Yazisa:

I-solder ye-PCB esebenzayo ibalulekile kwindibano eyimpumelelo kunye nokusebenza kweesekethe zombane. I-soldering efanelekileyo iqinisekisa uxhulumaniso lombane oluthembekileyo, oluchaphazela ngokuthe ngqo ukusebenza kwesekethe jikelele.Esi sikhokelo sibanzi siya kuphonononga iindlela ezahlukeneyo, iintlobo, kunye neendlela ezibandakanyekayo kwi-solder ye-PCB. Ngokuqonda le miba, unokwenza izigqibo ezinolwazi xa ukhetha iinkqubo ezifanelekileyo ze-welding kunye nezixhobo.

PCB isishwankathelo sokuthengisa:

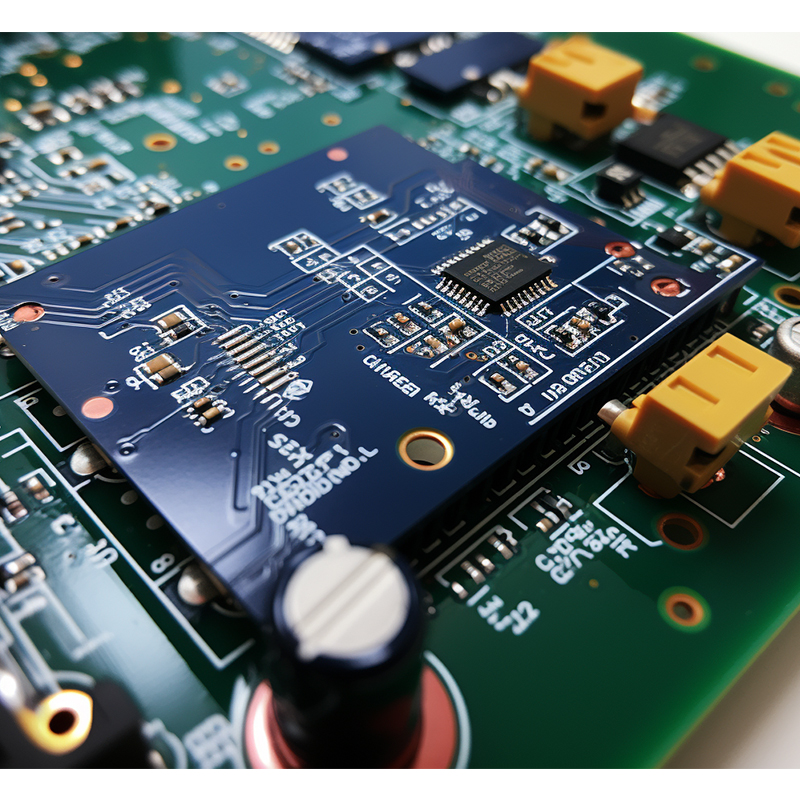

Ukuwelda kwePCB, ekwabizwa ngokuba yi-soldering, kubandakanya ukwenza uqhagamshelo lombane oluthembekileyo phakathi kwezinto zombane kunye neebhodi zesekethe. Idlala indima ebalulekileyo ekuqinisekiseni ukusebenza okuqhelekileyo kwesekethe yonke. Iindlela ezahlukeneyo zokuthambisa zisetyenziswa kwindibano yePCB, nganye ineengenelo zayo kunye nokuqwalaselwa kwayo.

Funda malungaItekhnoloji yokuthengisa yePCB:

A. PCB inkqubo welding:

Ukuze ufezekise i-weld eyimpumelelo, kubalulekile ukulandela inkqubo eneenkcukacha. Eli candelo liza kuchaza inkqubo yenyathelo ngenyathelo le-PCB yokuthengisela. Kwakhona iya kugubungela ukulungiselela amacandelo PCB for soldering kunye nolwandlalo izixhobo eziyimfuneko kunye nezixhobo.

B. Ubuchule obuqhelekileyo be-PCB bokuthengisa:

I-soldering ngomngxuma:

Ngokusebenzisa i-soldering ye-hole yindlela esetyenziswa ngokubanzi ebandakanya amacandelo e-soldering ngokusebenzisa imingxuma esele igrunjwe ngaphambili kwibhodi yesekethe. Eli candelo liza kunika inkcazo yendlela ye-black-hole soldering, ixoxe ngeenzuzo zayo kunye nokungalunganga, kwaye igxininise iindlela ezifanelekileyo kunye nokusetyenziswa.

