokudala imingxuma emincinci. Ezi vias ke metallized ukudala uqhagamshelo zombane phakathi umaleko ezahlukeneyo.

4. Ukufakwa kobhedu okungenambane:

Ukuqinisekisa uqhagamshelo olusebenzayo lombane phakathi kweeleya, i-electroless copper deposition isetyenziswa.Kule nkqubo, iindonga zomngxuma ogrunjiweyo zigqunywe ngomgca omncinci kakhulu wobhedu oqhubekileyo ngokuntywiliselwa kweekhemikhali. Olu luhlu lobhedu lusebenza njengembewu yenkqubo ye-electroplating elandelayo, ukuphucula ukunamathela ngokubanzi kunye nokuhamba kobhedu.

5. Lamination kunye nokucinezela:

Imveliso ye-HDI Technology PCB ibandakanya imijikelo emininzi yokulatyuza kunye nokucinezela apho iileya ezahlukeneyo zebhodi yesekethe zipakishwe kwaye zidityaniswe kunye.Uxinzelelo oluphezulu kunye nokushisa kusetyenziswa ukuqinisekisa ukudibanisa okufanelekileyo kunye nokuphelisa naziphi na iipokethi zomoya okanye i-voids. Inkqubo ibandakanya ukusetyenziswa kwezixhobo ezikhethekileyo zokuthambisa ukufezekisa ubukhulu bebhodi obufunwayo kunye nokuzinza koomatshini.

6. Ukufakwa kobhedu:

I-Copper plating idlala indima ebalulekileyo kwi-PCBs zobuchwepheshe be-HDI njengoko iseka ukuhanjiswa kombane okuyimfuneko.Inkqubo ibandakanya ukucwina ibhodi yonke kwisisombululo sobhedu kunye nokugqithiswa kombane kuyo. Ngokusebenzisa inkqubo ye-electroplating, ubhedu lufakwe phezu kwebhodi yesekethe, ukwenza iisekethe, umkhondo kunye neempawu zomhlaba.

7. Unyango lomphezulu:

Ukunyangwa komphezulu kuyinyathelo elibalulekileyo kwinkqubo yokuvelisa ukukhusela iisekethe kunye nokuqinisekisa ukuthembeka kwexesha elide.Ubuchwephesha bonyango obuqhelekileyo bomgangatho we-HDI ubuchwepheshe bePCB bubandakanya isilivere yokuntywiliselwa, igolide yokuntywila, izigcina-manzi ze-organic solderability (OSP), kunye ne-electroless nickel/igolide yokuntywila (ENIG). Ezi teknoloji zibonelela ngomaleko okhuselayo okhusela i-oxidation, iphucula ukuthengiselana, kunye nokunciphisa ukudibanisa.

8. Uvavanyo kunye noLawulo loMgangatho:

Uvavanyo olungqongqo kunye namanyathelo olawulo lomgangatho ayafuneka phambi kokuba iiPCB zobuchwepheshe ze-HDI zidityaniswe kwizixhobo zombane.Ukuhlolwa kwe-Optical Automated (AOI) kunye novavanyo lombane (E-test) luhlala lwenziwa ukuze kubonwe kwaye kulungiswe naziphi na iziphene okanye iingxaki zombane kwisekethe. Ezi mvavanyo ziqinisekisa ukuba imveliso yokugqibela ihlangabezana neenkcukacha ezifunekayo kwaye isebenza ngokuthembekileyo.

Ukuququmbela:

I-HDI Technology PCBs ziye zaliguqula ishishini lombane, liququzelela uphuhliso lwezixhobo zombane ezincinci, ezikhaphukhaphu, nezinamandla ngakumbi.Ukuqonda inkqubo yokuvelisa entsonkothileyo emva kwezi bhodi kuqaqambisa inqanaba lokuchaneka kunye nobuchule obufunekayo ukuvelisa iiPCBs zobuchwephesha beHDI. Ukusuka kuyilo lokuqala ngokugrumba, ukucwenga kunye nokulungisa umphezulu, inyathelo ngalinye libalulekile ukuqinisekisa ukusebenza okuphezulu kunye nokuthembeka. Ngokusebenzisa ubuchule bokuvelisa obukumgangatho ophezulu kunye nokubambelela kwimigangatho engqongqo yolawulo lomgangatho, abavelisi banokuhlangabezana neemfuno ezihlala zitshintsha kwimarike yezobuchwephesha kwaye bavule indlela yempumelelo entsha.

Ixesha lokuposa: Sep-02-2023

Emva