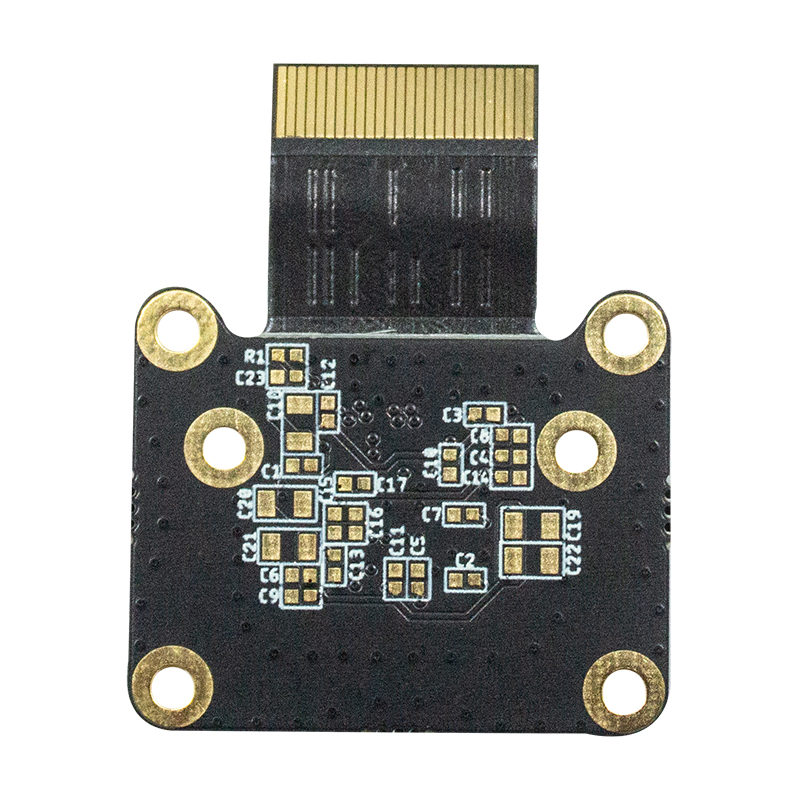

I-PCB (iBhodi yeSekethe eShicileleyo) licandelo elibalulekileyo kwiimveliso zombane zanamhlanje, ezivumela ukudityaniswa kunye nemisebenzi yamacandelo ahlukeneyo e-elektroniki. Inkqubo yemveliso yePCB ibandakanya amanyathelo angundoqo aliqela, elinye lawo kukufaka ubhedu kwi-substrate. Eli nqaku siza kujonga iindlela zokubeka ubhedu kwi-PCB substrates ngexesha lenkqubo yokuvelisa, kwaye sijonge kwiindlela ezahlukeneyo ezisetyenziswayo, ezifana ne-electroless copper plating kunye ne-electroplating.

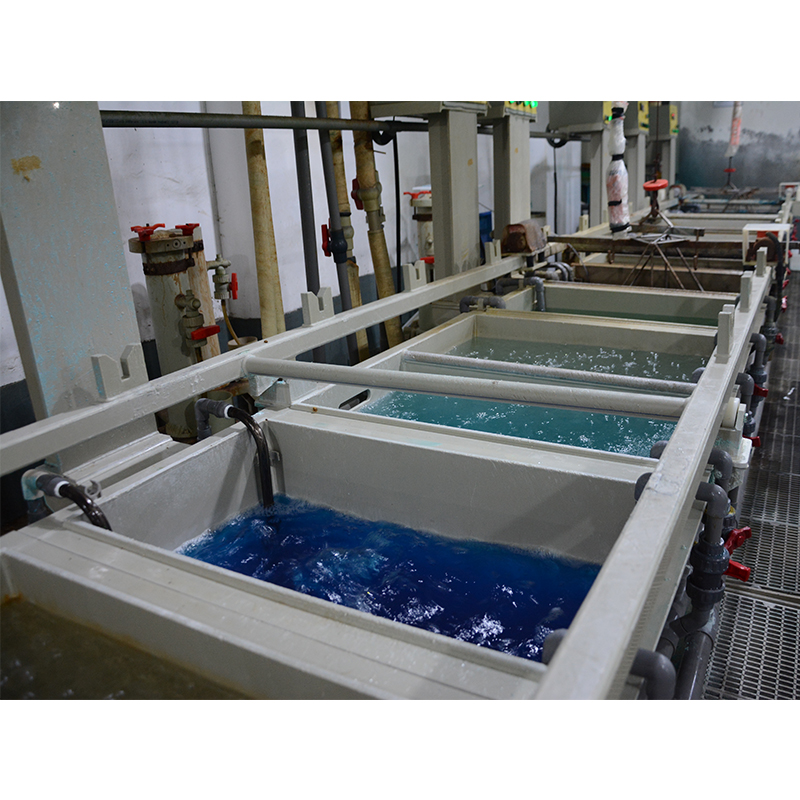

I-1.I-electroless copper plating: inkcazo, inkqubo yeekhemikhali, iingenelo, izinto ezingeloncedo kunye neendawo zokusetyenziswa.

Ukuqonda ukuba yintoni i-electroless copper plating, kubalulekile ukuqonda ukuba isebenza njani. Ngokungafaniyo ne-electrodeposition, exhomekeke kumbane wangoku wokubekwa kwesinyithi, i-electroless copper plating yinkqubo ye-autophoretic. Ibandakanya ukucuthwa kweekhemikhali ezilawulwayo zeeyoni zethusi kwi-substrate, okukhokelela kuluhlu olufana kakhulu kunye nolulungelelanisiweyo lobhedu.

Coca i-substrate:Ucoce ngokucokisekileyo umphezulu we-substrate ukususa naziphi na izingcolisi okanye ii-oxide ezinokuthintela ukunamathela. Ukuqalisa: Isisombululo esisebenzayo esiqulethe i-catalyst yentsimbi exabisekileyo efana ne-palladium okanye iplatinam isetyenziselwa ukuqalisa inkqubo ye-electroplating. Esi sisombululo sinceda ukufakwa kobhedu kwi-substrate.

Gxila kwisisombululo seplating:Gxininisa i-substrate esebenzayo kwisisombululo se-electroless copper plating. Isisombululo se-plating siqulethe i-ion zethusi, ii-agent zokunciphisa kunye nezongezo ezahlukeneyo ezilawula inkqubo yokubeka.

Inkqubo ye-Electroplating:I-arhente yokunciphisa kwisisombululo se-electroplating ngokwekhemikhali inciphisa i-ion zobhedu kwii-athomu zobhedu zesinyithi. Ezi athom ke zibophelela kumphezulu osebenzayo, zenza umaleko oqhubekayo kunye nofanayo wobhedu.

