I-HDI (i-High Density Interconnect) i-PCB e-rigid-flex imele i-pinacle ye-teknoloji yebhodi yesekethe eprintiweyo ephambili, edibanisa iingenelo ze-high-density wiring capabilities kunye nokuguquguquka kweebhodi eziqinileyo.Eli nqaku lijolise ekucaciseni inkqubo yokwenziwa kwe-HDI eqinile-eguquguqukayo ye-PCB kwaye ibonelele ngengqiqo ebalulekileyo kwisakhiwo sayo, izixhobo kunye namanyathelo okuvelisa angundoqo.Ngokuqonda izinto ezintsonkothileyo ezibandakanyekayo, iinjineli kunye nabayili banokuluphucula uyilo lwabo kwaye basebenzisane ngokufanelekileyo nabavelisi ukuguqula iimbono zabo ezintsha zibe yinyani.

1. QondaHDI eqinile bhetyebhetye PCB:

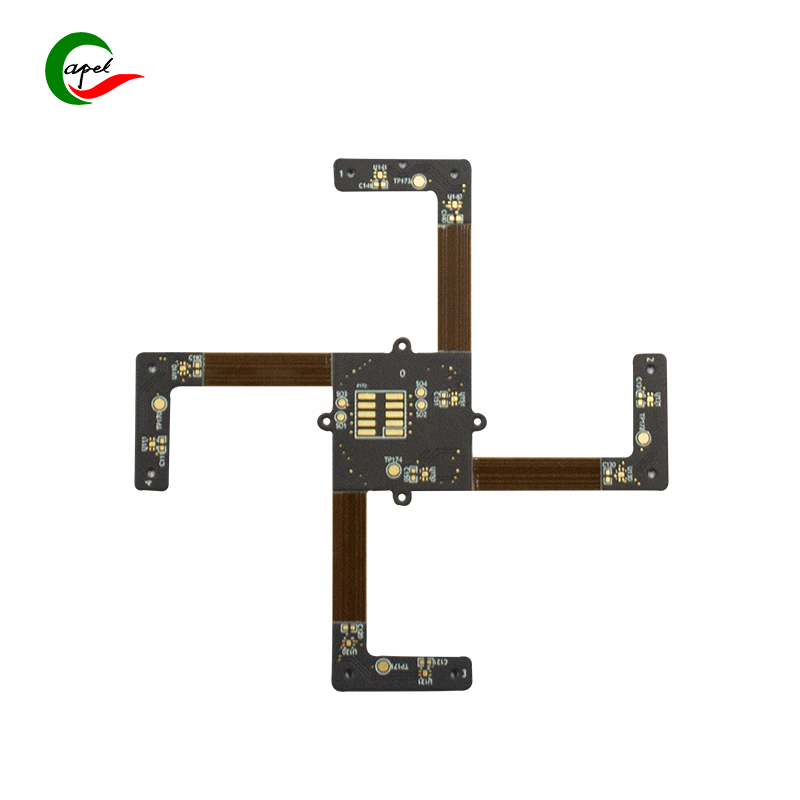

I-HDI (i-High Density Interconnect) i-rigid-flex PCB yindlela ephuculweyo yebhodi yesekethe eprintiweyo edibanisa iingenelo ze-high-density interconnection kunye nokuguquguquka.Le ndibaniselwano ikhethekileyo ibenza bafaneleke ngokufanelekileyo ukuhlangabezana neemfuno zezixhobo zombane zanamhlanje.

Uqhagamshelo olunoxinaniso oluphezulu lubhekiselele ekukwazini ukuphumeza amacandelo anoxinano oluphezulu kunye nendlela yomqondiso phakathi kwesithuba sebhodi esinyiniweyo.Njengoko imfuno yezixhobo ezincinci, ezixineneyo ziqhubeka zikhula, itekhnoloji ye-HDI yenza ukuba uyilo kunye nokuveliswa kweesekethe ezinzima kwizinto ezincinci. Ukuxinana koqhagamshelwano olongeziweyo kuvumela ukusebenza okungakumbi ukuba kudityaniswe kwizixhobo ezincinci, kuzenze zisebenze ngakumbi kwaye zibe namandla.

