Xa ibhodi yesekethe ye-FPC eguquguqukayo igobile, iintlobo zoxinzelelo kumacala omabini omgca ongundoqo ziyahluka.

Oku kungenxa yemikhosi eyahlukeneyo esebenza ngaphakathi nangaphandle kwendawo egobileyo.

Kwicala elingaphakathi lendawo egobileyo, i-FPC iphantsi koxinzelelo loxinzelelo. Oku kungenxa yokuba impahla ixinzelelwe kwaye icinezelwe njengoko igoba ngaphakathi. Olu xinzelelo lunokubangela ukuba iileya ngaphakathi kwe-FPC zinyanzeliswe, ezinokubangela ukuba i-delamination okanye ukuqhekeka kwecandelo.

Ngaphandle kwendawo egobileyo, i-FPC iphantsi koxinzelelo loxinzelelo. Oku kungenxa yokuba impahla yoluliwe xa igotywe ngaphandle. Ukulandelela ubhedu kunye nezinto eziqhubayo kwiindawo zangaphandle zinokuthi zibe phantsi koxinzelelo olunokuthi luphazamise ingqibelelo yesiphaluka. Ukunciphisa uxinzelelo kwi-FPC ngexesha lokugoba, kubalulekile ukuyila isiphaluka se-flex usebenzisa izinto ezifanelekileyo kunye nobuchule bokwenza. Oku kubandakanya ukusebenzisa izixhobo ezinokuguquguquka okufanelekileyo, ubukhulu obufanelekileyo, kunye nokuqwalasela i-radius ye-bend encinci ye-FPC. Ukuqiniswa okwaneleyo okanye izakhiwo zenkxaso nazo zingaphunyezwa ukusabalalisa uxinzelelo ngakumbi kwisekethe.

Ngokuqonda iintlobo zoxinzelelo kunye nokuthatha iingqwalasela ezifanelekileyo zoyilo, ukuthembeka kunye nokuqina kweebhodi zeesekethe eziguquguqukayo ze-FPC xa zigobile okanye ziguquguqukayo zingaphuculwa.

Oku kulandelayo yingqwalasela ethile yoyilo enokunceda ukuphucula ukuthembeka kunye nokuqina kweebhodi zesekethe eziguquguqukayo ze-FPC xa zigobile okanye zigobile:

Ukukhethwa kwezinto:Ukukhetha imathiriyeli efanelekileyo kubalulekile. I-substrate eguquguqukayo kunye nokuguquguquka okulungileyo kunye namandla omatshini kufuneka asetyenziswe. I-polyimide eguquguqukayo (PI) yinto eqhelekileyo ngenxa yokuzinza kwayo kwe-thermal kunye nokuguquguquka.

Uyilo lweSekethe:Uyilo olufanelekileyo lwesekethe lubalulekile ukuqinisekisa ukuba iitrayiti zokuqhuba kunye namacandelo abekwe kwaye ahanjiswe ngendlela yokunciphisa uxinzelelo loxinzelelo ngexesha lokugoba. Kunconywa ukusebenzisa iikona ezijikelezileyo endaweni yeekona ezibukhali.

UQiniso kunye neZakhiwo zeNkxaso:Ukongeza ukomeleza okanye izakhiwo zenkxaso ecaleni kweendawo zokugoba ezibalulekileyo kunokunceda ukusasaza uxinzelelo ngakumbi kwaye kuthintele umonakalo okanye ukuncipha. Iingqimba zokuqiniswa okanye iimbambo zingasetyenziselwa kwiindawo ezithile zokuphucula ukunyaniseka komatshini.

Irediyasi yokugoba:Ubuncinci berediya yokugoba kufuneka ichazwe kwaye iqwalaselwe ngexesha lesigaba soyilo. Ukugqithisa i-radius ye-bend encinci kuya kubangela ukugxininiswa koxinzelelo olugqithisileyo kunye nokungaphumeleli.

Ukhuseleko kunye ne-Ecapsulation:Ukukhuselwa okunje ngeengubo ezihambelanayo okanye izinto zokufaka i-encapsulation kunokubonelela ngamandla ongezelelweyo omatshini kunye nokukhusela iisekethe kwizinto ezisingqongileyo ezifana nokufuma, uthuli kunye neekhemikhali.

