Indibano ye-PCB e-Rigid-flex yitekhnoloji yobuchule obutsha nobuguquguqukayo obudibanisa iingenelo zeebhodi zesekethe eziqinileyo neziguquguqukayo (PCBs). Eli nqaku lijolise ekunikezeni isikhokelo esibanzi kwindibano yePCB eguquguqukayo, iqaqambisa inkqubo yayo yokuvelisa, ingqwalasela yoyilo, izicelo kunye neenzuzo.

Isiqulatho:

Yintoni ibhodi yebhodi engqongqo-flex?

Inkqubo yokuvelisa ibhodi yebhodi eqinile-flex

Iingqwalasela zoYilo oluPhambili kwiiPCB zeRigid-Flex

Izinto ezilungileyo zebhodi eqinile-flex

Izicelo eziqhelekileyo zeNdibano ye-Rigid-Flex PCB

Iingcebiso zokuPhumelela kweNdibano yePCB eRigid-Flex

Imingeni yeNdibano ye-Rigid-Flex PCB kunye neMida

Ukuququmbela

Yintoni ibhodi yebhodi engqongqo-flex?

Indibano yePCB eguquguqukayo ibandakanya ukudibanisa iiPCB eziqinileyo neziguquguqukayo zibe yiyunithi enye. Ivumela ukudalwa kweesekethe eziyinkimbinkimbi ezintathu-dimensional (3D) ngendlela ehlangeneyo nefanelekileyo. Inxalenye eqinile inika uzinzo kunye nenkxaso, ngelixa inxalenye eguquguqukayo ivumela ukugoba kunye nokujika.

Inkqubo yokwenziwa kwendibano yebhodi yeRigid-Flex:

Inkqubo yokwenziwa kwendibano yePCB eguquguqukayo ibandakanya amanyathelo amaninzi. Ezi zibandakanya uyilo lwePCB, ukukhetha izinto, ukwenziwa kwesekethe, indibano yecandelo, uvavanyo kunye nokuhlolwa kokugqibela. Sebenzisa izixhobo ezikhethekileyo kunye nobuchule bokuqinisekisa ukuhlangana okuthembekileyo phakathi kweendawo eziqinileyo neziguquguqukayo.

Inyathelo lokuqala kukuyila uyilo lwePCB.Oku kubandakanya ukumisela ukubekwa kwamacandelo kunye nomkhondo kuzo zombini iinxalenye eziqinileyo neziguquguqukayo zebhodi.

Ukukhethwa kwezinto:Ukukhetha izinto ezichanekileyo kubalulekile ekuthembekeni kwebhodi kunye nokuguquguquka. Oku kubandakanya ukukhethwa kwee-substrates eziqinileyo ezifana ne-FR4 kunye nezixhobo eziguquguqukayo ezifana ne-polyimide okanye i-polyester.

Ukwenziwa kweSekethe:Inkqubo yokwenziwa kwe-PCB ibandakanya amanyathelo amaninzi abandakanya ukucoca, ukusebenzisa iileya zobhedu, ukudibanisa ukwenza umkhondo wesekethe, ukongeza imaski ye-solder kunye ne-silkscreening yokuchongwa kwecandelo. Inkqubo yenziwa ngokwahlukileyo kwiindawo eziqinileyo kunye neziguquguqukayo zebhodi.

INdibano yeCandelo:Amacandelo ke axhonywe kumacandelo aqinileyo naguquguqukayo ebhodi esebenzisa iSurface Mount Technology (SMT) okanye ngeHole Technology (THT). Ukunyamekela okukhethekileyo kuthathwa ukuze kuqinisekiswe ukuba amacandelo abekwe ngokufanelekileyo kwaye ngokukhuselekileyo kuzo zombini izinto eziqinileyo kunye neziguquguqukayo.

Ukudibanisa:Inkqubo yokudibanisa ibalulekile ukuqinisekisa uxhulumaniso oluthembekileyo phakathi kweendawo eziqinileyo kunye neziguquguqukayo zebhodi. Sebenzisa i-adhesives, ubushushu, kunye noxinzelelo ukuze ubophe ngokuqinileyo amaqhekeza kunye. Ngenxa yale njongo, izixhobo ezikhethekileyo kunye nobuchule busetyenziswa, njengokusetyenziswa kwe-laminators okanye ukufudumeza okulawulwayo.

