Eli nqaku liza kubonelela ngombono obanzi wenkqubo yonyango yomphezulu weFPC Flex PCB yokuvelisa. Ukususela kukubaluleka kokulungiswa komphezulu kwiindlela ezahlukeneyo zokugubungela umphezulu, siya kugubungela ulwazi oluphambili ukukunceda uqonde kwaye uphumeze inkqubo yokulungiselela umphezulu ngokufanelekileyo.

Intshayelelo:

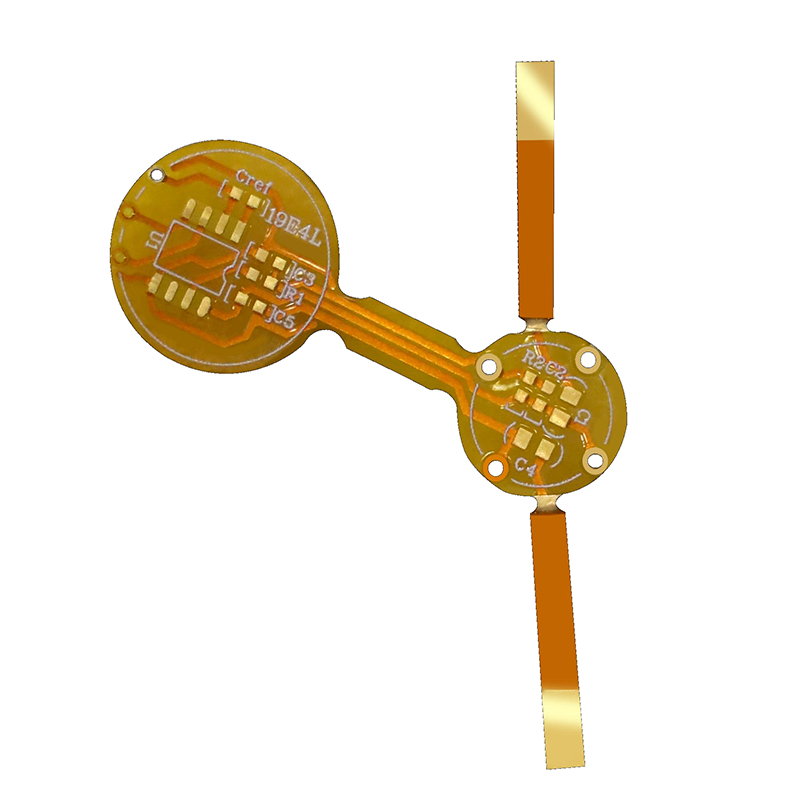

Ii-PCB eziguquguqukayo (iiBhodi zeSekethe eziShicilelekayo eziFlexible) zifumana ukuthandwa kuwo wonke amashishini ahlukeneyo ngenxa yokuguquguquka kwazo kunye nokukwazi ukuziqhelanisa neemilo ezintsonkothileyo. Iinkqubo zamalungiselelo omphezulu zidlala indima ebalulekileyo ekuqinisekiseni ukusebenza ngokupheleleyo kunye nokuthembeka kwezi sekethe ezibhetyebhetye. Eli nqaku liza kubonelela ngombono obanzi wenkqubo yonyango yomphezulu weFPC Flex PCB yokuvelisa. Ukususela kukubaluleka kokulungiswa komphezulu kwiindlela ezahlukeneyo zokugubungela umphezulu, siya kugubungela ulwazi oluphambili ukukunceda uqonde kwaye uphumeze inkqubo yokulungiselela umphezulu ngokufanelekileyo.

Imixholo:

1. Ukubaluleka konyango olungaphezulu kwi-FPC flex PCB yokwenziwa:

Unyango lomphezulu lubalulekile kwiFPC Flexible board mveliso njengoko isebenzela iinjongo ezininzi. Iququzelela i-soldering, iqinisekisa ukubambelela kakuhle, kwaye ikhusela i-conductive traces ukusuka kwi-oxidation kunye nokuthotywa kokusingqongileyo. Ukhetho kunye nomgangatho wonyango oluphezulu luchaphazela ngokuthe ngqo ukuthembeka kunye nokusebenza ngokubanzi kwe-PCB.

