Indlela yokulawula ngokufanelekileyo iingxabano phakathi kweengcingo zangaphakathi kunye nokudityaniswa kweepadi zangaphandle kwiibhodi zesekethe eziprintiweyo ezininzi?

Kwihlabathi le-electronics, iibhodi zeesekethe eziprintiweyo (PCBs) ziyindlela yokuphila edibanisa amacandelo ahlukeneyo kunye, evumela unxibelelwano olungenamthungo kunye nokusebenza. Ii-PCB zeMultilayer, ngakumbi, ziya zithandwa kakhulu ngenxa yokusebenza kwazo okuphuculweyo kunye noxinano lwamacandelo aphezulu. Nangona kunjalo, ubunzima babo budala umngeni wokulawula iingxabano phakathi kwemigca yangaphakathi kunye nokudibanisa kwangaphandle kweepadi.Kule bhlog, siza kuphonononga izicwangciso ezisebenzayo zokujongana nale ngxabano kwaye siqinisekise ukusebenza kakuhle kunye nokuthembeka.

1. Qonda impixano:

Ukusombulula ngempumelelo nayiphi na ingxaki, kubalulekile ukuqonda unobangela wayo. Ukungqubuzana phakathi kwemigca yangaphakathi kunye noqhagamshelwano lwangaphandle lwephedi luvela ngenxa yeemfuno zabo ezahlukeneyo. Umkhondo wangaphakathi ufuna ububanzi obuncinci kunye nezithuba zomzila woxinaniso oluphezulu, ngelixa iipadi zangaphandle zifuna iisayizi ezinkulu ze-soldering yecandelo kunye nokudibanisa ngokomzimba. Ukungqubuzana phakathi kwezi mfuno kunokukhokelela kwiingxaki ezahlukeneyo, ezifana nokulahlekelwa kwengqibelelo yomqondiso, ukuveliswa kobushushu obugqithisileyo, kunye neebhulukhwe zombane. Ukuqaphela nokuqonda le mpixano linyathelo lokuqala lokufumana isisombululo.

2. Lungiselela uyilo:

Isitshixo sokulawula iingxabano silele ekuphuculeni uyilo lwe-PCBs ezinemigangatho emininzi. Oku kunokufezekiswa ngezi zicwangciso zilandelayo:

-Ukucwangciswa kogcino ngononophelo:I-stackup ecatshangelwe kakuhle ibalulekile ekulinganiseni iimfuno zomkhondo wangaphakathi kunye neepads zangaphandle. Ukubeka iileya zeempawu zangaphakathi kufutshane ne-midplane ye-stackup ye-PCB kuvumela ukuthintela okulawulwayo kunye nomgangatho ongcono wengqibelelo. Ngakolunye uhlangothi, ukubeka iipads zangaphandle kwinqanaba langaphandle kunika ukufikeleleka okungcono kwinqanaba.

-Ubuchule bokwenza iintambo ezifanelekileyo:Sebenzisa ubuchule bocingo obufana ne-microvias kunye ne-vias eyimfama ukudibanisa imigca yangaphakathi kwiipadi zangaphandle. Idayamitha encinci ye-microvia ibonelela ngoxinaniso oluphezulu lwendlela ngaphandle kokubeka esichengeni umgangatho wophawu. I-Vis eyimfama idibanisa kuphela imigangatho embalwa emeleneyo, inika umkhondo wangaphakathi indlela ethe ngqo kwiipads zangaphandle ngaphandle kokuwela yonke i-PCB.

-Iimdance ehambelanayo ingqwalasela:Ukungahambelani kokuphazamiseka phakathi kwemigca yangaphakathi kunye neepadi zangaphandle kunokubangela ukubonakaliswa komqondiso kunye nokuthotywa kokusebenza. Sebenzisa iindlela zokuthelekisa ezithintelayo ezinje ngolawulo lwe-dielectric engaguqukiyo, ububanzi bomkhondo obuphuculweyo, kunye nokupheliswa okufanelekileyo kokuqinisekisa imiqondiso engaguqukiyo kuyo yonke iPCB.

- Ulawulo lobushushu:Ukupholisa okwaneleyo kubalulekile ekusebenzeni okuthembekileyo kwePCB. Yila ii-PCBs ezine-thermal vias ukuhambisa ngokufanelekileyo ubushushu obuveliswa ngamacandelo abekwe kufutshane neepads zangaphandle ukuya kumaleko angaphakathi.