Uvavanyo:Emva kokuhlanganisana, iibhodi zivavanywa ngokucokisekileyo ukuze kuqinisekiswe ukusebenza nokuthembeka. Oku kubandakanya uvavanyo lombane, uvavanyo olusebenzayo, kunye novavanyo olunokwenzeka lokusingqongileyo ukuze kuqinisekiswe ukusebenza kwebhodi engqongqo phantsi kweemeko ezahlukeneyo.

Uhlolo lokugqibela:Ukuhlolwa kokugqibela kwenziwa ukujonga umgangatho wendibano kunye nokuqinisekisa ukuba akukho ziphene okanye iingxaki kwimveliso egqityiweyo. Eli nyathelo libandakanya ukuhlolwa okubonakalayo, imilinganiselo yobukhulu, kunye naluphi na olunye uvavanyo olufunekayo kwisicelo.

Imiba ephambili yoyilo lweePCBs eziguquguqukayo:

Ukuyila i-PCB eguquguqukayo elukhuni kufuna uqwalaselo ngononophelo lwemiba eyahlukeneyo enje ngeradiyasi yokugoba, ukupakishwa komaleko, ukubekwa kwendawo ethambileyo, kunye nokubekwa kwecandelo. Ubuchule bokuyila obufanelekileyo buqinisekisa ukusebenza kakuhle kunye nokuthembeka kwemveliso yokugqibela.

Irediyasi yokugoba:Iibhodi ze-Rigid-flex zivumelekile ukuba zigobe kwaye zigobe, kodwa zine-radius ye-bend encinci engafanele igqithwe. I-radius ye-bend yeyona radius encinci ibhodi inokugoba ngaphandle kokonakalisa isekethe okanye ibangele uxinzelelo lomatshini. Xa uyila ukucwangciswa kwamacandelo kunye nomkhondo, kubalulekile ukuqwalasela i-radius ye-bend yeendawo eziguquguqukayo ukuqinisekisa ukunyaniseka kwabo ngexesha lokugoba.

Isipakisho seLayer:Isitaki somaleko sibhekisa kulungiselelo lweeleya ezahlukeneyo zePCB. Kwi-PCB eguquguqukayo engqongqo, kuhlala kukho iileya eziqinileyo neziguquguqukayo. I-stackup kufuneka icwangciswe ngononophelo ukuqinisekisa ukudibanisa okufanelekileyo phakathi kweendawo eziqinileyo kunye neziguquguqukayo kunye nokubonelela ngokusebenza okwaneleyo kombane ngelixa udibana neemfuno zokugoba kunye nokusonga.

Uyilo lweNdawo eFlex:Indawo eguquguqukayo yePCB eguquguqukayo yindawo apho kuya kwenzeka ukugoba okanye ukugoba. Le mimandla kufuneka ibekwe ngobuchule ukuphepha ukuphazamiseka kumacandelo, izihlanganisi, kunye nezakhiwo zoomatshini. Kubalulekile ukuqwalasela ukuqhelaniswa kunye nendawo yeendawo eziguquguqukayo zokunciphisa uxinzelelo kumacandelo abalulekileyo ngexesha lokusebenza.

Ukubekwa kwelungu:Ukubekwa kwamacandelo kwi-PCB eqinile-i-flexible kufuneka icwangciswe ngononophelo ukuphepha ukuphazamisa indawo ye-flex kunye ne-akhawunti nayiphi na intshukumo ngexesha lokugoba. Amacandelo abalulekileyo kufuneka abekwe kwiindawo eziqinileyo, ngelixa amacandelo amancinci angafakwa kwiindawo eziguquguqukayo. Ukubekwa kwecandelo kufuneka kuqwalaselwe ukusebenza kwe-thermal yebhodi kunye nokukwazi ukutshabalalisa ubushushu.