Ukugqitywa komphezulu kwiFPC Flex PCB mveliso kusebenzela iinjongo eziphambili ezininzi.Okokuqala, iququzelela i-soldering, iqinisekisa ukudibanisa okufanelekileyo kwamacandelo e-elektroniki kwi-PCB. Unyango lomphezulu luphucula ukuthengiseka kuqhagamshelo olunamandla noluthembekileyo phakathi kwecandelo kunye nePCB. Ngaphandle kokulungiswa okufanelekileyo kwendawo, i-solder joints ingaba buthathaka kwaye iyakwazi ukungaphumeleli, okubangelwa ukungasebenzi kakuhle kunye nomonakalo onokwenzeka kwisiphaluka sonke.

Omnye umba obalulekileyo wokulungiswa komphezulu kwiFPC Flex PCB yokuvelisa kukuqinisekisa ukuncamathela okulungileyo.Ii-FPC eziguquguqukayo ze-PCB zihlala zifumana ukugoba kunye nokuguquguquka ngexesha lobomi babo benkonzo, nto leyo ibeka uxinzelelo kwi-PCB kunye namalungu ayo. Unyango oluphezulu lunikeza umaleko wokukhusela ukuqinisekisa ukuba icandelo linamathele ngokuqinileyo kwi-PCB, ukuthintela ukuchithwa okunokwenzeka okanye umonakalo ngexesha lokuphatha. Oku kubaluleke kakhulu kwizicelo apho uxinzelelo lomatshini okanye ukungcangcazela kuqhelekileyo.

Ukongezelela, unyango olungaphezulu lukhusela i-conductive traces kwi-FPC Flex PCB kwi-oxidation kunye nokuthotywa kokusingqongileyo.Ezi PCB zihlala zisesichengeni sezinto ezahlukeneyo zokusingqongileyo ezifana nokufuma, utshintsho lobushushu kunye neekhemikhali. Ngaphandle kokulungiswa okwaneleyo komphezulu, iitrayisi eziqhubayo zinokugqwala ngokuhamba kwexesha, kubangele ukungaphumeleli kombane kunye nokungaphumeleli kwesekethe. Unyango lomphezulu lusebenza njengesithintelo, ukukhusela i-PCB kwindalo kunye nokwandisa ubomi bayo kunye nokuthembeka.

I-2.Iindlela zonyango eziqhelekileyo zokwenziwa kwe-FPC flex PCB:

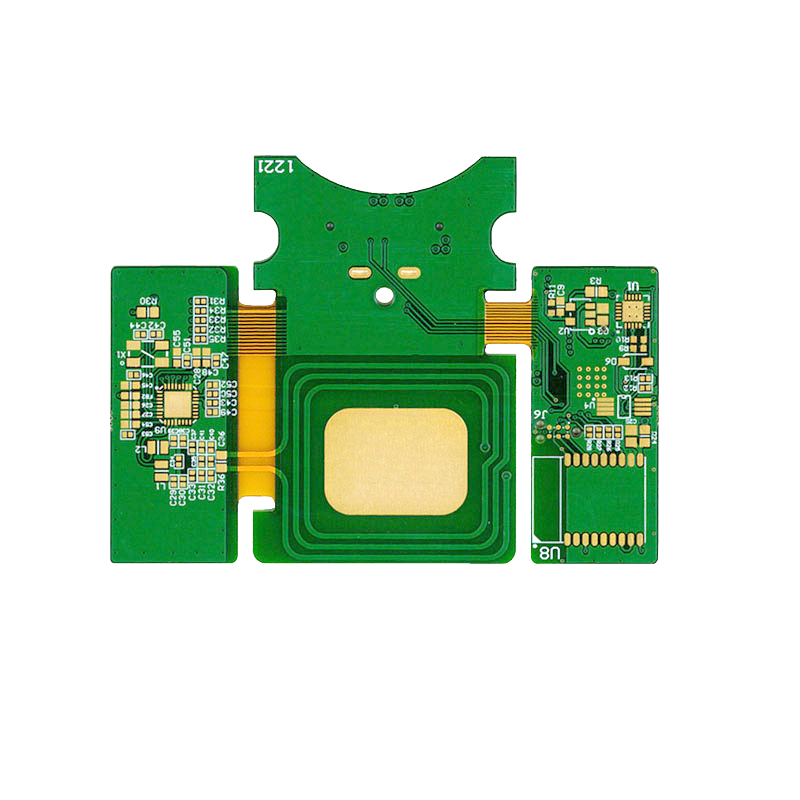

Eli candelo liza kuxubusha ngokubanzi iindlela zonyango ezisetyenziswa ngokuqhelekileyo kwi-FPC Flexible iibhodi zokuvelisa, kuquka i-Hot Air Solder Leveling (HASL), i-Electroless Nickel Immersion Gold (ENIG), i-Organic Solderability Preservative (OSP), i-Immersion Tin (ISn) kunye ne-electroplating (E-plating). Indlela nganye iya kuchazwa kunye nezinto eziluncedo kunye nezingeloncedo.