Ukuba bhetyebhetye lolunye uphawu oluphambili lweePCBs zeHDI eziqinileyo. Oku kuguquguquka kuvumela ibhodi ukuba igobe, isongwe okanye ijijwe ngaphandle kokuchaphazela ukusebenza okanye ukuthembeka.Ukuba bhetyebhetye kuluncedo ngakumbi kwizixhobo zombane ezifuna uyilo lomzimba oluntsonkothileyo okanye ezifuna ukumelana nokungcangcazela, ukothuka, okanye imeko-bume egqithisileyo. Kwakhona kwenza ukudityaniswa komthungo kwamacandelo e-elektroniki ukusuka kumacandelo ebhodi yeesekethe ahlukeneyo, ukuphelisa imfuno yokudibanisa okanye iintambo ezongezelelweyo.

Ukusebenzisa itekhnoloji yeHDI ibonelela ngeenzuzo ezininzi.Okokuqala, iphucula kakhulu imfezeko yesignali ngokunciphisa umgama phakathi kwamacandelo kunye noqhagamshelo, ukunciphisa ilahleko yesiginali, i-crosstalk kunye nokuphazamiseka kwe-electromagnetic. Oku kwandisa ukusebenza kunye nokuthembeka kwi-high-speed digital applications kunye neRF. Okwesibini, i-HDI eqinile-eguquguqukayo i-PCB inokunciphisa kakhulu ubungakanani kunye nobunzima bezixhobo zombane. Itekhnoloji ye-HDI iphelisa imfuno yokudibanisa okongeziweyo, iintambo, kunye nokudibanisa ibhodi ukuya kwibhodi, evumela ukudibanisa, ukuyila okulula. Oku kubaluleke kakhulu kumashishini afana ne-aerospace kunye nombane ophathwayo wabathengi, apho ukonga ubunzima kunye nendawo kubalulekile. Ukongeza, itekhnoloji ye-HDI ikwaphucula ukuthembeka kwezixhobo zombane. Ngokunciphisa inani le-interconnects, ii-PCB ze-HDI eziqinileyo zinciphisa umngcipheko wokungaphumeleli ngenxa yoxhumo oluxekekileyo okanye ukudinwa kwe-solder joint. Oku kuphucula umgangatho wemveliso kwaye kwandisa ukuthembeka kwexesha elide.

Izicelo ze-HDI eziqinileyo zifumaneka kumashishini ahlukeneyo, kuquka i-aerospace, izixhobo zonyango, unxibelelwano kunye ne-electronics yabathengi.Kwishishini le-aerospace, ii-PCB ze-HDI ezi-rigid-flex zisetyenziswa kwiinkqubo zokulawula inqwelomoya, ii-avionics, kunye neenkqubo zonxibelelwano ngenxa yobukhulu bazo obubambeneyo, ubunzima bokukhanya, kunye nokukwazi ukumelana neemeko ezinzima. Kwicandelo lezonyango, zisetyenziswa kwizixhobo ezifana ne-pacemakers, iinkqubo zokuxilonga zonyango, kunye nezixhobo ezifakelwayo. I-Telecommunications kunye ne-electronics zabathengi zixhamla kubungakanani obuncitshisiweyo kunye nokusebenza okuphuculweyo kwe-HDI eqinile-flex PCBs kwii-smartphones, iipilisi, izinto ezinxitywayo kunye nezinye izixhobo eziphathekayo.

2.Inkqubo yokuvelisa i-HDI eqinile-eguquguqukayo ye-PCB: Inyathelo nenyathelo

A. Imiqobo yoyilo kwaye ulungiselele iifayile zeCAD:

Isinyathelo sokuqala kwi-HDI engqongqo-flex inkqubo yokuvelisa i-PCB kukuqwalasela imiqobo yoyilo kunye nokulungiselela iifayile ze-CAD. Imiqobo yoyilo idlala indima ebalulekileyo ekumiseleni ukusebenza kwePCB, ukuthembeka, kunye nokwenziwa. Eminye imiqobo yoyilo ebalulekileyo ekufuneka iqwalaselwe zezi:

Ubungakanani bomlinganiselo:

Ubungakanani bePCB buxhomekeke kwiimfuno zesixhobo esetyenziswa kuso. Kuyimfuneko ukuqinisekisa ukuba iPCB ingena kwindawo echongiweyo ngaphandle kokuchaphazela ukusebenza okanye ukuthembeka.

Ukuthembeka:

Uyilo lwePCB kufuneka luthembeke kwaye lukwazi ukumelana neemeko zokusebenza ezilindelekileyo. Izinto ezifana nobushushu, ukufuma, ukungcangcazela kunye noxinzelelo lomatshini kufuneka ziqwalaselwe ngexesha lenkqubo yoyilo.