Umqondiso weMfezeko:IiPCB eziguquguqukayo eziguquguqukayo zihlala zifuna uqwalaselo ngononophelo lwemfezeko yomqondiso. Ukugoba kunye nokugoba kwe-PCB kunokubangela ukungahambelani kwe-impedance, ukubonakalisa umqondiso kunye nemiba ye-crosstalk. Kubalulekile ukuqwalasela umkhondo womzila kunye nolawulo lwe-impedance ukugcina imfezeko yomqondiso kuyo yonke ibhodi.

Imiqobo yoomatshini:Izithintelo zoomatshini ezifana nokuchasana nokothuka, ukungcangcazela, kunye nokwandiswa kwe-thermal kufuneka kuqwalaselwe ngexesha lesigaba soyilo. Iindawo eziqinileyo kunye neziguquguqukayo zebhodi kufuneka zenzelwe ukujamelana noxinzelelo lwemishini ngaphandle kokuphazamisa ingqibelelo yesiphaluka.

Imiqobo yokwenziwa kwemveliso:Uyilo lokwenziwa kwezinto lubalulekile kukwenziwa ngempumelelo kweePCB eziguquguqukayo. Imiba efana nobubanzi bomkhondo obuncinci, ngendawo, ukuxinana kobhedu, kunye nokunyamezelana kwemveliso kufuneka kuthathelwe ingqalelo ukuze kuqinisekiswe ukuba uyilo luyafezekiswa ngaphakathi kwesakhono sokuvelisa kunye nemiqobo.

Izinto eziluncedo kwiibhodi eziguquguqukayo:

I-Rigid-flex PCBs ibonelela ngeenzuzo ezininzi ngaphezu kwee-PCB zemveli eziqinileyo okanye eziguquguqukayo. Ezi ziquka ukunciphisa ubungakanani kunye nobunzima, ukuthembeka okuphuculweyo, ukunyaniseka komqondiso ophuculweyo, ukunyuka kokuguquguquka koyilo, kunye nenkqubo yokuhlanganisana elula kunye novavanyo.

Ubungakanani obuncitshisiweyo kunye nobunzima:IiPCB eziguquguqukayo eziguquguqukayo zivumela ukudityaniswa kwezinto eziqinileyo kunye neziguquguqukayo ngaphakathi kwebhodi enye, ukuphelisa imfuno yokudibanisa kunye neentambo ezidibeneyo. Amacandelo ambalwa kunye ne-wiring yenza imveliso iyonke ibe yincinci kwaye ibe lula.

Ukuthembeka okuphuculweyo:IiPCB eziguquguqukayo ezinokuthembeka okuphezulu xa kuthelekiswa neePCB zemveli. Ukupheliswa kweziqhagamshelo kunye neentambo zokudibanisa kunciphisa amathuba okuba ungaphumeleli ngenxa yoxhumo olukhululekile okanye iingcingo eziphukileyo. Ukongezelela, inxalenye eguquguqukayo yebhodi inokumelana nokugoba kunye nokuguquguquka ngaphandle kokuphazamisa ingqibelelo yesiphaluka.

Ukwandiswa Kwembonakaliso yoMqondiso:Ukudibanisa iinxalenye eziqinileyo kunye neziguquguqukayo kwibhodi enye kunciphisa imfuno yokudibanisa okongeziweyo kunye nokunciphisa ukulahleka komqondiso kunye nokuphazamiseka. Iindlela zesignali ezimfutshane kunye nokunciphisa ukungaqhubeki kwe-impedance kuphucula umgangatho wesignali kunye nokunyaniseka.

Ukonyuka kokuguquguquka koyilo:I-Rigid-flex PCBs ibonelela abaqulunqi ukuguquguquka okukhulu kwifom factor kunye nokubekwa kwecandelo. Ukukwazi ukugoba kunye nokusonga iibhodi zeesekethe zenza ukuba kuhlanganiswe ngakumbi kunye noyilo loyilo, okuvumela iinjineli ukuba zilungele ukusebenza ngakumbi kwindawo encinci.