Uvavanyo kunye noQinisekiso:Ukuqhuba uvavanyo olubanzi kunye nokuqinisekiswa, kubandakanywa ukugoba koomatshini kunye novavanyo lwe-flex, kunokunceda ukuvavanya ukuthembeka kunye nokuqina kweebhodi zesekethe eziguquguqukayo ze-FPC phantsi kweemeko zehlabathi langempela.

Ingaphakathi lendawo egobileyo luxinzelelo, kwaye umphandle uyaxinana. Ubungakanani boxinzelelo bunxulumene nobukhulu kunye neradiyasi egobayo yebhodi yesekethe ye-FPC eguquguqukayo. Uxinzelelo olugqithisileyo luya kwenza i-FPC eguquguqukayo yebhodi yebhodi ye-lamination, i-foil fracture yobhedu kunye nokunye. Ngoko ke, ulwakhiwo lwe-lamination yebhodi yesekethe eguquguqukayo ye-FPC kufuneka icwangciswe ngokufanelekileyo kuyilo, ukuze iziphelo ezimbini zomgca osembindini womgangatho ogobileyo kufuneka zilingane kangangoko kunokwenzeka. Ngexesha elifanayo, i-radius yokugoba encinci kufuneka ibalwe ngokweemeko ezahlukeneyo zesicelo.

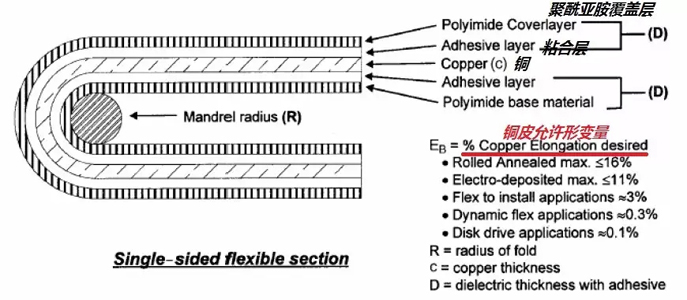

Imeko 1. Ubuncinane bokugotywa kwebhodi yesekethe yeFPC enecala elinye ebhetyebhetye iboniswe kulo mzobo ulandelayo:

Ubuncinane beradiyasi yokugoba ingabalwa ngale fomula ilandelayo: R= (c/2) [(100-Eb) /Eb]-D

Ubuncinci be-radius yokugoba ye-R =, ubukhulu be-c = isikhumba sobhedu (iyunithi m), ubukhulu be-D= ifilimu yokugubungela (m), ukuguqulwa okuvumelekileyo kwe-EB = isikhumba sobhedu (kulinganiswa ngepesenti).

I-deformation yesikhumba sobhedu iyahluka kunye neentlobo ezahlukeneyo zobhedu.

Ubuninzi be-deformation ye-A kunye nobhedu olucinezelweyo lungaphantsi kwe-16%.

Ubuninzi be-deformation ye-B kunye ne-electrolytic copper ingaphantsi kwe-11%.

Ngaphezu koko, umxholo wobhedu wezinto ezifanayo ukwahluka kwiimeko ezahlukeneyo zokusetyenziswa. Kwithuba elilodwa lokugoba, ixabiso elilinganiselweyo lemeko ebalulekileyo yokuphuka isetyenziswe (ixabiso yi-16%). Uyilo lokufakela ukugoba, sebenzisa ixabiso elincinci lokuguqulwa elichazwe yi-IPC-MF-150 (ubhedu oluqengqelekayo, ixabiso li-10%). Kwizicelo eziguquguqukayo eziguquguqukayo, ukuguqulwa kwesikhumba sobhedu ngu-0.3%. Ukusetyenziswa kwentloko yamagnetic, ukuguqulwa kwesikhumba sobhedu ngu-0.1%. Ngokumisela i-deformation evumelekileyo yesikhumba sobhedu, i-radius encinci ye-curvature ingabalwa.

Ukuguquguquka okuguquguqukayo: indawo yesi sicelo sesikhumba sobhedu sifezekiswa ngokuguqulwa. Ngokomzekelo, i-phosphor bullet kwikhadi le-IC yinxalenye yekhadi le-IC elifakwe kwi-chip emva kokufaka ikhadi le-IC. Kwinkqubo yokufakwa, igobolondo ikhubazekile ngokuqhubekayo. Lo mboniso wesicelo uguquguqukayo kwaye unamandla.