Pula womise:Emva kokuba ubukhulu bobhedu obufunwayo bufezekisiwe, i-substrate iyasuswa kwi-tank yokucoca kwaye ihlanjululwe ngokucokisekileyo ukususa nayiphi na imichiza eseleyo. Yomisa i-substrate ecwecwe ngaphambi kokuba uqhubekeke phambili. Inkqubo yokufakwa kwemichiza yobhedu Inkqubo yeekhemikhali yokufakwa kwe-electroless copper plating ibandakanya ukusabela kwe-redox phakathi kwee-ion zobhedu kunye nee-arhente zokunciphisa. Amanyathelo aphambili kwinkqubo abandakanya: Ukuqalisa: Ukusetyenziswa kwezixhobo zentsimbi ezihloniphekileyo ezifana ne-palladium okanye iplatinum ukuze kusebenze umphezulu we-substrate. I-catalyst inikezela ngeendawo eziyimfuneko zokudibanisa iikhemikhali ze-ion zethusi.

I-arhente yokunciphisa:I-arhente yokunciphisa kwisisombululo se-plating (ngokuqhelekileyo i-formaldehyde okanye i-sodium hypophosphite) iqalisa ukusabela kokunciphisa. Ezi zixhobo zinikezela ngee-electron kwii-ion zobhedu, ziguqulela kwii-athom zobhedu zesinyithi.

Ukusabela okuzenzekelayo:Ii-athomu zobhedu eziveliswe yi-reaction reaction yokunciphisa zisabela kunye ne-catalyst kumphezulu we-substrate ukwenza umaleko wobhedu ofanayo. Ukusabela kuyaqhubeka ngaphandle kwesidingo somsinga osetyenziswa ngaphandle, oko kuyenza "i-electroless plating."

Ulawulo lweqondo lokubekwa:Ukubunjwa kunye nokugxininiswa kwesisombululo se-plating, kunye neeparitha zenkqubo ezifana neqondo lokushisa kunye ne-pH, zilawulwa ngokucophelela ukuze kuqinisekiswe ukuba izinga lokubeka lilawulwa kwaye lifanayo.

Izinto eziluncedo kwi-electroless copper plating Uniformity:I-electroless copper plating ine-uniform egqwesileyo, iqinisekisa ubukhulu obufanayo kwiimo ezintsonkothileyo kunye neendawo ezihlaziyiweyo. Ukugquma okuHambayo: Le nkqubo ibonelela ngotyatyeko oluhambelanayo olubambelela kakuhle kwiisubstrates ezingaqhelekanga zejometri ezifana neePCB. Ukubambelela okulungileyo: I-electroless copper plating ine-adhesion eyomeleleyo kwizinto ezahlukeneyo ze-substrate, kuquka iiplastiki, iiseramics kunye neentsimbi. Ukucwenga okuKhethekileyo: Ukufakwa kwe-electroless copper plating kunokukhetha ukubeka ubhedu kwiindawo ezithile zesubstrate usebenzisa ubuchule bokugquma. Iindleko eziphantsi: Xa kuthelekiswa nezinye iindlela, i-electroless copper plating yindlela engabizi kakhulu yokufaka ubhedu kwi-substrate.

Izinto ezingeloncedo nge-electroless copper plating Izinga lokubekwa kancinci:Xa kuthelekiswa neendlela ze-electroplating, i-electroless copper plating inesantya esicothayo sokubeka, esinokwandisa ixesha elipheleleyo lenkqubo ye-electroplating. Ubungqingqwa obulinganiselweyo: I-electroless copper plating ifanelekile ngokubanzi ukubeka iileya zobhedu ezicekethekileyo kwaye ke ngoko ayifanelekanga kangako kwizicelo ezifuna ukufakwa okungqindilili. Ubunzima: Inkqubo idinga ukulawulwa ngokucophelela kweeparameters ezahlukeneyo, kubandakanywa ubushushu, i-pH kunye nokugxilwa kweekhemikhali, okwenza kube nzima ukuphumeza kunezinye iindlela ze-electroplating. Ulawulo lweNkunkuma: Ukulahlwa kwezisombululo zenkunkuma eziqulathe isinyithi esinzima esinetyhefu kunokudala imingeni yokusingqongileyo kwaye kufuna ukuphathwa ngononophelo.

Iindawo zosetyenziso lwe-electroless copper plating PCB Manufacturing:I-electroless copper plating isetyenziswa ngokubanzi ekwenzeni iibhodi zesekethe eziprintiweyo (PCBs) ukwenza imikhondo eqhubayo kwaye ifakwe kwimingxunya. Umzi-mveliso weSemiconductor: Udlala indima ebalulekileyo kwimveliso yezixhobo zesemiconductor ezifana nezithwala iitshiphu kunye nezakhelo ezikhokelayo. Imizi-mveliso yeemoto kunye ne-aerospace: I-electroless copper plating isetyenziselwa ukwenza izihlanganisi zombane, iiswitshi kunye nezixhobo eziphezulu ze-elektroniki. Iingubo ezihlobisayo kunye neziSebenzayo: I-electroless copper plating ingasetyenziselwa ukudala ukugqitywa kokuhlobisa kwiintlobo ezahlukeneyo ze-substrates, kunye nokukhuselwa kwe-corrosion kunye nokuphucula ukuhanjiswa kombane.

2.Ukufakwa kobhedu kwi-PCB substrate

Ukufakwa kobhedu kwi-PCB substrates linyathelo elibalulekileyo kwinkqubo yokwenziwa kwebhodi yesekethe eprintiweyo (PCB). Ubhedu ngokuqhelekileyo lusetyenziswa njengesixhobo sokulinganisa i-electroplating ngenxa yokuqhuba kakuhle kombane kunye nokunamathela okugqwesileyo kwi-substrate. Inkqubo yokucwenga ubhedu ibandakanya ukubeka umaleko obhityileyo wobhedu kumphezulu wePCB ukwenza iindlela zokuqhuba zemiqondiso yombane.

Inkqubo yokucwenga yobhedu kwi-PCB substrates idla ngokubandakanya la manyathelo alandelayo: ULungiselelo loMphezulu:

Coca ngokucokisekileyo i-substrate ye-PCB ukususa naziphi na izingcolisi, ii-oxides okanye ukungcola okunokuthi kuthintele ukunamathela kunye nokuchaphazela umgangatho wokubeka.

Ukulungiswa kwe-Electrolyte:

Lungiselela isisombululo se-electrolyte esine-copper sulfate njengomthombo we-ion zethusi. I-electrolyte ikwanezongezo ezilawula inkqubo yokucwenga, njengee-agent zokulinganisa, izikhanyisi, kunye nezilungisi ze-pH.

Electrodeposition:

Dipha i-substrate ye-PCB elungisiweyo kwisisombululo se-electrolyte kwaye usebenzise ngoku ngqo. I-PCB isebenza njengonxibelelwano lwe-cathode, ngelixa i-anode yethusi ikhona kwisisombululo. Okwangoku kubangela ukuba i-ion zobhedu kwi-electrolyte zicuthwe kwaye zifakwe kumphezulu we-PCB.

