Ihlabathi le-elektroniki lenze inkqubela phambili emangalisayo kumashumi eminyaka akutshanje, kwaye emva kwayo yonke imimangaliso ye-elektroniki kukho ibhodi yesekethe eprintiweyo (PCB). Ezi zinto zincinci kodwa ziyimfuneko zingumqolo phantse kuzo zonke izixhobo zombane. Iindidi ezahlukeneyo zeePCB zihlangabezana neemfuno ezahlukeneyo, uhlobo olunye yi-ENIG PCB.Kule bhlog, siza kuphonononga kwiinkcukacha ze-ENIG PCB, sityhila iimpawu zayo, ukusetyenziswa kunye nendlela eyahluke ngayo kwezinye iintlobo zePCB.

1.Yintoni ukuntywiliselwa igolide PCB?

Apha siza kubonelela ngokujonga nzulu kwiiPCB ze-ENIG, kubandakanya amacandelo azo, ulwakhiwo, kunye nenkqubo yegolide yokuntywiliselwa kwe-nickel engenambane esetyenziselwa ukwenziwa. Abafundi baya kuziqonda ngokucacileyo iimpawu ezizodwa ezenza i-ENIG PCBs igqame.

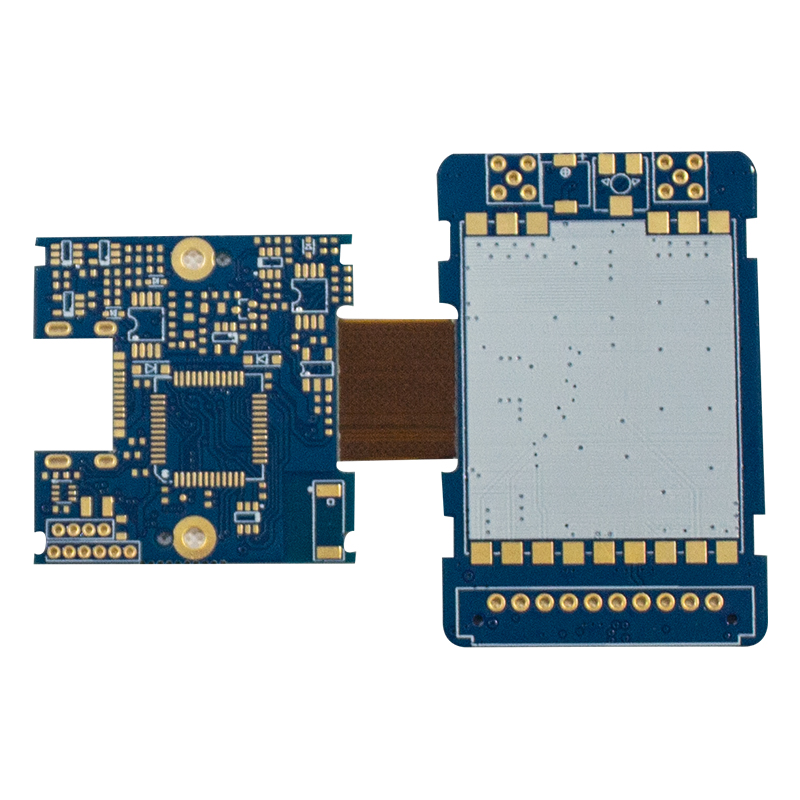

I-ENIG sisishunqulelo se-electroless nickel immersion gold plating, eyindlela eqhelekileyo yonyango lomphezulu kwimveliso yePCB.Inika isisombululo esinokwethenjelwa kunye neendleko ezifanelekileyo zokuqinisekisa ixesha elide kunye nokusebenza kwezixhobo zombane. Ii-PCB ze-ENIG zisetyenziswa ngokubanzi kumashishini afana nonxibelelwano, i-aerospace, i-elektroniki yabathengi, kunye nezixhobo zonyango.