Umgangatho weSoda yoMoya oshushu (HASL):

I-HASL yindlela yonyango esetyenziswa ngokubanzi ngenxa yokusebenza kwayo kunye nokusebenza kakuhle kweendleko. Le nkqubo ibandakanya ukugquma umphezulu wobhedu ngomaleko we-solder, othi emva koko ufudunyezwe ngomoya oshushu ukuze wenze umphezulu ogudileyo nosicaba. I-HASL inikezela ngokuthengisa okugqwesileyo kwaye iyahambelana neentlobo ezahlukeneyo zamacandelo kunye neendlela zokuthengisa. Nangona kunjalo, ikwanezithintelo ezinjengomphezulu ongalinganiyo kunye nomonakalo onokwenzeka kumanqaku abuthathaka ngexesha lokulungiswa.

I-Electroless Nickel Immersion Gold (ENIG):

I-ENIG lukhetho oludumileyo kwimveliso yesekethe eguqukayo ngenxa yokusebenza kwayo okuphezulu kunye nokuthembeka. Le nkqubo ibandakanya ukubeka umaleko obhityileyo wenikeli kumphezulu wobhedu ngokusabela kwekhemikhali, ethi intywiliselwe kwisisombululo se-electrolyte esinamasuntswana egolide. I-ENIG inokumelana nokugqwesa okugqwesileyo, ukusabalalisa ubukhulu obufanayo kunye nokuthengiswa okulungileyo. Nangona kunjalo, iindleko eziphezulu ezinxulumene nenkqubo kunye nemiba enokubakho yeephedi ezimnyama zezinye zezinto ezinokuthi ziqwalaselwe.

I-Organic Solderability Preservative (OSP):

I-OSP yindlela yonyango yomphezulu ebandakanya ukugquma umphezulu wobhedu ngefilimu ebhityileyo ephilayo ukuyinqanda kwi-oxidizing. Le nkqubo ihambelana nokusingqongileyo njengoko iphelisa imfuno yesinyithi esinzima. I-OSP ibonelela ngomphezulu othe tyaba kunye ne-solderability elungileyo, iyenza ilungele amacandelo epitch entle. Nangona kunjalo, i-OSP inobomi beshelufu obulinganiselweyo, inovakalelo ekuphatheni, kwaye ifuna iimeko ezifanelekileyo zokugcina ukugcina ukusebenza kwayo.

Itoti yokuntywiliselwa (ISn):

I-ISn yindlela yonyango engaphezulu ebandakanya ukuntywiliselwa kwesekethe eguquguqukayo kwibhafu yetoti etyhidiweyo. Le nkqubo yenza umaleko obhityileyo wetoti kumphezulu wobhedu, onobuchwephesha obugqwesileyo, ubucaba kunye nokumelana nokubola. I-ISn ibonelela ngokugqitywa komphezulu ogudileyo iyenza ilungele usetyenziso lwepitch entle. Nangona kunjalo, inokumelana nobushushu okulinganiselweyo kwaye inokufuna ukuphathwa okukhethekileyo ngenxa yobunzima be-tin.

Electroplating (E plating):

I-Electroplating yindlela eqhelekileyo yonyango lomphezulu kwimveliso yesekethe eguquguqukayo. Inkqubo ibandakanya ukubeka i-metal layer kwindawo yobhedu ngokusebenzisa i-electrochemical reaction. Ngokuxhomekeke kwiimfuno zesicelo, i-electroplating ifumaneka kwiinketho ezahlukeneyo ezifana negolide, isilivere, i-nickel okanye i-tin plating. Inika ukuqina okugqwesileyo, ukuthengiseka kunye nokumelana nomhlwa. Nangona kunjalo, kubiza kakhulu xa kuthelekiswa nezinye iindlela zonyango ezingaphezulu kwaye zifuna izixhobo ezinzima kunye nolawulo.