Ulawulo lweeparamitha zokucwenga:

Iiparamitha ezahlukeneyo zilawulwa ngononophelo ngexesha lenkqubo yokufakwa, kubandakanywa ukuxinana kwangoku, ubushushu, i-pH, ukuvuselela kunye nexesha lokucoca. Ezi parameters zinceda ukuqinisekisa ukufakwa okufanayo, ukunamathela, kunye nobukhulu obufunwayo bomgangatho wobhedu.

Unyango lwasemva kokutyalwa:

Nje ukuba ubungqingqwa bobhedu obunqwenelekayo bufikelelwe, iPCB iyasuswa kwindawo yokuhlambela kwaye ihlanjwe ukuze isuse nasiphi na isisombululo se-electrolyte esishiyekileyo. Unyango olongezelelweyo lwe-post-plating, olufana nokucoca umphezulu kunye nokugqithisa, lunokwenziwa ukuphucula umgangatho kunye nokuzinza kwe-copper plating layer.

Izinto ezichaphazela umgangatho we-electroplating:

Ukulungiswa komphezulu:

Ukucocwa ngokufanelekileyo kunye nokulungiswa kwendawo ye-PCB kubalulekile ukususa nayiphi na i-contaminants okanye i-oxide layers kunye nokuqinisekisa ukunamathela kakuhle kwe-plating yobhedu. Ukuqulunqwa kwesisombululo sePlating:

Ukuqulunqwa kwesisombululo se-electrolyte, kubandakanywa ukuxinwa kwe-sulfate yethusi kunye ne-additives, kuya kuchaphazela umgangatho we-plating. Ukubunjwa kwebhafu yokucoca kufuneka kulawulwe ngononophelo ukufezekisa iimpawu ezinqwenelekayo zokubekwa.

Iiparamitha zoKubeka:

Ukulawula iiparamitha zeplating ezifana noxinaniso lwangoku, ubushushu, i-pH, ukuvuselela kunye nexesha le-plating liyimfuneko ukuze kuqinisekiswe ukubekwa okufanayo, ukunamathela kunye nobukhulu bomgangatho wobhedu.

Imathiriyeli yeSubstrate:

Uhlobo kunye nomgangatho we-substrate ye-PCB iya kuchaphazela ukunamathela kunye nomgangatho we-copper plating. Iimathiriyeli ezahlukeneyo ze-substrate zinokufuna uhlengahlengiso kwinkqubo yokucwenga ukuze ufumane iziphumo ezilungileyo.

Uburhabaxa bomphezulu:

Uburhabaxa bomphezulu be-PCB substrate buya kuchaphazela ukunamathela kunye nomgangatho womaleko we-copper plating. Ukulungiswa okufanelekileyo komphezulu kunye nolawulo lweeparamitha zokucoca kunceda ukunciphisa iingxaki ezinxulumene noburhabaxa

Izinto eziluncedo kwi-PCB substrate copper plating:

Ukuhanjiswa kombane okugqwesileyo:

ICopper iyaziwa ngokusebenza kwayo okuphezulu kombane, iyenza ibe lolona khetho lufanelekileyo kwizixhobo zokucwenga zePCB. Oku kuqinisekisa ukuqhuba ngokufanelekileyo nangokuthembekileyo kwemiqondiso yombane. Ukunamathela okugqwesileyo:

I-Copper ibonisa ukunamathela ngokugqwesileyo kwiintlobo ezahlukeneyo ze-substrates, iqinisekisa ukuba ibhondi eyomeleleyo kunye nexesha elide phakathi kwengubo kunye ne-substrate.

Ukuxhathisa ukonakala:

Ubhedu lunokumelana nokugqwala okuhle, lukhusela amacandelo e-PCB asezantsi kunye nokuqinisekisa ukuthembeka kwexesha elide. I-Solderability: I-Copper plating ibonelela ngomphezulu ofanelekileyo wokuthengiswa, okwenza kube lula ukudibanisa amacandelo e-elektroniki ngexesha lokudibanisa.

Ukutshatyalaliswa kobushushu okwandisiweyo:

Ubhedu ngumqhubi olungileyo we-thermal, ovumela ukuchithwa kobushushu okusebenzayo kwee-PCBs. Oku kubaluleke kakhulu kwizicelo zamandla aphezulu.

Unyino kunye nemingeni ye-electroplating yobhedu:

Ulawulo lokutyeba:

Ukufezekisa ulawulo oluchanekileyo phezu kobunzima be-copper layer kunokuba ngumngeni, ngakumbi kwiindawo ezintsonkothileyo okanye izithuba ezixineneyo kwi-PCB. Ukufana: Ukuqinisekisa ukufakwa okufanayo kobhedu kuwo wonke umhlaba wePCB, kubandakanywa iindawo ezihlaziyiweyo kunye neempawu ezintle, kunokuba nzima.

Iindleko:

Ubhedu lwe-Electroplating lunokubiza kakhulu xa kuthelekiswa nezinye iindlela zokufaka i-electroplating ngenxa yeendleko zeekhemikhali zetanki yokubeka, izixhobo kunye nokugcinwa.

Ulawulo lweNkunkuma:

Ukulahlwa kwezisombululo zeplating ezichithiweyo kunye nokucocwa kwamanzi amdaka aqulethe ii-ion zobhedu kunye nezinye iikhemikhali kufuna iindlela ezifanelekileyo zokulawula inkunkuma ukunciphisa impembelelo yokusingqongileyo.

Ukuntsonkotha kweNkqubo:

Ubhedu lwe-Electroplating lubandakanya iiparamitha ezininzi ezifuna ukulawulwa ngononophelo, ezifuna ulwazi olukhethekileyo kunye nokuseta okuntsonkothileyo kweplating.

3.Ukuthelekisa phakathi kwe-electroless copper plating kunye ne-electroplating

Ukusebenza kunye nokwahluka komgangatho:

Kukho iiyantlukwano ezininzi ekusebenzeni kunye nomgangatho phakathi kwe-electroless copper plating kunye ne-electroplating kule miba ilandelayo:

I-electroless copper plating yinkqubo yokubeka imichiza engadingi umthombo wamandla wangaphandle, ngelixa i-electroplating ibandakanya ukusebenzisa i-current ngqo ukufaka umaleko wobhedu. Lo mahluko kwiindlela zokubeka kunokukhokelela kwiiyantlukwano kumgangatho wokugquma.

I-electroless copper plating ibonelela ngokubekeka okufanayo ngaphezulu komphezulu we-substrate yonke, kubandakanywa iindawo ezihlaziyiweyo kunye neempawu ezintle. Oku kungenxa yokuba ukucwenga kwenzeka ngokulinganayo kuyo yonke imiphezulu nokuba ijongwe phi na. I-Electroplating, ngakolunye uhlangothi, inokuba nobunzima ekufezekiseni i-deposition efanayo kwiindawo ezinzima okanye ezinzima ukufikelela kuzo.

