Intshayelelo

Kwesi sithuba sebhlog, siza kuxoxa ngezicwangciso eziliqili ezisebenzayo kunye nezona ndlela zilungileyo zokuthintela ukudodobala kwePCB eguquguqukayo, ngaloo ndlela ukhusela izixhobo zakho zombane kwiintsilelo ezinokubakho.

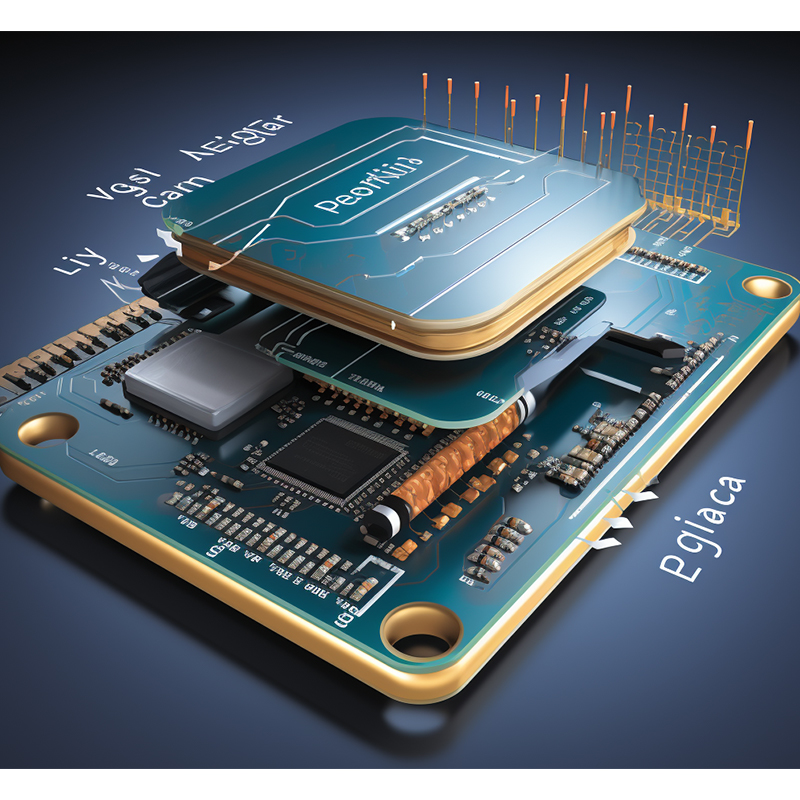

I-Delamination ngumba obaluleke kakhulu odla ngokubetha iibhodi zesekethe eziprintiweyo eziqinileyo (PCBs) ngexesha lobomi babo benkonzo. Lo mcimbi ubhekisa ekwahlukaneni kweeleya kwi-PCB, okukhokelela kunxibelelwano olubuthathaka kunye nokusilela kwecandelo. Njengomvelisi okanye umyili, kubalulekile ukuqonda oonobangela be-delamination kwaye uthathe amanyathelo okuthintela ukuqinisekisa uzinzo lwexesha elide kunye nokuthembeka kwePCB yakho.

I. Qonda delamination kwi PCB rigid-flex

I-Delamination ibangelwa yimiba eyahlukeneyo ngexesha lokuvelisa, ukudibanisa, kunye nokuphatha izigaba ze-PCB eziguquguqukayo. Uxinzelelo lwe-thermal, ukufunxa umswakama kunye nokukhethwa kwezinto ezingafanelekanga zizinto eziqhelekileyo ze-delamination. Ukuchonga nokuqonda ezi zizathu kubalulekile ekuphuhliseni iindlela zokuthintela ezisebenzayo.

1. Uxinzelelo lwe-thermal: I-Coefficient of thermal expansion (CTE) ukungalingani phakathi kwezinto ezahlukeneyo kunokukhokelela ekuxinzezeleni okugqithiseleyo ngexesha lokuhamba ngebhayisikili ye-thermal, ekhokelela kwi-delamination.Xa i-PCB ifumana utshintsho lobushushu, iileya ziyakhula kwaye zikhontrakthi ngamaxabiso ahlukeneyo, zidala uxinezeleko kwiibhondi phakathi kwazo.

2. Ukufunxwa kokufuma: I-PCB eguquguqukayo engqongqo ihlala ityhilekile kwindawo yokufuma ephezulu kwaye ifunxa lula ukufuma.Iimolekyuli zamanzi zinokungena kumphezulu webhodi ngokusebenzisa i-microcracks, i-voids, okanye ukuvuleka okungavalwanga kakuhle, okubangela ukwanda kwendawo, ukudumba, kwaye ekugqibeleni i-delamination.

3. Ukukhethwa kweMathiriyeli: Ukuqwalaselwa ngononophelo kweempawu eziphathekayo kubalulekile ekuthinteleni ukuchithwa.Kubalulekile ukukhetha i-laminate efanelekileyo, i-adhesive kunye nonyango lwangaphezulu ukubonelela ngokufunxa okuphantsi komswakama kunye nokuzinza okufanelekileyo kwe-thermal.

