Njengoko imfuno eguquguqukayo kunye nezisombululo ze-elektroniki ezidibeneyo ziqhubeka zisanda, ii-PCB eziguquguqukayo ziye zaba lukhetho oludumileyo kuyilo lwe-PCB kunye nemveliso. Ezi bhodi zidibanisa iingenelo zeePCB eziqinileyo neziguquguqukayo ukubonelela ngoguquko oluphuculweyo ngaphandle kokuncama ukuqina kunye nokusebenza. Ukuyila ii-PCBs ezithembekileyo neziphuculweyo eziguquguqukayo, ukuqonda ngokucokisekileyo uqwalaselo lwe-stack-up lubalulekile. Ulwakhiwo lwe-stack-up lumisela ilungiselelo kunye nesakhiwo se-PCB, esichaphazela ngokuthe ngqo ukusebenza kwayo kunye nokwenziwa.Esi sikhokelo esibanzi siya kuphonononga ubunzima be-stackups ye-PCB eqinile-flex, ibonelela ngezimvo ezixabisekileyo ukunceda abaqulunqi benze izigqibo ezinolwazi ngexesha lenkqubo yoyilo. Iya kugubungela imiba eyahlukeneyo ebandakanya ukhetho lwemathiriyeli, ukubeka umaleko, ukuqwalaselwa kwemfezeko yomqondiso, ulawulo lwe-impedance, kunye nemiqobo yokuvelisa. Ngokuqonda izinto ezintsonkothileyo ze-PCB eziqinileyo eziguquguqukayo, abaqulunqi banokuqinisekisa ukuthembeka kunye nokuthembeka koyilo lwabo. Baza kwandisa imfezeko yomqondiso, banciphise ukuphazamiseka kwe-electromagnetic (EMI) kwaye baququzelele iinkqubo ezifanelekileyo zokuvelisa. Nokuba umtsha kuyilo lwePCB oluguquguqukayo okanye ujonge ukonyusa ulwazi lwakho, esi sikhokelo siya kuba sisixhobo esixabisekileyo, esikuvumela ukuba uhambe ngokuntsonkotha koqwalaselo lokupakisha kunye noyilo olukumgangatho ophezulu, izisombululo eziguquguqukayo zePCB zoluhlu lweemveliso.

1.Yintoni ibhodi eqinileyo-flex?

