Ukungahoyi umgangatho wokwakha webhodi kunokukhokelela kwiingxaki ezahlukeneyo ngexesha lophuhliso lwePCB. Oku kunokubandakanya ubunzima bokuvelisa, isivuno esiphantsi, kunye nokusilela kwangaphambi kwexesha kwizicelo zehlabathi lokwenyani. Nangona kunjalo, kukho iindlela zoyilo ezisebenzayo zokunciphisa ezi zothuso zinzima kunye nezibizayo. Ngoko,masiqale siphendule umbuzo wakho: "Yintoni kanye kanye inkqubo yePCB Fabrication?" uze ungene kukubaluleka kokuqonda le nkqubo yophuhliso oluyimpumelelo lwePCB.

Uyazibuza ukuba ungayijika njani imbono yakho enkulu ibe yibhodi yesekethe ebambekayo eprintiweyo (PCB)? Ewe, thatha lula, masingangxameli kwinkqubo yokwenza okwangoku.Ukuqonda uqhagamshelo olusisiseko kunye namanyathelo adibanisa isikimu okanye ingqikelelo kwindalo eyiyo yePCB kubalulekile. Ngokuthatha ixesha lokuphonononga kwiwebhu entsonkothileyo yamagama kunye nokuxhomekeka kwawo omnye komnye, sinokuvula indlela yohambo olutyibilikayo lokwenziwa kwePCB.

Intshayelelo kuPhuhliso lwePCB:

Ngaba uyazibuza ukuba ungazizisa njani izinto ezintsha zoyilo lwebhodi yesekethe ebomini? Kulapho uphuhliso lwePCB lungena khona! Yinkqubo enika umdla ukuthatha uyilo lwakho ukusuka kwingcinga ukuya kwimveliso ngelixa uqinisekisa umgangatho ophezulu. Ngokusebenzisa amanqanaba amathathu aphambili oyilo, ukwenziwa kunye novavanyo, asiyiyekeli inzame yokuzisa iziphumo ezigqwesileyo. Kwaye, lungela uhambo oluphindaphindayo njengoko silungisa kakuhle kwaye sicokisa uyilo lwakho ngexesha elibekelweyo lophuhliso ukwenza owona msebenzi ubalaseleyo. Zilungiselele ukubukela umbono wakho ube yinyani engaqhelekanga!

Intshayelelo kwi-PCB Manufacturing:

Ngaba ukulungele ukuguqula amaphupha oyilo lwebhodi yesekethe abe yinyani? Ukwenziwa kwePCB yinkqubo ebalulekileyo ekujikeni izicwangciso zakho zibe yinyani ebonakalayo. Luhambo olunamanyathelo amabini aguqukayo oluqala ngokuyilwa kwebhodi, apho itekhnoloji ye-cutting-edge ibumba ngobunono kwaye imise uyilo lwakho. Ukusuka apho, jonga ngoloyiko njengoko sitshintshela ngaphandle komthungo kwihlabathi elinomdla lendibano yebhodi yesekethe eprintiweyo (PCBA). Iingcali zethu ezinezakhono zibandakanya ngokugqibeleleyo izinto ezintsonkothileyo, ziqinisekisa ukusebenza kakuhle kunye nokusebenza. Nathi ecaleni kwakho, umbono wakho webhodi uya kuchuma kwaye udlule okulindelekileyo, uvula indlela yempumelelo engenakulinganiswa. Zilungiselele ukuguqula umhlaba ngezinto ezintsha zakho!

Lungela uvavanyo lwePCB:

Ngaba usondele ekugqibezeleni ibhodi yakho yesekethe ye-state-of-the-art? Ngoku lixesha lokukhulula amandla okwenene ovavanyo lwePCB ngamandla ayo. Njengenqanaba lesithathu elibalulekileyo kwinkqubo yophuhliso lwePCB, uvavanyo (olwaziwa ngokuba lubonelelo) lwenzeka kwangoko emva kokwenziwa. Eli nqanaba libalulekileyo lenzelwe ukuvavanya ukuba ibhodi yakho inakho na ukwenza ngokungenasiphako isigunyaziso sayo sokusebenza. Akukho ndleko iye yagcinwa kwinkqubo yethu yovavanyo olucokisekileyo, iqaqambisa naziphi na iingxaki okanye iindawo ezifuna ukuphuculwa komsebenzi. Sixhobe ngolu lwazi luxabisekileyo, siqala omnye umjikelo wokudibanisa ngokukhawuleza utshintsho loyilo ukutyhala ibhodi yakho ekusebenzeni okuphezulu. Yiba namava okonwaba kokufezeka xa umbono wakho uba yinyani!

