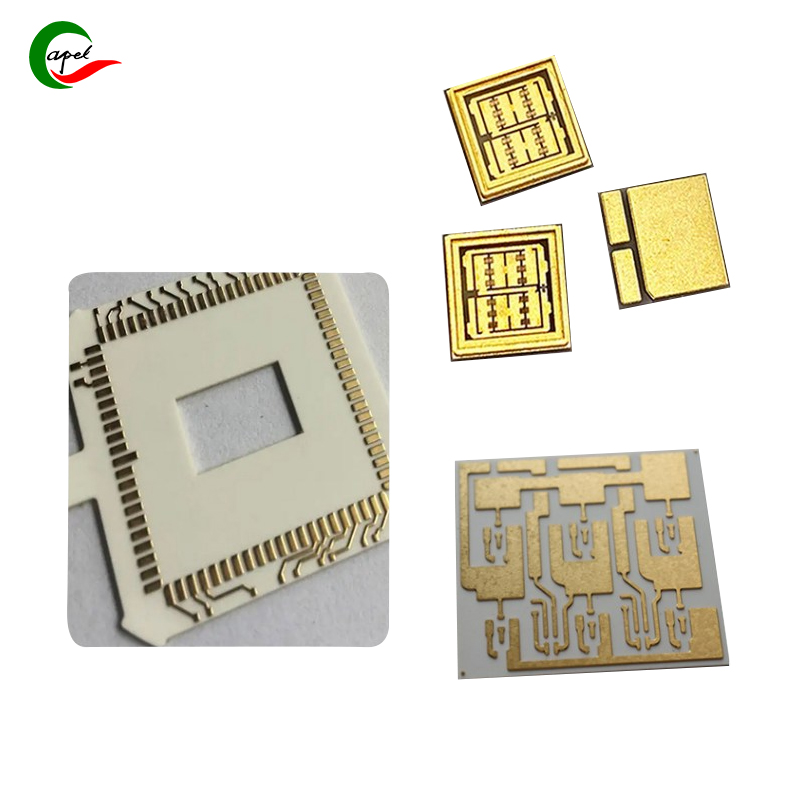

Kule post blog, siza kuphonononga iintlobo ezahlukeneyo zoyilo lwebhodi yesekethe yeceramic kunye neempawu zabo ezizodwa.

Iibhodi zeesekethe zeCeramic ziya zithandwa kakhulu ngenxa yeenzuzo zazo ezininzi ngaphezu kwezixhobo zebhodi yesekethe yesiqhelo efana ne-FR4 okanye i-polyimide. Iibhodi zeesekethe zeCeramic ziba lukhetho lokuqala kwizicelo ezahlukeneyo ngenxa ye-conductivity egqwesileyo ye-thermal, ukumelana nobushushu obuphezulu kunye namandla afanelekileyo omatshini. Njengoko imfuno isanda, kukwanjalo nolwahlulo loyilo lwebhodi yesekethe yeceramic ekhoyo kwimarike.

1. Ibhodi yesekethe esekwe kwi-alumina:

I-aluminiyam oxide, eyaziwa ngokuba yi-aluminium oxide, yinto esetyenziswa ngokubanzi kwiibhodi zeesekethe ze-ceramic. Ineempawu ezigqwesileyo zokugquma umbane kwaye ifanelekile kwizicelo ezifuna amandla aphezulu e-dielectric. Iibhodi zeesekethe ze-alumina ze-ceramic ziyakwazi ukumelana nobushushu obuphezulu, zibenze zilungele ukusetyenziswa kwizicelo zamandla aphezulu ezifana ne-electronics yamandla kunye neenkqubo zemoto. Ukugqitywa kwayo okugudileyo kunye ne-coefficient ephantsi yokwandiswa kwe-thermal kwenza kube yinto efanelekileyo kwizicelo ezibandakanya ulawulo lwe-thermal.