IiPCB ze-ENIG zenziwe ngamacandelo amathathu aphambili: i-nickel, igolide, kunye ne-barrier layer.Umaleko wesithintelo udla ngokwenziwa umaleko obhityileyo we-nickel engena-electro efakwe phezu kwemikhondo yobhedu kunye neepads zePCB. Lo maleko wenickel usebenza njengesithintelo sokusasaza, ukuthintela ubhedu ekufudukeleni kumaleko wegolide ngexesha lokubekwa kwegolide. Emva kokusebenzisa i-nickel layer, igolide elincinci lifakwe phezulu. Umaleko wegolide ubonelela nge-conductivity egqwesileyo, ukuqina kunye nokumelana nokubola. Ikwabonelela ngezinga lokukhusela kwi-oxidation, ukuqinisekisa ukusebenza kwexesha elide le-PCB kunye nokuthembeka.

Inkqubo yokwenziwa kwe-ENIG PCB ibandakanya amanyathelo amaninzi. Okokuqala, i-PCB iphathwa kwaye icocwe ukuze isuse ungcoliseko kunye neeoksidi kumphezulu wobhedu. I-PCB iye intywiliselwe kwibhafu yokubeka i-nickel engena-electroless, apho i-chemical reaction ibeka umaleko we-nickel kwiitrayisi zobhedu kunye neepads. Emva kokuba i-nickel ifakwe, hlambulula kwaye ucoce i-PCB kwakhona ukususa nayiphi na imichiza eseleyo. Okokugqibela, i-PCB intywiliselwa kwibhafu yegolide kwaye umaleko obhityileyo wegolide ubekwe kumphezulu we-nickel ngokusabela kokufuduswa. Ubunzima bomgca wegolide bunokwahluka ngokuxhomekeke kwisicelo esithile kunye neemfuno. I-ENIG PCB ibonelela ngeenzuzo ezininzi ngaphezu kolunye unyango olungaphezulu. Enye yeenzuzo eziphambili ngumgangatho wayo osicaba kunye nofanayo, oqinisekisa ukuthengiswa okugqwesileyo kwaye uwenze ulungele iinkqubo zokuhlanganisa i-Surface Mount Technology (SMT). Imiphezulu yegolide nayo ixhathisa kakhulu kwi-oxidation, inceda ukugcina uqhagamshelo oluthembekileyo lombane ngokuhamba kwexesha.

Olunye uncedo lwe-ENIG PCBs kukukwazi ukubonelela ngokuzinzileyo kunye nokuhambelana kwee-solder joints.Indawo ethe tyaba kunye negudileyo yomaleko wegolide ikhuthaza ukumanzisa okulungileyo kunye nokunamathela ngexesha lenkqubo ye-solder, okukhokelela kwi-solder eqinile kwaye ethembekileyo.

I-ENIG PCBs zikwaziwa ngokusebenza kwazo okuphezulu kombane kunye nemfezeko yomqondiso.Uluhlu lwe-nickel lusebenza njengesithintelo, luthintela ubhedu ukuba lusasazeke kuluhlu lwegolide kunye nokugcina iimpawu zombane zesekethe. Kwelinye icala, umaleko wegolide unokumelana nokunxibelelana okuphantsi kunye nokuhanjiswa kombane okugqwesileyo, ukuqinisekisa ukuhanjiswa komqondiso okuthembekileyo.

2.Iinzuzo ze-ENIG PCB

Apha sijonga kwiingenelo ze-ENIG PCBs ezinje ngokuthengiswa okuphezulu, ukuqina, ukumelana nokugqwala kunye nokuhanjiswa kombane. Ezi zibonelelo zenza i-ENIG PCB ilungele uluhlu olubanzi lwezicelo

I-ENIG PCB okanye i-Electroless Nickel Immersion Gold PCB ibonelela ngeenzuzo ezininzi ngaphezulu kolunye unyango olungaphezulu, iyenza ilungele uluhlu olubanzi lwezicelo kwishishini le-elektroniki. Makhe sihlolisise ezinye zezi ngenelo ngokweenkcukacha.