I-electroless copper plating inokufikelela kwi-aspect ratio ephezulu (ireyishini yefitsha yobude ukuya kububanzi) kune-electroplating. Oku kuyenza ilungele usetyenziso olufuna iipropati zomlinganiselo ophezulu, ezifana nemingxuma kwii-PCBs.

I-electroless copper plating ngokubanzi ivelisa indawo egudileyo, ethe tyaba kune-electroplating.

I-Electroplating ngamanye amaxesha inokubangela ukungalingani, iidiphozithi ezingenanto okanye ezingenanto ngenxa yokutshintsha koxinano lwangoku kunye neemeko zokuhlambela. Umgangatho webhondi phakathi komgangatho wobhedu kunye ne-substrate inokwahluka phakathi kwe-electroless copper plating kunye ne-electroplating.

I-electroless copper plating ibonelela ngokunamathela okungcono ngenxa yendlela yokudibanisa iikhemikhali yobhedu olungenambane kwi-substrate. I-Plating ixhomekeke kumatshini kunye ne-electrochemical bonding, enokuthi ibangele amabhondi abuthathaka kwezinye iimeko.

Uthelekiso lweendleko:

I-Chemical Deposition vs. Electroplating: Xa uthelekisa iindleko ze-electroless copper plating kunye ne-electroplating, izinto ezininzi kufuneka ziqwalaselwe:

Iindleko zemichiza:

I-electroless copper plating ifuna iikhemikhali ezibiza kakhulu xa kuthelekiswa ne-electroplating. Iikhemikhali ezisetyenziswa kwi-electroless plating, efana ne-ejenti yokunciphisa kunye nezinzisi, ngokubanzi zikhethekileyo kwaye zibiza.

Iindleko zezixhobo:

Iiyunithi zokucwenga zifuna izixhobo ezintsonkothileyo nezixabisayo, kubandakanywa izixhobo zombane, izilungisi kunye ne-anode. Iinkqubo zokucwenga zobhedu ezingenambane zilula kwaye zifuna amacandelo ambalwa.

Iindleko zokugcina:

Izixhobo zokufaka iiplanga zinokufuna ukulondolozwa kwamaxesha athile, ulungelelwaniso, kunye nokutshintshwa kwee-anode okanye ezinye izinto. Iisistim ze-electroless copper plating ngokubanzi zifuna ukugcinwa okuncinci kwaye zineendleko eziphantsi zokulondolozwa.

Ukusetyenziswa kweMichiza yokuPlatha:

Iinkqubo zokucoca zisebenzisa iikhemikhali zokucoca ngesantya esiphezulu ngenxa yokusetyenziswa kwamandla ombane. Ukusetyenziswa kweekhemikhali zeenkqubo zokucwenga ze-electroless copper kuphantsi kuba i-electroplating reaction yenzeke ngokusabela kweekhemikhali.

Iindleko zolawulo lwenkunkuma:

I-Electroplating ivelisa inkunkuma eyongezelelweyo, kubandakanywa iibhafu zokuhlamba ezichithiweyo kunye nokuhlanjululwa kwamanzi angcolileyo ngee-ion zetsimbi, ezifuna unyango olufanelekileyo kunye nokulahlwa. Oku kwandisa ixabiso elipheleleyo lokutyalwa. I-electroless copper plating ivelisa inkunkuma encinci kuba ayixhomekeke ekuboneleleni okuqhubekayo kwee-ion zetsimbi kwindawo yokuhlambela.

Ukuntsonkotha kunye neMiceli mngeni yoMbane kunye nokuBekwa kweMichiza:

I-Electroplating ifuna ukulawulwa ngononophelo lweeparamitha ezahlukeneyo ezinje ngoxinaniso lwangoku, ubushushu, i-pH, ixesha lokutya kunye nokuvuselela. Ukufezekisa ukubekwa okufanayo kunye neempawu ezinqwenelekayo zokucwenga kunokuba ngumngeni, ngakumbi kwiijometri ezintsonkothileyo okanye iindawo eziphantsi zangoku. Ukwandiswa kokwakhiwa kwebhafu yokubeka kunye neeparamitha kunokufuna uvavanyo olubanzi kunye nobuchule.

I-electroless copper plating nayo ifuna ulawulo lweeparamitha ezinjengokunciphisa ukugxininiswa kwe-arhente, ubushushu, i-pH kunye nexesha lokucoca. Nangona kunjalo, ulawulo lwezi parameters alubalulekanga ngokubanzi kwi-electroless plating kune-electroplating. Ukufezekisa iipropathi ezinqwenelekayo zeplating, ezinje ngereyithi yokubeka, ubukhulu, kunye nokuncamathela, kusenokufuna ukwenziwa kunye nokujongwa kwenkqubo yokubekwa.

Kwi-electroplating kunye ne-electroless copper plating, ukunamathela kwizinto ezahlukeneyo ze-substrate kunokuba ngumngeni oqhelekileyo. Unyango lwangaphambili lwe-substrate surface ukususa ukungcola kunye nokukhuthaza ukunamathela kubaluleke kakhulu kuzo zombini iinkqubo.

Ukulungisa iingxaki kunye nokusombulula ingxaki kwi-electroplating okanye i-electroless copper plating kufuna ulwazi olukhethekileyo kunye namava. Imiba enjengoburhabaxa, ukudityaniswa kokungalinganiyo, i-voids, ukugquma, okanye ukuncamathelisa kakubi kunokwenzeka ngexesha leenkqubo zombini, kwaye ukuchonga oyena nobangela kunye nokuthatha amanyathelo okulungisa kunokuba ngumngeni.

Umda wosetyenziso lwetekhnoloji nganye:

I-Electroplating iqhele ukusetyenziswa kumashishini ahlukeneyo abandakanya i-electronics, i-automotive, i-aerospace kunye nobucwebe obufuna ulawulo oluchanekileyo oluchanekileyo, ukugqiba umgangatho ophezulu kunye neempawu ezibonakalayo ezinqwenelekayo. Isetyenziswa ngokubanzi ekugqityweni kokuhlobisa, iingubo zentsimbi, ukukhuselwa kwe-corrosion kunye nokuveliswa kwecandelo lombane.

I-electroless copper plating isetyenziswa ikakhulu kwishishini le-elektroniki, ngakumbi xa kusenziwa iibhodi zeesekethe eziprintiweyo (PCBs). Isetyenziselwa ukwenza iindlela zokuqhuba, imiphezulu ethengiswayo kunye nokugqitywa komphezulu kwiiPCB. I-Electroless copper plating ikwasetyenziselwa ukwenza isinyithi iiplastiki, ukuvelisa unxibelelwano lobhedu kwiipakethe ze-semiconductor, kunye nezinye izicelo ezifuna ukufakwa okufanayo kunye nokuhambelana nobhedu.

