Kule post yebhlog, siza kuphonononga izinto ekufuneka siziqwalasele xa ukhetha imathiriyeli yefilim yee-PCB ezibhetyebhetye kwaye ibonelele ngezimvo ezixabisekileyo ukukunceda wenze isigqibo esinolwazi.

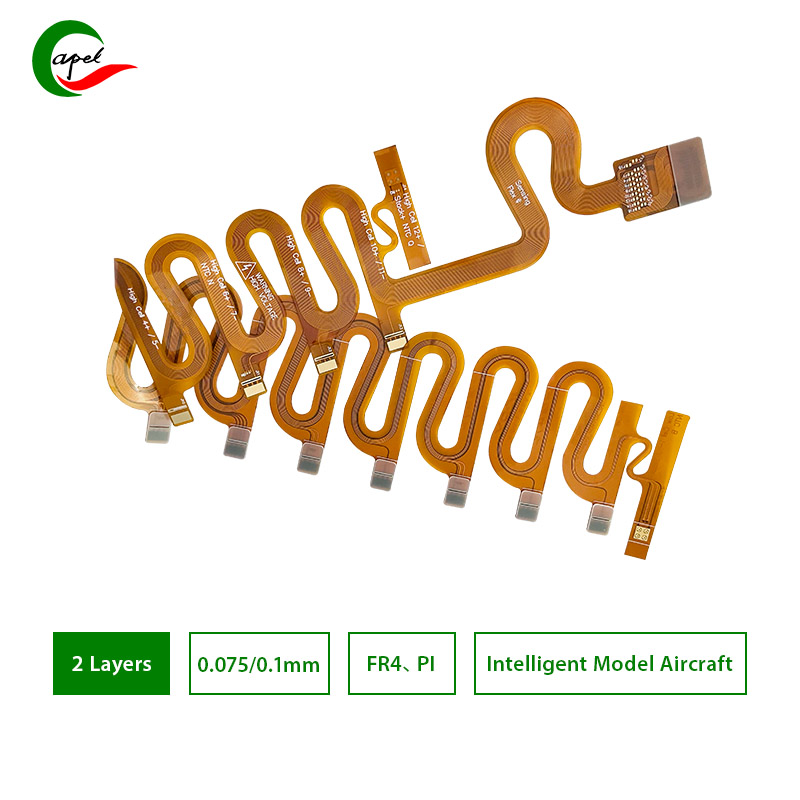

Kule minyaka yangoku,iiPCB ezibhetyebhetye(iibhodi zeesekethe eziprintiweyo eziguquguqukayo) ziye zafumana ukuthandwa ngenxa yokukwazi ukuhambelana nemilo enzima, ukuphucula ukusebenza kombane, kunye nokunciphisa ubunzima kunye neemfuno zendawo. Ezi bhodi zeesekethe eziguquguqukayo zisetyenziswa ngokubanzi kumashishini ahlukeneyo, kubandakanywa iimoto, i-electronics yabathengi, izixhobo zonyango kunye ne-aerospace. Inkalo ephambili yokuyila ii-PCB eziguquguqukayo kukukhetha izinto ezifanelekileyo zefilimu ukuqinisekisa ukusebenza okufunekayo kunye nokuthembeka.

1. Ukuba bhetyebhetye kunye nokugoba :

Ii-PCB eziguquguqukayo ziyaziwa ngokuba bhetyebhetye kunye nokukwazi ukugoba. Ke ngoko, izixhobo zefilimu ezincinci ezisetyenziselwa ukwakha iisekethe ezinjalo kufuneka zibe nokuguquguquka okuhle kunye nokugoba. Enye into esetyenziswa ngokuqhelekileyo yifilimu ye-polyimide (PI). I-Polyimide ineepropathi ezigqwesileyo zoomatshini ezinje ngokuqina kokuqina okuphezulu, uzinzo oluhle lobushushu kunye nokumelana neekhemikhali okugqwesileyo, kuyenza ilungele izicelo zePCB eziguquguqukayo. Ukongeza, iifilimu zecrystal polymer (LCP) zikwadume ngokuguquguquka okugqwesileyo kunye nozinzo olubalaseleyo.

