I-Delamination kwi-PCB inokukhokelela kwimiba yokusebenza ebalulekileyo, ngakumbi kwi-rigid-flex designs apho zombini izinto eziqinileyo kunye neziguquguqukayo zidityanisiwe. Ukuqonda indlela yokuthintela i-delamination kubalulekile ekuqinisekiseni ubomi obude kunye nokuthembeka kwezi ndibano zinzima. Eli nqaku liza kuphonononga iingcebiso ezisebenzayo zokuthintela i-PCB delamination, igxile kwi-PCB lamination, ukuhambelana kwezinto, kunye neparameters machining elungiselelwe.

Ukuqonda PCB Delamination

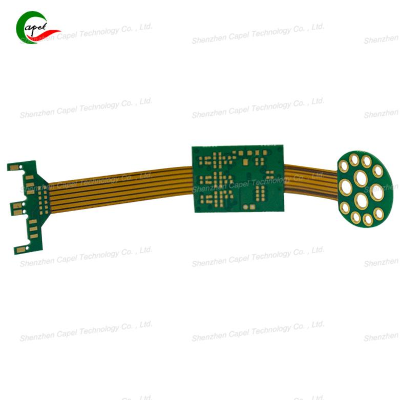

I-Delamination yenzeka xa iileya ze-PCB zahlukana ngenxa yezinto ezahlukeneyo, kubandakanya uxinzelelo lwe-thermal, ukufunxa ukufuma, kunye noxinzelelo lomatshini. KwiiPCB eziguquguqukayo eziqinileyo, umceli mngeni uyanda ngenxa yeempawu ezahlukeneyo zezinto eziqinileyo neziguquguqukayo. Ke ngoko, ukuqinisekisa ukuhambelana phakathi kwezi zixhobo linyathelo lokuqala lokuthintela i-delamination.

Qinisekisa ukuhambelana kwezinto zePCB

Ukukhethwa kwezixhobo kubalulekile ekuthinteleni i-delamination. Xa uyila i-PCB eguquguqukayo eqinile, kubalulekile ukukhetha izixhobo ezinee-coefficients zokwandiswa kwe-thermal ezifanayo. Oku kuhambelana kunciphisa uxinzelelo ngexesha lokuhamba ngebhayisikile ye-thermal, enokukhokelela kwi-delamination. Ukongezelela, qwalasela i-adhesive esetyenziswe kwinkqubo yokuhlambalaza. I-adhesives ekumgangatho ophezulu eyenzelwe ngokukodwa u-rigid-flex applications inokwandisa kakhulu amandla ebhondi phakathi kweeleya.

Inkqubo yokuLamination PCB

Inkqubo yokuthambisa linqanaba elibalulekileyo kwimveliso yePCB. I-lamination efanelekileyo iqinisekisa ukuba iileyile zihambelana kakuhle komnye nomnye, ukunciphisa umngcipheko we-delamination. Nanga amanye amacebiso asebenzayo e-PCB lamination:

Ubushushu kunye noLawulo loxinzelelo: Qinisekisa ukuba inkqubo yokucoca iqhutywe kwiqondo lokushisa elichanekileyo kunye noxinzelelo. Ukushisa okuphezulu kakhulu kunokunciphisa izinto eziphathekayo, ngelixa uxinzelelo olungonelanga lunokubangela ukubambelela kakubi.

Vacuum Lamination: Ukusebenzisa i-vacuum ngexesha lenkqubo ye-lamination kunokunceda ukuphelisa amaqamza omoya anokubangela iindawo ezibuthathaka kwibhondi. Obu buchule buqinisekisa uxinzelelo olufana ngakumbi kwiileya zePCB.

Ixesha lokuphumla: Vumela ixesha elaneleyo lokunyanga ukuze i-adhesive idibanise ngokufanelekileyo. Ukukhawuleza le nkqubo kunokukhokelela ekunamatheleni okungaphelelanga, okwandisa umngcipheko we-delamination.

I-Optimized Rigid-Flex PCB Machining Parameters

Iiparamitha zoMatshini zidlala indima ebalulekileyo kwimfezeko yeePCB eziguquguqukayo. Nanga amanye amacebiso omatshini alungiselelwe ukuthintela i-delamination:

IiTekhnoloji Zokubhola: Sebenzisa amasuntswana okomba afanelekileyo kunye nezantya zokunciphisa ukuveliswa kobushushu ngexesha lenkqubo yokomba. Ukushisa okugqithisileyo kunokunciphisa i-adhesive bond kwaye kukhokelela kwi-delamination.

Indlela kunye nokusika: Xa uhambisa okanye usika i-PCB, qinisekisa ukuba izixhobo zibukhali kwaye zigcinwe kakuhle. Izixhobo ezinqabileyo zingabangela uxinzelelo olugqithisileyo kunye nobushushu, ukuphazamisa ukunyaniseka kweeleyile.

Edge Unyango: Phatha ngokufanelekileyo imiphetho yePCB emva komatshini. Oku kunokubandakanya ukugudisa okanye ukutywina imiphetho ukunqanda ukungena kokufuma, okunokuthi kube negalelo kwi-delamination ekuhambeni kwexesha.

Iingcebiso eziSebenzayo zoThintelo lwe-PCB Delamination

Ukongeza kwezi zicwangciso zingentla, qwalasela la macebiso asebenzayo alandelayo:

Ulawulo lokusingqongileyo: Gcina iiPCB kwindawo elawulwayo ukuthintela ukufunxwa komswakama. Ukufuma kunokuwenza buthathaka ibhondi yokuncamathelisa kwaye ikhokelele kwi-delamination.

Uvavanyo lwarhoqo: Ukuphumeza uvavanyo oluthe gqolo lwee-PCB ngeempawu zokusilela ngexesha lenkqubo yokuvelisa. Ukufunyanwa kwangethuba kunokunceda ukunciphisa imiba ngaphambi kokuba inyuke.

Uqeqesho kunye noKwazisa: Qinisekisa ukuba bonke abasebenzi ababandakanyekayo kwinkqubo yokwenziwa kwe-PCB baqeqeshelwa ezona ndlela zilungileyo zokusebenzisa i-lamination kunye ne-machining. Ukuqonda izinto ezinegalelo kwi-delamination kunokukhokelela ekuthathweni kwezigqibo ezingcono.

Ixesha lokuposa: Oct-31-2024

Emva