Ukudibanisa lula kunye nenkqubo yokuvavanya:I-Rigid-flex PCBs yenza lula inkqubo yendibano ngokunciphisa inani lamacandelo kunye nokudibanisa okufunekayo. Oku kwenza indibano ekhawulezayo nesebenzayo. Ukongezelela, ukuphelisa izixhumi kunciphisa ithuba lokungahambi kakuhle okanye imiba yoxhulumaniso ngexesha lendibano. Inkqubo yokuhlanganisa eyenziwe lula ithetha iindleko eziphantsi kunye nexesha elikhawulezayo lokuthengisa.

Usetyenziso oluqhelekileyo lwendibano yePCB eguquguqukayo:

Iindibano ze-PCB eziguquguqukayo zisetyenziswa kwiintlobo ngeentlobo zamashishini, kubandakanywa izixhobo zonyango, i-aerospace, i-automotive, i-electronics yabathengi, kunye nokunye. Ilungele usetyenziso olufuna umbane obambeneyo nothembekileyo kwiindawo ezinomngeni.

Izixhobo zonyango:Iindibano ze-PCB eziguquguqukayo ziqhele ukusetyenziswa kwizixhobo zonyango ezifana ne-pacemakers, iimpompo ze-insulin, kunye neemonitha zempilo ezinokunxitywa. Ezi zixhobo zifuna ubungakanani obuncinci, ukuqina kunye nokuguquguquka ukumelana nokunyakaza kunye nokudibana komzimba. Itekhnoloji ye-Rigid-flex ivumela iisekethe ezidibeneyo kunye nezithembekileyo ezidibeneyo kwizixhobo zonyango.

I-Aerospace:Iindibano ze-PCB eziguquguqukayo zifanelekile kwizicelo ze-aerospace apho ukunciphisa ubunzima, imiqobo yendawo kunye nokuthembeka zizinto eziphambili. Zisetyenziselwa kwiinkqubo ze-avionics zeenqwelomoya, izixhobo zonxibelelwano, iinkqubo zokuhamba kunye neepaneli zokulawula. Itekhnoloji ye-Rigid-flex yenza ukuba ukukhanya, iinkqubo zombane ezihlangeneyo kwiinkqubo ze-aerospace.

Iimoto:Usetyenziso lweemoto lufuna ii-elektroniki ezirhabaxa nezithembekileyo ezinokumelana nokungcangcazela, utshintsho lobushushu, kunye noxinzelelo lomatshini. Iindibano ze-PCB eziguquguqukayo zisetyenziswa kwiiyunithi zokulawula iimoto, iinkqubo zokuncedisa abaqhubi abaphambili (ADAS), i-infotainment kunye neenkqubo zokulawula injini. Itekhnoloji ye-Rigid-flex iqinisekisa uyilo lokugcina indawo kunye nokwandisa ukuqina.

Ii-Electronics zabathengi:Iindibano zePCB eziguquguqukayo zisetyenziswa ngokubanzi kwizixhobo ezahlukeneyo zombane zabathengi ezinje ngee-smartphones, iitafile, izixhobo ezinxitywayo kunye neeconsoles zomdlalo. Ubume obunobumbano kunye nobubhetyebhetye bePCBs eziguquguqukayo zenza ukusebenza okuphezulu, ukuphuculwa koyilo lobuhle, kunye namava angcono omsebenzisi. Benza ukuba abavelisi benze izixhobo ezibhityileyo, ezikhaphukhaphu, nezisebenzayo ngakumbi.

Izixhobo zoShishino:Kwizixhobo zoshishino apho ukuthembeka kunye nokuqina kubaluleke kakhulu, iindibano zePCB eziguquguqukayo zisetyenziswa kwiinkqubo zokulawula, iirobhothi, ulawulo lwamandla, kunye nokufumana idatha. Ukudityaniswa kwamacandelo aqinileyo kunye nokuguquguqukayo kwenza ukusetyenziswa ngokufanelekileyo kwendawo, ukunciphisa i-wiring, kunye nokwandisa ukuchasana neemeko zokusebenza ezinzima.

Iingcebiso zendibano yePCB eqinileyo eguquguqukayo:

Ukuqinisekisa ngempumelelo indibano yePCB eguquguqukayo engqongqo, eyona ndlela ilungileyo kufuneka ilandelwe, njengokukhethwa komenzi ochanekileyo, ukuphatha izinto ezifanelekileyo kunye nokugcinwa, ulawulo olusebenzayo lwe-thermal, kunye novavanyo olucokisekileyo kunye neenkqubo zokuhlola.

