Kule post yebhlog, siza kuxoxa ngeengcebiso ezingama-20 eziqinisekisiweyo zokonga iindleko zePCB ezinokukunceda ulungelelanise inkqubo yakho yokuvelisa kwaye ekugqibeleni wandise inzuzo yakho.

Kwihlabathi lanamhlanje elikhuphisana kakhulu leemveliso ze-elektroniki, ukufumana iindlela zokunciphisa iindleko kunye nokunyusa ukusebenza kakuhle kubalulekile kulo naliphi na ishishini. Iibhodi zeesekethe eziprintiweyo (PCBs) zidlala indima ebalulekileyo ekusebenzeni kwezixhobo zombane, kwaye ukulungelelanisa iinkqubo zabo zokuvelisa kunokukhokelela ekugcinweni kweendleko ezibalulekileyo.

1. Cwangcisa kunye nobuchule bokuyila: Isinyathelo sokuqala sokugcina iindleko siqala ukusuka kwinqanaba loyilo.Khuthaza iqela lakho ukuba liyile ii-PCBs ngobuchule obusengqondweni, ukuqinisekisa ukubekwa kwecandelo, umkhondo, kunye nokunciphisa ubungakanani bebhodi.

2. Ukwandisa ukhetho lwamacandelo: Ukukhetha amacandelo angabizi kakhulu ahlangabezana neemfuno zeprojekthi kunokuchaphazela kakhulu iindleko zePCB.Thelekisa amaxabiso avela kubaboneleli abahlukeneyo kwaye uqinisekise ukuhambelana noyilo lwakho.

3. Ukunciphisa inani leeleya: Ukunciphisa inani leeleya zePCB kunokunciphisa kakhulu iindleko zemveliso.Hlalutya uyilo lwakho kwaye uvavanye ukuba iileya ezingeyomfuneko zinokushenxiswa ngaphandle kokuchaphazela ukusebenza.

4. Ukwenziwa kweepaneli kuyilo lwePCB yakho: Ukwenza iipaneli kuyilo lwePCB yakho kubandakanya ukucwangcisa iikopi ezininzi zoyilo olufanayo kwiqela elinye.Itekhnoloji ikhulisa ukusetyenziswa kwezinto kunye nokwandisa ukusebenza kakuhle kwemveliso, okukhokelela ekugcinweni kweendleko.

5. Beka emgangathweni iinkcukacha zakho zePCB: Lungiselela imilinganiselo kulo lonke uyilo lwakho ukuze uzuze kuqoqosho lwesikali.Le ndlela ikuvumela ukuba u-odole amanani amakhulu kwaye uthethe amaxabiso angcono kunye nomenzi.

6. Khetha i-Surface Mount Technology (SMT): Amacandelo e-SMT abiza ixabiso eliphantsi kwaye akhawuleze ukudityaniswa kunalawo aphuma kumngxuma.Ukutshintshela kwi-SMT kunceda ukunciphisa iindleko zemveliso ngelixa ugcina umgangatho.

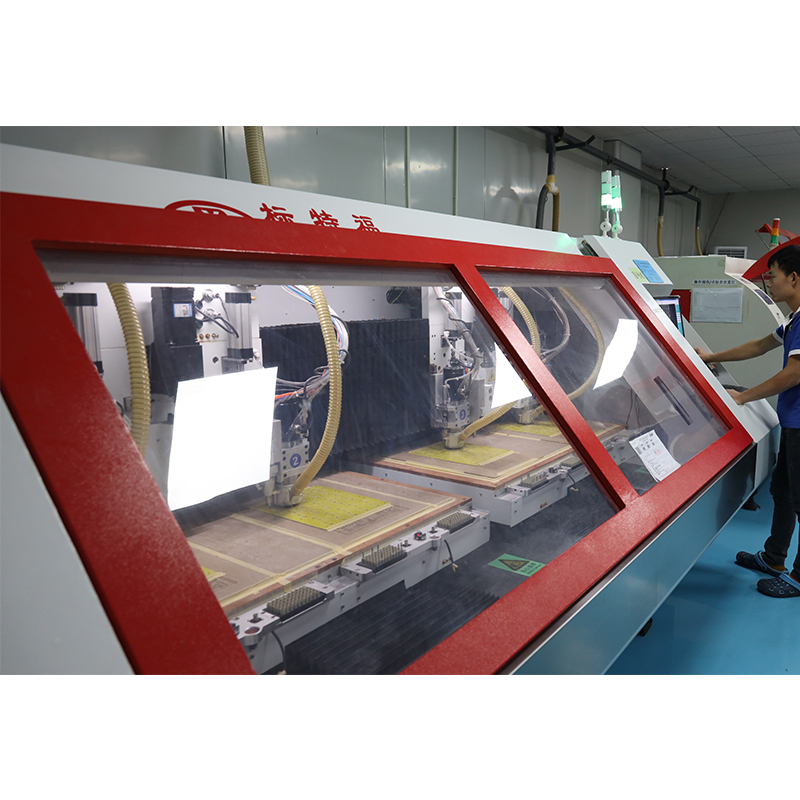

7. Lungiselela indibano yePCB: Sebenza ngokusondeleyo neefektri zendibano zePCB ukwenza lula inkqubo yokuhlanganisa.Itekhnoloji esebenzayo efana noomatshini bokubeka ngokuzenzekelayo kunye ne-solder paste stencil inokugcina ixesha kunye nokunciphisa iimpazamo.

