Kwimveliso yombane, i-surface Mount technology (SMT) indibano yenye yeenkqubo eziphambili zokuveliswa ngempumelelo kwezixhobo zombane.Indibano ye-SMT idlala indima ebalulekileyo kumgangatho jikelele, ukuthembeka kunye nokusebenza kakuhle kweemveliso zombane. Ukukunceda ukuba uqonde ngcono kwaye uqhelane ne-PCB assembly , iCapel iya kukukhokelela ekuphononongeni iziseko ze-SMT refactoring. kwaye uxoxe ngokuba kutheni kubaluleke kangaka ekwenzeni izinto zombane.

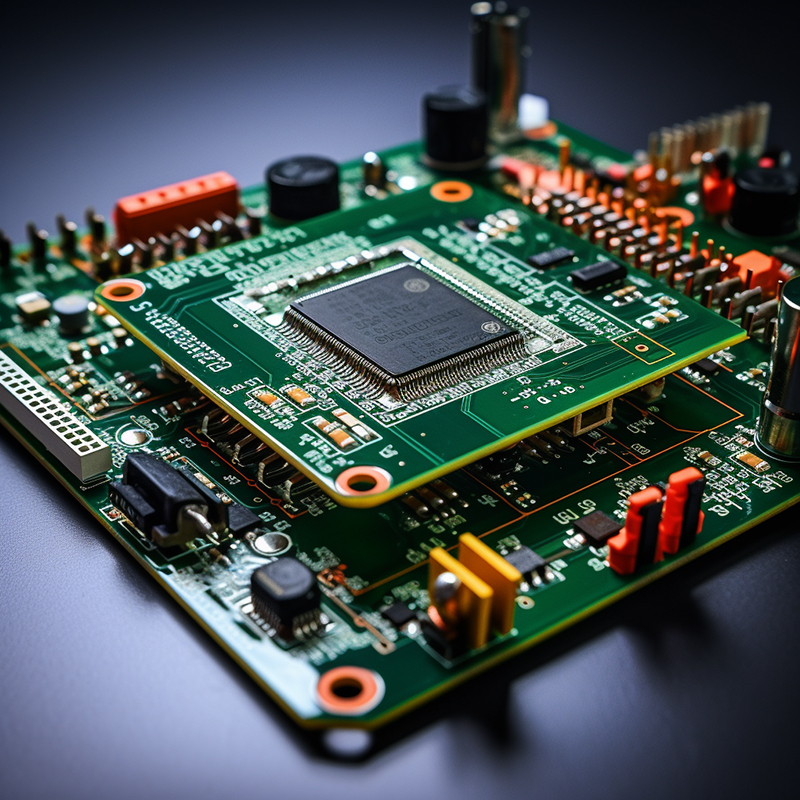

Indibano ye-SMT, ekwabizwa ngokuba yindibano ye-surface Mount, yindlela yokufakwa kwezixhobo ze-elektroniki kumphezulu webhodi yesekethe eprintiweyo (PCB).Ngokungafaniyo neteknoloji ngokusebenzisa umngxuma (THT), leyo ifaka amacandelo ngokusebenzisa imingxunya kwi-PCB, indibano ye-SMT ibandakanya ukubeka amacandelo ngokuthe ngqo kumphezulu webhodi. Kwiminyaka yakutshanje, le teknoloji ifumene ukuthandwa ngokubanzi ngenxa yeenzuzo zayo ezininzi ngaphezu kwe-THT, ezifana nokuxinana kwecandelo eliphezulu, ubungakanani bebhodi encinci, ukuphuculwa kwemfezeko yesignali, kunye nokwanda kwesantya sokuvelisa.

Ngoku, makhe siphengulule kwiziseko zendibano ye-SMT.

1. Ukubekwa kwelungu:Inyathelo lokuqala kwindibano ye-SMT libandakanya ukubekwa okuchanekileyo kwamacandelo e-elektroniki kwi-PCB. Oku kuqhele ukwenziwa kusetyenziswa umatshini wokukhetha kunye nendawo okhetha ngokuzenzekelayo amacandelo kwi-feeder kwaye uwabeke ngokuchanekileyo ebhodini. Ukubekwa ngokufanelekileyo kwamacandelo kubalulekile ekuqinisekiseni ukusebenza ngokufanelekileyo kunye nokuthembeka kwezixhobo ze-elektroniki.