I-solderability egqwesileyo:

IiPCB ze-ENIG zinokuthengiswa okugqwesileyo, zizenza zilungele iinkqubo zendibano yeSurface Mount Technology (SMT). Umaleko wegolide ongaphezulu kwesithintelo se-nickel ubonelela ngomphezulu osicaba kunye nofanayo, ukukhuthaza ukumanzisa okulungileyo kunye nokubambelela ngexesha le-soldering. Oku kubangela ukudibanisa okunamandla, okuthembekileyo kwe-solder, ukuqinisekisa ingqibelelo kunye nokusebenza kwendibano yePCB.

Ukuqina:

IiPCB ze-ENIG ziyaziwa ngokuhlala kwazo ixesha elide kunye nokuphila ixesha elide. Uluhlu lwegolide lusebenza njengengubo yokukhusela, inika iqondo lokukhusela kwi-oxidation kunye nokubola. Oku kuqinisekisa ukuba iPCB inokumelana neemeko ezirhabaxa zokusingqongileyo, kubandakanywa ukufuma okuphezulu, utshintsho lobushushu kunye nokuvezwa kweekhemikhali. Ukuqina kwe-ENIG PCBs kuthetha ukuthembeka okukhulu kunye nobomi obude, okubenza bafanelekele izicelo ezifuna ukusebenza kwexesha elide.

Ukuxhathisa ukonakala:

I-electroless nickel layer kwi-ENIG PCB yenza umqobo phakathi kwemikhondo yobhedu kunye nomaleko wegolide. Lo mqobo uthintela ubhedu ekufudukeleni kwigolide ngexesha lokubekwa kwegolide. Ke ngoko, i-ENIG PCB ibonisa ukuxhathisa okugqwesileyo kokutya nakwindawo ezonakalisayo. Oku kubenza balungele usetyenziso apho iiPCBs zinokuchanabeka kubumanzi, iikhemikhali okanye ezinye iiarhente ezidlekayo.

Ukuqhuba:

I-ENIG PCB iqhuba kakhulu enkosi kumaleko ayo egolide. Igolide ngumqhubi ogqwesileyo wombane kwaye inokuhambisa imiqondiso ngokufanelekileyo kwiiPCB. Umphezulu wegolide ofanayo uqinisekisa ukuchasana koqhagamshelwano oluphantsi, ukunciphisa nayiphi na ilahleko yesignali enokubakho okanye ukuthotywa. Oku kwenza i-ENIG PCB ilungele usetyenziso olufuna ukuhanjiswa komqondiso wesantya esiphezulu kunye nesantya esiphezulu, esifana nonxibelelwano, i-aerospace kunye ne-elektroniki yabathengi.

Ukuthe tyaba komphezulu:

IiPCB ze-ENIG zinomphezulu othe tyaba kunye nofanayo, obaluleke kakhulu kwinkqubo yokuhlanganisana engaguqukiyo nethembekileyo. Umphezulu osicaba uqinisekisa ukuhanjiswa kwe-solder paste ngexesha lokuprintwa kwe-stencil, ngaloo ndlela kuphuculwe umgangatho odibeneyo we-solder. Ikwaququzelela ukubekwa ngokuchanekileyo kwamacandelo okunyuka komphezulu, ukunciphisa umngcipheko wokungahambi kakuhle okanye iisekethe ezimfutshane. Umphezulu othe tyaba we-ENIG PCBs wonyusa ukusebenza kakuhle kwemveliso kwaye ukhokelela kwiindibano zePCB ezikumgangatho ophezulu.

Ukuhambelana kweNgxowa-mali:

IiPCB ze-ENIG nazo ziyahambelana nenkqubo yokudibanisa iingcingo, apho iingcingo ezibuthathaka zibotshelelwa kwi-PCB ukwenza uqhagamshelo lombane. Uluhlu lwegolide lunikeza indawo efanelekileyo kakhulu yokudibanisa ucingo, ukuqinisekisa ukuba intambo yocingo eyomeleleyo kwaye ethembekileyo. Oku kwenza ukuba iiPCB ze-ENIG zibe lolona khetho lubalaseleyo kwizicelo ezifuna ukudityaniswa kocingo, ezinje nge-microelectronics, i-automotive electronics kunye nezixhobo zonyango.