Amava aMandla eNdibano yePCB:

Ukuthatha ibhodi yakho yesekethe ukusuka kwingcamango ukuya kwinyani akuzange kube lula ngeenkonzo zethu eziphambili zendibano yePCB. Njengento ephambili kwinkqubo yokwenziwa kwePCB, iPCBA ivula indlela yokudityaniswa komthungo wamacandelo ebhodi yesekethe kwiibhodi ezingenanto. Ngeenkqubo zokuwelda ezichanekileyo, amagcisa ethu aziingcali aguqula uyilo lwakho lube ngumsebenzi wobugcisa osebenza ngokupheleleyo. Nokuba ufuna iTekhnoloji ye-Surface Mount (SMT) okanye ngeTekhnoloji yeHole (THT), itekhnoloji yethu yodidi oluphezulu iqinisekisa ukuchaneka okugqibeleleyo kunye nokuphunyezwa okungenasiphako. Sithembe ukuba wenze umbono wakho uphile kwaye ubone umgangatho wethu ongalinganiyo weenkonzo zendibano yePCB.

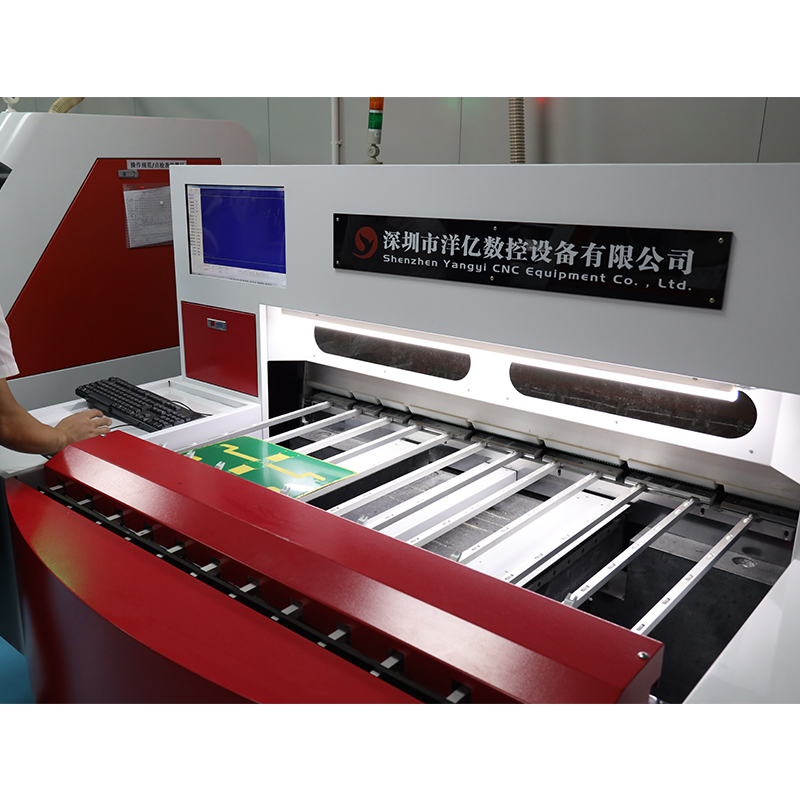

Ukuphonononga iNkqubo yokuVeliswa kwePCB:

Ngaba wakha wazibuza ukuba uyilo lwebhodi yakho lwenzeka njani? Inkqubo yethu yokwenziwa kwePCB ephucukileyo iya kuqinisekisa ukuba umbono wakho uba yinyani. Le nkqubo yesinyathelo-nge-nyathelo ithatha iphakheji yakho yoyilo kwaye iyiguqule ibe yisakhiwo somzimba esihambelana neenkcukacha ze tee yakho. Sidibanisa iteknoloji entsha kunye nengqalelo ecokisekileyo kwiinkcukacha ukunika iibhodi zakho inkangeleko entsha. Ukusuka ekudaleni uyilo lwebhodi ukuya etching, ukomba, kwaye ekugqibeleni ukugqiba ukubamba, iqela lethu leengcaphephe liqinisekisa ukuba inyathelo ngalinye lenziwa ngokungenasiphako. Yiba namava okuchaneka kwethu kunye nokugqwesa kwimveliso yePCB kwaye ubukele uyilo lwakho luphila kanye phambi kwamehlo akho.