Ubuncinane berediyasi yokugoba ye-PCB enecala elinye eguquguqukayo ixhomekeke kwizinto eziliqela, kuquka izinto ezisetyenzisiweyo, ubukhulu bebhodi, kunye neemfuno ezithile zesicelo. Ngokuqhelekileyo, i-radius egobekayo yebhodi yesekethe ye-flex imalunga namaxesha angama-10 ubukhulu bebhodi. Umzekelo, ukuba ubukhulu bebhodi yi-0.1mm, i-radius yokugoba encinci malunga ne-1mm. Kubalulekile ukuqaphela ukuba ukugoba ibhodi ngaphantsi kwe-radius ye-bend encinci kunokubangela ukugxininiswa koxinzelelo, ukunyanzeliswa kweendlela zokuqhuba, kunye nokuqhekeka okanye ukuchithwa kwebhodi. Ukugcina ingqibelelo yombane kunye nomatshini wesekethe, kubalulekile ukuthobela i-bend radii ecetyiswayo. Kucetyiswa ukuba udibane nomenzi okanye umthengisi webhodi eguquguqukayo kwizikhokelo ezithile zerediyasi zokugoba kunye nokuqinisekisa ukuba uyilo kunye neemfuno zesicelo ziyafezekiswa. Ukongeza, ukwenza uvavanyo lomatshini kunye nokuqinisekiswa kunokunceda ukumisela uxinzelelo olukhulu ibhodi enokumelana nayo ngaphandle kokubeka esichengeni ukusebenza kwayo kunye nokuthembeka.

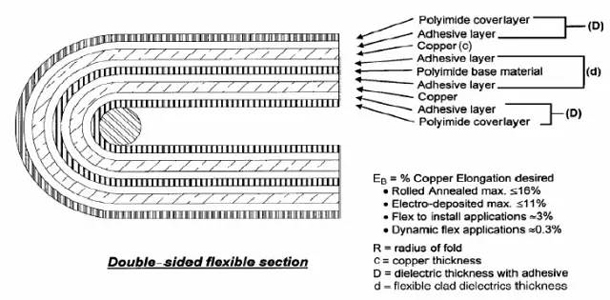

Imeko 2, ibhodi enamacala amabini yeFPC ibhodi yesekethe eguquguqukayo ngolu hlobo lulandelayo:

Phakathi kwazo: R= ubuncinci berediyasi yokugoba, iyunithi m, c= ubukhulu besikhumba sobhedu, iyunithi m, D= ukugquma kwefilimu ubukhulu, iyunithi mm, EB= ukuguqulwa kwesikhumba sobhedu, kulinganiswa ngepesenti.

Ixabiso le-EB liyafana neli lingasentla.

D= ukutyeba okuphakathi kobubanzi, iyunithi M

Ubuncinci berediyasi yokugoba ye-FPC enamacala amabini (i-Flexible Printed Circuit) ibhodi yesekethe eguquguqukayo idla ngokuba nkulu kunephaneli yecala elinye. Oku kungenxa yokuba iiphaneli ezinamacala aphindwe kabini zinemikhondo eqhubayo kumacala omabini, anokuthi achaphazeleke ngakumbi kuxinzelelo kunye noxinzelelo ngexesha lokugoba. Ubuncinane berediyasi yokugoba ye-FPC enamacala amabini flex pcb baord idla ngokuba ngamaxesha angama-20 ubukhulu bebhodi. Ukusebenzisa umzekelo ofanayo nangaphambili, ukuba ipleyiti yi-0.1mm ubukhulu, i-radius ye-bend encinci malunga ne-2mm. Kubaluleke kakhulu ukulandela izikhokelo zomenzi kunye neenkcukacha zokugoba iibhodi ze-pcb ze-FPC ezinamacala amabini. Ukugqithisa i-radius ye-bend ekhuthazwayo kunokonakalisa i-trace conductive, kubangele i-delamination yomaleko, okanye kubangele ezinye iingxaki ezichaphazela ukusebenza kwesekethe kunye nokuthembeka. Kucetyiswa ukuba udibane nomenzi okanye umthengisi kwizikhokelo ezithile zerediyasi zokugoba, kunye nokwenza uvavanyo lomatshini kunye nokuqinisekiswa kokuqinisekisa ukuba ibhodi inokumelana nokugoba okufunekayo ngaphandle kokuphazamisa ukusebenza kwayo.

Ixesha lokuposa: Jun-12-2023

Emva