Khetha umenzi othembekileyo:Ukukhetha umenzi ofanelekileyo kubalulekile kwindibano yePCB eqinileyo eguquguqukayo. Khangela umenzi onamava ovelisa iiPCB eziguquguqukayo eziqinileyo kunye nerekhodi yokuhambisa iimveliso ezikumgangatho ophezulu. Qwalasela ubuchule babo, amandla okuvelisa, iziqinisekiso, kunye nophononongo lwabathengi.

Qonda iimfuno zoyilo:Uqhelene neemfuno zoyilo lweebhodi eziqinileyo-flex. Oku kuquka ukuqonda imiqobo yoomatshini kunye nezombane ezifana neemfuneko zokugoba kunye nokugoba, ukubekwa kwecandelo kunye nokuqwalaselwa kwemfezeko yomqondiso. Sebenza ngokusondeleyo nomyili wePCB yakho ukuqinisekisa ukuba uyilo lulungiselelwe ukwenziwa kunye nokuhlanganisa.

Ukuphathwa kweMathiriyeli eyiyo kunye noGcino:Iibhodi ze-Rigid-flex zinokonakala ngokulula ngokuphathwa kakubi kunye nokugcinwa okungafanelekanga. Qinisekisa ukuba umenzi ulandela iinkqubo ezifanelekileyo zokuphatha izinto, kubandakanywa nokukhusela iindawo eziguquguqukayo ukusuka ekugobeni okugqithisileyo okanye uxinzelelo. Kwakhona, gcina iibhodi eziqinileyo-eziguquguqukayo kwindawo elawulwayo ukuthintela ukufunxa ukufuma okanye ukuvezwa kwamaqondo obushushu aphezulu.

Ulawulo olusebenzayo lobushushu:Iindibano zePCB eziguquguqukayo zinokuba namacandelo avelisa ubushushu. Ulawulo olufanelekileyo lwe-thermal lubalulekile ukuqinisekisa ukusebenza okuthembekileyo kunye nokuthintela ukungaphumeleli okuhlangeneyo kwe-solder. Qwalasela ubuchule obunje nge-thermal vias, izisasazeli zobushushu, okanye iipads ze-thermal ukulawula ngokufanelekileyo ukutshatyalaliswa kobushushu. Sebenza kunye nomvelisi ukwandisa uyilo lolawulo olusebenzayo lwe-thermal.

Uvavanyo olucokisekileyo kunye nokuhlolwa:Uvavanyo olungqongqo kunye nokuhlolwa kuyafuneka ukuchonga nayiphi na imiba ngexesha lendibano kunye nokuqinisekisa ukuthembeka kwemveliso yokugqibela. Ukuphumeza iprotocol yovavanyo olubanzi olubandakanya uvavanyo lombane, uvavanyo olusebenzayo kunye nokuvavanya ukuthembeka. Yenza uhlolo olucokisekileyo olubonakalayo ukuze ufumane naziphi na iziphoso okanye iziphazamiso kwindibano.

Ukusebenzisana nabavelisi:Gcina unxibelelwano oluvulekileyo kwaye usebenze ngokusondeleyo nabavelisi kuyo yonke inkqubo yendibano. Xoxa ngengqwalasela yoyilo, iimfuno zemveliso kunye nayo nayiphi na imiba ethile. Uphonononga rhoqo kwaye uvumele iiprototypes okanye iisampulu zokuqinisekisa ukuba izinto ozilindeleyo ziyafezekiswa. Le ndlela yentsebenziswano iya kunceda ukusombulula nayiphi na imiba enokubakho kwangethuba kwaye iqinisekise indibano yePCB eqinileyo eguquguqukayo.

Imingeni kunye nemida yendibano yePCB eguquguqukayo:

Ngelixa indibano ye-PCB engqongqo-flex ineengenelo ezininzi, ikwabonelela ngemingeni kunye nemida. Oku kubandakanya iindleko eziphezulu zokwenziwa kwemveliso, ukunyuswa koyilo kunye nobunzima bokuvelisa, ukufumaneka okunyiniweyo kwezixhobo ezikhethekileyo zokuvelisa, kunye nomngcipheko ophezulu wokwenza iziphene.

