Yazisa:

Iprototyping yePCB ekhawulezayo, ngakumbi ukudityaniswa kwamacandelo epitch-pitch, kufuna ubuchule kunye nokuchaneka. Njengoko itekhnoloji iqhubeka nokuhambela phambili, ukwenziwa kwebhodi yesekethe kuya kuba nzima kwaye kufuna. Ngaphezulu kweminyaka eyi-15 yamava kwintsimi, iCapel yinkampani ehamba phambili edibanisa ubuchwephesha bezobugcisa kunye nokuvuselela rhoqo ukuhambisa izisombululo ezingenakulinganiswa.Kule post yebhlog, siza kuntywila kwiindlela, imiceli mngeni, kunye nezona ndlela zilungileyo zokuchwetheza ngokukhawuleza kwe-PCB enezinto ezinophawu oluhle, ngelixa sijonga amandla okuvelisa eCapel angenakuthelekiswa nanto.

Funda malunga nezixhobo zepitch-pitch:

Amacandelo adlala indima ebalulekileyo kwizixhobo ze-elektroniki zale mihla njengoko zivumela ukuhanjiswa kwesantya esiphezulu, ukwenza i-miniaturization kunye nokusebenza okuphuculweyo. Isithuba se-pin lala macandelo singaphantsi kwe-0.8 mm, nto leyo eyenza ukubekwa kwazo okuchanekileyo kwi-PCB kube nzima ngakumbi. Ke ngoko, kubalulekile ukwamkela ubuchule obuthile kunye neendlela zokuqinisekisa ngempumelelo iprototyping.

Izixhobo zoyilo zePCB eziphucukileyo zokwenziwa komboniso okhawulezayo:

Ukuze kusetyenziswe ngokukuko amacandelo acokisekileyo okukhawulezayo kweprototyping yePCB, izixhobo zoyilo eziphambili zePCB kufuneka zisetyenziswe. I-Software efana ne-Altium Designer, i-Eagle okanye i-KiCad inikezela ngeempawu ezifana nokubekwa kwecandelo elichanekileyo, uhlalutyo lwengqibelelo yesignali kunye nemisebenzi yomzila ngokuzenzekelayo, enceda kakhulu ukulungiswa koyilo. Iqela leengcaphephe likaCapel linobuchule bokusebenzisa ezi zixhobo ukuqinisekisa elona nqanaba liphezulu lokuchaneka ngexesha leprototyping.

Izinto ekufuneka uziqwalasele xa ubeka amacandelo epitch-pitch:

Xa uyila uyilo lwe-PCB enamalungu epitch-pitch entle, kubalulekile ukuqwalasela imiba ethile ukuqinisekisa ukusebenza ngokupheleleyo kunye nokwenziwa. Nantsi eminye imiba ebalulekileyo:

1. Uyilo lwePad: Ubungakanani bePad kunye nemilo yingqwalasela ebalulekileyo kwi-solder efanelekileyo kunye noqhagamshelwano oluhle lombane kunye necandelo.Iinjineli ezinamava zaseCapel ziyila ngokucokisekileyo iipads ezisekelwe kwiimfuno ezithile zamacandelo e-fine-pitch, ukubonelela nge-solderability egqwesileyo kunye nokuthembeka.

2. Iitrayisi kunye ne-vias: Imiqondiso enesantya esiphezulu edlula kumacandelo e-fine-pitch ifuna umzila ngononophelo ukunciphisa ingxolo, ukuthomalalisa umqondiso, kunye nokungahambelani kwe-impedance.Ngokufanelekileyo ngokubeka kunye neendlela zokulandela umkhondo ezifana nokuthelekisa ubude kunye nokwahlukana kwendlela yokwahlulahlula inceda ukugcina imfezeko yomqondiso.

3. Ulawulo lwe-Thermal: Izixhobo ze-Fine-pitch zivelisa ubushushu obuninzi ngexesha lokusebenza.Ulawulo olwaneleyo lwe-thermal ngokusetyenziswa kwee-heat sinks, i-thermal vents, okanye ukubeka iipads ezishushu ngaphantsi kwamacandelo kubalulekile ekuthinteleni ukushisa kunye nokuqinisekisa ukuthembeka kwexesha elide.

4. UYilo lweMveliso (DFM): Sebenzisana neqela elinamava laseCapel ngexesha lesigaba soyilo lwePCB ukuqinisekisa ukuba ukhetho loyilo luyahambelana namandla abo okuvelisa.Ukuphucula uyilo lokwenziwa kwezinto kunceda ukunciphisa iimpazamo zeprototyping kunye nokuphucula ukusebenza kakuhle kwenkqubo.

Imingeni yePrototyping kunye nezisombululo:

Iprototyping yePCB eKhawulezayo enamalungu anepitch-pitch inika imingeni ekhethekileyo. Nangona kunjalo, ngamava abanzi kaCapel kunye nobuchule obusebenzayo, le mingeni inokuncitshiswa ngokulula.