3.Izilumkiso zokukhetha indlela yonyango echanekileyo kwi-FPC flex PCB yokwenziwa:

Ukukhetha umphezulu ochanekileyo wokugqitywa kweesekethe eziguquguqukayo ze-FPC kufuna uqwalaselo ngononophelo lwemiba eyahlukeneyo efana nesicelo, iimeko zokusingqongileyo, iimfuno ze-solderability, kunye nokusebenza kakuhle kweendleko. Eli candelo liza kunika isikhokelo ekukhetheni indlela efanelekileyo esekelwe kwezi ngqwalasela.

Zazi iimfuno zabathengi:

Phambi kokuphonononga kunyango olukhoyo olukhoyo, kubalulekile ukuba ube nokuqonda okucacileyo kweemfuno zabathengi. Qwalasela ezi nkalo zilandelayo:

Isicelo:

Qinisekisa usetyenziso olucetywayo lweFPC yakho ebhetyebhetye PCB. Ngaba yeyombane wabathengi, iimoto, izixhobo zonyango okanye zoshishino? Ishishini ngalinye linokuba neemfuno ezithile, ezifana nokuchasana nobushushu obuphezulu, iikhemikhali okanye uxinzelelo lomatshini.

Imiqathango yokusingqongileyo:

Vavanya iimeko zokusingqongileyo eza kudibana nazo iPCB. Ngaba iya kuba sesichengeni sokufuma, ukufuma, amaqondo obushushu agqithisileyo okanye izinto ezidlekayo? Ezi zinto ziya kuba nefuthe kwindlela yokulungiswa komphezulu wokubonelela ngokhuseleko olungcono kwi-oxidation, i-corrosion kunye nokunye ukuthotywa.

Iimfuno zeSolderability:

Hlalutya iimfuno ze-solderability ze-FPC eziguquguqukayo ze-PCB. Ngaba ibhodi iya kuhamba nge-soldering ye-wave okanye inkqubo ye-reflow soldering? Unyango lomphezulu olwahlukileyo lunokuhambelana okwahlukileyo kunye nolu buchule bokuwelda. Ukuthathela ingqalelo oku kuya kuqinisekisa ukuba amalungu e-solder athembekileyo kwaye athintele iingxaki ezifana neziphene ze-solderability kwaye zivule.

Phonononga iindlela zoNyango kumphezulu:

Ngokuqonda okucacileyo iimfuno zabathengi, lixesha lokuphonononga unyango olukhoyo lomphezulu:

I-Organic Solderability Preservative (OSP):

I-OSP yiarhente yonyango lomphezulu edumileyo ye-FPC ebhetyebhetye kwiPCB ngenxa yokusebenza kakuhle kweendleko kunye neempawu zokhuselo lokusingqongileyo. Inika umaleko omncinci okhuselayo okhusela i-oxidation kwaye iququzelele i-soldering. Nangona kunjalo, i-OSP inokuba nokhuseleko olulinganiselweyo kwiimeko ezingqongileyo kunye nobomi obufutshane beshelufu kunezinye iindlela.

I-Electroless Nickel Immersion Gold (ENIG):

I-ENIG isetyenziswa kakhulu kumashishini ahlukeneyo ngenxa yokuthengiswa kwayo okugqwesileyo, ukuxhathisa umhlwa kunye nokucaba. Umaleko wegolide uqinisekisa uqhagamshelo oluthembekileyo, ngelixa umaleko we-nickel ubonelela ngokumelana ne-oxidation egqwesileyo kunye nokukhuselwa kwemekobume eqatha. Nangona kunjalo, i-ENIG iyabiza kakhulu xa ithelekiswa nezinye iindlela.

Igolide Elukhuni Eyenziwe Ngombane (Igolide Elukhuni):

Igolide enzima yomelele kakhulu kwaye ibonelela ngokuthembeka okugqwesileyo koqhagamshelwano, okwenza ukuba ilungele izicelo ezibandakanya ukufakwa ngokuphindaphindiweyo kunye neendawo zokunxiba eziphezulu. Nangona kunjalo, lolona khetho lubiza kakhulu kwaye alunakufunwa kulo lonke usetyenziso.

I-Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG):

I-ENEPIG yi-arhente yonyango yomhlaba osebenzayo ofanelekileyo kwizicelo ezahlukeneyo. Idibanisa izibonelelo ze-nickel kunye negolide kunye nenzuzo eyongeziweyo ye-palladium ephakathi umaleko, ibonelela ngokugqwesa ukubonda ngocingo kunye nokuxhathisa ukubola. Nangona kunjalo, i-ENEPIG ithande ukubiza kakhulu kwaye inzima ukuyiqhuba.