2. I-Aluminiyam nitride (AlN) ibhodi yesekethe yeceramic:

Iibhodi zesekethe ze-aluminiyam ze-nitride ze-ceramic zine-conductivity ephezulu ye-thermal xa kuthelekiswa ne-alumina substrates. Ngokuqhelekileyo zisetyenziswa kwizicelo ezifuna ukutshatyalaliswa kobushushu obusebenzayo, njengokukhanya kwe-LED, iimodyuli zamandla, kunye nezixhobo ze-RF / microwave. Iibhodi zeesekethe ze-Aluminiyam ze-nitride zigqwesa kwizicelo eziphezulu ze-frequency ngenxa yokulahleka kwazo kwe-dielectric ephantsi kunye nomgangatho obalaseleyo wesibonakaliso. Ukongeza, iibhodi zeesekethe ze-AlN zikhaphukhaphu kwaye zinobuhlobo nokusingqongileyo, zizenza zibe lukhetho olufanelekileyo kumashishini ahlukeneyo.

3. I-silicon nitride (Si3N4) ibhodi yesekethe yeceramic:

Iibhodi zesekethe ye-Silicon nitride ceramic ziyaziwa ngamandla abo omatshini kunye nokumelana nokothuka kwe-thermal. Ezi panels ziqhele ukusetyenziswa kwiindawo ezinzima apho utshintsho olugqithisileyo lobushushu, uxinzelelo oluphezulu, kunye nezinto ezinobungozi zikhona. Iibhodi zeesekethe ze-Si3N4 zifumana izicelo kumashishini afana ne-aerospace, ukukhusela, kunye neoli kunye negesi, apho ukuthembeka kunye nokuqina kubalulekile. Ukongeza, i-silicon nitride ineempawu ezilungileyo zokugquma umbane, iyenza ibe lolona khetho lubalaseleyo kusetyenziso lwamandla aphezulu.

4. I-LTCC (i-co-fired ceramic co-fired board) ibhodi yesekethe:

Iibhodi zeesekethe ze-LTCC zenziwe kusetyenziswa iiteyiphu ze-ceramic ezininzi eziprintwe kwiscreen kunye neepatheni zokuqhuba. Iileya zipakishwe kwaye emva koko zitshiswe kumaqondo obushushu aphantsi, ukwenza ibhodi yesekethe exineneyo kwaye ethembekileyo. Itekhnoloji ye-LTCC ivumela amacandelo e-passive afana ne-resistors, i-capacitors kunye ne-inductors ukuba idibaniswe ngaphakathi kwebhodi yesekethe ngokwayo, ivumela i-miniaturization kunye nokusebenza okuphuculweyo. Ezi bhodi zilungele unxibelelwano olungenazingcingo, ii-elektroniki zemoto, kunye nezixhobo zonyango.

5. Ibhodi yesekethe ye-HTCC (i-ceramic co-fired co-fired) ibhodi yesekethe:

Iibhodi zeesekethe ze-HTCC zifana neebhodi ze-LTCC ngokwenkqubo yokuvelisa. Nangona kunjalo, iibhodi zeHTCC zigxothwa kumaqondo obushushu aphezulu, okukhokelela ekunyukeni kwamandla omatshini kunye namaqondo obushushu aphezulu okusebenza. Ezi bhodi zidla ngokusetyenziswa kwizicelo zobushushu obuphezulu ezifana nezinzwa zemoto, i-electronics ye-aerospace, kunye nezixhobo zokwemba i-downhole. Iibhodi zesekethe zeHTCC zinozinzo olubalaseleyo lwe-thermal kwaye ziyakwazi ukumelana nokuhamba ngebhayisekile kubushushu obugqithisileyo.

Isishwankathelo

Iindidi ezahlukeneyo zeebhodi zeesekethe ze-ceramic zenzelwe ukuhlangabezana noluhlu olubanzi lweemfuno ezikhethekileyo kwishishini. Kungakhathaliseki ukuba zizicelo zamandla aphezulu, ukutshatyalaliswa kobushushu obusebenzayo, iimeko zokusingqongileyo ezigqithisileyo okanye iimfuno ze-miniaturization, ukuyila kwebhodi yesekethe ye-ceramic kunokuhlangabezana nezi mfuno. Njengoko itekhnoloji iqhubeka nokuhambela phambili, iibhodi zeesekethe ze-ceramic kulindeleke ukuba zidlale indima ebalulekileyo ekwenzeni iinkqubo zombane ezintsha nezithembekileyo kuwo wonke amashishini.

Ixesha lokuposa: Sep-25-2023

Emva