2. Amacebo okuthintela ukudelamination

Ngoku ukuba siyasiqonda isizathu, makhe sijonge amacebo abalulekileyo okuthintela ukudodobala kwePCB eqinileyo:

1. Iingqwalasela ezifanelekileyo zoyilo:

a) Nciphisa ubukhulu bobhedu:Ubuninzi bobhedu obugqithisileyo budala uxinzelelo olukhulu ngexesha lokuhamba ngebhayisikile eshushu. Ke ngoko, ukusebenzisa ubuncinci bobunzima bobhedu obufunekayo kwandisa ukuguquguquka kwePCB kwaye kunciphisa umngcipheko we-delamination.

b) Ubume bomaleko obulungelelanisiweyo:Zama ukusasazwa okufanayo kweeleya zobhedu ngaphakathi kweendawo eziqinileyo neziguquguqukayo zePCB. Ulungelelwaniso olufanelekileyo lunceda ukugcina i-symmetrical ukwanda kwe-thermal kunye nokucutha, ukunciphisa amandla okuba ne-delamination.

c) Unyamezelo oluLawulwayo:Phumeza ukunyamezela okulawulwayo kubungakanani bomngxunya, ngedayamitha kunye nobubanzi bokulandelela ukuqinisekisa ukuba uxinzelelo ngexesha lokutshintsha kwe-thermal lusasazwa ngokulinganayo kuyo yonke i-PCB.

d) Iifillet kunye neefilthi:Iifillet zinciphisa amanqaku oxinzelelo, zinceda ukufezekisa utshintsho olugudileyo kunye nokunciphisa amandla okufumana i-delamination.

2. Ukukhethwa kwezinto:

a) IiLaminates zeTg eziphezulu:Khetha i-laminates ezinobushushu obuphezulu beglasi (Tg) njengoko zibonelela ngokuxhathisa ubushushu obungcono, ukunciphisa ukungahambelani kwe-CTE phakathi kwezinto, kunye nokunciphisa iinkqubo zokukhwela ibhayisekile ezishushu ezinobungozi.

b) Imathiriyeli ye-CTE ephantsi:Khetha imathiriyeli enamaxabiso aphantsi e-CTE ukunciphisa ukungafani kokwanda kwe-thermal phakathi kweeleya ezahlukeneyo, ngaloo ndlela unciphisa uxinzelelo kunye nokuphucula ukuthembeka okupheleleyo kwee-PCB eziguquguqukayo.

c) Izinto ezikhusela ukufuma:Khetha izixhobo ezinokufunxa ukufuma okuphantsi ukunciphisa umngcipheko wokufunxa ngenxa yokufunxa ukufuma. Cinga ukusebenzisa iingubo ezikhethekileyo okanye izitywini ukukhusela iindawo ezisesichengeni zePCB ekungeneni kokufuma.

3. IiNdlela zokuVelisa ezomeleleyo:

a) Ukuphazamiseka okuLawulwayo:Phumeza inkqubo yokwenziwa kwe-impedance elawulwayo yokunciphisa utshintsho loxinzelelo kwi-PCB ngexesha lokusebenza, ngaloo ndlela unciphisa umngcipheko wokuphazamiseka.

b) UGcino noPhatho olululo:Gcina kwaye uphathe ii-PCB kwindawo elawulwayo kunye nokufuma okulawulwayo ukunqanda ukufunxwa kokufuma kunye nemiba enxulumene nokudodobala.

c) Uvavanyo kunye noHlolo:Uvavanyo olungqongqo kunye neenkqubo zokuhlola ziyenziwa ukuze kuchongwe naziphi na iziphene ezinokubakhona kwimveliso ezinokuthi zibangele i-delamination. Ukuphumeza iindlela zovavanyo ezingonakalisiyo ezinje ngebhayisekile eshushu, i-microsectioning, kunye nokuskena i-acoustic microscopy inokunceda ekubhaqeni i-delaminations efihliweyo kwangoko.

Ukuqukumbela

Ukuthintela i-delamination ye-PCBs eguquguqukayo engqongqo kubalulekile ekuqinisekiseni ixesha elide kunye nokusebenza okuthembekileyo. Ungawunciphisa umngcipheko we-delamination ngokuqonda oonobangela kunye nokuthatha amanyathelo okhuseleko afanelekileyo ngexesha loyilo, ukukhetha izinto eziphathekayo, kunye nokuveliswa.Ukuphumeza ulawulo olululo lwe-thermal, ukusebenzisa izixhobo ezineepropati ezifanelekileyo, ukusebenzisa iindlela zokuvelisa ezomeleleyo, kunye nokuqhuba uvavanyo olucokisekileyo kunokuphucula kakhulu umgangatho kunye nokuthembeka kwee-PCB eziguquguqukayo. Ngokulandela la maqhinga kunye nokuhlala usexesheni kwinkqubela phambili yamva nje yemathiriyeli kunye nobugcisa bokwenza, unokuqinisekisa uphuhliso oluyimpumelelo lweePCBs ezizinzileyo nezithembekileyo ezinegalelo kuzinzo kunye nemfezeko yezixhobo zakho zombane.

Ixesha lokuposa: Sep-20-2023

Emva