Yiba nombono woyilo lwakho olufanelekileyo kwiCopper Clad Laminate:

Khawufane ucinge uyilo lwebhodi yakho yesekethe egqibeleleyo ephunyezwe kumgangatho ophezulu weCopper Clad Laminate. Ngetekhnoloji yethu yezobugcisa bemeko yobugcisa, sikwenza ukuba ubone uyilo lwakho luthatha imilo kwaye siqinisekise ukuba zonke iinkcukacha zenziwa ngokuchanekileyo.

Susa ngobuchwephesha ubhedu olugqithisileyo ukuveza umkhondo kunye neepads:

Amagcisa ethu anezakhono ahamba umgama owongezelelekileyo ukuya etch okanye ukususa naluphi na ubhedu olugqithileyo kumaleko angaphakathi ePCB. Ngokwenza njalo, sityhila imikhondo enzima kunye neepads ezibaluleke kakhulu ekusebenzeni kakuhle kweesekethe ze-elektroniki.

Yenza ngokuchanekileyo iZigqibo zoMaleko wePCB owomeleleyo:

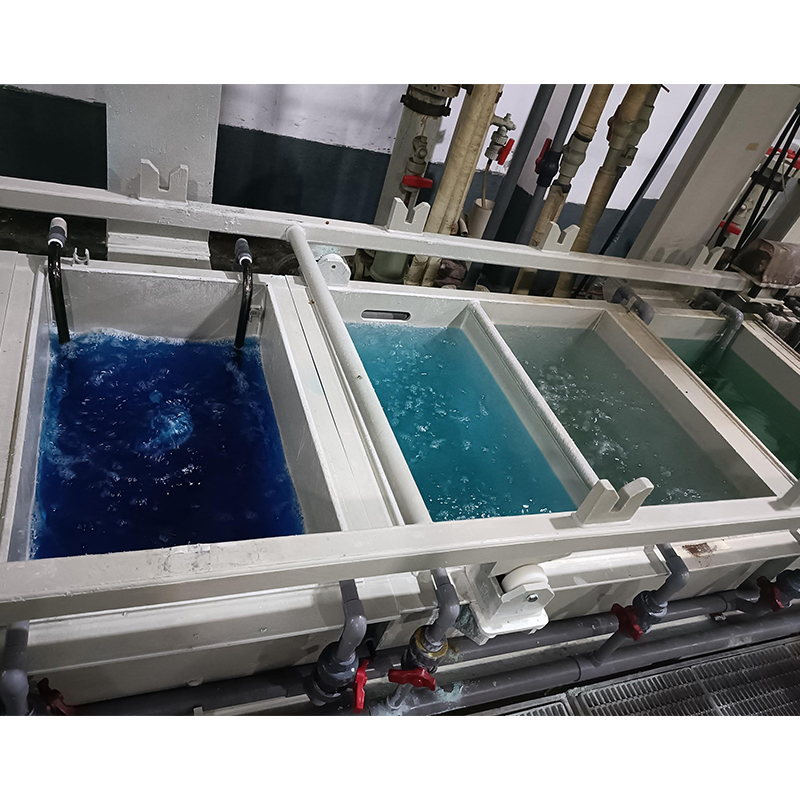

Iingcali zethu ezinamava zithatha PCB yakho umaleko stackups ukuya kwinqanaba elilandelayo ngobuchule laminating izixhobo zebhodi yesekethe kunye. Ngokusebenzisa ukufudumala okulawulwa ngokucokisekileyo kunye neenkqubo zokucinezela, siqinisekisa ukudibanisa okukhuselekileyo nokuthembekileyo kumaqondo aphezulu. Unokuzithemba iibhodi zakho ukuba zimelane nezona meko zinzima.

Ukugrumba imingxuma yokufakwa ngokukhuselekileyo kunye noqhagamshelo:

Siyakuqonda ukubaluleka kokunyuswa okukhuselekileyo kunye noqhagamshelo olugqibeleleyo. Ubuchwephesha bethu bokugrumba obuphezulu busivumela ukuba senze imingxunya echanekileyo yezixhobo zokuxhoma, izikhonkwane zomngxunya kunye ne-vias, ukuqinisekisa ukudityaniswa komthungo kwePCB kwimveliso yokugqibela.