2. I-Dielectric engaguqukiyo kunye nelahleko factor :

I-dielectric constant and dissipation factor of the film material idlala indima ebalulekileyo ekumiseleni ukusebenza kweePCB eziguquguqukayo. Ezi zakhiwo zibonelela ngengqiqo kwikhono lezinto zokuhambisa iimpawu zombane ngaphandle kokulahlekelwa okukhulu. Amaxabiso e-dielectric asezantsi kunye ne-dissipation factor values alungele usetyenziso olukwi-high-frequency kuba anciphisa ukulahleka komqondiso kwaye aqinisekise ukusebenza okuthembekileyo. Ezinye izinto ezisetyenziswa ngokuqhelekileyo ifilimu ye-dielectric ephantsi yi-polyimide kunye ne-LCP.

3. Uzinzo lwe-Thermal kunye nokumelana nobushushu:

IiPCB eziguquguqukayo zihlala zisesichengeni sokutshintsha kweemeko zamaqondo obushushu, ngakumbi kwiinkqubo zemoto kunye ne-aerospace. Ke ngoko, ukukhetha izixhobo zefilimu ezinozinzo oluhle kakhulu lwe-thermal kunye nokuchasana kubalulekile ukuqinisekisa ukusebenza kakuhle kunye nokuthembeka. Iifilimu ze-polyimide ezinobushushu obuphezulu, ezifana ne-Kapton®, zisetyenziswa ngokubanzi kwi-PCB eguquguqukayo yokuvelisa ngenxa yokukwazi ukujamelana namaqondo okushisa aphezulu ngelixa begcina ingqibelelo yesakhiwo. Iifilimu ze-LCP, ngakolunye uhlangothi, zinozinzo olufanayo lwe-thermal kwaye zinokuqwalaselwa njengezinye iindlela.

4. Ukuhambelana kweMichiza:

Izinto zefilim ezibhityileyo ezisetyenziswa kwiiPCB ezibhetyebhetye kufuneka zihambelane ngokwekhemikhali nendawo ethile ezibekwe kuyo. Ngexesha lokudityaniswa kwePCB kunye nokuphathwa, ukuvezwa kwizinto ezifana nezinyibilikisi, abacoci, kunye nee-fluxes kufuneka ziqwalaselwe. I-Polyimide inokumelana neekhemikhali okugqwesileyo kwaye lukhetho lokuqala kwezona zicelo zePCB ezibhetyebhetye.

5. Ukuhambelana okuncamathelayo:

Izinto bhanyabhanya ezibhityileyo zihlala zilanywa ngamaleko ancamathelayo ukwenza ulwakhiwo olomeleleyo kwiiPCB eziguquguqukayo. Ke ngoko, kubalulekile ukukhetha izinto zefilimu ezihambelana nenkqubo yokuncamathelisa ekhethiweyo. Izinto eziphathekayo kufuneka zidibanise kakuhle kunye ne-adhesive ukuqinisekisa ibhondi eyomeleleyo kunye nokugcina ingqibelelo ye-PCB eguquguqukayo. Ngaphambi kokugqiba izinto zefilimu, kucetyiswa ukuba iinkqubo ezithile zokubambelela zivavanywe ukuhambelana nokuqinisekisa ukudibanisa okuthembekileyo.

6. Ukufumaneka kunye neendleko:

Ekugqibeleni, ubukho bezinto zefilimu kunye neendleko kufuneka ziqwalaselwe kwinkqubo yokhetho. Ngelixa i-polyimide ifumaneka ngokubanzi kwaye ineendleko ezifanelekileyo, ezinye izinto ezifana ne-LCP zinokubiza kakhulu. Ukuphonononga iimfuno zeprojekthi, imiqobo yohlahlo lwabiwo-mali, kunye nokufumaneka kwentengiso kuya kunceda ukumisela eyona filim imathiriyeli yoyilo lwakho olubhetyebhetye lwePCB.

Isishwankathelo, ukukhetha imathiriyeli yefilimu efanelekileyo kwi-PCB yakho ebhetyebhetye kubalulekile ekuqinisekiseni ukusebenza kakuhle, ukuthembeka kunye nokuqina kwexesha elide.Izinto ezinjengokuguquguquka kunye nokugoba, ukuguquguquka kwe-dielectric kunye nokulahlekelwa kwezinto, ukuzinza kwe-thermal kunye nokuchasana, ukuhambelana kweekhemikhali, ukuhambelana kwe-adhesive, kunye nokufumaneka kunye neendleko kufuneka zihlolwe ngokucophelela ngexesha lokukhetha. Ngokuqwalasela le miba kunye nokwenza uphando olunzulu, unokwenza isigqibo esinolwazi esiya kukhokelela kwi-PCB eyilwe kakuhle, ekumgangatho ophezulu ebhetyebhetye kwisicelo sakho esithile.

Ixesha lokuposa: Sep-21-2023

Emva