Yazisa:

Ukwenziwa kwe-PCB eguquguqukayo kudlala indima ebalulekileyo kushishino lokwenziwa kombane. Njengoko iteknoloji ihambela phambili, imfuno yeePCB eziguquguqukayo inyuke kakhulu. Kwesi sikhokelo sokugqibela, siza kuphonononga ulwakhiwo lwePCB ebhetyebhetye, uyilo, kunye neentlobo zokupakishwa. Kubalulekile ukuqonda la magama angundoqo alandelayo:Ukwenziwa kwe-PCB eguquguqukayo, i-Flexible PCB Structure, i-Flexible PCB yokutyeba koCopper, i-Flexible PCB Solder Mask, i-Flexible PCB Layout, i-Flexible PCB Adhesive Sheet, kunye ne-Flexible PCB Layup Types njengoko zibalulekile ekuphuculeni imveliso yakho.Ibalulekile.

1. Ulwazi olusisiseko lokwenziwa kwe-PCB eguquguqukayo:

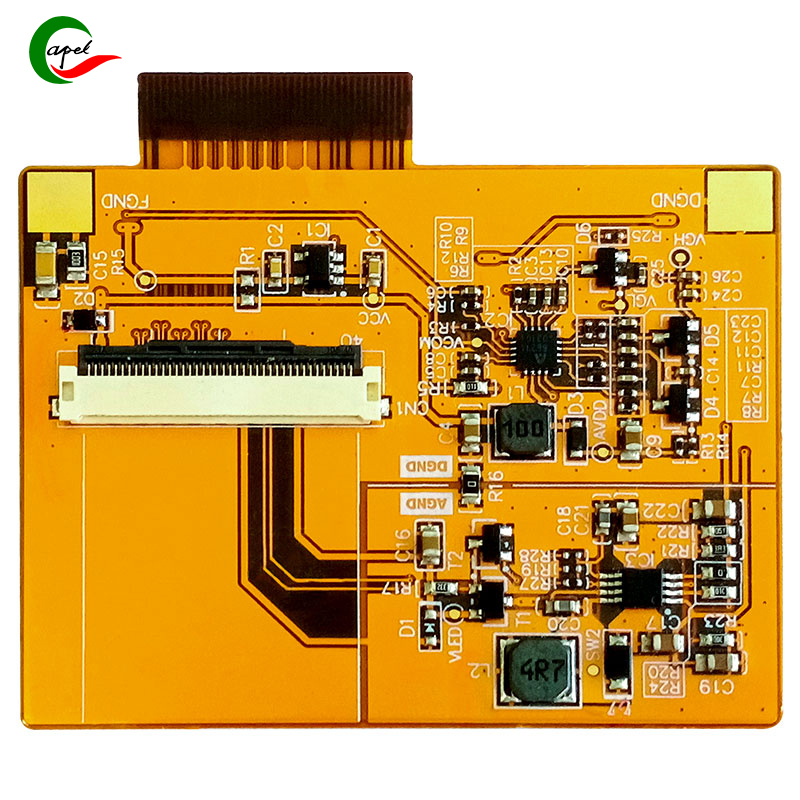

A. Inkcazo kunye neempawu zebhodi eguquguqukayo: I-PCB eguquguqukayo, eyaziwa ngokuba yi-flexible circuit, yibhodi yesiphaluka eprintiweyo enokuthi igobe, igobe, okanye ijike ngaphandle kokuphuka. Banikezela ngeenzuzo ezininzi ngaphezulu kweePCB eziqinileyo, kubandakanya ukuguquguquka, ukukhanya, kunye nokuqina. Ezi zakhiwo zibenza bafaneleke kwiintlobo ezahlukeneyo zezicelo, ngakumbi ezo zifuna i-elektroniki edibeneyo kunye ne-bandable.

B. Isakhiwo se-PCB esiguquguqukayo: Inkqubo yokwakhiwa kwe-PCB eguquguqukayo ibandakanya ukusetyenziswa kwee-substrates eziguquguqukayo. Ii-substrates ezisetyenziswa ngokuqhelekileyo ziyi-polyimide kunye ne-polyester, ezibonelela ngokuguquguquka okuyimfuneko kunye neempawu zokugquma ezifunekayo kwii-PCB eziguquguqukayo. Ezi substrates zifumana uthotho lwamanyathelo okuvelisa anje nge-etching, plating, kunye ne-lamination ukwenza ipateni yesekethe efunekayo.

C. Qonda ubukhulu bobhedu kwi-PCB eguquguqukayo: Ukutyeba kobhedu kudlala indima ebalulekileyo ekusebenzeni kwe-PCB eguquguqukayo. Imisela umthamo wangoku wokuthwala, i-impedance, kunye nokuguquguquka kwe-PCB. Ukukhetha ukutyeba kobhedu okwahlukileyo kunokwenziwa ngokweemfuno ezithile zoyilo. Ubhedu olushinyeneyo lubonelela ngezakhono eziphezulu zokuthwala zangoku kodwa lukwanciphisa nokuguquguquka kwePCB. Ulungelelwaniso olufanelekileyo kufuneka lwenziwe phakathi kwezi zinto ukuze kuphunyezwe ukusebenza ngokupheleleyo.