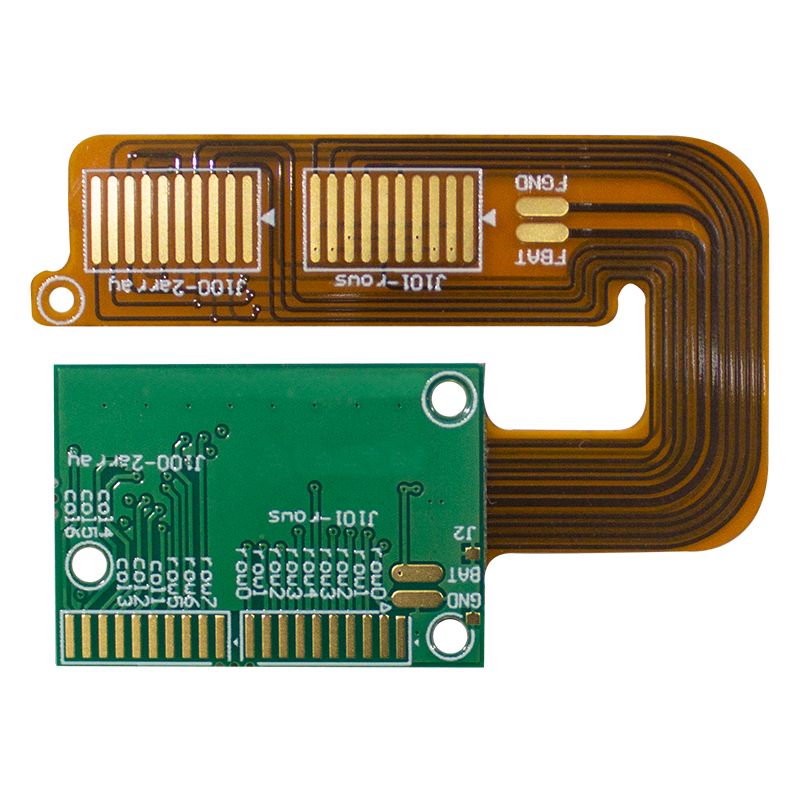

Ibhodi ye-Rigid-flex, eyaziwa ngokuba yi-rigid-flex ibhodi yesekethe eprintiweyo (PCB), yi-PCB edibanisa i-substrates eqinile kwaye eguquguqukayo kwibhodi enye.Idibanisa iingenelo zeePCB eziqinileyo neziguquguqukayo ukukhulisa ukuguquguquka koyilo kunye nokuqina. Kwibhodi engqongqo-eguquguqukayo, inxalenye eqinile yenziwe ngezinto ze-PCB zendabuko (ezifana ne-FR4), ngelixa inxalenye eguquguqukayo yenziwe ngezinto eziguquguqukayo ze-PCB (ezifana ne-polyimide). Ezi nxalenye ziqhagamshelwe nge-plated ngokusebenzisa imingxuma okanye i-flex connectors ukwenza ibhodi enye edibeneyo. Amacandelo aqinileyo abonelela ngenkxaso kunye nokuzinza kumacandelo, izihlanganisi, kunye nezinye izinto zoomatshini, ezifana ne-PCB eqinileyo esemgangathweni. Inxalenye eguquguqukayo, ngakolunye uhlangothi, ivumela ibhodi yesiphaluka ukuba igobe kwaye igobe, ivumela ukuba ingene kwizixhobo zombane ezinendawo encinci okanye iimilo ezingaqhelekanga. Iibhodi eziguquguqukayo eziqinileyo zibonelela ngeenzuzo ezininzi ngaphezu kweePCB zesintu eziqinileyo okanye eziguquguqukayo. Banciphisa imfuno yeziqhagamshelo kunye neentambo, ukugcina indawo, ukunciphisa ixesha lokuhlanganisana, kunye nokwandisa ukuthembeka ngokuphelisa amanqaku anokuthi angaphumeleli. Ukongeza, iibhodi eziqinileyo eziguquguqukayo zenza lula inkqubo yoyilo ngokwenza lula ukunxibelelana phakathi kweendawo eziqinileyo kunye neziguquguqukayo, ukunciphisa ubunzima bomzila kunye nokuphucula ingqibelelo yesiginali. Iibhodi eziguquguqukayo eziqinileyo zidla ngokusetyenziswa kwizicelo apho indawo incinci okanye ibhodi kufuneka ihambelane nemilo ethile okanye iprofayili. Zihlala zifumaneka kwi-aerospace, izixhobo zonyango, i-elektroniki yeemoto kunye ne-elektroniki ephathekayo apho ubukhulu, ubunzima kunye nokuthembeka zizinto eziphambili. Ukuyila kunye nokuvelisa iibhodi eziguquguqukayo eziqinileyo zifuna ulwazi olukhethekileyo kunye nobuchule ngenxa yokudibanisa izinto eziqinileyo neziguquguqukayo kunye nokudibanisa. Ngoko ke, kubalulekile ukusebenza kunye nomvelisi we-PCB onamava okwaziyo ukujongana nobunzima bokwenza ibhodi eqinile-flex.

2.Kutheni kubalulekile uqwalaselo flex pcb stacking?

Imfezeko yoomatshini:

I-Rigid-flex PCBs ziyilelwe ukubonelela ngokuguquguquka kunye nokuthembeka. Ukucwangciswa kwe-stacking kumisela ukucwangciswa kweengqimba eziqinileyo kunye neziguquguqukayo, ukuqinisekisa ukuba ibhodi inokumelana nokugoba, ukujija kunye nolunye uxinzelelo lomatshini ngaphandle kokuphazamisa ingqibelelo yayo yesakhiwo. Ulungelelwaniso olufanelekileyo lomaleko lubalulekile ekuthinteleni ukudinwa kwePCB, ukugxininiswa koxinzelelo, kunye nokusilela ekuhambeni kwexesha.

Ukulungiselela isithuba:

Iibhodi ze-Rigid-flex zisetyenziswa ngokubanzi kwizixhobo zombane ezihlangeneyo ezinendawo encinci. Ulungelelwaniso olucwangcisiweyo luvumela abaqulunqi ukuba basebenzise ngokufanelekileyo indawo ekhoyo ngokucwangcisa iileya kunye namalungu ngendlela eyandisa ukusetyenziswa kwendawo ye-3D. Oku kwenza ukuba ii-PCB zifakwe kwiindawo ezivaliweyo eziqinileyo, izixhobo ezincinci kunye nezinto ezintsonkothileyo. Umqondiso weMfezeko:

Ingqibelelo yomqondiso we-PCB eguquguqukayo eqinile ibalulekile ekusebenzeni kwayo ngokufanelekileyo. Ulungelelwaniso lokupakisha ludlala indima ebalulekileyo ekwandiseni imfezeko yomqondiso ngokuthathela ingqalelo izinto ezinje nge-impedance elawulwayo, umzila wothumelo lomzila, kunye nokunciphisa i-crosstalk. Uyilo olunengqikelelo olunengqikelelo lunokuqinisekisa umzila osebenzayo wemiqondiso enesantya esiphezulu, ukunciphisa ukuthotywa komqondiso, kunye nokuqinisekisa ukuhanjiswa kwedatha ngokuchanekileyo.

Ulawulo lobushushu:

Izixhobo zombane zivelisa ubushushu, kwaye ulawulo olufanelekileyo lwe-thermal lubalulekile ekuthinteleni ukutshisa kunye nomonakalo onokwenzeka kumacandelo. Uqwalaselo olupakishiweyo lweePCB eziguquguqukayo eziguquguqukayo luvumela ukubekwa kobuchule kwe-vias ye-thermal, iileya zobhedu, kunye neesinki zobushushu ukwenzela ukutshabalalisa ubushushu obusebenzayo. Ngokuqwalasela imiba ye-thermal ngexesha lenkqubo yoyilo lwe-stack-up, abayili banokuqinisekisa ixesha elide le-PCB kunye nokuthembeka.

Iingqwalasela zokuVelisa:

Uqwalaselo lokupakisha luchaphazela inkqubo yokwenziwa kwePCB eguquguqukayo. Inquma ulandelelwano apho iileyile zidibaniswe kunye, ukulungelelaniswa kunye nokubhaliswa kweengqungquthela eziguquguqukayo kunye eziqinileyo, kunye nokubekwa kwamacandelo. Ngokukhetha ngononophelo ulungelelwaniso lwe-stack-up, abaqulunqi banokuhlengahlengisa inkqubo yokuvelisa, ukunciphisa iindleko zokuvelisa, kunye nokunciphisa umngcipheko weempazamo zokuvelisa.