1. Ukufumana icandelo: Amalungu e-fine-pitch ahlala enamaxesha amade okukhokela okanye ukufumaneka okunyiniweyo, nto leyo eyenza ukuba ukufumana kwawo kube ngumceli mngeni ngakumbi.Uthungelwano olubanzi lwababoneleli baseCapel kunye nobudlelwane obuqinileyo buqinisekisa ukufikelela ngexesha elifanelekileyo kumacandelo aphezulu, ukuqinisekisa ukuveliswa okungaphazanyiswa.

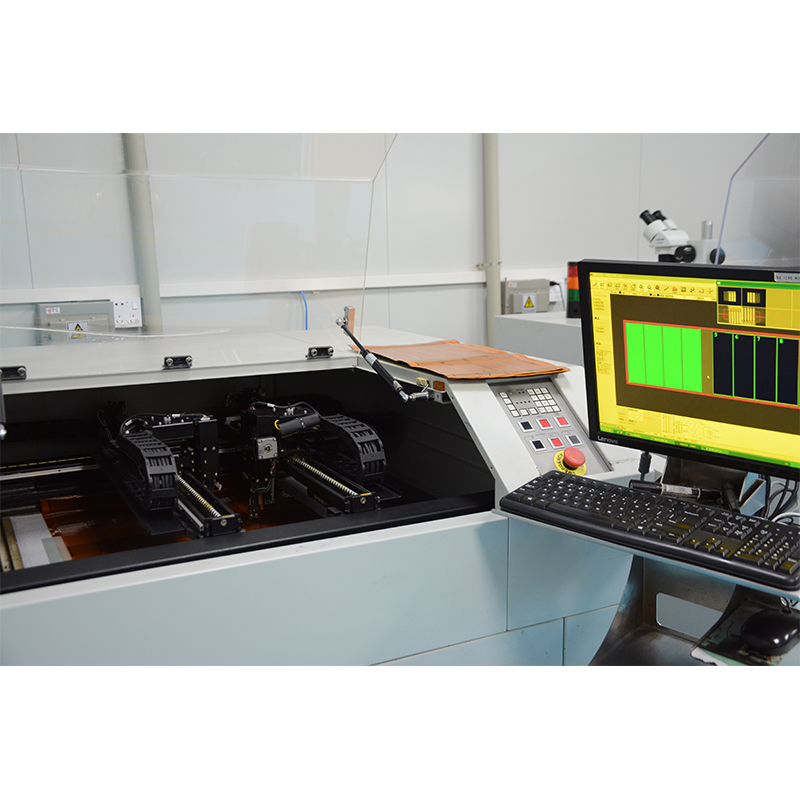

2. I-Welding: I-Welding pitch components ifuna ukuchaneka okuphezulu.I-Capel isebenzisa iteknoloji yendibano ephakamileyo efana ne-ovens reflows kunye neeprofayili zokushisa ezilawulwayo, oomatshini bokubeka ngokuzenzekelayo kunye nokuhlolwa kwe-solder paste ukuze kuqinisekiswe ukuba i-solder idibeneyo.

3. Uvavanyo kunye noHlolo: Ngexesha lesigaba seprototyping, uvavanyo olucokisekileyo kunye nokuhlolwa kubalulekile ukuchonga iziphene ezinokubakho ezifana neebhulorho ze-solder, ukuvula, okanye amatye amangcwaba.I-Capel yenza uhlolo olungqongqo lwekhwalithi isebenzisa i-automated optical inspection (AOI), ukuhlolwa kwe-X-reyi kunye novavanyo lokuskena umda ukuqinisekisa ukuba iiprototypes azinasiphako.

Izakhono zokuvelisa ze-Capel ezingenakulinganiswa:

Ukuzibophelela kukaCapel kumgangatho ophakamileyo kunye nokuqhubela phambili kwezobuchwepheshe kuyenze iqabane elithembekileyo kwishishini lemveliso yePCB.Ubuchule obukhulu bale nkampani, obuncediswa ngamaziko emveliso akwinqanaba eliphezulu kunye nokubambelela kwimigangatho yomgangatho wamazwe ngamazwe, kwenza ukuba ibonelele ngesakhono sokuvelisa esingenakuthelekiswa nanto.

Ukuququmbela:

Iprototyping ekhawulezileyo yeePCBs kusetyenziswa amacandelo epitch-pitch ifuna ulwazi olukhethekileyo kunye nezakhono. Ngeminyaka eyi-15 yamava, ubuchule kunye nokuzibophelela ekuveliseni izinto ezintsha eziqhubekayo, iCapel ibekwe kwindawo ekhethekileyo ukuhlangabezana nale mingeni kwaye igqithise okulindelekileyo.Ukusebenza noCapel kuqinisekisa iiprototypes ezingenasiphako, iinkqubo ezisebenzayo zokuvelisa kunye nenkxaso engenakulinganiswa kwinqanaba ngalinye leprojekthi. Themba iingcaphephe ze-Capel ukuba zivelise iprototype ye-PCB yakho ebomini ngelixa uhlangabezana nezona mfuno zinzima kushishino lwangoku lwe-elektroniki.

Ixesha lokuposa: Oct-18-2023

Emva