2. Isicelo sokuncamathelisa i-Solder:Emva kokunyuka kwamacandelo, sebenzisa i-solder paste (umxube we-solder particles kunye ne-flux) kwiipads ze-PCB. I-solder paste isebenza njengento encamathelayo yethutyana, ibambe amacandelo endaweni ngaphambi kokuba i-soldering. Kwakhona kunceda ukwenza uqhagamshelwano lombane phakathi kwecandelo kunye nePCB.

3. Reflow soldering:Inyathelo elilandelayo kwindibano ye-SMT kukuphinda kufakwe i-solder. Oku kubandakanya ukufudumeza i-PCB ngendlela elawulwayo ukunyibilikisa i-solder paste kwaye wenze i-solder esisigxina. I-reflow soldering ingenziwa ngokusebenzisa iindlela ezahlukeneyo ezifana ne-convection, i-infrared radiation okanye isigaba somphunga. Ngethuba le nkqubo, i-solder paste iguqula ibe yimeko etyhidiweyo, igeleza kwi-component lead kunye ne-PCB pads, kwaye iqina ukwenza uqhagamshelwano oluqinileyo lwe-solder.

4. Ukuhlolwa nokulawula umgangatho:Emva kokuba inkqubo ye-solder igqityiwe, i-PCB iya kudlula ukuhlolwa okungqongqo kunye nemilinganiselo yokulawula umgangatho ukuze kuqinisekiswe ukuba onke amacandelo abekwe ngokuchanekileyo kwaye i-solder joints iphezulu. Ukuhlolwa kwe-Automated Optical Inspection (AOI) kunye neendlela zokuhlola ze-X-ray ziqhele ukusetyenziswa ukufumanisa naziphi na iziphene okanye ukungahambi kakuhle kwindibano. Nakuphi na ukungangqinelani okufunyenwe ngexesha lokuhlolwa kuyalungiswa phambi kokuba iPCB iye kwinqanaba elilandelayo lokwenziwa.

Ke, kutheni indibano ye-SMT ibaluleke kangaka kwimveliso yombane?

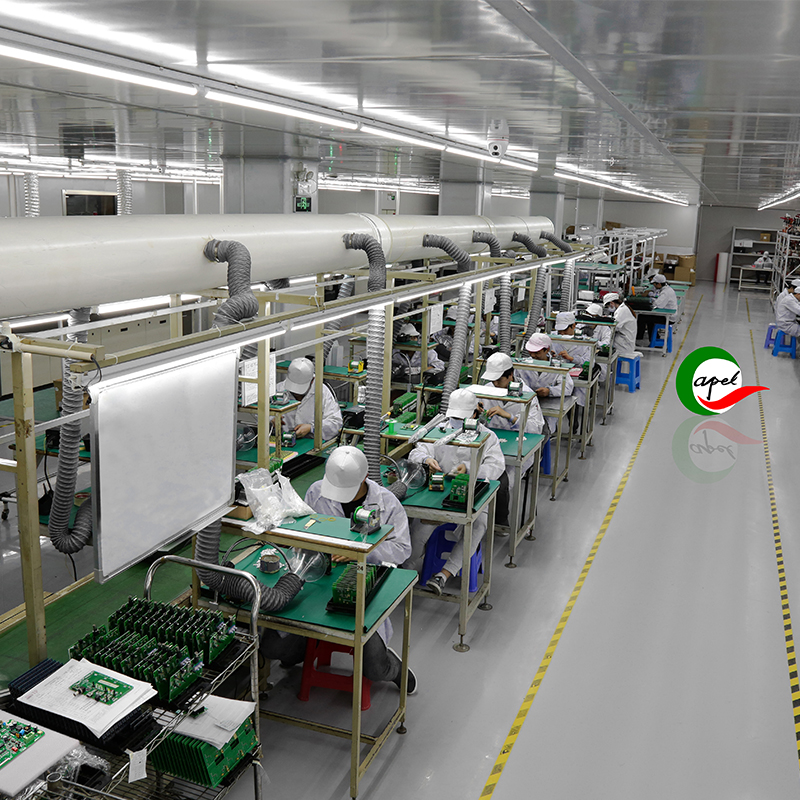

1. Ukusebenza kweendleko:Indibano ye-SMT inenzuzo yeendleko ngaphezu kwe-THT njengoko inciphisa ixesha lokuvelisa ngokubanzi kwaye yenza lula inkqubo yokuvelisa. Ukusetyenziswa kwezixhobo ezizenzekelayo zokubekwa kwecandelo kunye ne-soldering kuqinisekisa imveliso ephezulu kunye neendleko eziphantsi zabasebenzi, okwenza kube yindlela ephumelelayo yoqoqosho yokuvelisa ubuninzi.