3.Izixhobo eziphambili ze-PCB eziqinileyo eziguquguqukayo

Xa uyila isitaki sePCB esiqinileyo, kukho amacandelo aphambili ekufuneka uwaqwalasele. La macandelo adlala indima ebalulekileyo ekuboneleleni ngenkxaso yolwakhiwo oluyimfuneko, uqhagamshelo lombane, kunye nokuguquguquka kuyilo lwePCB lulonke. Oku kulandelayo ngamacandelo aphambili ogcino lwePCB elukhuni:

Umaleko ongqongqo:

Umaleko oqinileyo ngokuqhelekileyo wenziwa kwizinto ezisisiseko eziqinileyo ezifana ne-FR-4 okanye izinto ezifanayo. Lo maleko unika amandla oomatshini kunye nokuzinza kwi-PCB. Ikwafaka amacandelo kwaye ivumela ukufakwa kwezixhobo zokunyuka komphezulu (SMD) kunye nezixhobo zokuphuma komngxuma. Umaleko oqinileyo ubonelela ngesiseko esiluqilima somaleko oguquguqukayo kwaye uqinisekisa ulungelelwaniso olufanelekileyo kunye nobungqongqo bePCB yonke.

Umaleko obhetyebhetye:

Uluhlu oluguquguqukayo luquka izinto ezisisiseko eziguquguqukayo ezifana ne-polyimide okanye izinto ezifanayo. Lo maleko uvumela iPCB ukuba igobe, igobe, kwaye ijike. I-flex layer kulapho uninzi lweesekethe kunye noqhagamshelo lombane lukhoyo. Inika ubhetyebhetye oluyimfuneko kwizicelo ezifuna ukuba iPCB igobe okanye ihambelane neemilo okanye izithuba ezahlukeneyo. Ukuguquguquka kwalo maleko kufuneka kuqwalaselwe ngononophelo ukuqinisekisa ukuba kuyahlangabezana neemfuno zesicelo.

Umaleko wokuncamathelisa:

I-adhesive layer ngumaleko obhityileyo wezinto ezincamathelayo ezisetyenziswa phakathi komgangatho oqinileyo kunye ne-flexible layer. Injongo yayo ephambili kukudibanisa iileyile eziqinileyo kunye neziguquguqukayo kunye, ukubonelela ngokunyaniseka kwesakhiwo kwi-laminate. Iqinisekisa ukuba iileyile zihlala zixhunywe ngokuqinileyo omnye komnye nangexesha lokugoba okanye ukugoba. I-adhesive layer iphinda isebenze njengesixhobo se-dielectric, ibonelela nge-insulation phakathi kwemigangatho. Ukukhethwa kwezinto ezincamathelayo kubaluleke kakhulu njengoko kufuneka kube neempawu ezintle zokudibanisa, amandla aphezulu e-dielectric, kunye nokuhambelana nesiseko.

Ukomelezwa kunye nokugquma:

Iziqinisekiso kunye nokugqunywa ziileya ezongezelelweyo zihlala zongezwa kwisitaki sePCB ukomeleza amandla omatshini, ukhuseleko, kunye nokuthembeka. Ukuqiniswa kunokubandakanya izinto ezifana ne-FR-4 okanye i-polyimide-based-adhesive-free sheets e-laminated kwiindawo ezithile zeengqimba eziqinileyo okanye eziguquguqukayo ukubonelela ngokuqina kunye nenkxaso eyongezelelweyo. Imiphezulu ye-PCB igqunywe ngezigqubuthelo ezinje ngeemaski ze-solder kunye neengubo ezikhuselayo ukuzikhusela kwizinto ezisingqongileyo ezinjengokufuma, uthuli, kunye noxinzelelo lomatshini.

La macandelo aphambili asebenza kunye ukwenza ugcino lwePCB oluyilwe ngononophelo oluyilwe ngononophelo oluhlangabezana neemfuno zesicelo. Ukunyaniseka kwesakhiwo kunye nokuguquguquka okubonelelwa ngamaleko aqinileyo kwaye aguquguqukayo, kunye neengqimba ezinamathele, ziqinisekisa ukuba i-PCB inokumelana nokugoba okanye ukuguquguquka kweentshukumo ngaphandle kokuphazamisa ingqibelelo yesekethe. Ukongeza, ukusetyenziswa kwezinto eziqinisayo kunye nokugquma kwandisa ukuthembeka kunye nokukhuselwa kwePCB. Ngokukhetha ngononophelo kunye nokuyila la macandelo, iinjineli zinokwenza i-stackups eqinile kwaye ethembekileyo ye-PCB.