Umqondiso weMfezeko:

Uyilo kufuneka luthathele ingqalelo imfezeko yomqondiso ukunciphisa umngcipheko wokuthomalalisa umqondiso, ingxolo, okanye uphazamiseko. Isantya esiphezulu sedijithali kunye neempawu ze-RF zifuna umzila ngononophelo kunye nolawulo lokuthintela.

Ulawulo lobushushu:

Ulawulo lwe-thermal lubalulekile ekuthinteleni ukushisa kunye nokuqinisekisa ukusebenza kakuhle kwezinto ze-elektroniki. Ukutshatyalaliswa kobushushu kunokufezekiswa ngokubeka ngokufanelekileyo ii-vias ze-thermal, ii-sinks zobushushu, kunye neepads ezishushu. Isoftware yeCAD isetyenziselwa ukwenza iifayile zoyilo zePCB. Ivumela abaqulunqi ukuba bachaze ukupakishwa komaleko, ukubekwa kwecandelo kunye nokulandela umkhondo wobhedu. Isoftware yeCAD ibonelela ngezixhobo kunye nobuchule bokumela ngokuchanekileyo kunye nombono woyilo, okwenza kube lula ukuchonga kunye nokulungisa naziphi na iingxaki ezinokuthi zibekho phambi kwemveliso.

B. UKhetho lweMathiriyeli kunye noYilo loLuhlulo:

Emva kokulungiselela iifayile zeCAD, inyathelo elilandelayo kukukhethwa kwezinto kunye noyilo lwe-layup. Ukukhetha izinto ezifanelekileyo kubalulekile ekuqinisekiseni ukuba ii-PCB ze-HDI eziguquguqukayo zifezekisa ukusebenza kombane okufunekayo, ulawulo lwe-thermal, kunye nokuthembeka koomatshini. Izinto zomaleko eziqinileyo, ezifana ne-FR-4 okanye i-laminates ephezulu yokusebenza, zibonelela ngenkxaso yomatshini kunye nokuzinza. Uluhlu oluguquguqukayo ngokuqhelekileyo lwenziwe ngefilimu ye-polyimide okanye i-polyester yokuguquguquka kunye nokuqina. Inkqubo yoyilo lwe-stackup ibandakanya ukumisela ukulungelelaniswa kweeleyile ezahlukeneyo, kubandakanywa iileya eziqinileyo kunye neziguquguqukayo, ubukhulu bobhedu, kunye nezixhobo ze-dielectric. Uyilo lwe-stackup kufuneka luqwalasele izinto ezinje ngemfezeko yomqondiso, ulawulo lwe-impedance, kunye nokuhanjiswa kwamandla. Ukubekwa ngokufanelekileyo komaleko kunye nokukhethwa kwezinto kunceda ukuqinisekisa ukuhanjiswa kwesignali ngokufanelekileyo, ukunciphisa i-crosstalk kunye nokubonelela ukuguquguquka okuyimfuneko.

C. Ukugrunjwa kweLaser kunye nokwenziwa komngxuma omncinci:

Ukuqhuba iLaser linyathelo elibalulekileyo ekudaleni uxinaniso oluphezulu lwe-microvias kwii-HDI PCB. IMicrovias yimingxunya emincinci esetyenziselwa ukudibanisa iileya ezahlukeneyo zePCB, ivumela uqhagamshelo oluphezulu loxinaniso. Ukugrumba ngeLaser kunika iingenelo ezininzi kuneendlela zokomba zemveli. Ivumela imingxuma emincinci, ivumela ukuxinana kwendlela ephezulu kunye noyilo oluxineneyo ngakumbi. I-Laser drilling nayo inika ukuchaneka okukhulu kunye nokulawula, ukunciphisa umngcipheko wokungahambi kakuhle okanye umonakalo kwizinto ezijikelezileyo. Kwinkqubo yokugaya i-laser, i-laser beam egxininisiweyo isetyenziselwa ukucima izinto eziphathekayo, ukudala imingxuma emincinci. Imingxuma emva koko yenziwe ngesinyithi ukunika i-conductivity phakathi kwamaleko, ivumela ukuhanjiswa okusebenzayo kwemiqondiso.