Ukuthotyelwa kweRoHS:

IiPCB ze-ENIG zinobuhlobo nokusingqongileyo kwaye ziyahambelana nomyalelo woMqathango wezinto ezinobungozi (RoHS). Inkqubo yokubekwa kwe-ENIG ayibandakanyi naziphi na izinto ezinobungozi, oko kuyenza ikhuseleke kwaye ikhuseleke ngakumbi kokusingqongileyo kunolunye unyango olungaphezulu olunokuba nezinto eziyityhefu.

3.ENIG PCB vs. nezinye iintlobo PCB

Uthelekiso olubanzi kunye nezinye iintlobo ze-PCB eziqhelekileyo ezifana ne-FR-4, i-OSP, i-HASL kunye ne-Immersion Silver PCB iya kugxininisa iimpawu ezizodwa, iingenelo kunye nokungalunganga kwi-PCB nganye.

FR-4 PCB:I-FR-4 (i-Flame Retardant 4) yinto esetyenziswa ngokubanzi kwi-PCB substrate material. Yiresin ye-epoxy eyomelezwe ngeentsinga zeglasi elukiweyo kwaye yaziwa ngeempawu zayo ezilungileyo zokugquma umbane. I-FR-4 PCB inezi mpawu zilandelayo:

inzuzo:

Amandla omatshini alungileyo kunye nokuqina

Ukufakelwa kombane okugqwesileyo

Iindleko ezisebenzayo kwaye zifumaneka ngokubanzi

ukusilela:

Ayilunganga usetyenziso lwefrikhwensi ephezulu ngenxa yokulahleka okuphezulu kwe-dielectric

Ukuhanjiswa kwe-thermal encinci

Ukufunxa ngokulula ukufuma ngokuhamba kwexesha, kubangela utshintsho lwe-impedance kunye nokunciphisa umqondiso

Kwizicelo ezifuna ukuhanjiswa komqondiso we-frequency ephezulu, i-ENIG PCB ikhethwa ngaphezu kwe-FR-4 PCB kuba i-ENIG inikezela ukusebenza okungcono kombane kunye nokulahleka komqondiso osezantsi.

OSP PCB:I-OSP (i-Organic Solderability Preservative) lunyango lomphezulu olusetyenziswa kwii-PCBs ukukhusela imikhondo yobhedu kwi-oxidation. I-OSP PCB inezi mpawu zilandelayo:

inzuzo:

Ihambelana nendalo kwaye i-RoHS iyahambelana

Iindleko eziphantsi xa kuthelekiswa nolunye unyango olungaphezulu

Ilungele ukuguda kunye nokuthe tyaba

ukusilela:

Ubomi beshelufu buphantsi; Umaleko okhuselayo uyehla ngokuhamba kwexesha

Ukuchasana okulinganiselweyo kumswakama kunye neendawo ezinzima

Ukumelana nobushushu obuncinci

Xa ukuxhathisa umhlwa, ukuqina kunye nobomi benkonzo obandisiweyo kubalulekile, i-ENIG PCB ikhethwa ngaphezu kwe-OSP PCB ngenxa ye-oxidation ephezulu ye-ENIG kunye nokukhuselwa komhlwa.

Tshiza iPCB:HASL (Hot Air Solder Leveling) yindlela unyango umphezulu apho

I-PCB intywiliselwa kwi-solder etyhidiweyo kwaye emva koko ihanjiswe ngomoya oshushu. I-HASL PCB inezi mpawu zilandelayo:

inzuzo:Iindleko ezisebenzayo kwaye zifumaneka ngokubanzi

Solderability elungileyo kunye coplanarity

Ifanelekile ngokusebenzisa amacandelo umngxuma

ukusilela:

Umphezulu awulingani kwaye kukho imiba enokubakho ye-coplanarity

Iingubo ezishinyeneyo zisenokungahambelani nenxalenye yepitch entle

Ichaphazeleka kumothuko we-thermal kunye ne-oxidation ngexesha le-reflow soldering

Ii-PCB ze-ENIG zikhethwa kune-HASL PCBs kwizicelo ezifuna ukuthengiswa okugqwesileyo, umphezulu othe tyaba, ukubumbana okungcono, kunye nokuhambelana nezinto ezinobumba obucolekileyo.

