Ehlabathini leebhodi zesekethe eziprintiweyo (PCBs), ukhetho lokugqiba umphezulu lubalulekile ekusebenzeni ngokubanzi kunye nobomi obude bezixhobo zombane. Unyango olungaphezulu lubonelela ngengubo ekhuselayo yokuthintela i-oxidation, ukuphucula ukuthengiselana, kunye nokwandisa ukuthembeka kombane kwePCB. Olunye uhlobo lwePCB oludumileyo yiPCB yobhedu eshinyeneyo, eyaziwa ngokukwazi kwayo ukuphatha imithwalo yangoku ephezulu kunye nokubonelela ngolawulo olungcono lobushushu. Nangona kunjalo,umbuzo osoloko uvela ngowokuba: Ngaba iiPCB zobhedu ezishinyeneyo zinokuveliswa ezinemiphetho eyahlukileyo? Kweli nqaku, siza kuphonononga iindlela ezahlukeneyo zokugqiba umphezulu ezikhoyo kwiiPCB zobhedu olungqingqwa kunye neengqwalasela ezibandakanyekayo ekukhetheni ukugqiba okufanelekileyo.

1.Funda malunga nee-PCB ze-Heavy Copper

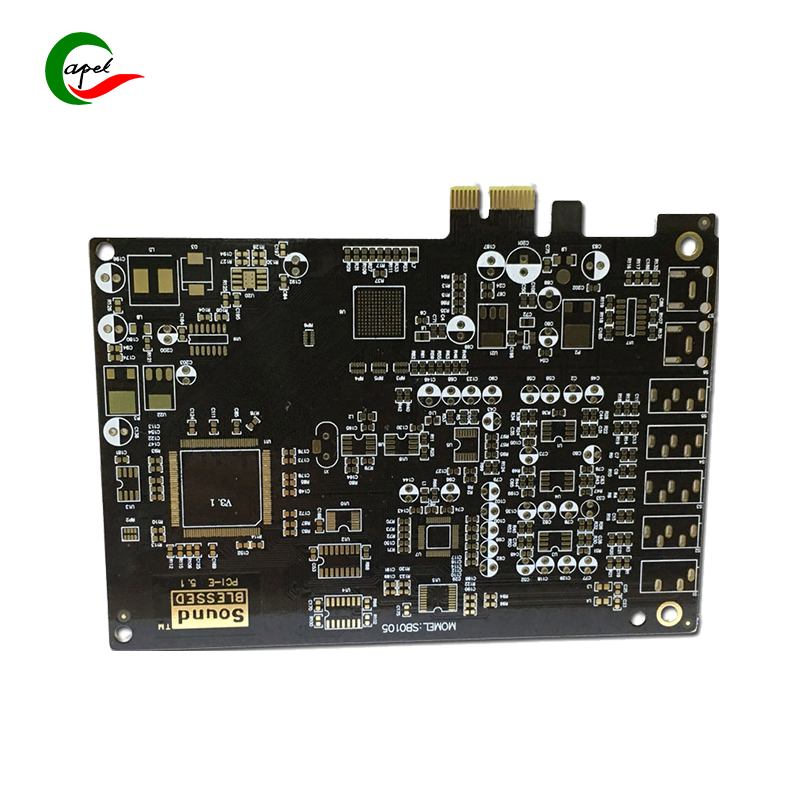

Ngaphambi kokuba ujonge kukhetho lokugqibezela umphezulu, kuyafuneka ukuba uqonde ukuba yintoni iPCB yobhedu kunye neempawu zayo ezithile. Ngokubanzi, iiPCB ezinobunzima bobhedu obungaphezulu kwe-3 ounces (105 µm) zithathwa ngokuba ziiPCB zobhedu ezishinyeneyo. Ezi bhodi zenzelwe ukuthwala imisinga ephezulu kwaye zichithe ubushushu ngokufanelekileyo, okwenza zilungele umbane wamandla, i-automotive, izicelo ze-aerospace kunye nezinye izixhobo ezineemfuno eziphezulu zamandla. IiPCB zobhedu ezishinyeneyo zibonelela nge-thermal conductivity egqwesileyo, amandla aphezulu oomatshini kunye nokuhla kwamandla ombane asezantsi kune-PCBs eziqhelekileyo.