4.ISikhokelo esiBanzi ngeNyathelo kwiiNkqubo zokuLungisa uMphezulu kwiFPC flex PCB yokuvelisa:

Ukuqinisekisa ukuphunyezwa ngempumelelo kweenkqubo zokulungiselela umphezulu, kubalulekile ukulandela indlela ecwangcisiweyo. Eli candelo liza kubonelela ngesikhokelo esineenkcukacha ngenyathelo ngalinye esigubungela ukunyangwa kwangaphambili, ukucocwa kweekhemikhali, ukufakwa kwe-flux, ukugquma komphezulu kunye neenkqubo zonyango emva kokunyanga. Inyathelo ngalinye licaciswa ngokucokisekileyo, liqaqambisa ubuchule obufanelekileyo kunye nezenzo ezilungileyo.

Inyathelo 1: Ukusetyenzwa kwangaphambili

Unyango lwangaphambili linyathelo lokuqala lokulungiswa komphezulu kwaye libandakanya ukucocwa kunye nokususwa kongcoliseko lomhlaba.

Okokuqala jonga umphezulu nawuphi na umonakalo, ukungafezeki okanye ukubola. Le miba kufuneka isonjululwe phambi kokuba kuthathwe amanyathelo angaphaya. Emva koko, sebenzisa umoya oxinzelelweyo, ibrashi, okanye ivacuum ukususa naziphi na iintwanantwana, uthuli, okanye ubumdaka. Ukosuleleka okunenkani ngakumbi, sebenzisa isinyibilikisi okanye isicoci sekhemikhali esenzelwe ngokukodwa imathiriyeli engaphezulu. Qinisekisa ukuba umphezulu womile kakuhle emva kokucoca, njengoko ukufuma okushiyekileyo kunokuthintela iinkqubo ezilandelayo.

Inyathelo lesi-2: Ukucoca ngemichiza

Ukucocwa kweekhemikhali kubandakanya ukususa nayiphi na inkunkuma eseleyo kumphezulu.

Khetha ikhemikhali efanelekileyo yokucoca ngokusekelwe kwizinto ezingaphezulu kunye nohlobo lokungcola. Faka isicoci ngokulinganayo kumphezulu kwaye uvumele ixesha elaneleyo lokunxibelelana ukuze ususwe ngempumelelo. Sebenzisa ibhrashi okanye i-pad yokucoca ukuze uhlambe ngobumnene umphezulu, ubeke ingqalelo kwiindawo ezinzima ukufikelela kuzo. Hlanza umphezulu kakuhle ngamanzi ukususa nayiphi na intsalela yesicoci. Inkqubo yokucoca imichiza iqinisekisa ukuba umphezulu ucoceke ngokupheleleyo kwaye ulungele ukusetyenzwa okulandelayo.

Inyathelo 3: Isicelo seFlux

Ukusetyenziswa kwe-flux kubaluleke kakhulu kwi-brazing okanye inkqubo ye-soldering njengoko ikhuthaza ukunamathela okungcono kunye nokunciphisa i-oxidation.

Khetha uhlobo olufanelekileyo lwe-flux ngokwezinto eziza kudibaniswa kunye neemfuno zenkqubo ethile. Faka i-flux ngokulinganayo kwindawo edibeneyo, uqinisekise ukugubungela ngokupheleleyo. Qaphela ukuba ungasebenzisi i-flux engaphezulu njengoko inokubangela iingxaki zokuthengisela. I-Flux kufuneka isetyenziswe ngokukhawuleza ngaphambi kokuba i-soldering okanye inkqubo ye-soldering igcine ukusebenza kwayo.

Inyathelo lesi-4: Ukugquma umphezulu

Iingubo zomphezulu zinceda ukukhusela iindawo ezivela kwiimeko zokusingqongileyo, zithintele ukubola kunye nokuphucula ukubonakala kwazo.

Ngaphambi kokufaka isambatho, lungiselela ngokwemiyalelo yomenzi. Gcoba idyasi ngononophelo usebenzisa ibrashi, irola okanye isitshizi, uqinisekise ngokulinganayo kwaye ugudileyo. Qaphela ukomiswa okucetyiswayo okanye ukunyanga ubude phakathi kweedyasi. Ukuze ufumane iziphumo ezingcono, gcina iimeko ezifanelekileyo zokusingqongileyo ezifana namanqanaba obushushu kunye nokufuma ngexesha lokunyanga.