Umphezulu wokuxhoma i-solder:

I-soldering yentaba engaphezulu, ekwabizwa ngokuba yi-soldering teknoloji ye-surface Mount (SMT), iqhele ukusetyenziselwa ukwenza izinto ezincinci ze-elektroniki. Eli candelo liza kubonelela ngesishwankathelo sobuchwepheshe bokuthengisa be-SMT, izibonelelo zayo, imida, kunye nengqwalasela ephambili yokuphunyezwa ngempumelelo.

I-pitch welding entle:

I-Soldering ye-fine-pitch components inokubonisa imingeni ekhethekileyo ngenxa ye-pitch esondeleyo yezikhonkwane. Eli candelo livavanya ubunzima obunxulumene ne-soldering-pitch-pitch components kwaye inikezela ngeengcebiso kunye nezilumkiso zokuphumeza i-solder joints echanekileyo. Ukongeza, izixhobo eziphambili kunye nezixhobo ezinceda ukufezekisa ukuwelda okuchanekileyo kuya kuxoxwa.

Ukuwelda kwebhodi eqinile-flex:

I-Rigid-flex welding ibhekisela kwinkqubo yamacandelo e-soldering kwibhodi yesekethe eguquguqukayo ehlanganiswe nenxalenye eqinile. Eli candelo liza kwazisa iteknoloji emva rigid-flex soldering, ukuxoxa imingeni echaphazelekayo, kunye nokubonelela ngezisombululo zokuqinisekisa udidi oluphezulu lwe-solder kwiindibano zePCB eziguquguqukayo.

I-HDI PCB yokuthengisela:

Uqhagamshelo olunoxinano oluphezulu (HDI) PCBs lubonisa uyilo oluntsonkothileyo kunye noxinaniso oluphezulu lwecandelo. I-Soldering HDI PCB ifuna ulwazi olukhethekileyo. Eli candelo liphonononga ubunzima be-soldering HDI PCBs, liqaqambisa ubuchule obufunekayo, kwaye lixoxa ngeenzuzo kunye nokuqwalaselwa kwe-HDI PCB yokuthengisela.

Iingcebiso zokuphumelela kwi-PCB soldering:

A. Ukulungiselela noCwangciso:

Ukuthengiswa kwePCB okuyimpumelelo kuqala ngolungiselelo olululo kunye nocwangciso. Eli candelo lixoxa ngokubaluleka koyilo lwePCB kunye nokubekwa kwecandelo ukwenza lula inkqubo yokuthengisela. Kuya kuphinda kugxininise imfuneko yokukhetha ubuchule obuchanekileyo bokudibanisa ngokusekelwe kuyilo lwe-PCB kunye nokubaluleka kokusetyenziswa okuchanekileyo kwe-solder paste.

B. Inkqubo yokuwelda kunye nokukhethwa kwezixhobo:

Ukukhetha izixhobo zokuwelda ezichanekileyo kunye nezixhobo kubalulekile ukufezekisa iziphumo ze-welding eziyimpumelelo. Eli candelo liya kukukhokela ekumiseleni izixhobo ezifanelekileyo kunye nezixhobo zomsebenzi othile. Kwakhona kuya kuxubusha izinto ezinokuthi ziqwalaselwe xa ukhetha izinto ze-welding kwaye ugxininise ukubaluleka kokusebenzisa iiprofayili zokushisa ezifanelekileyo.

C. Ulawulo loMgangatho kunye noHlolo:

Ukuphunyezwa kwemilinganiselo yokulawula umgangatho kunye nokuhlolwa kokuhlolwa ngexesha lenkqubo ye-welding kubaluleke kakhulu ekuqinisekiseni amajoyina athembekileyo e-solder. Eli candelo lixubusha iindlela zokuhlola ezidibeneyo ze-solder, kunye neendlela zokuhlola eziphambili kunye nezixhobo ezinokuthi zisetyenziswe ukuvavanya umgangatho we-weld.

Isiphelo:

Isishwankathelo, esi sikhokelo sibanzi sibandakanya ukubaluleka kokusebenza ngokufanelekileyo kwe-PCB kunye nefuthe le-soldering echanekileyo ekusebenzeni kwesekethe. Ngokukhetha inkqubo efanelekileyo ye-solder kunye nobuchule, unokufikelela kwi-solder esemgangathweni ophezulu. Ukulungiswa okufanelekileyo, ukukhetha izixhobo ngocoselelo, kunye nolawulo olucokisekileyo lomgangatho zizitshixo zokuphumelela kwi-PCB soldering. Utyalo-mali kwizixhobo zodidi oluphezulu kunye nokulandela ezona ndlela zilungileyo ziya kuvelisa iziphumo ezigqwesileyo kwindibano yePCB.

Ixesha lokuposa: Nov-07-2023

Emva