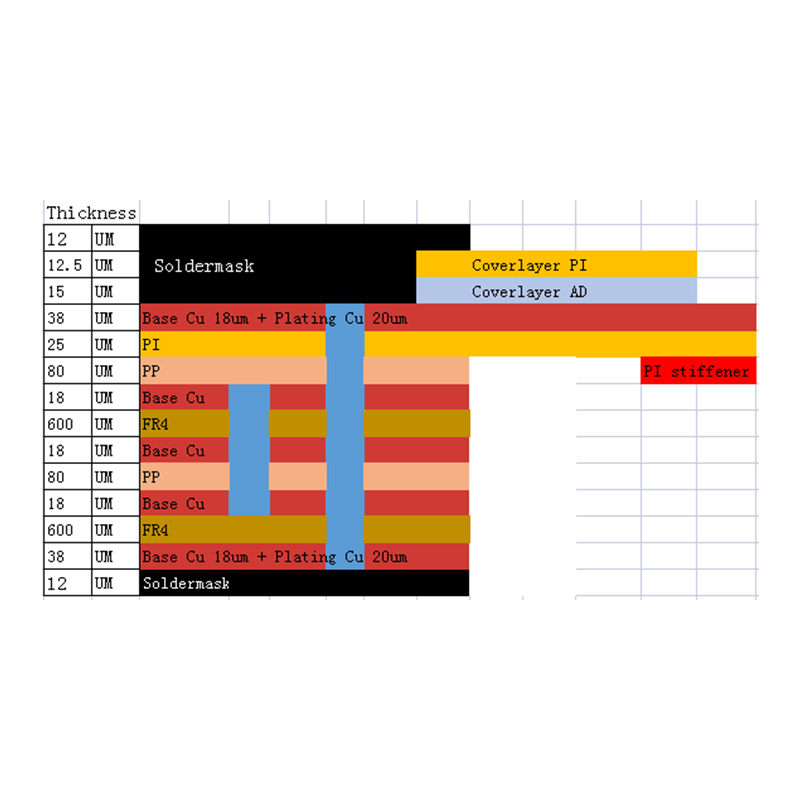

4.Rigid-flex PCB uqwalaselo stackup uhlobo

Xa uyila i-stackups ye-PCB eguquguqukayo, iintlobo ezahlukeneyo zoqwalaselo zingasetyenziswa ngokuxhomekeke kwiimfuno ezithile zesicelo. Ukucwangciswa kwe-stack-up kugqiba inani leeleyile ezibandakanyiweyo kuyilo kunye nokucwangciswa kweereyile eziqinileyo neziguquguqukayo. Ezi zilandelayo zintathu iintlobo eziqhelekileyo zoqwalaselo lwe-PCB elukhuni-flex:

I-1 umaleko we-lamination eqinileyo kunye nethambileyo:

Kolu lungelelwaniso, i-PCB iqulathe umaleko omnye wezinto eziqinileyo kunye nomaleko omnye wezinto eziguquguqukayo. Umaleko oqinileyo unika uzinzo oluyimfuneko kunye nenkxaso, ngelixa i-flexible layer ivumela i-PCB ukuba iguquke kwaye igobe. Olu lungelelwaniso lufanelekile kwizicelo ezifuna ukuguquguquka okulinganiselwe kunye noyilo olulula.

Iileya ezi-2 zokuqina kunye nezithambileyo eziphezulu:

Kolu lungelelwaniso, i-PCB inemigangatho emibini - umaleko oqinileyo kunye nomgangatho oguquguqukayo. Umaleko oqinileyo ufakwe phakathi kweeleya ezimbini eziguquguqukayo, udala ilungiselelo "lencwadi". Olu lungelelwaniso lubonelela ngokuguquguquka okukhulu kwaye luvumela uyilo oluntsonkothileyo ngakumbi usebenzisa amacandelo kumacala omabini ePCB. Inika ukuguquguquka okungcono ekugobeni kunye nokugoba kunoqwalaselo lomaleko omnye.

I-Multi-layer eqinile kunye ne-soft superposition:

Kolu lungelelwaniso, i-PCB iqulathe iileya ezininzi - indibaniselwano yeeleya eziqinileyo neziguquguqukayo. Iileya zibekwe phezu komnye, zitshintshana phakathi kweeleya eziqinileyo neziguquguqukayo. Olu lungelelwaniso lubonelela ngelona nqanaba liphezulu lokuguquguquka kwaye livumela uyilo olunzima kakhulu usebenzisa amacandelo amaninzi kunye neesekethe. Ifanelekile kwizicelo ezifuna ukuguquguquka okuphezulu kunye noyilo oludibeneyo.

Ukukhethwa koqwalaselo lwe-stackup engqongqo-flex kuxhomekeke kwizinto ezifana nezinga lokuguquguquka okufunekayo, ubunzima boyilo lwesekethe, kunye nemiqobo yendawo. Iinjineli kufuneka zivavanye ngononophelo iimfuno zesicelo kunye nemida ukumisela ulungelelwaniso olufanelekileyo lokupakisha.

Ukongeza kulwakhiwo oluqinileyo lwe-laminate, ezinye izinto ezinjengokukhethwa kwezinto, ubukhulu bomaleko ngamnye, kunye ne-design kunye noyilo loqhagamshelo nazo zidlala indima ebalulekileyo ekumiseleni ukusebenza ngokubanzi kunye nokuthembeka kwee-PCB eziguquguqukayo. Kubalulekile ukusebenza ngokusondeleyo nomenzi we-PCB kunye neengcali zokuyila ukuqinisekisa ukuba uqwalaselo olukhethiweyo lwe-stackup luhlangabezana neemfuno ezithile kunye nemigangatho yesicelo.

Ngokukhetha ukucwangciswa kwe-stackup ye-rigid-flex efanelekileyo kunye nokuphucula ezinye iiparameters zokuyila, iinjineli zinokusebenzisa ii-PCB ezithembekileyo, eziphezulu ezisebenza ngokungqongqo ezihlangabezana neemfuno ezizodwa zezicelo zabo.