2. Ukwenziwa kancinci:Umkhwa wophuhliso lwezixhobo zombane zincinci kwaye zixinene ngakumbi. Indibano ye-SMT yenza ukuba kuncitshiswe izinto zombane ngokufaka izinto ezinophawu oluncinci. Oku akuphuculi nje ukuphatheka, kodwa kuvula amathuba oyilo olutsha kubaphuhlisi bemveliso.

3. Ukusebenza okuphuculweyo:Ekubeni amacandelo e-SMT axhonywe ngqo kumphezulu we-PCB, iindlela zombane ezimfutshane zivumela imfezeko yomqondiso engcono kunye nokuphucula ukusebenza kwezixhobo zombane. Ukunciphisa i-parasitic capacitance kunye ne-inductance kunciphisa ilahleko yesignali, i-crosstalk kunye nengxolo, ukuphucula ukusebenza ngokubanzi.

4. Ukuxinana kwecandelo eliphezulu:Xa kuthelekiswa ne-THT, indibano ye-SMT inokufikelela kuxinzelelo lwamacandelo aphezulu kwi-PCB. Oku kuthetha ukuba imisebenzi emininzi inokudityaniswa kwindawo encinci, ivumela uphuhliso lwezixhobo zombane ezintsonkothileyo nezityebileyo. Oku kubaluleke ngakumbi kumashishini apho indawo idla ngokunqongophala, njengeefowuni eziphathwayo, ii-elektroniki zabathengi, kunye nezixhobo zonyango.

Ngokusekelwe kolu hlalutyo lungentla,ukuqonda iziseko zendibano ye-SMT kubalulekile kuye nabani na obandakanyekayo ekwenzeni izinto zombane. Indibano ye-SMT ibonelela ngeenzuzo ezininzi ngaphezulu kwetekhnoloji yemveli yokuphuma komngxuma, kubandakanya ukusebenza kakuhle kweendleko, amandla okwenza izinto ezincinci, ukuphuculwa kokwenziwa komsebenzi, kunye nokuxinana kwecandelo eliphezulu. Njengoko imfuno yezixhobo ze-elektroniki ezincinci, ezikhawulezayo, nezithembekileyo ziqhubeka zikhula, indibano ye-SMT iya kudlala indima ebalulekileyo ekufezekiseni ezi mfuno.I-Shenzhen Capel Technology Co., Ltd. inefektri yayo ye-PCB yendibano kwaye ibonelele ngale nkonzo ukususela ngo-2009. Ngeminyaka eyi-15 yamava eprojekthi ecebileyo, ukuhamba kwenkqubo engqongqo, ubuchule obugqwesileyo bobugcisa, izixhobo ezizenzekelayo ezizenzekelayo, inkqubo yokulawula umgangatho obanzi, kunye noCapel Iqela leengcaphephe zengcali ukubonelela abathengi behlabathi ngokuchaneka okuphezulu, umgangatho ophezulu okhawulezayo ukujika iPCB Hlanganisa iprototyping. Ezi mveliso ziquka indibano ye-PCB eguquguqukayo, indibano ye-PCB engqongqo, indibano ye-PCB engqongqo, indibano ye-HDI ye-PCB, indibano ye-PCB ephezulu-frequency kunye nendibano ekhethekileyo yePCB. Iinkonzo zethu zokuthengisa kwangaphambili kunye neenkonzo zobugcisa zasemva kokuthengisa kunye nokuhanjiswa kwangethuba kwenza abathengi bethu babambe ngokukhawuleza amathuba entengiso kwiiprojekthi zabo.

Ixesha lokuposa: Aug-24-2023

Emva