Inyathelo lesi-5: Inkqubo yasemva kokulungiswa

Inkqubo yonyango emva kokunyanga ibaluleke kakhulu ukuqinisekisa ukuba ixesha elide lokutyalwa komhlaba kunye nomgangatho opheleleyo wendawo elungiselelwe.

Emva kokuba i-coating iphiliswe ngokupheleleyo, jonga nayiphi na impazamo, amaqamza okanye ukungalingani. Lungisa ezi ngxaki ngokugalela okanye ukupolisha umphezulu, ukuba kuyimfuneko. Ukugcinwa rhoqo kunye nokuhlolwa kubalulekile ukuchonga naziphi na iimpawu zokuguga okanye umonakalo kwi-coating ukwenzela ukuba kulungiswe ngokukhawuleza okanye kusetyenziswe kwakhona xa kuyimfuneko.

Ulawulo lwe-5.Umgangatho kunye noVavanyo kwi-FPC flex PCB yokuvelisa inkqubo yonyango lomphezulu:

Ulawulo lomgangatho kunye novavanyo luyimfuneko ukuze kuqinisekiswe ukusebenza kweenkqubo zokulungisa umphezulu. Eli candelo liza kuxubusha iindlela ezahlukeneyo zokuvavanya, kubandakanywa ukuhlolwa okubonakalayo, ukuvavanywa kokubambelela, ukuvavanywa kwe-solderability, kunye nokuvavanya ukuthembeka, ukuqinisekisa umgangatho ohambelanayo kunye nokuthembeka kokuveliswa kwe-FPC Flex PCBs.

Ukuhlolwa okubonakalayo:

Ukuhlolwa okubonakalayo kuyinyathelo elisisiseko kodwa elibalulekileyo kulawulo lomgangatho. Ibandakanya ukuhlola ngokubonakalayo umphezulu we-PCB naziphi na iziphene ezifana nemikrwelo, i-oxidation okanye ungcoliseko. Olu hlolo lunokusebenzisa izixhobo zamehlo okanye imakroskopu ukubona naziphi na izinto ezingaqhelekanga ezinokuchaphazela ukusebenza okanye ukuthembeka kwePCB.

Uvavanyo lokuncamathela:

Uvavanyo lwe-adhesion lusetyenziselwa ukuvavanya amandla okubambelela phakathi konyango lomphezulu okanye i-coating kunye ne-substrate engaphantsi. Olu vavanyo luqinisekisa ukuba isiphelo sibotshelelwe ngokuqinileyo kwi-PCB, ukuthintela nakuphi na ukuqhawuka kwangaphambi kwexesha okanye ukuxobula. Ngokuxhomekeke kwiimfuno ezithile kunye nemigangatho, iindlela ezahlukeneyo zokuvavanya ukunamathela zinokusetyenziswa, njengovavanyo lweteyiphu, uvavanyo lokukrwempa okanye uvavanyo lokutsala.

Uvavanyo lweSolderability:

Uvavanyo lwe-Solderability luqinisekisa amandla onyango lwangaphezulu ukuququzelela inkqubo ye-soldering. Olu vavanyo luqinisekisa ukuba i-PCB esetyenzisiweyo iyakwazi ukwenza i-solder joints ezomeleleyo nezithembekileyo kunye namacandelo e-elektroniki. Iindlela eziqhelekileyo zovavanyo lwe-solderability ziquka uvavanyo lwe-solder float, uvavanyo lwe-solder wetting balance, okanye uvavanyo lokulinganisa ibhola ye-solder.

UVavanyo lokuthembeka:

Uvavanyo lokuthembeka luvavanya ukusebenza kwexesha elide kunye nokuqina kwe-FPC Flex PCBs ephathwayo phantsi kweemeko ezahlukeneyo. Olu vavanyo lwenza abavelisi bavavanye ukuxhathisa kwePCB kwibhayisekile yobushushu, ukufuma, ukubola, uxinzelelo kumatshini, kunye nezinye izinto zokusingqongileyo. Uvavanyo olukhawulezileyo lobomi kunye novavanyo lokulinganisa okusingqongileyo, olufana nokuhamba ngebhayisekile eshushu, uvavanyo lwesitshizi setyuwa okanye uvavanyo lokungcangcazela, zihlala zisetyenziselwa uvavanyo lokuthembeka.