5.Iizinto ekufuneka ziqwalaselwe xa ukhetha iRigid-Flex PCB Stacking Configuration

Xa ukhetha i-rigid-flex PCB stackup configuration, kukho izinto ezininzi ekufuneka ziqwalaselwe ukuqinisekisa ukusebenza kakuhle kunye nokuthembeka. Nazi izinto ezintlanu ezibalulekileyo ekufuneka uzikhumbule:

Umqondiso weMfezeko:

Ukhetho lokucwangciswa kwe-stackup lunokuchaphazela kakhulu ingqibelelo yesiginali yePCB. Umkhondo wemiqondiso kwiileya eziguquguqukayo unokuba neempawu ezahlukeneyo ze-impedance xa kuthelekiswa neengqimba eziqinileyo. Kubalulekile ukukhetha ukucwangciswa kwe-stackup okunciphisa ilahleko yesignali, i-crosstalk, kunye ne-impedance mismatch. Iindlela ezifanelekileyo zokulawula i-impedance kufuneka zisetyenziswe ukugcina imfezeko yomqondiso kuyo yonke i-PCB.

IiMfuno zokuGuquguquka:

Inqanaba lokuguquguquka elifunekayo kwi-PCB yingqwalasela ebalulekileyo. Usetyenziso olwahlukileyo lunokuba neemfuno ezahlukeneyo zokugoba kunye nokugoba. Ukucwangciswa kwe-stackup kufuneka kukhethwe ukulungiselela ukuguquguquka okufunekayo ngelixa uqinisekisa ukuba i-PCB ihlangabezana nazo zonke iimfuno zokusebenza komatshini kunye nombane. Inani kunye nokulungelelaniswa kweeleya eziguquguqukayo kufuneka zinqunywe ngononophelo ngokusekelwe kwiimfuno ezithile zesicelo.

Izithintelo zesithuba:

Isithuba esikhoyo kwimveliso okanye isixhobo sinokuphembelela kakhulu ukhetho lokucwangciswa kwe-stack-up. Uyilo olubambeneyo olunendawo enyiniweyo ye-PCB lunokufuna ulungelelwaniso lwe-multi-layer engqongqo-eguquguqukayo ukwandisa ukusetyenziswa kwendawo. Kwelinye icala, uyilo olukhulu luvumela ukuguquguquka ngakumbi xa ukhetha ulungelelwaniso lwe-stack-up. Ukuphucula ukupakisha ukulingana indawo ekhoyo ngaphandle kokuyekethisa ukusebenza okanye ukuthembeka kubalulekile.

Ulawulo lobushushu:

Ulawulo olusebenzayo lwe-thermal lubalulekile ekukhuseleni ukwakhiwa kobushushu, obunokuchaphazela ukusebenza kunye nokuthembeka kweesekethe kunye namacandelo. Ukukhethwa kobumbeko be-stackup kufuneka kuthathelwe ingqalelo ukutshatyalaliswa kobushushu. Umzekelo, ukuba iPCB ivelisa ubushushu obuninzi, inokufuna i-layup enceda ukutshabalalisa ubushushu, njengokubandakanya iintsimbi zentsimbi okanye ukusebenzisa i-thermal vias. Amacandelo okufudumeza kufuneka abekwe ngobuchule kwisitaki ukuze achithe ubushushu ngokufanelekileyo.

Ukwenziwa kweNgcaciso kunye neNdibano:

Ubume be-stack-up ekhethiweyo kufuneka kube lula ukuyilwa kunye nokudibanisa. Izinto ezifana nokulula kokuvelisa, ukuhambelana neenkqubo zokuvelisa kunye nobuchwepheshe bendibano, kunye nokufumaneka kwezinto ezifanelekileyo kufuneka kuthathelwe ingqalelo. Umzekelo, ulungelelwaniso oluthile lokupakisha lunokufuna iindlela ezikhethekileyo zokuvelisa okanye lunokuba nemida kwizinto ezinokusetyenziswa. Ukusebenza nomvelisi wePCB kwangethuba kwinkqubo yoyilo kubalulekile ekuqinisekiseni ukuba ubumbeko olukhethiweyo lunokuveliswa kwaye ludityaniswe ngokufanelekileyo.

Ngokuphonononga ngononophelo ezi zinto zintlanu, iinjineli zinokwenza isigqibo esinolwazi malunga nokukhetha uqwalaselo lokupakisha lwe-PCB elukhuni. Kucetyiswa kakhulu ukuba usebenze kunye nengcali yokuvelisa kunye nendibano ukuqinisekisa ukuba uqwalaselo olukhethiweyo luhlangabezana nazo zonke iimfuno zoyilo kwaye luhambelana nenkqubo yokuvelisa. Ukwenza ngokwezifiso i-stackup ukulungisa imfezeko yesignali, ukuguquguquka, imiqobo yendawo, ulawulo lwe-thermal kunye neengqwalasela zokuvelisa kuya kubangela isisombululo esomeleleyo nesithembekileyo se-PCB.

6.Iingqwalasela zoyilo lwe-PCB eqinileyo eguquguqukayo

Xa uyila ukupakishwa kwePCB eguquguqukayo, kukho izinto ezininzi ezibalulekileyo ekufuneka ziqwalaselwe ukuqinisekisa ukusebenza okufanelekileyo kunye nokuthembeka. Nazi iingqwalasela ezintlanu eziphambili zoyilo:

Ukwabiwa koMaleko kunye neSymmetry:

Ukwabiwa kwe-Layer kwi-stackup kubalulekile ekufezekiseni ukulingana kunye ne-symmetry kuyilo. Oku kunceda ukuthintela imfazwe okanye imiba buckling ngexesha lenkqubo ukugoba. Kunconywa ukuba ube nenani elifanayo leengqimba kwicala ngalinye lebhodi ye-flex kwaye ubeke i-flex layer phakathi kwe-stack. Oku kuqinisekisa ukuhanjiswa koxinzelelo olulinganayo kunye nokunciphisa umngcipheko wokungaphumeleli.