3. Intsebenziswano nonxibelelwano:

Ukulawula ungquzulwano kuyilo lwePCB kaninzi kufuna intsebenziswano phakathi kwabathathi-nxaxheba abohlukeneyo, abanje ngeenjineli zoyilo, abavelisi bePCB, kunye neengcali zendibano. Ukugcina amajelo onxibelelwano asebenzayo kubalulekile ekuqinisekiseni ukuba wonke umntu uyayiqonda imiqobo kunye neemfuno zoyilo. Iintlanganiso zarhoqo kunye neengxoxo zinokunceda ukulungelelanisa okulindelweyo kunye nokusombulula iingxabano ngokusombulula iingxaki ekwabelwana ngazo.

4. Ukulinganisa kunye nohlalutyo:

Sebenzisa ukulinganisa kunye nezixhobo zokuhlalutya ukuqinisekisa ukusebenza kombane kuyilo lwakho, imfezeko yomqondiso, kunye neempawu zobushushu. Ezi zixhobo zibonelela ngokuqonda okubanzi kokuziphatha kwe-PCB, ukunceda ekuchongeni iingxabano ezinokubakho kunye noyilo lobuchule ngaphambi kokwenziwa kwemveliso. Ukulinganisa kwakhona kunceda ukwandisa umzila wesignali kunye nokuqinisekisa ukuhambelana kwe-impedance phakathi kwemigca yangaphakathi kunye neepads zangaphandle.

5. Iprototyping kunyeuvavanyo:

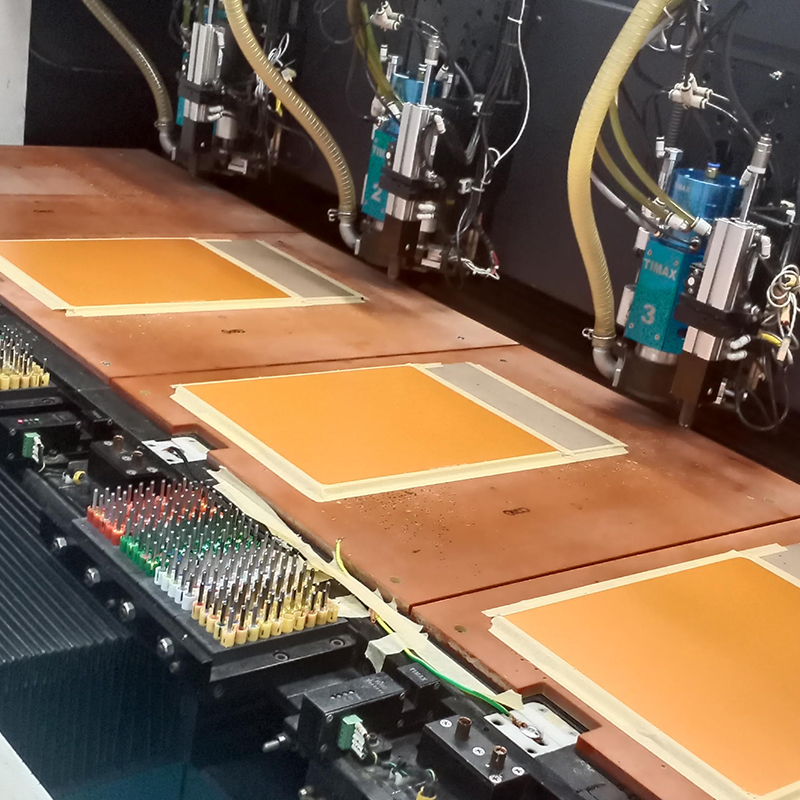

Iprototyping kunye novavanyo ngamanyathelo abalulekileyo okuqinisekisa ukusebenza koyilo kunye nokusombulula naziphi na iingxabano eziseleyo. Ngokubeka iliso elibukhali kwi-PCB ngexesha lovavanyo, iinjineli zinokuchonga iindawo apho iingxabano ziqhubeka kwaye ziphucule ngakumbi uyilo. Iprototyping ikwabonelela nethuba lokuqinisekisa iindlela zolawulo lobushushu kunye nokuqinisekisa ukuthembeka kwePCB iyonke.

Isishwankathelo

Ukulawula ungquzulwano phakathi komkhondo wangaphakathi kunye nokudityaniswa kweepadi zangaphandle kwii-PCB ezininzi zifuna indlela epheleleyo edibanisa iindlela zokuyila eziphuculweyo, unxibelelwano olusebenzayo, ukulinganisa kunye nezixhobo zokuhlalutya, kunye nokuvavanya ngokucokisekileyo. Ngokuqonda oonobangela bongquzulwano kunye nokuphumeza izicwangciso ezixoxiwe, unokufezekisa uyilo olulungeleleneyo oluqinisekisa ukusebenza ngokubanzi, ukuthembeka, kunye nokusebenza kwe-PCB yakho yamanqanaba amaninzi.

Ixesha lokuposa: Sep-26-2023

Emva