2.Ukubaluleka konyango lomphezulu kwi-Heavy Copper Pcb Manufacturing:

Ukulungiswa komphezulu kudlala indima ebalulekileyo ekukhuseleni imikhondo yobhedu kunye neepads ukusuka kwi-oxidation kunye nokuqinisekisa ukuba amalungu athembekileyo e-solder. Basebenza njengomqobo phakathi kobhedu oluveziweyo kunye namacandelo angaphandle, ukuthintela ukubola kunye nokugcina i-solderability. Ukongeza, ukugqitywa komphezulu kunceda ukubonelela ngomphezulu osicaba wokubekwa kwecandelo kunye neenkqubo zokubopha ucingo. Ukukhetha umphezulu ochanekileyo ogqityiweyo kwiiPCB zobhedu ezishinyeneyo kubalulekile ekwandiseni ukusebenza kwazo kunye nokuthembeka.

3.Ukhetho lonyango olungaphezulu kwi-PCB ye-Heavy Copper:

Umgangatho wesoda yomoya oshushu (HASL):

I-HASL yenye yezona ndlela zonyango ze-PCB zemveli nezingabizi kakhulu. Kule nkqubo, i-PCB intywiliselwa kwindawo yokuhlambela ye-solder etyhidiweyo kwaye i-solder engaphezulu iyasuswa kusetyenziswa imela yomoya oshushu. I-solder eseleyo yenza umaleko ongqindilili kumphezulu wobhedu, ukuwukhusela ekudlekeni. Nangona i-HASL isetyenziswa ngokubanzi indlela yonyango lomphezulu, ayilolona khetho lungcono kwiiPCB zobhedu ezishinyeneyo ngenxa yezinto ezahlukeneyo. Amaqondo obushushu aphezulu okusebenza abandakanyekayo kule nkqubo anokubangela uxinzelelo lwe-thermal kumaleko obhedu angqingqwa, abangele i-warping okanye i-delamination.

Ukuntywiliselwa kwe-nickel yegolide engenambane (ENIG):

I-ENIG lukhetho oludumileyo lonyango oluphezulu kwaye yaziwa ngokulungela kwayo ukuwelda kunye nokuxhathisa umhlwa. Kubandakanya ukufaka umaleko obhityileyo wenikeli engena-electro kwaye emva koko ugalele umaleko wegolide entywiliselwayo kumphezulu wobhedu. I-ENIG inomphezulu othe tyaba, ogudileyo, uwenza ulungele izinto ezinobumba obucolekileyo kunye nokudibanisa ngocingo lwegolide. Ngelixa i-ENIG inokusetyenziswa kwiiPCB zobhedu ezishinyeneyo, kubalulekile ukuqwalasela ubukhulu bomaleko wegolide ukuqinisekisa ukhuseleko oluluqilima kwimisinga ephezulu kunye neziphumo zobushushu.

I-Electroless Nickel Plating Electroless Palladium Immersion Gold (ENEPIG):

I-ENEPIG lunyango oluphezulu lwendawo olubonelela ngokugqwesa ukuthengiswa, ukuxhathisa ukubola kunye nokubopha ucingo. Kubandakanya ukubeka umaleko wenikeli engena-electro, emva koko umaleko we-electroless palladium, kwaye ekugqibeleni umaleko wegolide yokuntywiliselwa. I-ENEPIG ibonelela ngokuqina okugqwesileyo kwaye ingafakwa kwiiPCB zobhedu ezishinyeneyo. Ibonelela ngokugqityezelwa komphezulu womphezulu, iyenza ilungele usetyenziso lwamandla aphezulu kunye nezixhobo zokulinganisa.

Itoti yokuntywiliselwa (ISn):

Itoti yokuntywiliselwa yenye indlela yonyango olulolunye olungaphezulu lweePCB zobhedu ezishinyeneyo. Intywilisela iPCB kwisisombululo esisekwe kwitoti, yenze umaleko obhityileyo wetoti kumphezulu wobhedu. Itoti yokuntywiliselwa ibonelela ngokuthengiswa okugqwesileyo, indawo ethe tyaba, kwaye ihambelana nokusingqongileyo. Nangona kunjalo, enye ingcamango xa usebenzisa i-tin yokucwiliswa kwii-PCB zobhedu ezishinyeneyo kukuba ubukhulu be-tin layer kufuneka ilawulwe ngononophelo ukuze kuqinisekiswe ukhuseleko olwaneleyo kwi-oxidation kunye nokuhamba okuphezulu kwangoku.