D. Ukufakwa kwemichiza yobhedu:

I-electroless copper plating yinyathelo eliphambili kwinkqubo yokwenziwa kweebhodi ze-HDI eziqinileyo-flex. Inkqubo ibandakanya ukubeka umaleko obhityileyo wobhedu ngaphakathi kwemicropores nakumphezulu wePCB. Ukubaluleka kwe-electroless copper plating kumandla ayo okuqinisekisa uqhagamshelo oluthembekileyo lombane kunye nokuhanjiswa komqondiso olungileyo. Umaleko wobhedu ugcwalisa i-microvias kwaye udibanise iileya ezahlukeneyo ze-PCB, zenze indlela yokuqhuba imiqondiso. Ikwabonelela ngomphezulu othengiswayo wokudibanisa icandelo. Inkqubo yokucwenga yobhedu engena-electro ibandakanya amanyathelo amaninzi, kubandakanywa ukulungiswa komphezulu, ukusebenza kunye nokubekwa. I-PCB icocwa kuqala kwaye isebenze ukukhuthaza ukunamathela. Ukusabela kweekhemikhali kusetyenziselwa ukusebenzisa isisombululo esiqulethe iiyoni zobhedu kumphezulu wePCB, ukubeka umaleko obhityileyo wobhedu.

E. Ukugqithiselwa koMfanekiso kunye neLithography:

Ukuhanjiswa komfanekiso kunye ne-photolithography zizinto zenkqubo yokuvelisa i-PCB eqinile ye-HDI. La manyathelo abandakanya ukusebenzisa i-photoresist imathiriyeli ukwenza ipateni yesekethe kumphezulu we-PCB kwaye iveze ukukhanya kwe-UV ngokusebenzisa i-photomask enepateni. Ngexesha lenkqubo yokudlulisa umfanekiso, i-photoresist imathiriyeli isetyenziswa kumphezulu wePCB. Izixhobo zePhotoresist zinovelwano kukukhanya kwe-UV kwaye zinokuvezwa ngokukhethiweyo. I-PCB ke ilungelelaniswe ne-photomask enepateni kunye nokukhanya kwe-UV kudlula kwiindawo ezicacileyo ze-photomask ukubonisa i-photoresist. Emva kokuvezwa, i-PCB iphuhliswa ukususa i-photoresist engabonakaliyo, ishiya ipateni yesekethe efunekayo. Ezi patheni zisebenza njengemigangatho yokukhusela kwiinkqubo ezilandelayo. Ukudala umkhondo wesiphaluka, iikhemikhali ze-etching zisetyenziselwa ukususa ubhedu olungafunekiyo. Imimandla engagutyungelwe yi-photoresist ibonakaliswe kwi-etchant, ekhetha ukususa ubhedu, ishiya imikhondo yesekethe efunwayo.

F. Inkqubo ye-Etching kunye ne-electroplating:

Injongo yenkqubo ye-etching kukususa ubhedu olugqithisileyo kunye nokudala imikhondo yesekethe kwi-HDI eqinile-flex PCB. I-Etching ibandakanya ukusebenzisa i-etchant, ngokuqhelekileyo i-asidi okanye isisombululo sekhemikhali, ngokukhetha ukususa ubhedu olungafunekiyo. I-etching ilawulwa ngumaleko we-photoresist okhuselayo okhusela i-etchant ekuhlaseleni imikhondo yesekethe efunekayo. Lawula ngononophelo ixesha kunye noxinzelelo lwe-etchant ukufezekisa ububanzi obufunwayo kunye nobunzulu. Emva kwe-etching, i-photoresist eseleyo iyahluthwa ukuze iveze imikhondo yesiphaluka. Inkqubo yokuhlutha ibandakanya ukusebenzisa i-solvents ukunyibilika nokususa i-photoresist, ukushiya imikhondo yesekethe ecocekileyo kwaye echazwe kakuhle. Ukuqinisa umkhondo wesekethe kunye nokuqinisekisa ukuhanjiswa okufanelekileyo, inkqubo yokubeka iyadingeka. Oku kubandakanya ukubeka umaleko owongezelelweyo wobhedu kwimikhondo yesekethe ngokusebenzisa inkqubo yokubeka i-electroplating okanye i-electroless plating. Ubukhulu kunye nokufana kwe-copper plating kubaluleke kakhulu ekufezekiseni uxhumano oluthembekileyo lombane.