Ngokuphumeza ulawulo olubanzi lomgangatho kunye neenkqubo zokuvavanya, abavelisi banokuqinisekisa ukuba ii-FPC Flex PCBs eziphathwe ngomphezulu zithobela imigangatho efunekayo kunye neenkcukacha. La manyathelo anceda ukufumanisa naziphi na iziphene okanye ukungahambelani kwangoko kwinkqubo yokuvelisa ukuze kuthathwe amanyathelo okulungisa ngexesha kwaye kuphuculwe umgangatho wemveliso ngokubanzi kunye nokuthembeka.

6.Ukusombulula iingxaki zokulungiswa komphezulu kwiFPC flex PCB yokwenziwa:

Imiba yonyango lomphezulu inokuthi yenzeke ngexesha lenkqubo yokuvelisa, echaphazela umgangatho uwonke kunye nokusebenza kwe-FPC eguquguqukayo ye-PCB. Eli candelo liza kuchonga imiba yolungiselelo lomphezulu oqhelekileyo kwaye libonelele ngeengcebiso zokulungisa iingxaki ukoyisa ngempumelelo le mingeni.

Ukubambelela kakubi:

Ukuba isiphelo asibambeleli ngokufanelekileyo kwi-PCB substrate, kunokubangela i-delamination okanye ukuxobula. Oku kungenxa yobukho bezingcolisi, uburhabaxa obungonelanga bomphezulu, okanye ukungasebenzi komphezulu onganelanga. Ukulwa noku, qiniseka ukuba umphezulu we-PCB ucocwe ngokucokisekileyo ukuze ususe nakuphi na ukungcoliseka okanye intsalela phambi kokuphatha. Ukongeza, lungisa uburhabaxa bomphezulu kwaye uqinisekise iindlela ezifanelekileyo zokusebenzisa umphezulu, njengonyango lweplasma okanye ukusebenza kweekhemikhali, zisetyenziselwa ukomeleza ukunamathela.

Ukwaleka okungalinganiyo okanye ubukhulu be-plating:

Ukwaleka okungalinganiyo okanye ubukhulu be-plating bunokuba sisiphumo solawulo olungonelanga lwenkqubo okanye ukwahluka koburhabaxa bomphezulu. Le ngxaki ichaphazela ukusebenza kunye nokuthembeka kwePCB. Ukoyisa le ngxaki, misela kwaye ubeke iliso kwiiparamitha zenkqubo ezifanelekileyo ezifana nokugquma okanye ixesha lokutya, ubushushu kunye noxinzelelo lwesisombululo. Ziqhelanise neendlela ezifanelekileyo zokuphazamisa okanye zokuphazamisa ngexesha lokugquma okanye ukugquma ukuqinisekisa ukusasazwa okufanayo.

Ukufakwa kwi-Oxidation:

Ii-PCB eziphathwa ngomphezulu zinokuthi zifakwe kwi-oxidize ngenxa yokuvezwa kukufuma, umoya, okanye ezinye ii-oxidizing agents. I-oxidation inokukhokelela ekuthengiseni okubi kunye nokunciphisa ukusebenza ngokubanzi kwe-PCB. Ukunciphisa i-oxidation, sebenzisa unyango olululo olusemgangathweni olufana ne-organic coatings okanye iifilimu ezikhuselayo ukubonelela ngomqobo ngokuchasene nokufuma kunye ne-oxidizing agents. Sebenzisa iindlela ezifanelekileyo zokuphatha nokugcina ukuze unciphise ukuba sesichengeni somoya nokufuma.

Usulelo:

Ukungcoliswa komphezulu we-PCB kunokuchaphazela kakubi ukunamathela kunye nokuthengiswa komphezulu wokugqiba. Ukungcola okuqhelekileyo kubandakanya uthuli, ioli, iminwe, okanye intsalela kwiinkqubo zangaphambili. Ukulwa noku, misela inkqubo yokucoca esebenzayo yokususa nayiphi na into engcolileyo ngaphambi kokulungiswa komphezulu. Sebenzisa iindlela ezifanelekileyo zokulahla ukunciphisa ukudibana kwezandla okanye ezinye iindawo zosulelo.

Ukuthengiseka kakubi:

Ukuthengiswa okulambathayo kunokubangelwa kukungabikho kokusebenza komphezulu okanye ukungcoliseka kumphezulu wePCB. Ukuthengiswa kakubi kunokukhokelela kwiziphene ze-weld kunye namalungu abuthathaka. Ukuphucula i-solderability, qinisekisa iindlela ezifanelekileyo zokuvula umphezulu onjengonyango lweplasma okanye ukusebenza kweekhemikhali zisetyenziselwa ukunyusa ukumanzisa komphezulu we-PCB. Kwakhona, sebenzisa inkqubo yokucoca esebenzayo ukususa nayiphi na into engcolileyo enokuthi ithintele inkqubo ye-welding.