Ukuveza imikhondo efihliweyo kunye neepads kumphezulu:

Siyaqhubeka sithatha indlela ecokisekileyo xa sibhala okanye sisusa naluphi na ubhedu olugqithileyo kumaleko angaphezulu ebhodi. Ngokwenza oku, sityhila umkhondo oyilwe kakuhle kunye neepads ezivumela iisekethe zakho ukuba zichume.

Imingxunya eyomeleziweyo kunye ne-vias yokusebenza okuphezulu:

Ukusebenza kwebhodi yakho yeyona nto iphambili kuthi. Sisebenzisa itekhnoloji yethu ye-plating ye-state-of-the-art, siqinisa i-pinholes kunye ne-vias ukwandisa ukuhanjiswa kunye nokuqinisekisa ukuthembeka okuhlala ixesha elide.

Khusela i-PCB yakho ngengubo ekhuselayo okanye imaski yesolder:

Siyazingca ngokubonelela ngokhuseleko olongezelelweyo lwebhodi yakho. Iqela lethu lifaka imaski ekhuselayo okanye i-solder kwindawo yokwandisa ubomi bePCB kwaye iyikhusele kwizinto zokusingqongileyo.

Yenza ibhodi yakho ibe yeyakho ngoshicilelo lwesikrini:

umfanekiso webrand yakho ubalulekile. Yiyo loo nto sinikezela ngeendlela zoshicilelo lwesikrini ezinokwenziwa ngokwezifiso kwiiPCB zakho. Yongeza izalathisi zesalathiso kunye nepolarity, iilogo, okanye naluphi na olunye uphawu ukwahlula imveliso yakho kwezo zikhuphisana nawe.

Lungiselela inkangeleko yakho yePCB ngokugqitywa kobhedu ozikhethelayo:

Sikholelwa ngokuqinileyo ukuba ngomzamo omncinci ngakumbi, ulindelo lwakho lungagqithiswa. Ukongezwa kwe-aesthetics, sinikezela ngenketho yokongeza ukugqitywa kobhedu kwiindawo ezithile zomgangatho webhodi ukuze kuqinisekiswe ukubukeka okuphuculweyo kunye nobuchwephesha.

Ngoku, makhe sintywizise ukuba kuthetha ukuthini oku kuphuhliso lwePCB:

Njengoko untywila kwihlabathi lophuhliso lwePCB, inkqubo yethu yokuvelisa ebanzi iqinisekisa ukuba uyilo lwakho luphuma kanye njengoko ubunombono walo. Ukusuka kumfanekiso kunye nokugxumeka ukuya ekubhobhozeni, ukucwenga kunye nokongeza iingubo zokukhusela, inyathelo ngalinye lenziwa ngokucokisekileyo ngokuchanekileyo kunye nobuchule. Yiva umahluko kwinkqubo yethu yokwenziwa kwePCB kwaye ubukele uyilo lwakho luphumelela kwiibhodi ezisebenza kakhulu.

Ukutyhila amandla okuqonda ukwenziwa kwePCB ngaphakathi nangaphandle:

Cinga ngokubaluleka kokufumana ukuqonda okunzulu kwenkqubo yokwenziwa kwePCB. Ngelixa ukwenziwa kwePCB ngokwayo kusenokungabandakanyi uyilo, ngumsebenzi ophambili ophuma ngaphandle ophathwa ngabavelisi bekhontrakthi abanamava (CMs). Ngelixa imveliso ngokwayo ingengomsebenzi woyilo, yenziwa ngononophelo ngokweenkcukacha ezichanekileyo ozinikezelayo kwiCM.

Ukuvula iiMfihlo ezingemva kokuPhunyezwa kwe-PCB eLungileyo: Yiba nomfanekiso ngqondweni wokubonelelwa kweplani yebhodi yesekethe egqibeleleyo eyenziwe yaphila kusetyenziswa iindlela zokwenza izinto zangoku. Ngobuchule bethu kwitekhnoloji ye-imaging-edge, sikwenza ukuba ubone zonke iinkcukacha zoyilo lwakho zithatha imilo ngokuchanekileyo.