4.Ubuchule bokubekwa kweCopper kwiintlobo ezahlukeneyo zePCB

I-PCB enecala elinye:

KwiiPCB ezinecala elinye, ukubekwa kobhedu ngokuqhelekileyo kwenziwa kusetyenziswa inkqubo yokuthabatha. I-substrate idla ngokusetyenziswa kwizinto ezingenayo i-conductive ezifana ne-FR-4 okanye i-phenolic resin, ehlanganiswe ngobhedu oluncinci kwelinye icala. Uluhlu lobhedu lusebenza njengendlela yokuqhuba isiphaluka. Inkqubo iqala ngokucoca kunye nokulungiswa kwendawo ye-substrate ukuqinisekisa ukunamathela kakuhle. Okulandelayo kusetyenziswa umaleko obhityileyo wezinto zefotoresist, ezivezwa kukukhanya kwe-UV ngefotomask ukuchaza ipateni yesekethe. Iindawo eziveziweyo zokuchasana ziyanyibilika kwaye emva koko zihlanjwe, ziveze umaleko wobhedu ongaphantsi. Iindawo zobhedu eziveziweyo zixhonywa kusetyenziswa i-etchant efana neferric chloride okanye i-ammonium persulfate. I-etchant isusa ngokukhethiweyo ubhedu oluveziweyo, lushiya ipateni yesekethe efunekayo. I-resistance eseleyo iyahluthwa ke, ishiye imikhondo yobhedu. Emva kwenkqubo ye-etching, i-PCB inokuthatha amanyathelo ongezelelweyo okulungisa umphezulu njengemaski ye-solder, ukuprintwa kwesikrini, kunye nokusetyenziswa kweeleyile ezikhuselayo zokuqinisekisa ukuqina kunye nokukhuselwa kwizinto ezisingqongileyo.

I-PCB enamacala amabini:

I-PCB enamacala amabini ineengqimba zobhedu kumacala omabini e-substrate. Inkqubo yokufaka ubhedu kumacala omabini ibandakanya amanyathelo ongezelelweyo xa kuthelekiswa neePCB ezisecaleni. Inkqubo ifana ne-PCB enecala elinye, iqala ngokucoca kunye nokulungiswa kwe-substrate surface. Umaleko wobhedu emva koko ufakwe kumacala omabini e-substrate usebenzisa i-electroless copper plating okanye i-electroplating. I-Electroplating iqhele ukusetyenziselwa eli nyathelo kuba ivumela ulawulo olungcono phezu kobunzima kunye nomgangatho we-copper layer. Emva kokuba umaleko wobhedu ufakwe, macala omabini aqatywe ngefotoresist kwaye ipateni yesekethe ichazwa ngokuvezwa kunye namanyathelo ophuhliso afana nalawo e-PCB esecaleni elinye. Iindawo zobhedu eziveziweyo ziye zifakwe ukuze zenze imikhondo yesekethe efunekayo. Emva kwe-etching, ukuxhathisa kuyasuswa kwaye i-PCB iqhubeka namanyathelo okuqhubela phambili afana nesicelo semaski ye-solder kunye nonyango lwangaphezulu ukugqiba ukuveliswa kwe-PCB enamacala amabini.

I-PCB yaManinzi:

Ii-PCB ze-Multilayer zenziwe ngeemaleko ezininzi zobhedu kunye nezixhobo zokugquma ezibekwe phezu kwenye. Ukubekwa kweCopper kwiiPCB ezininzi kubandakanya amanyathelo amaninzi okudala iindlela zokuqhuba phakathi kweeleya. Inkqubo iqala ngokuyila iileya ze-PCB ezizimeleyo, ezifana nee-PCB ezimacala mabini. Uluhlu ngalunye lulungisiwe kwaye i-photoresist isetyenziselwa ukuchaza ipateni yesekethe, ilandelwa yi-copper deposition nge-electroplating okanye i-electroless copper plating. Emva kokubekwa, umaleko ngamnye uqatywe ngezinto zokugquma (ngokuqhelekileyo i-epoxy-based prepreg okanye i-resin) kwaye emva koko ihlanganiswe kunye. Iileya zilungelelaniswa kusetyenziswa ukugrumba ngokuchanekileyo kunye neendlela zokubhalisa ngoomatshini ukuze kuqinisekiswe uqhagamshelo oluchanekileyo phakathi kweeleya. Nje ukuba iileyile zilungelelaniswe, i-vias yenziwa ngokugrumba imingxunya kwiimaleko kwiindawo ezithile apho uqhagamshelwano lufuneka khona. Ii-vias ke zityatyekwe ngobhedu kusetyenziswa i-electroplating okanye i-electroless copper plating ukwenza unxibelelwano lombane phakathi kwamaleko. Inkqubo iyaqhubeka ngokuphindaphinda ukupakishwa komaleko, ukugrumba, kunye namanyathelo okucwenga ubhedu kude kube zonke iileya ezifunekayo kunye nonxibelelwano lwenziwe. Isinyathelo sokugqibela sibandakanya unyango olungaphezulu, isicelo semaski ye-solder kunye nezinye iinkqubo zokugqiba ukugqiba ukuveliswa kwe-PCB yamanqanaba amaninzi.

UQhagamshelwano oluPhezulu loXinano (HDI) PCB:

I-HDI PCB yi-PCB enamaleko amaninzi eyilelwe ukwamkela ukuxinana kweesekethe kunye nefom encinci. Ukufakwa kobhedu kwii-HDI PCBs kubandakanya iindlela eziphucukileyo zokuvumela iimpawu ezintle kunye noyilo oluluqilima lwepitch. Inkqubo iqala ngokwenza iileya ezininzi ezibhityileyo, ezidla ngokubizwa ngokuba yi-core material. Ezi cores zinefoyile yobhedu ebhityileyo kwicala ngalinye kwaye zenziwe ngezinto ezisebenza kakuhle ze-resin ezifana ne-BT (i-Bismaleimide Triazine) okanye i-PTFE (i-Polytetrafluoroethylene). Izinto ezingundoqo zifakwe kunye ne-laminated kunye ukuze zenze isakhiwo se-multi-layer. I-Laser drilling isetyenziselwa ukudala ii-microvias, eziyimingxuma emincinci edibanisa iileya. I-Microvias idla ngokuzaliswa ngezinto zokuqhuba ezifana nobhedu okanye i-epoxy conductive. Emva kokuba i-microvias yenziwe, iileyile ezongezelelweyo zifakwe kunye ne-laminated. I-lamination elandelelanayo kunye nenkqubo yokugaya i-laser iyaphindwa ukwenza iileya ezininzi ezipakishwe kunye ne-microvia interconnects. Ekugqibeleni, ubhedu lufakwe kumphezulu we-HDI PCB kusetyenziswa ubuchule obunje nge-electroplating okanye i-electroless copper plating. Ukunikezelwa kweempawu ezintle kunye nokuxinana okuphezulu kweesekethe ze-HDI PCBs, ukubekwa kulawulwa ngononophelo ukuze kuphunyezwe ukutyeba nomgangatho wobhedu ofunekayo. Inkqubo iphela ngonyango olongezelelweyo lomphezulu kunye neenkqubo zokugqiba ukugqiba i-HDI PCB yokuvelisa, enokuthi ibandakanye isicelo semaski ye-solder, isicelo sokugqiba umphezulu kunye novavanyo.