Ukuntywiliselwa kwi-PCB yesilivere:Isilivere yokuntywiliselwa yindlela yonyango yomphezulu apho iPCB intywiliselwa kwibhafu yesilivere, idala umaleko obhityileyo wesilivere phezu kwemikhondo yobhedu. Ukuntywiliselwa kweSilver PCB inezi mpawu zilandelayo:

inzuzo:

I-conductivity yombane egqwesileyo kunye ne-solderability

Ukuba tyaba okuhle kunye ne-coplanarity

Ifanelekile kumalungu esandi esicolekileyo

ukusilela:

Ubuncinci ubomi beshelufu ngenxa yokonakala ngokuhamba kwexesha

Ubuthathaka ekuphathweni nasekungcolisekeni ngexesha lendibano

Ayifanelekanga kwizicelo zobushushu obuphezulu

Xa ukuqina, ukuxhathisa umhlwa kunye nobomi obandisiweyo beshelufu bufuneka, i-ENIG PCB ikhethwa ngaphezu kokuntywiliselwa kwi-PCB yesilivere kuba i-ENIG inokumelana okuphezulu nokonakala kunye nokuhambelana ngcono nezicelo zobushushu obuphezulu.

4.Ukusetyenziswa kwe-ENIG PCB

I-ENIG PCB (oko kukuthi i-Electroless Nickel Immersion Gold PCB) isetyenziswa ngokubanzi kumashishini ahlukeneyo ngenxa yeenzuzo zayo ezahlukeneyo ngaphezu kwezinye iintlobo zePCB.Eli candelo lihlola amashishini ahlukeneyo asebenzisa i-ENIG PCBs, egxininisa ukubaluleka kwabo kwi-electronics yabathengi, i-aerospace kunye nokukhusela, izixhobo zonyango. , kunye ne-industrial automation.

Iimveliso ze-elektroniki zabathengi:

IiPCB ze-ENIG zidlala indima ebalulekileyo kubathengi be-elektroniki apho ubungakanani obubambeneyo, ukusebenza ngesantya esiphezulu kunye nokuthembeka kubaluleke kakhulu. Zisetyenziswa kwii-smartphones, iitafile, iilaptops, iikhonsoli zomdlalo, kunye nezinye izixhobo zombane. Ukuqhuba okugqwesileyo kwe-ENIG kunye nelahleko ephantsi yokufaka iyenza ilungele usetyenziso olukwi-frequency ephezulu, ivumela ukuhanjiswa kwedatha ngokukhawuleza, imfezeko yesignali, kunye nokunciphisa ukuphazamiseka kwe-electromagnetic. Ukongeza, iiPCB ze-ENIG zibonelela ngokuthengiswa okulungileyo, okubalulekileyo ngexesha lokudityaniswa kwezinto ezintsonkothileyo ze-elektroniki.

I-Aerospace kunye noKhuseleko:

Ishishini le-aerospace kunye nokhuselo lineemfuno ezingqongqo kwiinkqubo zombane ngenxa yeemeko zokusebenza eziqatha, amaqondo obushushu agqithisileyo kunye nemigangatho ephezulu yokuthembeka. Ii-PCB ze-ENIG zisetyenziswa kakhulu kwii-avionics, iinkqubo zesathelayithi, izixhobo ze-radar kunye ne-electronics yebakala lomkhosi. Ukumelana nomhlwa okukhethekileyo kwe-ENIG kunye nokuqina kuyenza ifanelekele ubomi obandisiweyo benkonzo kwiindawo ezinomngeni. Ukongezelela, ubukhulu bayo obufanayo kunye nobukhulu buqinisekisa ukusebenza okuhambelanayo kunye nokuthembeka.