I-Organic solderability preservative (OSP):

I-OSP lunyango lomphezulu olwenza isambatho sendalo esikhuselayo kwimiphezulu yobhedu evelileyo. Inokuthengiswa kakuhle kwaye iyabiza. I-OSP ilungele usetyenziso lwamandla asezantsi ukuya kwaphakathi kwaye ingasetyenziswa kwiiPCB zobhedu ezishinyeneyo ukuba nje umthamo wangoku wokuthwala kunye neemfuno zokuchithwa kwe-thermal zihlangatyeziwe. Enye yezinto ekufuneka iqwalaselwe xa usebenzisa i-OSP kwiiPCB zobhedu ezishinyeneyo bubunzima obongezelelweyo botyatho lwendalo, obunokuthi buchaphazele ukusebenza kombane kunye nobushushu obupheleleyo.

4.Izinto ekufuneka ziqwalaselwe xa ukhetha ukugqitywa komphezulu kwiiPCB zeCopper eziManzi:Xa ukhetha umphezulu ogqityiweyo wobunzima.

PCB yobhedu, kukho izinto ezininzi ekufuneka ziqwalaselwe:

Ukuthwala kwangoku:

IiPCB zobhedu ezishinyeneyo zisetyenziswa ikakhulu kusetyenziso lwamandla aphezulu, ngoko ke kubalulekile ukukhetha umphezulu wokugqiba onokuthwala imithwalo yangoku ephezulu ngaphandle kokuxhathisa okubalulekileyo okanye ukufudumeza. Iinketho ezifana ne-ENIG, ENEPIG, kunye ne-tin yokuntywila zifanelekile ngokubanzi kwizicelo eziphezulu zangoku.

Ulawulo lobushushu:

I-PCB yobhedu eshinyeneyo yaziwa ngokuba yi-thermal conductivity egqwesileyo kunye nesakhono sokuchitha ubushushu. Ukugqitywa komphezulu akufanele kuthintele ukuhanjiswa kobushushu okanye kubangele uxinzelelo olugqithisileyo lwe-thermal kuluhlu lobhedu. Unyango oluphezulu olufana ne-ENIG kunye ne-ENEPIG zineengqimba ezibhityileyo ezihlala ziluncedo kulawulo lwe-thermal.

I-Solderability:

Ukugqitywa komphezulu kufuneka kunikeze i-solderability egqwesileyo yokuqinisekisa ukudibanisa okuthembekileyo kunye nokusebenza ngokufanelekileyo kwecandelo. Iinketho ezifana ne-ENIG, ENEPIG kunye ne-HASL zibonelela ngokuthembekileyo.

Ukuhambelana kwecandelo:

Qwalasela ukuhambelana komphezulu okhethiweyo ogqityiweyo kunye namacandelo athile aza kunyuswa kwi-PCB. Amalungu omgangatho ocolekileyo kunye nokudityaniswa kocingo lwegolide kunokufuna unyango olungaphezulu olufana ne-ENIG okanye i-ENEPIG.

Iindleko:

Iindleko zihlala zithathelwa ingqalelo ebalulekileyo kwimveliso ye-PCB. Iindleko zonyango olwahlukileyo lomphezulu ziyohluka ngenxa yezinto ezifana neendleko zempahla, ukuntsonkotha kwenkqubo kunye nezixhobo ezifunekayo. Vavanya impembelelo yeendleko zokugqitywa komphezulu okhethiweyo ngaphandle kokunciphisa ukusebenza kunye nokuthembeka.

IiPCB zobhedu ezishinyeneyo zibonelela ngezinto eziluncedo ezizodwa kusetyenziso lwamandla aphezulu, kwaye ukukhetha umphezulu ochanekileyo wokugqiba kubalulekile ekwandiseni ukusebenza kwazo kunye nokuthembeka.Ngelixa iinketho zemveli ezifana ne-HASL zisenokungafaneleki ngenxa yemicimbi yobushushu, unyango olungaphezulu olufana ne-ENIG, ENEPIG, i-tin yokuntywila kunye ne-OSP inokuqwalaselwa ngokuxhomekeke kwiimfuno ezithile. Izinto ezinjengokuthwala kwangoku, ulawulo lwe-thermal, ukuthengiswa, ukuhambelana kwecandelo kunye neendleko kufuneka zihlolwe ngononophelo xa ukhetha ukugqitywa kweePCB zobhedu ezishinyeneyo. Ngokwenza ukhetho olufanelekileyo, abavelisi banokuqinisekisa ukwenziwa ngempumelelo kunye nokusebenza kwexesha elide kweePCB zobhedu olutyebileyo kwiinkqubo ezahlukeneyo zombane neze-elektroniki.

Ixesha lokuposa: Sep-13-2023

Emva