Ngaba ujongene nokwanda kwe-thermal kunye nemiba yoxinzelelo lobushushu ngeePCB ezimacala amabini? Ungajongi ngakumbi, kule bhlog siza kukukhokela malunga nendlela yokusombulula ezi ngxaki ngokufanelekileyo. Kodwa ngaphambi kokuba singene kwizisombululo, masizazise.

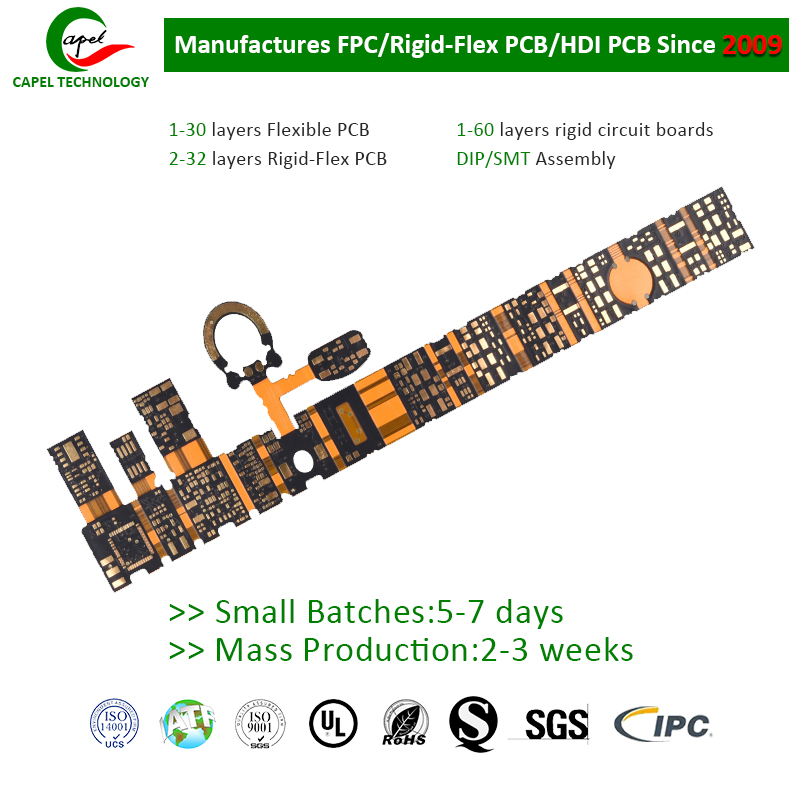

I-Capel ngumenzi onamava kwishishini lebhodi yesekethe kwaye sele ekhonza abathengi iminyaka eyi-15. Inefektri yayo yebhodi yesekethe eguquguqukayo, i-rigid-flex circuit board factory, i-smt ibhodi yesekethe yendibano yesiphaluka, kwaye iseke igama elihle ekuveliseni umgangatho ophezulu weebhodi zesekethe eziphakathi ukuya ekupheleni. Izixhobo zethu zokuvelisa ezizihambelayo eziphuma kumazwe angaphandle kunye neqela elizinikeleyo le-R&D zibonakalisa ukuzibophelela kwethu ekugqweseni. Ngoku, makhe sibuyele ekusombululeni ingxaki yokwanda kwe-thermal kunye noxinzelelo lwe-thermal kwii-PCB ezimacala amabini.

Ukwandiswa kobushushu kunye noxinzelelo lobushushu ziinkxalabo eziqhelekileyo kwishishini lemveliso yePCB. Ezi ngxaki zivela ngenxa yokungafani kwi-coefficient yokwanda kwe-thermal (CTE) yezinto ezisetyenziswa kwi-PCB. Xa kushushu, izinto zanda, kwaye ukuba amazinga okwandisa izinto ezahlukeneyo ahluka kakhulu, uxinzelelo lunokuphuhlisa kwaye lubangele ukusilela kwePCB. Ukusombulula imiba enjalo, nceda ulandele ezi zikhokelo:

1. Ukukhethwa kwezinto:

Khetha imathiriyeli ehambelana namaxabiso e-CTE. Ngokusebenzisa izixhobo ezinamazinga afanayo okwandisa, amandla okuxinzezeleka kwe-thermal kunye neengxaki ezinxulumene nokwandiswa zingancitshiswa. Qhagamshelana neengcali zethu okanye udibane nemigangatho yoshishino ukuze ufumanise ezona mathiriyeli zibalaseleyo kwiimfuno zakho ezithile.