2. Amacandelo aphambili okwenziwa kwe-PCB eguquguqukayo:

A. Imaski ye-solder ye-PCB eguquguqukayo: Imaski ye-solder ngumaleko okhuselayo ogqume imikhondo yobhedu engenanto kwi-PCB. Inceda ukuthintela iibhulorho ze-solder, ukubola, kunye neebhulukhwe zombane ngexesha le-welding. I-PCB eguquguqukayo isebenzisa imathiriyeli yemaski ekhethekileyo ye-solder ukuqinisekisa ukuguquguquka kunye nokuqina. Ukhetho lwemaski ye-solder ye-PCB eguquguqukayo kunye nenkqubo yesicelo ifuna ukuqwalaselwa ngononophelo kuyilo lwePCB kunye nokusetyenziswa kwayo.

B. I-Plexible PCB Layout: Uyilo lwePCB oluyilwe kakuhle, oluguquguqukayo lubaluleke kakhulu ekusebenzeni kakuhle kunye nokuthembeka. Ibandakanya ukubekwa kwamacandelo, ukuhanjiswa kwendlela yokulandela umkhondo, kunye nokuqwalaselwa kwemfezeko yomqondiso. Amacandelo kufuneka abekwe ngendlela evumela ukuba i-PCB igobe kwaye igobe ngokufanelekileyo. Umkhondo kufuneka uhanjiswe ukunciphisa uxinzelelo kwiindawo eziguquguqukayo kunye nokuqinisekisa ukuhanjiswa komqondiso osebenzayo. Iindlela ezigqwesileyo zokuyila uyilo lwePCB olubhetyebhetye lubandakanya ukusebenzisa imikhondo egobileyo, ukuphepha ii-engile ezibukhali, kunye nokuqinisekisa ucoceko olwaneleyo phakathi kweetrayisi.

C. Flexible PCB ancamathelise sheet: An sheet encamathelayo isetyenziswa kwimveliso PCB bhetyebhetye ukuba ibhondi umaleko ezahlukeneyo kunye. Inika amandla omatshini, ukuzinza, kunye nokugquma. Kukho iintlobo ezahlukeneyo zamaphepha ancamathelayo akhoyo, njengamaphepha asekelwe kwi-acrylic, amaphepha asekelwe kwi-epoxy, kunye namaphepha asekelwe kwirabha. Ukukhethwa kwephepha lokunamathela kuxhomekeke kwizinto ezifana nokumelana nobushushu, iimfuno zokuguquguquka, kunye nokuhambelana nezinye izinto. Ukukhetha iphepha lokuncamathelisa elifanelekileyo kubaluleke kakhulu ukuqinisekisa ukuthembeka kunye nokuqina kwePCB yakho ebhetyebhetye.

3. Iintlobo zokupakishwa ze-PCB eziguquguqukayo:

A. Intshayelelo ngokupakishwa kwePCB: Ugcino lwePCB lubhekisa kulungiselelo lweeleya ezahlukeneyo kwiPCB. Kwimveliso ye-PCB eguquguqukayo, ukupakishwa kudlala indima ebalulekileyo kwimfezeko yomqondiso, ulawulo lwe-impedance, kunye nolawulo lobushushu. Ngokukhetha ngononophelo kunye nokulungelelanisa iileya, abayili banokunyusa ukusebenza kweePCB eziguquguqukayo.

B. Iindidi ze-PCB eziQhelekileyo zokuLawula: Kukho iintlobo ezahlukeneyo zokubeka ezisetyenziselwa ukuveliswa kwe-PCB eguquguqukayo, kubandakanywa i-single-layer, i-dual-lay, kunye noqwalaselo lwe-multi-layer. Uhlobo ngalunye lokupakisha luneenzuzo kunye nemida. I-PCBs eguquguqukayo yoluhlu olunye lolona khetho lulula kwaye lungabizi kakhulu, kodwa banamandla okusebenzisa indlela. I-PCB eguquguqukayo ephindwe kabini ibonelela ngeendlela ezininzi zokudityaniswa kweengcingo kwaye inokwamkela uyilo oluntsonkothileyo. Ii-PCBs eziguquguqukayo ezininzi zibonelela ngokuguquguquka okukhulu kwendlela, kunye nolawulo oluphuculweyo lwe-impedance, kwaye inokuxhasa ukuxinana kwesekethe ephezulu. Nangona kunjalo, zintsonkothe ngakumbi kwaye zibiza imali eninzi ukuwenza.

Isishwankathelo:

Kwesi sikhokelo sibanzi, sigubungela yonke imiba yokwenziwa kwePCB ebhetyebhetye, kubandakanya ulwakhiwo, uyilo, imaski ye-solder, amashiti ancamathelayo, kunye neentlobo zokupakishwa. Ukuqonda ezi zinto ziphambili kuya kwenza abaqulunqi basebenzise ngokupheleleyo ukusebenza kunye nokuthembeka koyilo lwabo lwePCB olubhetyebhetye. Iinkqubo kunye nobuchwepheshe bubaluleke kakhulu ekuveliseni ii-PCB eziguquguqukayo, kwaye ngokulandela iindlela ezifanelekileyo, abavelisi banokuqinisekisa ukuhanjiswa kwekhwalithi ephezulu, iimveliso ezithembekileyo ukuhlangabezana neemfuno zoshishino lwe-elektroniki.

Ixesha lokuposa: Nov-10-2023

Emva