Vumela iinkosi zicoce indlela ngokususa ubhedu olugqithisileyo:

Amagcisa ethu anezakhono ahamba ngaphezulu nangaphaya ngokukrola ngobuchule okanye ngokususa nayiphi na intsalela yobhedu engafunekiyo kumaleko angaphakathi ePCB. Le nkqubo ityhila umkhondo onzima kunye neepads ezibaluleke kakhulu ekusebenzeni ngokungenamthungo kweesekethe ze-elektroniki.

Thatha isitaki sakho soMaleko wePCB ukuya kuMphakamo oMtsha:

Kunye neengcali zethu ezinamava kwihelm, sithatha PCB yakho umaleko stack ukuya kwinqanaba elilandelayo ngobuchule laminating izixhobo zebhodi yesekethe kunye. Ngokufudumeza ngononophelo kunye nokucofa, siqinisekisa ibhondi ekhuselekileyo nethembekileyo naphantsi kwezona meko zinzima kakhulu.

Ukugrunjwa kweMingxunya eChanekileyo yokuNgxunyeka kweLitye kunye noQhagamshelwano:

Siyakuqonda ukubaluleka okubalulekileyo kokunyuka okukhuselekileyo kunye noqhagamshelwano olungenasiphako. Yiyo loo nto iindlela zethu zokugrumba eziphambili zisivumela ukuba senze imingxunya echanekileyo yokufakwa kwecandelo, izikhonkwane zemingxuma kunye ne-vias. Qiniseka ukuba iPCB yakho iya kudibanisa ngaphandle komthungo kwimveliso yakho yokugqibela.

Ubuncwane obufihliweyo buvezwa ekukhanyeni ngokucolwa komphezulu obuthathaka:

ingqalelo yethu kwiinkcukacha ihlala injalo. Ngokuchukumisa ngononophelo, sinokuchwetheza ngobuchwephesha okanye sisuse ubhedu olugqithileyo kumphezulu webhodi. Ngokwenza oku, sazisa imikhondo eyilwe kakuhle kunye neepads ezinika amandla impumelelo yesekethe yakho. Imingxunya eyomeleziweyo kunye ne-vias yokusebenza kokuqina: Xa kuziwa ekusebenzeni kwebhodi, asiyekeleli. Sisebenzisa ubuchwephesha bokucwenga obukwinqanaba eliphezulu, someleza imingxunya kunye ne-vias yakho, sikhulisa ukuhanjiswa kombane kunye nokuqinisekisa ukuhlala ixesha elide.

Khusela i-PCB yakho ngengubo ekhuselayo okanye imaski yesolder:

Njengabakhuseli abaqinileyo beebhodi zeesekethe, sisebenzisa i-coating ekhuselayo okanye imaski ye-solder ukukhusela amacandelo ayo athambileyo kwizinto ezisingqongileyo. Sithembe ukuba sandise ubomi bayo.

Khulula isazisi sophawu lwakho ngoshicilelo olulodwa lwesikrini:

uphawu lwakho lufanelwe kukukhanya. Yiyo loo nto ukwenza ngokwezifiso kusembindini weenkonzo zethu. Khetha kwiinketho zethu zoshicilelo lwesikrini esinokwenziwa ngokwezifiso kwaye wongeze abaqulunqi bereferensi, iilogo okanye naluphi na olunye uphawu ukwenza iimveliso zakho zohluke.

Yandisa ubuhle ngokugqitywa kobhedu olukhethiweyo:

Sikholelwa ukuba ukugqwesa kukwiinkcukacha. Ukuphucula inkangeleko yebhodi, sinikezela ngokugqitywa kobhedu kwiindawo ezithile zomphezulu, ukuqinisekisa ukujongwa okucokisekileyo kunye nobungcali ngokupheleleyo.

Ngoku, masingene kwihlabathi lophuhliso lwePCB:

Qalisa kuhambo olungaqhelekanga njengoko sisenza uyilo lwakho luphile ngenkqubo yethu yokuvelisa. Ukusuka kumfanekiso kunye nokugxumeka ukuya ekubhobhozeni, ukucwenga kunye nokukhusela, inqanaba ngalinye libonisa ubugcisa kunye nokuchaneka. Yamkela umahluko owenziwe yinkqubo yethu yokwenziwa kwePCB kwaye ubukele indalo yakho idubula kwiibhodi ezisebenza kakhulu.