2. Iingqwalasela zoyilo:

Qwalasela uyilo lwePCB kunye noyilo lokunciphisa uxinzelelo lobushushu. Kuyacetyiswa ukuba kugcinwe amacandelo asusa ubushushu kude neendawo ezineenguqu ezinkulu zobushushu. Amacandelo okupholisa ngokufanelekileyo, ukusebenzisa i-vias ye-thermal, kunye nokubandakanya iipateni ze-thermal nako kunokunceda ukutshabalalisa ubushushu ngokufanelekileyo kunye nokunciphisa uxinzelelo.

3. Ukupakishwa komgangatho:

I-stackup ye-PCB enamacala amabini ichaphazela ukuziphatha kwayo kwe-thermal. I-layup elinganayo kunye ne-symmetrical layup inceda ukusabalalisa ukushisa ngokulinganayo, ukunciphisa ithuba loxinzelelo lwe-thermal. Qhagamshelana neenjineli zethu ukuphuhlisa i-layup ukulungisa imiba yakho yokwanda kwe-thermal.

4. Ukutyeba kobhedu kunye neengcingo:

Ubukhulu bobhedu kunye nobubanzi bomkhondo budlala indima ebalulekileyo ekulawuleni uxinzelelo lwe-thermal. Iingqimba zobhedu ezityebileyo zibonelela nge-conductivity engcono ye-thermal kwaye inokunciphisa imiphumo yokwandiswa kwe-thermal. Ngokunjalo, umkhondo obanzi unciphisa ukuxhathisa kunye nokunceda ekulahlekeni kobushushu obufanelekileyo.

5. Ukukhethwa kweemathiriyeli zangaphambi kwangaphambili kunye nezingundoqo:

Khetha i-prepreg kunye ne-core materials kunye ne-CTE efana ne-copper cladding ukunciphisa umngcipheko we-delamination ngenxa yoxinzelelo lwe-thermal. Ukunyangwa ngokufanelekileyo kunye nokudityaniswa kwe-prepreg kunye nemathiriyeli engundoqo ibalulekile ekugcineni ukuthembeka kwesakhiwo se-PCB.

6. Ukuphazamiseka okulawulwayo:

Ukugcina impedance elawulwayo kulo lonke uyilo lwePCB kunceda ukulawula uxinzelelo lobushushu. Ngokugcina iindlela zesignali zimfutshane kunye nokuthintela utshintsho olukhawulezileyo kububanzi bomkhondo, unokunciphisa utshintsho lwe-impedance olubangelwa kukwandiswa kwe-thermal.

7. Itekhnoloji yolawulo lobushushu:

Ukusebenzisa iindlela zokulawula ubushushu obufana neesinki zobushushu, iipads ze-thermal, kunye ne-thermal vias kunokunceda ukukhupha ubushushu ngokufanelekileyo. Ezi teknoloji zandisa ukusebenza kwe-thermal jikelele ye-PCB kunye nokunciphisa umngcipheko wokungaphumeleli okunxulumene noxinzelelo lwe-thermal.

Ngokuphumeza ezi zicwangciso, unokunciphisa kakhulu ukwanda kwe-thermal kunye neengxaki zoxinzelelo lwe-thermal kwii-PCB ezimacala amabini. ECapel, sinobugcisa kunye nezixhobo zokukunceda ukuba woyise le mingeni. Iqela lethu leengcaphephe linokubonelela ngesikhokelo esixabisekileyo kunye nenkxaso kuwo onke amanqanaba enkqubo yokwenziwa kwePCB yakho.

Musa ukuvumela ukwanda kobushushu kunye noxinzelelo lobushushu kuchaphazele ukusebenza kwePCB yakho enamacala amabini. Qhagamshelana neCapel namhlanje kwaye ufumane umgangatho kunye nokuthembeka okuza kunye neminyaka eyi-15 yamava kwishishini lebhodi yesekethe. Masisebenze kunye ukwakha iPCB edibanayo kwaye igqithise ubulindele.

Ixesha lokuposa: Oct-02-2023

Emva