8. Gwema ukuhlaziywa koyilo: Ukuhlaziywa rhoqo koyilo kwandisa iindleko ngenxa yesidingo sokuqhuba imveliso eyongezelelweyo kunye nezinto ezichithwayo.Qinisekisa uqinisekiso loyilo olucokisekileyo ukuze kuncitshiswe amathuba ohlengahlengiso.

9. Yenza uYilo lweMveliso (DFM) Uhlalutyo: Ukwenza uhlalutyo lweDFM kunokuchonga imiba enokubakho yokwenziwa kwangoko kwinqanaba loyilo.Ngokujongana nale miba ngaphambi kwexesha, unokuthintela iimpazamo ezibiza kakhulu kwinkqubo yakho yokuvelisa.

10. Sebenzisa i-software ye-Design Rule Checking (i-DRC): Ukusebenzisa i-software ye-DRC inceda ukufumanisa iimpazamo zoyilo kunye nokwaphulwa kwemithetho ngaphambi kokuthumela iifayile zoyilo zokwenza.Ukulungisa iimpazamo kwangethuba kunokonga ixesha nemali.

11. Lungiselela iifayile zeGerber: Lungiselela iifayile zakho zeGerber ukuze uqinisekise ukuchaneka kunye nokuphelisa izinto ezingeyomfuneko.Ukuphonononga ngokucokisekileyo amaxwebhu ukuphepha iimpazamo ezibiza imali eninzi yokwenza izinto.

12. Bavavanye rhoqo ababoneleli: Rhoqo phinda uvavanye ababoneleli bakho bePCB ukuqinisekisa ukuba ufumana olona mgangatho uphezulu ngexabiso elikhuphisanayo.Zibandakanye kuthethathethwano lwamaxabiso kwaye uqwalasele abanye ababoneleli ukuba ngaba kukho iindlela zokonga imali.

13. Sebenzisa iilayibrari eziyiliweyo: Ukudala iilayibrari zoyilo zamacandelo asetyenziswa ngokuqhelekileyo kunokonga ixesha kunye nokunciphisa iimpazamo.Ukusebenzisa kwakhona amacandelo asele eqinisekisiwe kuphelisa imfuno yokuphinda kuhlolwe kwaye kunciphisa iindleko zokuvelisa.

14. Qwalasela ukutshintshwa kwezinto: Phanda ezinye izixhobo kunye neendleko zazo ukuchonga imathiriyeli enokubakho endaweni enokunciphisa iindleko zizonke zePCB.Qinisekisa ukuba ukutshintshwa kuyahlangabezana neemfuno zakho zeprojekthi kunye nemigangatho yomgangatho.

15. Khetha iinkonzo ze-PCB ezithembekileyo ze-turnkey: Ababoneleli ngenkonzo ye-Turnkey PCB banikezela ngezisombululo ezibanzi kuquka ukuveliswa kwe-PCB kunye nendibano.Ukukhetha umthengisi othembekileyo konga ixesha, kunciphisa iindleko zokuthumela kunye nokunciphisa imizamo yokulungelelanisa.

16. Ukunciphisa iindleko ze-NRE: Iindleko zobunjineli ezingabuyiyo (NRE) zinokuchaphazela kakhulu ixabiso elipheleleyo lokuveliswa kwe-PCB.Ukulungelelanisa inkqubo yakho yemveliso kwaye unqande ukuphindaphinda okungeyomfuneko kunye notshintsho olufaka iindleko ezongezelelweyo ze-NRE.

17. Khetha ukugqiba komphezulu we-PCB ochanekileyo: Khetha ukugqiba kwePCB echanekileyo ngokusekelwe kwiimfuno zeprojekthi yakho kunye nohlahlo lwabiwo-mali.Iinketho ezifana ne-HASL, ENIG, kunye ne-OSP zibonelela ngeendleko ezahlukeneyo kunye nezakhono.

18. Ukwandisa ukusebenza kakuhle kwephaneli: Sebenza nabavelisi ukwandisa ukusebenza kwephaneli ngokulungisa uyilo lwephaneli nolungiselelo.Ukusetyenziswa kweephaneli okusebenzayo kunciphisa inkunkuma yezinto kwaye kunciphisa iindleko.

19. Lungiselela iinkqubo zakho zovavanyo: Lungisa iindlela zakho zokuvavanya ukunciphisa amazinga eempazamo kunye nokusebenza kwakhona okungeyomfuneko.Uvavanyo olusebenzayo luqinisekisa umgangatho wemveliso ophuculweyo ngelixa unciphisa iindleko ezinxulumene neePCB ezingaphumelelanga.

20. Lulula ulawulo lwesixokelelwano sonikezelo: Lawula ngokufanelekileyo ikhonkco lakho lokuthenga ngokudibanisa ii-odolo, ukongeza amanqanaba e-inventri, nokuchonga intsebenziswano enokubakho yokonga iindleko nababoneleli-nkonzo.

Ngokuphumeza ezi ngcebiso zokonga iindleko zePCB ezingama-20, ishishini lakho linokunciphisa kakhulu iindleko ngaphandle kokubeka esichengeni umgangatho.Gcina ukhumbula ukuba iimfuno zombutho ngamnye zinokwahluka, ngoko hlalutya iinkqubo zakho, usebenzisana neqela lakho, kwaye ukhethe isicwangciso esihlangabezana neenjongo zakho. Ngeenkqubo zokuvelisa eziphuculweyo, unokwandisa ukhuphiswano lwakho lwemarike kwaye ufezekise ukukhula okuzinzileyo.

Ixesha lokuposa: Oct-12-2023

Emva