Vula amandla angasetyenziswanga entsebenziswano engenamthungo:

Yiba nomfanekiso-ngqondweni wemvisiswano egqibeleleyo phakathi kombono wakho woyilo kunye nobuchule bomenzi wakho wekhontrakthi (CM). Siyaqonda ukuba kwiimeko ezininzi iCM yakho isenokungakwazi ukufikelela kwinjongo yakho yoyilo okanye iinjongo zokusebenza. Esi sikhewu solwazi sinokuthintela inkqubo yokwenza izigqibo kwaye sinokuchaphazela imiba ebalulekileyo efana nokukhethwa kwezinto eziphathekayo, ukwakheka, ngokubeka kunye nepateni, i-trace parameters, kunye nezinye izinto ezichaphazela kakhulu ukwenziwa kwezinto, isivuno semveliso, kunye nokusebenza emva kokuthunyelwa. PCB yakho.

Ukuvala umsantsa ngoKhetho lweMveliso olunolwazi:

E-Shenzhen Capel Technology Co., Ltd, sikholelwa ukuba intsebenziswano engenamthungo ngundoqo ekuvuleni amandla okwenene e-PCBs. Iqela lethu elizinikeleyo lisebenza ngokusondeleyo nawe ukuqonda iinjongo zakho zokusebenza, ukuvala umsantsa phakathi kwenjongo yakho yoyilo kunye nezigqibo zokwenziwa kwemveliso. Sixhotyiswe ngolu lwazi luxabisekileyo, siqinisekisa ukuba lonke ukhetho esilwenzayo, nokuba kukhetho lwemathiriyeli, ukwenziwa kakuhle koyilo, ngokuchanekileyo ngokubeka okanye ukulandelela iparameter tuning, ilungelelaniswe ngokugqibeleleyo neenjongo zakho.

Yandisa ukusebenza kwe-PCB kunye nokuqonda kwengcali yokuvelisa:

Ukuba neqabane elinamava elibuqondayo ubunzima bokwenziwa kwePCB kunokwenza umahluko. Ukutsalela kulwazi lwethu olunzulu lweenkqubo zokwenziwa kwemveliso kunye neempembelelo zazo kwii-PCBs, sizama ukwandisa yonke inkalo yenkqubo yokwenziwa kwemveliso. Ukusuka ekukhetheni imathiriyeli efanelekileyo ukuya kuyilo olululo kunye neeparamitha zendlela, sizama ngokungayekiyo ukwandisa ukwenziwa, isivuno semveliso kunye nokusebenza kwexesha elide kweePCB zethu.

Nika iCM yakho ngenjongo yoyilo kunye neenjongo zokusebenza:

Ukusebenzisana ngundoqo, kwaye sikholelwa ekuboneleleni iCM yakho ngolwazi olubalulekileyo kwinjongo yakho yoyilo kunye nokusebenza okulindelweyo. Sisusa nakuphi na ukungaqiniseki okunokuthi kwenzeke ngexesha lenkqubo yokuvelisa ngokuqinisekisa ukuba i-CM yakho iyakuqonda ngokupheleleyo ukhetho lwakho lwemathiriyeli, uyilo, ngendawo kunye nesitayile, umkhondo weparamitha, kunye nezinye izinto ezibalulekileyo. Oku kungafihlwa akuphuculi nje ukwenziwa kwe-PCB, kodwa kukwaphucula imveliso yemveliso kwaye iqinisekisa ukusebenza okugqwesileyo kweklasi emva kokusasazwa kwe-PCB.

Vula amandla apheleleyo ePCB yakho:

Nge-Shenzhen Capel Technology Co., Ltd. ecaleni kwakho, unokuqiniseka ukuba yonke inyathelo lenkqubo yokuvelisa iya kuhlangabezana nenjongo yakho yoyilo kunye neenjongo zokusebenza. Sikunye singasebenzisa amandla entsebenziswano ukwenza iiPCB ezingahlangani nje kuphela kodwa zigqithise ubulindele. Ungavumeli nakuphi na ukungaqiniseki kukubambezele - sijoyine ukuguqula uhambo lwakho lokwenziwa kwe-PCB kwaye ubone iziphumo ezimangalisayo zentsebenziswano efundisayo, ehambelanayo.