Izixhobo zonyango:

Kwicandelo lezonyango, ii-PCB ze-ENIG zisetyenziswa kwizicelo ezininzi, kubandakanywa neenkqubo zokubeka iliso kwisigulane, izixhobo zokuxilonga, izixhobo zokucinga, izixhobo zotyando kunye nezixhobo ezifakelwayo. I-ENIG's biocompatibility kunye nokumelana nomhlwa kuyenza ilungele izixhobo zonyango ezidibana nolwelo lomzimba okanye iinkqubo zokuvala inzala. Ukongeza, umphezulu we-ENIG ogudileyo kunye nokuthengiswa kuvumela uqhagamshelo oluchanekileyo kunye nokudityaniswa kwezinto ezintsonkothileyo ze-elektroniki kwizixhobo zonyango. ishishini elizenzekelayo:

Ii-PCB ze-ENIG zisetyenziswa ngokubanzi kwiinkqubo ezizisebenzelayo kwimizi-mveliso, kubandakanya neenkqubo zolawulo lwenkqubo, iirobhothi, iimoto zokuqhuba, izixhobo zombane, kunye nezinzwa. Ukuthembeka kunye nokungaguquguquki kwe-ENIG kuyenza ibe lolona khetho lubalaseleyo kwizicelo zemizi-mveliso ezifuna ukusebenza ngokuqhubekayo kunye nokuchasana neemeko ezingqongileyo. I-solderability egqwesileyo ye-ENIG iqinisekisa uqhagamshelo oluthembekileyo kumandla aphezulu kunye nezicelo zobushushu obuphezulu, ukubonelela ngokuhlala okuyimfuneko kunye nokuzinza kweenkqubo ezizenzekelayo zoshishino.

Ukongeza, iiPCB ze-ENIG zisetyenziswa kwamanye amashishini anje ngeemoto, ezonxibelelwano, amandla, kunye nezixhobo ze-IoT (kwi-Intanethi yeZinto).Ishishini leemoto lisebenzisa iiPCB ze-ENIG kwi-elektroniki yemoto, iiyunithi zokulawula iinjini, iinkqubo zokhuseleko kunye neenkqubo zokuzonwabisa. Iinethiwekhi zeTelecom zixhomekeke kwi-ENIG PCBs ukwakha izikhululo ezisisiseko, iirotha, iiswitshi kunye nezixhobo zonxibelelwano. Kwicandelo lamandla, iiPCB ze-ENIG zisetyenziswa ekuveliseni amandla, kwiinkqubo zokusasaza kunye neenkqubo zamandla ahlaziyekayo. Ukongezelela, ii-PCB ze-ENIG ziyinxalenye ebalulekileyo yezixhobo ze-IoT, ezidibanisa izixhobo ezahlukeneyo kunye nokwenza utshintshiselwano lwedatha kunye nokuzenzekelayo.

5.ENIG PCB yokuVeliswa kunye noYilo lweNgqwalasela

Xa kuyilwa kwaye kusenziwa iiPCB ze-ENIG, kukho izinto ezininzi ezibalulekileyo ekufuneka ziqwalaselwe ukuqinisekisa ukusebenza kakuhle kunye nokuthembeka. Nazi ezinye izikhokelo zoyilo eziphambili kunye neenkqubo zemveliso ezithe ngqo kwi-ENIG PCBs:

Uyilo lwePad:

Uyilo lwephedi lwe-ENIG PCB lubalulekile ekuqinisekiseni ukuthengiswa okufanelekileyo kunye nokuthembeka koqhagamshelo. IiPads kufuneka ziyilwe ngokwemilinganiselo echanekileyo, kubandakanywa ububanzi, ubude, kunye nezithuba, ukuze zivumelane neendawo zokukhokela kunye ne-solder paste. I-pad surface finish kufuneka igudiswe kwaye icoceke ukuvumela ukumanzisa okufanelekileyo ngexesha lenkqubo ye-soldering.