G. Usetyenziso lwemaski yeSolder kunye nendibano yecandelo:

Isicelo semaski ye-Solder kunye nendibano yecandelo ngamanyathelo abalulekileyo kwi-HDI eqinile-flex inkqubo yokuvelisa i-PCB. Sebenzisa imaski ye-solder ukukhusela imikhondo yobhedu kunye nokubonelela nge-insulation phakathi kwabo. Imaski yeSolder yenza umaleko okhuselayo kuwo wonke umphezulu wePCB, ngaphandle kweendawo ezifuna i-soldering, njengeepads zecandelo kunye ne-vias. Oku kunceda ukukhusela i-solder bridging kunye neebhulukhwe ezimfutshane ngexesha lendibano. Ukudityaniswa kwecandelo kubandakanya ukubeka amacandelo e-elektroniki kwi-PCB kunye nokuwathengisa endaweni. Amacandelo abekwe ngokucophelela kwaye ahambelane nephedi yokuhlalisa ukuqinisekisa ukudibanisa okufanelekileyo kombane. Sebenzisa ubuchule be-soldering njenge-reflow okanye i-wave soldering ngokuxhomekeke kuhlobo lwecandelo kunye neemfuno zendibano. Inkqubo ye-reflow soldering ibandakanya ukufudumeza i-PCB kwiqondo elithile elibangela ukuba i-solder inyibilike kwaye yenze uxhulumaniso olusisigxina phakathi kwecandelo elikhokelela kunye neepads ze-PCB. I-Wave soldering idla ngokusetyenziselwa izinto zokungena emngxunyeni, apho iPCB igqithiswa ngamaza atyhidiweyo ukuze yenze uqhagamshelwano.

H. Uvavanyo kunye noLawulo loMgangatho:

Isinyathelo sokugqibela kwinkqubo yokuvelisa i-HDI eqinile-flex PCB kukuvavanya kunye nokulawula umgangatho. Uvavanyo olungqongqo lubalulekile ukuqinisekisa ukusebenza kwePCB, ukuthembeka kunye nokusebenza. Yenza iimvavanyo zombane ukujonga iibhulukhwe ezimfutshane, ukuvula, kunye nokuqhubekeka. Oku kubandakanya ukusetyenziswa kombane okhethekileyo kunye nemisinga kwi-PCB kunye nokulinganisa impendulo usebenzisa izixhobo zovavanyo oluzenzekelayo. Uhlolo olubonakalayo lwenziwa kwakhona ukuqinisekisa umgangatho odibeneyo we-solder, ukubekwa kwecandelo, kunye nokucoceka ngokubanzi kwe-PCB. Inceda ukuchonga naziphi na iziphene ezinokubakho ezifana namacandelo angalungelelaniswanga, iibhulorho ze-solder, okanye ungcoliseko. Ukongeza, uhlalutyo loxinzelelo lwe-thermal lunokwenziwa ukuvavanya ukukwazi kwePCB ukumelana nokuhamba ngebhayisikile yobushushu okanye ukothuka kwe-thermal. Oku kubaluleke kakhulu kwizicelo apho i-PCB ibonakaliswe kutshintsho olugqithisileyo lobushushu. Ngexesha nasemva kwenyathelo ngalinye lenkqubo yokwenziwa, amanyathelo olawulo lomgangatho aphunyeziwe ukuqinisekisa ukuba iPCB iyahlangabezana nemigaqo nemigangatho efunekayo. Oku kubandakanya iiparamitha zenkqubo yokubeka iliso, ukulawulwa kwenkqubo yobalo (i-SPC), kunye nokwenza uphicotho lwamaxesha athile ukuze kuchongwe kwaye kulungiswe nakuphi na ukutenxa okanye ukuphambuka.

3. Imiceli mngeni ejongene nokwenza iibhodi zeHDI eziqinileyo:

Ukuvelisa iibhodi ze-HDI ezingqongqo-eziguquguqukayo zibonakalisa ubunzima kunye nemingeni ekufuneka ilawulwe ngononophelo ukuqinisekisa imveliso yomgangatho ophezulu.Le mingeni ijikeleza kwiindawo ezintathu eziphambili: ukulungelelaniswa okuchanekileyo, iziphene zomhlaba, kunye nokutshintsha kwe-impedance ngexesha lokuhlamba.