Ukuvula Amandla Afihliweyo:

Fumanisa amandla entsebenziswano engenamthungo phakathi kwakho kunye nomenzi wakho wekhontrakthi (CM). Siyaqonda ukuba iCM yakho ihlala ingenakuqonda kwinjongo yakho yoyilo kunye neenjongo zokusebenza. Lo mda unokuthintela inkqubo yokwenza izigqibo kwaye unokuchaphazela imiba ebalulekileyo efana nokukhethwa kwezinto eziphathekayo, ukulungiswa kwe-layout, i-VIA positioning, i-trace parameters, kunye nezinye izinto ezichaphazela ukwenziwa kwe-PCB, imveliso yemveliso, kunye nokusebenza emva kokuthunyelwa.

Ukuphucula ukuVeliswa ngoKhetho loYilo oluSmart:

E-Shenzhen Capel Technology Co., Ltd., sikholelwa ukuba ukuvula amandla okwenyani ePCB kuqala ngokhetho loyilo olukrelekrele. Ukwenziwa kweyona nto ilungileyo, sigxininisa kwizinto eziphambili ezinjengokugcina ucoceko olufanelekileyo phakathi kwezinto ezingaphezulu kunye nemiphetho yebhodi. Ukongeza, sikhetha ngononophelo izixhobo kunye ne-coefficient ephezulu yokwanda kwe-thermal (CTE) ukumelana ne-PCBAs, ngakumbi i-lead-free soldering. Ezi zigqibo zicokisekileyo zinokunqanda iingxaki zokuyila ngokutsha kwaye zigcine inkqubo yokuvelisa isebenza kakuhle. Ukongeza, ukuba uthatha isigqibo sokwenza ipaneli uyilo lwakho, siqinisekisa ukuba inyathelo ngalinye lendlela licingelwe kakuhle.

Ukuphucula ngokuchanekileyo isivuno sebhodi:

Ukuvelisa ngempumelelo akuthethi ukuthotyelwa kumgangatho. Nokuba kukho imiceli mngeni yokuvelisa, sinobuchwephesha bokuzisa isivuno esikhulu kwiibhodi zakho. Ngokomzekelo, ngokuphepha iiparitha zokuyila ezingaphandle kwendawo yokunyamezela kwisixhobo seCM, sinokunciphisa amathuba okuba ibhodi ingasetyenziswa. Ngeendlela zethu zokuvelisa izinto ezintsha, unokulindela ngokuzithemba iiPCB ezikumgangatho ophezulu ezihlangabezana neenjongo zakho zokusebenza.

Ukuqinisekisa ukuthembeka kuso sonke isicelo:

Ukuphumelela kwe-PCB kuxhomekeke kakhulu kuhlelo lwayo ngokwe-IPC-6011. Kwii-PCB eziqinileyo, amanqanaba amathathu ahlukeneyo okuhlela akhona, ebeka iiparameters ezithile zokwakha ukuthembeka okuphezulu kokusebenza. Indlela yethu ecokisekileyo iqinisekisa ukuba ibhodi yakho idibana okanye idlula ulwahlulo olufunekayo kusetyenziso olucetywayo. Ngokuphepha imigibe yeepaneli zesakhiwo esisezantsi, sinokuthintela ukuphathwa okungahambelaniyo okanye ukungaphumeleli kwangaphambili kweepaneli. Thembela i-Shenzhen Capel Technology Co., Ltd. ngokusebenza okufanayo kunye nokuthembekileyo.

Yandisa uhambo lwakho lwePCB:

I-Shenzhen Capel Technology Co., Ltd. Njengeqabane lakho olithembileyo, silandela inkqubo yokwenziwa kwe-PCB engqongqo kwaye siya kukunceda uqonde amandla apheleleyo e-PCB yakho. Sisebenza ngokubambisana ukuqinisekisa ukuba iCM yakho iyiqonda ngokupheleleyo injongo yoyilo kunye neenjongo zokusebenza. Ngokuvala umsantsa phakathi kombono wakho kunye nezigqibo zokwenziwa kwemveliso, sivula indlela yophumezo olungenamthungo, ukwenziwa kakuhle kwezinto, izivuno eziphezulu kunye nokuthembeka okungagungqiyo. Musa ukuvumela unxibelelwano olungalunganga lukubambezele kwimpumelelo- guqula indlela yakho ye-PCB kunye nathi kwaye ufumane iziphumo eziguqukayo zobudlelwane obulungelelanisiweyo ngokwenene.

Ixesha lokuposa: Sep-06-2023

Emva