Iindleko eziphezulu zokuvelisa:Iindibano zePCB eziguquguqukayo zidla ngokubiza kakhulu kuneendibano zePCB zemveli ngenxa yezinto ezongezelelweyo ezifunekayo, iinkqubo ezikhethekileyo zokuvelisa, kunye nobunzima obuphezulu. Iindleko zokwenziwa kwe-PCB eqinileyo kunye nendibano kufuneka ziqwalaselwe ngononophelo kwaye ziqingqelwe kwiprojekthi.

Ukonyuka koyilo kunye nobunzima bokuvelisa:Ngenxa yokudityaniswa kwezinto eziqinileyo neziguquguqukayo, uyilo lwePCBs eziguquguqukayo zifuna ubuchule kunye namava. Inkqubo yoyilo inzima ngakumbi njengoko ibandakanya ukugoba, ukugoba kunye nokubeka amacandelo. Iinkqubo zokuvelisa ezifana ne-lamination, i-drilling kunye ne-welding nazo ziba nzima ngakumbi ngenxa yokudibanisa izinto kunye nezakhiwo.

Ubukho obuNcinciweyo beZixhobo eziMiselweyo zokuVelisa:Indibano yePCB eguquguqukayo inokufuna izixhobo ezikhethekileyo zokuvelisa ezingengabo bonke abavelisi. Ubukho bezo zixhobo bunokunqongophala, nto leyo enokukhokelela kwixesha elide lokukhokela okanye imfuneko yokuvelisa imveliso kumaziko awodwa. Kubalulekile ukuqinisekisa ukuba umenzi okhethiweyo unezixhobo kunye nezakhono ezifunekayo kwindibano ye-PCB eguquguqukayo esebenzayo.

UMngcipheko oPhezulu woZiphene zokuVelisa:Ukuntsokotha kweendibano zePCB eziguquguqukayo zenza umngcipheko ophezulu wokwenza iziphene xa kuthelekiswa neendibano zePCB eziqinileyo. Iindawo ze-Flex kunye noqhagamshelwano oluthambileyo luchaphazeleka ngakumbi kumonakalo ngexesha lokuvelisa kunye nokudibanisa. Ukhathalelo olongezelelweyo kufuneka luthathwe ngexesha lokuphatha, ukuthengisela kunye nokuvavanya ukunciphisa umngcipheko weziphene.

Imingeni yovavanyo kunye nokuhlola:Iindibano zePCB eziguquguqukayo zinokuba ngumngeni ngakumbi ukuvavanya nokuhlola ngenxa yokudibanisa iindawo eziqinileyo neziguquguqukayo. Iindlela zovavanyo lwesintu ezifana ne-flying probe okanye ibhedi yovavanyo lwezikhonkwane zisenokungalungeli kuyilo oluntsonkothileyo oluguquguqukayo. Uvavanyo oluqhelekileyo kunye neendlela zokuhlola zingafuneka, zongeza ubunzima kunye neendleko kwinkqubo yokuvelisa.

Nangona le mingeni kunye nemida, iindibano ze-PCB eziguquguqukayo zibonelela ngeenzuzo ezizodwa malunga nokugcinwa kwendawo, ukuthembeka, kunye nokuqina, okubenza babe ukhetho lokuqala lwezicelo ezineemfuno ezithile. Le mingeni ingasonjululwa ngokufanelekileyo ngokusebenza ngokusondeleyo nomvelisi onamava kunye noqwalaselo ngononophelo loyilo nolwakhiwo, okukhokelela kwindibano yePCB eguquguqukayo enempumelelo.