UYilo lwentambo kunye nokuThanda:

Uyilo lweentambo kunye neetrayisi kwi-PCB kufuneka ziqwalaselwe ngononophelo. Ukuhanjiswa kweentambo kunye nomkhondo kufuneka kucwangciswe ukunciphisa uxinzelelo kunye nokuthintela umonakalo ngexesha lokugoba. Kuyacetyiswa ukuba uhambise iintambo eziguquguqukayo kakhulu kunye nomkhondo kude neendawo ezinoxinzelelo oluphezulu lokugoba, njengendawo ekufutshane yokugoba okanye ukugoba. Ukongeza, ukusebenzisa iikona ezingqukuva endaweni yeekona ezibukhali kunokunciphisa uxinzelelo kunye nokuphucula ukuguquguquka kwePCB.

IiPlanethi ezisemhlabeni kunye nezaMandla:

Ukuhanjiswa kwenqwelomoya ephantsi kunye namandla kubaluleke kakhulu ukugcina ingqibelelo yomqondiso ochanekileyo kunye nokuhanjiswa kwamandla. Kuyacetyiswa ukuba kwabiwe umhlaba ozinikeleyo kunye neenqwelomoya zamandla ukubonelela ngokulinganayo kunye nokuhanjiswa kwamandla okuzinzileyo kuyo yonke iPCB. Ezi maleko zikwasebenza njengezikhuselo ze-electromagnetic interference (EMI). Ukubekwa ngendlela eyiyo kweendlela zomhlaba kunye nokuthungelwa kweendlela kubalulekile ekunciphiseni uthintelo lomhlaba kunye nokuphucula ukusebenza kwe-EMI.

Uhlalutyo lwemfezeko yoMqondiso:

Ingqibelelo yomqondiso ibalulekile ekusebenzeni okuqhelekileyo kwePCB. Umkhondo wophawu kufuneka ucwangciswe ngononophelo ukunciphisa ukungaqhubeki kwe-impedance, crosstalk, kunye nokubonakaliswa komqondiso. Abaqulunqi be-PCB kufuneka basebenzise izixhobo zesoftware ukwenza uhlalutyo lwemfezeko yomqondiso ukwandisa ububanzi bomkhondo kunye nesithuba, ukugcina i-impedance elawulwayo, kunye nokuqinisekisa imfezeko yomqondiso kuyo yonke i-PCB eguquguqukayo.

Iindawo eziguquguqukayo kunye nezigobileyo:

Izahlulo eziguquguqukayo neziqinileyo zePCB zineemfuno ezahlukeneyo malunga nokuguquguquka nokugoba. Kuyimfuneko ukuchaza kunye nokuchonga iindawo ezithile zamacandelo aguquguqukayo kunye aqinile. Ummandla we-flexible kufuneka uguquguquke ngokwaneleyo ukulungiselela i-radius bend efunekayo ngaphandle kokugxininisa umkhondo okanye amacandelo. Izindlela zokuqiniswa ezifana neembambo okanye iingubo ze-polymer zingasetyenziselwa ukwandisa amandla omatshini kunye nokuthembeka kweendawo eziguquguqukayo.

Ngokuthathela ingqalelo le miba yoyilo, iinjineli zinokuphuhlisa ngokupheleleyo i-PCB eqinileyo eguquguqukayo. Kubalulekile ukusebenza nabavelisi bePCB ukuqonda amandla abo, ukhetho lwemathiriyeli, kunye nokunciphisa ukwenziwa. Ukongeza, ukubandakanya iqela lemveliso kwangethuba kwinkqubo yoyilo kunokuncedisa ukusombulula nayiphi na imiba yokwenziwa kwezinto kunye nokuqinisekisa uguquko olugudileyo ukusuka kuyilo ukuya kwimveliso. Ngokunikela ingqalelo kwi-maleko yokusabalalisa, umzila kunye nokulandelela ukubekwa, umhlaba kunye neenqwelomoya zamandla, ingqibelelo yesignali kunye neendawo eziguquguqukayo eziguquguqukayo, abaqulunqi banokudala ii-PCB ezithembekileyo nezisebenzayo ngokupheleleyo.

Itekhnoloji yoyilo lwe-7.Layer ye-pcb eguquguqukayo engqongqo

Xa uyila iibhodi eziguquguqukayo eziqinileyo, ubuchule bokuyila umaleko budlala indima ebalulekileyo ekuqinisekiseni ukusebenza okuchanekileyo kunye nokuthembeka. Nazi iindlela ezine eziphambili zoyilo loyilo:

I-lamination elandelelanayo:

I-lamination elandelelanayo yitekhnoloji esetyenziswa ngokuqhelekileyo kwi-rigid-flex board production. Kule ndlela, iileya ezahlukeneyo eziqinileyo kunye neziguquguqukayo zenziwe ngokwahlukeneyo kwaye zifakwe i-laminated kunye. Iileya eziqinileyo ziqhele ukwenziwa kusetyenziswa iFR4 okanye izinto ezifanayo, ngelixa iileya eziguquguqukayo zenziwe kusetyenziswa i-polyimide okanye ii-substrates ezifanayo eziguquguqukayo. I-lamination elandelelanayo ibonelela ngokuguquguquka okukhulu ekukhetheni umaleko kunye nobukhulu, ukuvumela ulawulo olukhulu kwiipropati zombane kunye nezomatshini ze-PCB. UkuLanyiswa koFikelelo kabini:

Kwi-lamination yokufikelela kabini, i-vias igrunjwa kumaleko aqinileyo kwaye athambileyo ukuvumela ukufikelela kumacala omabini ePCB. Le teknoloji ibonelela ngokuguquguquka okukhulu ekubekweni kwecandelo kunye nokulandela umkhondo. Ikwaxhasa ukusetyenziswa kwee-vias ezingaboniyo nezingcwatywayo, ezinceda ekunciphiseni ukubala kweleya kunye nokuphucula imfezeko yomqondiso. I-lamination ye-Dual-channel lamination iluncedo ngakumbi xa kuyilwa ii-PCBs ezintsonkothileyo eziguquguqukayo ezinamaleko amaninzi kunye nemiqobo yesithuba esiqinileyo.

I-Z-axis encamathelayo encamathelayo:

I-Z-axis i-adhesive conductive isetyenziselwa ukuseka ukudibanisa kombane phakathi komgangatho oqinileyo kunye nomgangatho oguquguqukayo kwibhodi e-rigid-flex. Isetyenziswe phakathi kweepads conductive kwi-flexible layer kunye neepads ezihambelanayo kwi-rigid layer. I-adhesive iqulethe iinqununu ze-conductive ezenza iindlela zokuqhuba xa zixinzelelwe phakathi kweengqimba ngexesha le-lamination. I-Z-axis i-adhesive conductive inika uqhagamshelwano oluthembekileyo lombane ngelixa igcina ukuguquguquka kwe-PCB kunye nokunyaniseka koomatshini.

Ulungelelwaniso lwe-Hybrid stacking:

Kwi-hybrid stacking configuration, indibaniselwano yeeleyile eziqinileyo kunye neziguquguqukayo zisetyenziselwa ukudala i-stack ye-customized layer. Oku kwenza abaqulunqi bakwazi ukwenza ngcono ubeko lwePCB ngokusekelwe kwiimfuno ezithile zoyilo. Ngokomzekelo, iileyile eziqinileyo zingasetyenziselwa ukunyuswa kwamacandelo kunye nokubonelela ngokuqina komatshini, ngelixa iileyile eziguquguqukayo zingasetyenziselwa ukuhambisa iimpawu kwiindawo apho ukuguquguquka kuyadingeka. Ulungelelwaniso lwe-Hybrid stacking lubonelela abaqulunqi ngeqondo eliphezulu lokuguquguquka kunye nokwenziwa ngokwezifiso kuyilo oluntsonkothileyo lwePCB elukhuni.

Ngokusebenzisa obu buchule boyilo lomaleko, abayili banokudala iiPCB eziguquguqukayo eziqinileyo ezomeleleyo kwaye zisebenza. Nangona kunjalo, kubalulekile ukusebenzisana ngokusondeleyo nomenzi we-PCB ukuqinisekisa ukuba iteknoloji ekhethiweyo iyahambelana nobuchule babo bokuvelisa. Unxibelelwano phakathi koyilo kunye namaqela avelisayo lubalulekile ekusombululeni nayiphi na imiba enokubakho kunye nokuqinisekisa utshintsho olungenamagingxigingxi ukusuka kuyilo ukuya kwimveliso. Ngobuchule boyilo olufanelekileyo, abaqulunqi banokufikelela ekusebenzeni kombane okufunekayo, ukuguquguquka komatshini kunye nokuthembeka kwiiPCB eziguquguqukayo.

8.Rigid-flexible PCB lamination inkqubela phambili

Ukuhambela phambili kwitekhnoloji ye-lamination yePCB engqongqo yenze inkqubela phambili kwiinkalo ezahlukeneyo. Nazi iindawo ezine zenkqubela phambili ephawulekayo:

Utshintsho lweMathiriyeli:

Ukuqhubela phambili kwisayensi yezinto kwenze ukuba kube lula ukuphuhliswa kwezinto ezintsha ze-substrate ezenzelwe ngokukodwa iibhodi eziguquguqukayo. Ezi zixhobo zibonelela ngokuguquguquka okukhulu, ukuqina, kunye nokuchasana nobushushu kunye nokufuma. Kwimigangatho eguquguqukayo, izinto ezifana ne-polyimide kunye ne-liquid crystal polymer (LCP) zibonelela ngokuguquguquka okugqwesileyo ngelixa ugcina iimpawu zombane. Kwimigangatho eqinile, izinto ezifana ne-FR4 kunye ne-laminates ephezulu yokushisa kunokubonelela ngokufanelekileyo kunye nokuthembeka. Iisekethe eziprintiweyo ze-3D:

Itekhnoloji yoshicilelo ye-3D iye yaguqula amashishini amaninzi, kubandakanya ukwenziwa kwePCB. Ukukwazi ukuprinta i-3D trace conductive ngqo kwi substrates eziguquguqukayo kuvumela uyilo oluntsonkothileyo noluntsokothileyo lwePCB. Itekhnoloji iququzelela iprototyping ekhawulezayo kunye nokwenza ngokwezifiso, ivumela abaqulunqi ukuba benze izinto ezizodwa zefom kwaye badibanise amacandelo ngokuthe ngqo kwiileya eziguquguqukayo. Ukusetyenziswa kweesekethe eziprintiweyo ze-3D kwii-PCB eziguquguqukayo eziguquguqukayo kwandisa ukuguquguquka koyilo kunye nokunciphisa imijikelo yophuhliso.