Ulungelelwaniso oluchanekileyo lubalulekile kwiibhodi ze-HDI eziguquguqukayo kuba zibandakanya iileya ezininzi kunye nezinto ezimele zibekwe ngokuchanekileyo. Ukufezekisa ulungelelwaniso oluchanekileyo kufuna ukuphathwa ngononophelo kunye nokubekwa kweeleya ezahlukeneyo ukuqinisekisa ukuba i-vias kunye namanye amacandelo alungelelaniswe ngokufanelekileyo. Nakuphi na ukungahambi kakuhle kunokubangela iingxaki ezinkulu ezifana nokulahlekelwa ngumqondiso, iifutshane, okanye ukuphuka. Abavelisi kufuneka batyale imali kwizixhobo eziphambili kunye nobuchwepheshe bokuqinisekisa ulungelelwaniso oluchanekileyo kuyo yonke inkqubo yokuvelisa.

Ukuphepha iziphene ezingaphezulu ngomnye ucelomngeni olukhulu. Ngethuba lokwenziwa kwenkqubo yokuvelisa, iziphene ezingaphezulu ezifana nemikrwelo, amazinyo, okanye ukungcola kunokwenzeka, okuchaphazela ukusebenza kunye nokuthembeka kweebhodi ze-HDI rigid-flex.Ezi ziphene zinokuphazamisana nokudibanisa kombane, zichaphazela ingqibelelo yomqondiso, okanye zibangele ukuba ibhodi ingaphumeleli ngokupheleleyo. Ukuthintela iziphene zomhlaba, amanyathelo angqongqo okulawula umgangatho kufuneka athathwe, kubandakanywa ukuphatha ngokucophelela, ukuhlolwa rhoqo, kunye nokusetyenziswa kwendawo ecocekileyo ngexesha lokuvelisa.

Ukunciphisa utshintsho lwe-impedance ngexesha le-lamination kubalulekile ekugcineni ukusebenza kombane kwiibhodi ze-HDI rigid-flex.Ukwanyisa kubandakanya ukusebenzisa ubushushu kunye noxinzelelo ukudibanisa iileya ezahlukeneyo. Nangona kunjalo, le nkqubo inokubangela utshintsho kwi-dielectric engaguqukiyo kunye nobubanzi be-conductor, okukhokelela kutshintsho olungathandekiyo lwe-impedance. Ukulawula inkqubo yokulambisa ukunciphisa olu tshintsho kufuna ulawulo oluchanekileyo lobushushu, uxinzelelo, kunye nexesha, kunye nokubambelela ngokungqongqo kwiinkcukacha zoyilo. Ukongeza, uvavanyo oluphambili kunye neendlela zokuqinisekisa zinokuqeshwa ukuqinisekisa ukuba i-impedance efunekayo iyagcinwa.

Ukoyisa le mingeni ekuveliseni iibhodi ze-HDI flex zifuna abaqulunqi kunye nabavelisi ukuba basebenze ngokusondeleyo kunye kuyo yonke inkqubo.Abaqulunqi kufuneka baqwalasele ngononophelo imiqobo yokuvelisa kwaye banxibelelane ngokufanelekileyo nabavelisi. Kwelinye icala, abavelisi kufuneka baqonde iimfuno zoyilo kunye nezithintelo ukuze kuphunyezwe inkqubo efanelekileyo yokuvelisa. Ukusebenzisana kunceda ukujongana nemiba enokwenzeka kwangethuba kwisigaba soyilo kwaye iqinisekisa ukuba inkqubo yokuvelisa ilungiselelwe iibhodi ezikumgangatho ophezulu weHDI rigid-flex.

Isiphelo:

Inkqubo yokwenziwa kwe-HDI i-rigid-flex PCB luluhlu lwamanyathelo anzima kodwa abalulekileyo afuna iteknoloji yezakhono, ezichanekileyo nezithembekileyo.Ukuqonda inqanaba ngalinye lenkqubo kwenza iCapel ikwazi ukwandisa amandla abo okubonelela ngemveliso egqwesileyo ngexesha elibekiweyo. Ngokubeka phambili iinzame zokuyila ngokubambisana, i-automation kunye nokuphuculwa kwenkqubo eqhubekayo, iCapel inokuhlala phambili kwi-HDI i-rigid-flex PCB yokuvelisa kunye nokuhlangabezana nemfuno ekhulayo yeebhodi ezininzi ezisebenzayo kunye neziphezulu kumashishini.

Ixesha lokuposa: Sep-15-2023

Emva