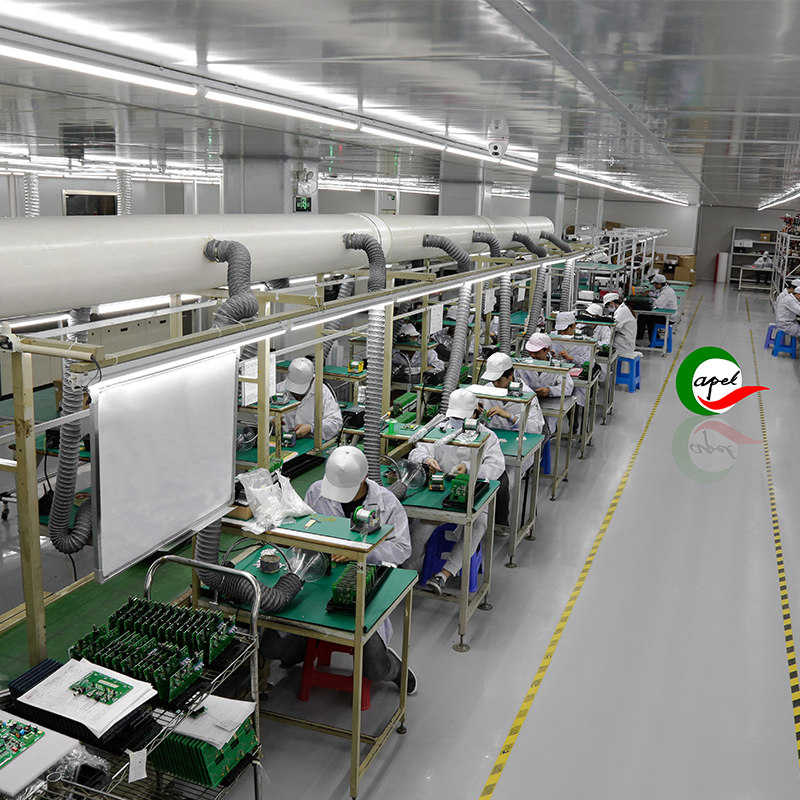

Indibano ye-PCB eguquguqukayo yitekhnoloji enamandla enokuthi isetyenziswe ukwenza izixhobo zombane ezivelisa izinto ezintsha kunye necwecwe.Iimpawu zayo ezizodwa kunye neenzuzo ziyenza ilungele usetyenziso olubanzi kumashishini. Nangona kunjalo, ukuqwalaselwa ngokucophelela koyilo, ukuveliswa kunye nenkqubo yokuhlanganisa kubalulekile ukuqinisekisa ukuphunyezwa ngempumelelo. Ukuqukumbela, ukuqonda inkqubo yokuvelisa, ukuqwalaselwa koyilo, izicelo, iingenelo kunye nemida yendibano yePCB eguquguqukayo iyimfuneko kwiinjineli, abayili kunye nabavelisi. Ngokusebenzisa amandla obu buchwepheshe buphucukileyo, i-cutting-edge kunye ne-electronics ethembekileyo inokuphuhliswa ukuhlangabezana neemfuno zamashishini anamhlanje avela ngokukhawuleza.I-Shenzhen Capel Technology Co., Ltd. yaseka umzi-mveliso wayo oqinileyo we-flex pcb ngo-2009 kwaye iyingcali yeFlex Rigid Pcb Manufacturer. Ngeminyaka eyi-15 yamava eprojekthi etyebileyo, ukuhamba kwenkqubo engqongqo, ubuchule obugqwesileyo bobugcisa, izixhobo ezizenzekelayo ezizenzekelayo, inkqubo yokulawula umgangatho obanzi, kwaye uCapel uneqela leengcali zeengcali ukubonelela abathengi behlabathi ngokuchaneka okuphezulu, umgangatho ophezulu we-1-32 layer rigid flex. ibhodi, i-hdi Rigid Flex Pcb, iRigid Flex Pcb Fabrication, i-rigid-flex pcb assembly, i-fast turn rigid flex indibano ye-pcb, i-prototypes ye-pcb ekhawulezayo yokuphendula i-pre-intengiso kunye neenkonzo zobugcisa emva kokuthengisa kunye nokunikezelwa ngexesha elifanelekileyo kwenza abathengi bethu bakwazi ngokukhawuleza babambe amathuba emarike kwiiprojekthi zabo.

Ixesha lokuposa: Aug-29-2023

Emva