7. Uphuhliso lwexesha elizayo lweFPC flex board yokwenziwa konyango lomphezulu:

Intsimi yokugqitywa komphezulu kwii-PCB eziguquguqukayo ze-FPC iyaqhubeka nokuvela ukuze ihlangabezane neemfuno zetekhnoloji kunye nezicelo ezikhulayo. Eli candelo liza kuxoxa ngophuhliso olunokwenzeka kwixesha elizayo kwiindlela zonyango ezingaphezulu ezifana nemathiriyeli emitsha, ubugcisa bokugquma obuphambili, kunye nezisombululo ezihambelana nokusingqongileyo.

Uphuhliso olunokwenzeka kwixesha elizayo lonyango lomphezulu we-FPC kukusetyenziswa kwemathiriyeli emitsha eneempawu eziphuculweyo.Abaphandi baphonononga ukusetyenziswa kweenoveli kunye nezixhobo zokuphucula ukusebenza kunye nokuthembeka kwe-FPC eguquguqukayo yePCB. Ngokomzekelo, iingubo zokuziphilisa ziphandwa, ezinokulungisa nawuphi na umonakalo okanye imikrwelo kumphezulu we-PCB, ngaloo ndlela ukwandisa ixesha lokuphila kunye nokuqina. Ukongeza, imathiriyeli ephuculweyo ye-thermal conductivity iyaphononongwa ukuphucula isakhono se-FPC sokuchitha ubushushu ukuze kusebenze ngcono kwizicelo zobushushu obuphezulu.

Olunye uphuhliso lwexesha elizayo kukuqhubela phambili kobugcisa bokugquma.Iindlela ezintsha zokugquma ziyaphuhliswa ukunika ukuchaneka ngakumbi kunye nokufana okufanayo kwimigangatho yeFPC. Ubuchwephesha obufana ne-Atomic Layer Deposition (ALD) kunye ne-Plasma ephuculweyo ye-Chemical Vapor Deposition (PECVD) ivumela ulawulo olungcono lobuninzi bokugquma kunye nokubunjwa, okukhokelela ekuphuculeni ukuthengiswa kunye nokubambelela. Obu buchwephesha bokugquma obuphambili bunamandla okunciphisa ukuguquguquka kwenkqubo kunye nokuphucula ukusebenza kakuhle kwemveliso.

Ukongeza, kukho ugxininiso olwandayo kwizisombululo zonyango lomphezulu ohambelana nokusingqongileyo.Ngemimiselo ehlala ikhula kunye neenkxalabo malunga nefuthe lemo engqongileyo yeendlela zokulungiselela umphezulu wemveli, abaphandi baphonononga ezinye izisombululo ezikhuselekileyo, ezizinzileyo. Ngokomzekelo, iingubo ezisekelwe emanzini zifumana ukuthandwa ngenxa yokukhutshwa kwazo okuphantsi kwe-volatile organic compound (VOC) xa kuthelekiswa neengubo ezithwala i-solvent. Ukongeza, iinzame ziyaqhubeka ukuphuhlisa iinkqubo zokurhweba ezihambelana nokusingqongileyo ezingavelisi iimveliso eziyityhefu okanye inkunkuma.

Ukushwankathela,inkqubo yonyango lomphezulu idlala indima ebalulekileyo ekuqinisekiseni ukuthembeka nokusebenza kwebhodi ethambileyo ye-FPC. Ngokuqonda ukubaluleka kokulungiswa komphezulu kunye nokukhetha indlela efanelekileyo, abavelisi banokuvelisa iisekethe eziphezulu eziguquguqukayo ezihlangabezana neemfuno zamashishini ahlukeneyo. Ukuphunyezwa kwenkqubo yonyango oluphezulu olucwangcisiweyo, ukuqhuba iimvavanyo zokulawula umgangatho, kunye nokujongana ngokufanelekileyo nemiba yonyango lomphezulu kuya kuba negalelo kwimpumelelo kunye nobomi obude be-FPC eguquguqukayo ye-PCBs kwimarike.

Ixesha lokuposa: Sep-08-2023

Emva