Ibhodi yesekethe ethambileyo:

IiPCB eziguquguqukayo, ezikwabizwa ngokuba ziisekethe eziguquguqukayo, ziyilelwe ukuba zibe bhetyebhetye kwaye zikwazi ukuziqhelanisa neemilo ezahlukeneyo okanye ukugoba ngexesha lokusebenza. Ukufakwa kobhedu kwii-PCB eziguquguqukayo kubandakanya iindlela ezithile ezihlangabezana neemfuno zokuguquguquka kunye nokuqina. Ii-PCB eziguquguqukayo zinokuba cala-nye, zinamacala amabini, okanye zinemigangatho emininzi, kunye neendlela zokubeka ubhedu ziyahluka ngokusekelwe kwiimfuno zoyilo. Ngokubanzi, iiPCB ezibhetyebhetye zisebenzisa ifoyile yobhedu ebhityileyo xa kuthelekiswa neePCBs eziqinileyo ukuphumeza ukuguquguquka. Kwii-PCB eziguquguqukayo ezinecala elinye, inkqubo iyafana ne-PCB enecala elinye, oko kukuthi, umaleko obhityileyo wobhedu ufakwa kwi-substrate eguquguqukayo usebenzisa i-electroless copper plating, i-electroplating, okanye indibaniselwano yazo zombini. Kwi-PCB enamacala amabini okanye ngamanqwanqwa amaninzi, inkqubo ibandakanya ukubeka ubhedu kumacala omabini e-substrate eguquguqukayo usebenzisa i-electroless copper plating okanye i-electroplating. Ukuthathela ingqalelo iimpawu ezizodwa zoomatshini bezinto eziguquguqukayo, i-deposition ilawulwa ngokucophelela ukuze kuqinisekiswe ukunamathela okulungileyo kunye nokuguquguquka. Emva kokufakwa kobhedu, i-PCB eguquguqukayo ihamba ngeenkqubo ezongezelelweyo ezifana nokubhola, ipateni yesekethe, kunye namanyathelo onyango angaphezulu ukwenza i-circuitry efunekayo kunye nokugqiba ukuveliswa kwe-PCB eguquguqukayo.

5.Ukuqhubela phambili kunye noTshintsho kwi-Copper Deposition kwi-PCBs

Uphuhliso lweTekhnoloji yamva nje: Ukutyhubela iminyaka, itekhnoloji yokubeka ubhedu kwii-PCBs iqhubekile nokuvela kunye nokuphucula, okukhokelela ekusebenzeni okwandisiweyo kunye nokuthembeka. Olunye lophuhliso lwamva nje lwetekhnoloji kwi-PCB yokubeka ubhedu lubandakanya:

Itekhnoloji yeplating ephezulu:

Itekhnoloji entsha yokucwenga, efana ne-pulse plating kunye ne-reverse pulse plating, ziye zaphuhliswa ukuze kufezekiswe ukubekwa kobhedu okucokisekileyo nokufanayo. Ezi teknoloji zinceda ukoyisa imiceli mngeni enje ngoburhabaxa bomphezulu, ubungakanani beenkozo kunye nokuhanjiswa kobuninzi ukuphucula ukusebenza kombane.

Ukwenziwa kwesinyithi ngokuthe ngqo:

Ukwenziwa kwe-PCB yesiNtu kubandakanya amanyathelo amaninzi okudala iindlela zokuqhuba, kuquka nokufaka umaleko wembewu phambi kokutyatyekwa kobhedu. Ukuphuhliswa kweenkqubo ze-metallization ngokuthe ngqo kuphelisa imfuno yoluhlu lwembewu eyahlukileyo, ngokwenza lula inkqubo yokuvelisa, ukunciphisa iindleko kunye nokuphucula ukuthembeka.

Itekhnoloji yeMicrovia:

IMicrovias yimingxunya emincinci edibanisa iileya ezahlukeneyo kwi-PCB ye-multilayer. Inkqubela phambili kwitekhnoloji ye-microvia efana nokugrumba i-laser kunye ne-plasma etching yenza ukuba kudalwe ii-microvias ezincinci, ezichanekileyo, ezivumela iisekethe eziphezulu zoxinzelelo kunye nokuphucula imfezeko yomqondiso. I-Surface Finish Innovation: Ukugqitywa komphezulu kubalulekile ekukhuseleni imikhondo yobhedu kwi-oxidation kunye nokubonelela nge-solderability. Uphuhliso kubuchwepheshe bonyango lomphezulu, njenge-Immersion Silver (ImAg), i-Organic Solderability Preservative (OSP), kunye ne-Electroless Nickel Immersion Gold (ENIG), ibonelela ngokhuseleko olungcono lwe-corrosion, ukuphucula i-solderability, kunye nokwandisa ukuthembeka ngokubanzi.

I-Nanotechnology kunye neCopper Deposition: I-Nanotechnology idlala indima ebalulekileyo ekuqhubeleni phambili ukufakwa kobhedu kwe-PCB. Ezinye izicelo ze-nanotechnology ekufakweni kobhedu ziquka:

I-Nanoparticle-based plating:

I-nanoparticles yobhedu inokudityaniswa kwisisombululo sokucoca ukunyusa inkqubo yokubeka. Ezi nanoparticles zinceda ukuphucula ukunamathela kobhedu, ubungakanani bengqolowa kunye nokusabalalisa, ngaloo ndlela ukunciphisa ukumelana nokuphucula ukusebenza kombane.

Izinto zokuqhuba eziNanostructured:

Izinto ezenziwe nge-nanostructured, ezifana ne-carbon nanotubes kunye ne-graphene, zinokudityaniswa kwii-substrates ze-PCB okanye zisebenze njengezigcwalisi eziqhubayo ngexesha lokubeka. Ezi zixhobo zine-conductivity ephezulu yombane, amandla omatshini kunye neempawu ze-thermal, ngaloo ndlela ziphucula ukusebenza ngokubanzi kwe-PCB.

Nanocoating:

I-Nanocoating ingafakwa kumphezulu we-PCB ukuphucula ukuguda komphezulu, ukuqina kunye nokukhuselwa komhlwa. Ezi zogquma zihlala zenziwe kwi-nanocomposites ezinika ukhuseleko olungcono kwizinto ezisingqongileyo kunye nokwandisa ubomi be-PCB.

Uqhagamshelo lweNanoscale:Uqhagamshelo lweNanoscale, olunje ngeenanowires kunye neenanorods, ziyaphononongwa ukuze kusebenze iisekethe eziphezulu zoxinaniso kwiiPCB. Ezi zakhiwo ziququzelela ukuhlanganiswa kweesekethe ezininzi kwindawo encinci, evumela ukuphuhliswa kwezixhobo ezincinci zombane ezihlangeneyo.