Izixhobo ezizinzisiweyo ezithambileyo:

Enye intuthuko enkulu kwitekhnoloji ye-lamination kukudityaniswa ngokuthe ngqo kwamacandelo kwi-flexible layer ye-PCB eguquguqukayo. Ngokufakela amacandelo afana ne-resistors, i-capacitors kunye ne-microcontrollers kwii-substrates eziguquguqukayo, abaqulunqi banokuphinda banciphise ubukhulu be-PCB kunye nokuphucula imfezeko yesignali. Obu buchwephesha buvumela uyilo oluthe kratya kunye nolukhaphukhaphu, luyenza ilungele usetyenziso olunemithintelo yendawo eqinileyo.

Iingcingo zombane ezikhawulezayo:

Njengoko imfuno yonxibelelwano ngesantya esiphezulu iqhubeka ikhula, inkqubela phambili kwitekhnoloji ye-lamination yenza ukuba i-wiring ye-speed-speed high-speed signaling wiring kwi-PCBs eqinile-eguquguqukayo. Sebenzisa ubuchule obuphezulu obunjengokulawulwa kwendlela yokuthintela, ukudityaniswa kweendlela ezimbini, kunye noyilo lwemicrostrip okanye umgca westrip ukugcina imfezeko yomqondiso kunye nokunciphisa ukulahleka komqondiso. Iingqwalaselo zoyilo zikwaqwalasela imiphumo yokudibanisa, i-crosstalk, kunye nezibonakaliso zokubonisa. Ukusetyenziswa kwezinto ezikhethekileyo kunye neenkqubo zokuvelisa kunceda ukufezekisa ukusebenza kwesantya esiphezulu se-PCB eqinile-flex.

Ukuqhubela phambili okuqhubekayo kwitekhnoloji ye-regid-flex lamination ivumela uphuhliso lwezixhobo zombane ezihlangeneyo, eziguquguqukayo, kunye nezipheleleyo. Ukuqhubela phambili kwizinto ezintsha, iisekethe eziprintiweyo ze-3D, izinto eziguquguqukayo ezifakwe kunye nomzila wesignali wesantya esiphezulu zibonelela abaqulunqi ngokuguquguquka okukhulu kunye namathuba okudala i-PCB entsha kunye nethembekileyo yoyilo lwe-PCB eguquguqukayo. Njengoko itekhnoloji iqhubeka nokuvela, abaqulunqi kunye nabavelisi kufuneka bahlale behlaziywa kwaye basebenzisane ngokusondeleyo ukuze bathathe ithuba lenkqubela phambili yamva nje kwaye bafezekise ukusebenza kwePCB eguquguqukayo.

Isishwankathelo,ukuyila kunye nokukhetha uqwalaselo lwe-PCB ye-stackup echanekileyo eguqu-guqukayo ibalulekile ekufezekiseni ukusebenza kakuhle, ukuthembeka, kunye nokuguquguquka. Ngokuqwalasela izinto ezifana nengqibelelo yomqondiso, iimfuno zokuguquguquka kunye nemiqobo yokuvelisa, abaqulunqi banokwenza i-stackup ukuhlangabezana neemfuno zabo zesicelo. Inkqubela phambili eqhubekayo kwitekhnoloji yemathiriyeli ibonelela ngamathemba abanzi woyilo oluphuculweyo lwe-elektroniki. Izinto ezintsha ze-substrate ezenzelwe ii-PCB eziguquguqukayo eziqinileyo ziphucula ukuguquguquka, ukuqina, kunye nobushushu kunye nokuxhathisa ukufuma. Ukongeza, ukudibanisa amacandelo ngokuthe ngqo kwi-flex layer kunciphisa ngakumbi ubungakanani kunye nobunzima bePCB, iyenza ilungele izicelo ezinemiqobo yesithuba esiqinileyo. Ukongeza, ukuqhubela phambili kwitekhnoloji ye-lamination kunika amathuba anomdla. Ukusetyenziswa kwetekhnoloji yoshicilelo ye-3D inokwenza uyilo oluntsonkothileyo kwaye iququzelele ukuchwetheza ngokukhawuleza kunye nokwenza ngokwezifiso.

Ukongeza, ukuqhubela phambili kwitekhnoloji yokuhambisa umqondiso wesantya esiphezulu kwenza ukuba ii-PCB eziguquguqukayo zikwazi ukufikelela kunxibelelwano olusebenzayo noluthembekileyo.

Njengoko itekhnoloji iqhubeka nokuvela, abaqulunqi kufuneka bahlale benolwazi ngenkqubela phambili yamva nje kwaye basebenze ngokusondeleyo nabavelisi. Ngokunyusa ukuqhubela phambili kwemathiriyeli kunye nobugcisa bokwenza, abayili banokwenza izinto ezintsha nezithembekileyo zoyilo lwePCB oluguquguqukayo ukuhlangabezana neemfuno zeshishini le-elektroniki elihlala litshintsha. Ngesithembiso soyilo oluphuculweyo lwe-electronics, ikamva le-PCB eqinile-eguqukayo ye-stackups ibonakala ithembisa.

Ixesha lokuposa: Sep-12-2023

Emva