Imiceli mngeni kunye nezalathiso zexesha elizayo: Ngaphandle kwenkqubela phambili ebalulekileyo, imingeni emininzi kunye namathuba aseleyo okuphucula ngakumbi ukufakwa kobhedu kwiiPCB. Eminye imiceli mngeni ephambili kunye nezalathiso zexesha elizayo ziquka:

Gcwalisa iKopolo kwiZakhiwo eziPhakamileyo zoMphakathi:

Izakhiwo zomlinganiselo ophezulu ezifana ne-vias okanye i-microvias zinika imingeni ekuphumezeni okufanayo kunye nokuzaliswa kobhedu okuthembekileyo. Uphando olongezelelweyo luyafuneka ukuphuhlisa ubuchule bokucwenga obuphambili okanye iindlela zokuzalisa ezizezinye ukoyisa le mingeni kunye nokuqinisekisa ukubekwa okuchanekileyo kobhedu kwizakhiwo zomlinganiso ophezulu.

Ukunciphisa Ububanzi bomkhondo weCopper:

Njengoko izixhobo ze-elektroniki zisiba zincinci kwaye zixinene ngakumbi, imfuno yemitha yobhedu encinci iyaqhubeka ikhula. Umceli mngeni kukufezekisa ukufakwa kobhedu okufanayo kunye nokuthembekileyo ngaphakathi kwale mizila emxinwa, ukuqinisekisa ukusebenza kombane okuhambelanayo kunye nokuthembeka.

Enye imathiriyeli yomqhubi:

Ngelixa ubhedu sesona sixhobo sisetyenziswa ngokuqhelekileyo, izixhobo ezizezinye ezifana nesilivere, i-aluminium, kunye ne-carbon nanotubes zihlolwa ngeempawu zazo ezizodwa kunye neenzuzo zokusebenza. Uphando lwexesha elizayo lunokujolisa ekuphuhliseni ubuchule bokubekwa kwezi zixhobo zokuqhuba ezizezinye ukoyisa imiceli mngeni efana nokuncamathela, ukuxhathisa, kunye nokuhambelana neenkqubo zokwenziwa kwePCB. NgokusingqongileyoIinkqubo ezinobubele:

Ishishini le-PCB lihlala lisebenzela iinkqubo ezihambelana nokusingqongileyo. Uphuhliso lwexesha elizayo lunokujolisa ekunciphiseni okanye ekupheliseni ukusetyenziswa kweekhemikhali ezinobungozi ngexesha lokufakwa kobhedu, ukwandisa ukusetyenziswa kwamandla, kunye nokunciphisa ukuveliswa kwenkunkuma ukunciphisa impembelelo yokusingqongileyo yokwenziwa kwePCB.

Ukulinganisa okuPhezulu kunye noModeli:

Ukulinganisa kunye nobuchule bokwenza imodeli bunceda ukwandisa iinkqubo zokubeka ubhedu, ukuqikelela indlela yokuziphatha kweeparamitha zokubeka, kunye nokuphucula ukuchaneka kunye nokusebenza kakuhle kokwenziwa kwePCB. Inkqubela phambili yexesha elizayo inokubandakanya ukudibanisa ukulinganisa okuphambili kunye nezixhobo zemodeli kuyilo kunye nenkqubo yokuvelisa ukwenza ulawulo olungcono kunye nokwenza ngcono.

6.UQinisekiso loBulunga kunye noLawulo lweCopper Deposition ye-PCB Substrates

Ukubaluleka koqinisekiso lomgangatho: Uqinisekiso lomgangatho lubalulekile kwinkqubo yokubekwa kobhedu ngezi zizathu zilandelayo:

Ukuthembeka kweMveliso:

Ukubekwa kobhedu kwi-PCB kwenza isiseko soqhagamshelo lombane. Ukuqinisekisa umgangatho wokubekwa kobhedu kubalulekile ekusebenzeni okuthembekileyo kunye nexesha elide lezixhobo zombane. Ukubekwa kobhedu okulambathayo kunokukhokelela kwiimpazamo zoqhagamshelo, ukunciphisa umqondiso, kunye nokwehliswa kokuthembeka kwePCB ngokupheleleyo.

Ukusebenza kombane:

Umgangatho we-copper plating uchaphazela ngokuthe ngqo ukusebenza kombane wePCB. Ubukhulu obufanayo bobhedu kunye nokusabalalisa, ukugqitywa komphezulu ogudileyo, kunye nokubambelela ngokufanelekileyo kubalulekile ukufezekisa ukuchasana okuphantsi, ukuhanjiswa kwesignali okusebenzayo, kunye nokulahlekelwa kwesignali encinci.

Nciphisa iindleko:

Ukuqinisekiswa komgangatho kunceda ukuchonga nokuthintela iingxaki kwangethuba kwinkqubo, ukunciphisa imfuno yokuphinda kusetyenzwe okanye kucinywe ii-PCB ezineziphene. Oku kunokonga iindleko kunye nokuphucula ukusebenza kakuhle kwemveliso.

Ukwaneliseka koMthengi:

Ukubonelela ngeemveliso ezikumgangatho ophezulu kubalulekile ekwanelisekeni kwabathengi kunye nokwakha igama elihle kwishishini. Abathengi balindele iimveliso ezithembekileyo nezizinzileyo, kwaye uqinisekiso lomgangatho luqinisekisa ukuba ukubekwa kobhedu kuyahlangabezana okanye kugqithise oko kulindelweyo.

Uvavanyo kunye neendlela zokuhlola ukufakwa kobhedu: Iindlela ezahlukeneyo zokuvavanya kunye nokuhlola zisetyenziselwa ukuqinisekisa umgangatho wokubekwa kobhedu kwiiPCB. Ezinye iindlela eziqhelekileyo ziquka:

UHlolo oluBonakalayo:

Ukuhlola okubonwayo yindlela esisiseko nebalulekileyo yokubona iziphene ezicacileyo ezinje ngemikrwelo, izibonda okanye uburhabaxa. Olu hlolo lunokwenziwa ngesandla okanye ngoncedo lwe-automated optical inspection (AOI) inkqubo.

Imakroskopu:

I-Microscopy kusetyenziswa ubuchule obufana nokuskena i-electron microscopy (SEM) inokubonelela ngohlalutyo oluneenkcukacha lokubeka ubhedu. Iyakwazi ukujonga ngokucophelela ukugqitywa kwendawo, ukunamathela kunye nokufana komgangatho wobhedu.

Uhlalutyo lweX-reyi:

Iindlela zokuhlalutya i-X-ray, ezifana ne-X-ray fluorescence (XRF) kunye ne-X-ray diffraction (XRD), zisetyenziselwa ukulinganisa ukubunjwa, ubukhulu kunye nokusabalalisa iidiphozithi zethusi. Obu buchule bunokuchonga ukungcola, ukubunjwa kwe-elemental, kunye nokufumanisa nakuphi na ukungahambelani kwi-deposition yobhedu.

Uvavanyo loMbane:

Yenza iindlela zokuvavanya umbane, kubandakanywa imilinganiselo yokuchasana kunye nokuvavanya ukuqhubeka, ukuvavanya ukusebenza kombane kwiidiphozithi zobhedu. Ezi mvavanyo zinceda ekuqinisekiseni ukuba umaleko wobhedu une-conductivity efunekayo kwaye akukho zivula okanye ezimfutshane ngaphakathi kwe-PCB.

Uvavanyo lwamandla e-Peel:

Uvavanyo lwamandla e-peel lulinganisa amandla okudibanisa phakathi kobhedu kunye ne-PCB substrate. Imisela ukuba idiphozithi yobhedu inamandla okwaneleyo okumelana nokuphathwa okuqhelekileyo kunye neenkqubo zokwenziwa kwePCB.

Imigangatho yeshishini kunye nemimiselo: Ushishino lwePCB lulandela imigangatho eyahlukeneyo yoshishino kunye nemimiselo yokuqinisekisa umgangatho wokubekwa kobhedu. Eminye imigangatho ebalulekileyo kunye nemimiselo ibandakanya:

IPC-4552:

Lo mgangatho uxela iimfuno zenikeli engena-electroless/igolide yokuntywiliselwa (ENIG) yonyango lomphezulu oluqhele ukusetyenziswa kwiiPCB. Ichaza ubuncinci begolide ubukhulu, ubukhulu be-nickel kunye nomgangatho womphezulu wonyango oluthembekileyo noluhlala ixesha elide lwe-ENIG.

IPC-A-600:

Umgangatho we-IPC-A-600 ubonelela ngezikhokelo zokwamkelwa kwe-PCB, kubandakanywa imigangatho yokuhlelwa kobhedu, iziphene zomhlaba kunye neminye imigangatho yomgangatho. Isebenza njengesalathiso sokuhlolwa okubonakalayo kunye neendlela zokwamkelwa kokufakwa kobhedu kwiiPCB. RoHS Directive:

Isithintelo sezinto ezinobungozi (i-RoHS) ithintela ukusetyenziswa kwezinto ezithile ezinobungozi kwiimveliso zombane, kubandakanya ilothe, imekyuri kunye necadmium. Ukuthobela umyalelo we-RoHS kuqinisekisa ukuba iidiphozithi zobhedu kwii-PCB azinazinto eziyingozi, zizenza zikhuseleke kwaye zikhuseleke ngakumbi kokusingqongileyo.

ISO 9001:

I-ISO 9001 ngumgangatho wehlabathi weenkqubo zolawulo lomgangatho. Ukuseka nokuphumeza inkqubo yolawulo lomgangatho osekwe kwi-ISO 9001 iqinisekisa ukuba iinkqubo ezifanelekileyo kunye nolawulo zikhona ukuze zisoloko zihambisa iimveliso ezihlangabezana neemfuno zabathengi, kuquka nomgangatho wokubekwa kobhedu kwiiPCB.

Ukunciphisa imiba eqhelekileyo kunye neziphene: Ezinye iingxaki eziqhelekileyo kunye neziphene ezinokuthi zenzeke ngexesha lokufakwa kobhedu ziquka:

Ukuncamathela okunganelanga:

Ukubambelela kakubi komgangatho wobhedu kwi-substrate kunokukhokelela kwi-delamination okanye i-peelling. Ukucocwa okufanelekileyo komphezulu, ukurhaxa ngoomatshini, kunye nonyango lokukhuthaza ukuncamathelisa kunokunceda ukunciphisa le ngxaki.

Ukutyeba kobhedu okungalinganiyo:

Ubunzima bobhedu obungalinganiyo bunokubangela ukuhanjiswa okungahambelaniyo kunye nokuthintela ukuhanjiswa komqondiso. Ukuphucula iiparamitha zokucwenga, ukusebenzisa i-pulse okanye i-reverse pulse plating kunye nokuqinisekisa ukuphazamiseka okufanelekileyo kunokuncedisa ukufezekisa ubukhulu bobhedu obufanayo.

I-Voids kunye nePinholes:

I-Voids kunye ne-pinholes kwi-copper layer inokonakalisa ukudibanisa kombane kunye nokwandisa umngcipheko wokubola. Ulawulo olululo lweeparamitha zeplating kunye nokusetyenziswa kwezongezo ezifanelekileyo kunokunciphisa ukwenzeka kwe-voids kunye neepinholes.

Uburhabaxa bomphezulu:

Uburhabaxa obugqithisileyo bomphezulu bunokuchaphazela kakubi ukusebenza kwe-PCB, kuchaphazela ukuthengiswa kunye nokuthembeka kombane. Ukulawulwa ngokufanelekileyo kweeparameters zokubeka ubhedu, unyango lwangaphambili kunye neenkqubo emva kokunyanga kunceda ukufezekisa ukugqitywa kwendawo.

Ukunciphisa le miba kunye neziphene, ulawulo lwenkqubo olufanelekileyo kufuneka luphunyezwe, ukuhlolwa rhoqo kunye novavanyo kufuneka lwenziwe, kwaye imigangatho yeshishini kunye nemimiselo kufuneka ilandelwe. Oku kuqinisekisa ukubekwa kobhedu okungaguquguqukiyo, okuthembekileyo kunye nomgangatho ophezulu kwi-PCB. Ukongeza, ukuphuculwa kwenkqubo eqhubekayo, ukuqeqeshwa kwabasebenzi, kunye neendlela zokunika ingxelo zinceda ukuchonga iindawo zokuphucula kunye nokujongana nemiba enokubakho ngaphambi kokuba ibe nzulu ngakumbi.

Ukufakwa kobhedu kwi-PCB substrate linyathelo elibalulekileyo kwinkqubo yokwenziwa kwePCB. I-electroless copper deposition kunye ne-electroplating ziindlela eziphambili ezisetyenziswayo, nganye ineenzuzo zayo kunye nemida. Inkqubela phambili yetekhnoloji iyaqhubeka nokuqhuba izinto ezintsha ekubekeni ubhedu, ngaloo ndlela iphucula ukusebenza kwePCB kunye nokuthembeka.Ukuqinisekiswa komgangatho kunye nolawulo kudlala indima ebalulekileyo ekuqinisekiseni ukuveliswa kweePCB ezikumgangatho ophezulu. Njengoko imfuno yezixhobo zombane ezincinci, ezikhawulezayo, nezithembeke ngakumbi ziqhubeka zisanda, ngokunjalo nesidingo sokuchaneka kunye nokugqwesa kubuchwepheshe bokubekwa kobhedu kwi-PCB substrates. Qaphela: Ubalo lwamagama kwinqaku lumalunga namagama angama-3,500, kodwa nceda uqaphele ukuba inani lokwenyani lamagama linokwahluka kancinane ngexesha lokuhlela nokufunda.

Ixesha lokuposa: Sep-13-2023

Emva