Landela ububanzi kunye nesithuba:

Umkhondo ububanzi kunye nezithuba kufuneka zihambelane nemigangatho yoshishino kunye neemfuno ezikhethekileyo zePCB. Ukuqinisekisa ubungakanani obuchanekileyo kunokuthintela iingxaki ezinjengokuphazamiseka komqondiso, iisekethe ezimfutshane, kunye nokungazinzi kombane.

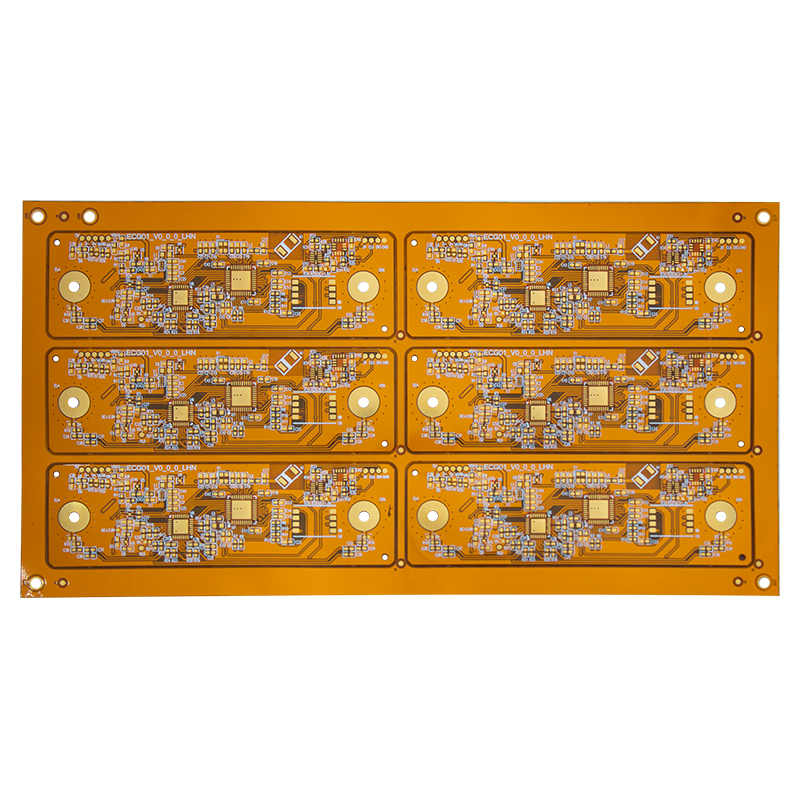

Ubukhulu bebhodi kunye nokufana:

I-ENIG PCB inomaleko we-nickel engena-electro kunye nomaleko wegolide ontywilisiweyo. Ubukhulu bePlating kufuneka ilawulwe ngaphakathi kokunyamezelwa okuthile ukuqinisekisa ukugqunywa okufanayo komphezulu wePCB yonke. Ubukhulu beplating obufanayo bubalulekile ekusebenzeni kombane okungaguquguqukiyo kunye neendawo ezithembekileyo ze-solder.

Usetyenziso lwemaski yeSolder:

Ukusetyenziswa ngokufanelekileyo kwe-solder mask kubalulekile ekukhuseleni umkhondo we-PCB kunye nokuthintela iibhulorho ze-solder. Imaski yesoda kufuneka isetyenziswe ngokulinganayo nangokuchanekileyo ukuqinisekisa ukuba iphedi eveziweyo inendawo efunekayo yokuvula imaski yesolder yezixhobo zokuthambisa.

Uyilo lwesakhelo se-Solder Cola:

Xa i-surface Mount iteknoloji (SMT) isetyenziselwa ukuhlanganisa icandelo, iistensile ze-solder paste zisetyenziselwa ukufaka ngokuchanekileyo i-solder pads kwi-PCB pads. Uyilo lwe-stencil kufuneka luhambelane ngokuchanekileyo kunye noyilo lwephedi kwaye luvumele ukubekwa okuchanekileyo kwe-solder paste ukuqinisekisa ukubunjwa okudibeneyo kwe-solder ngexesha lokuhamba kwakhona.

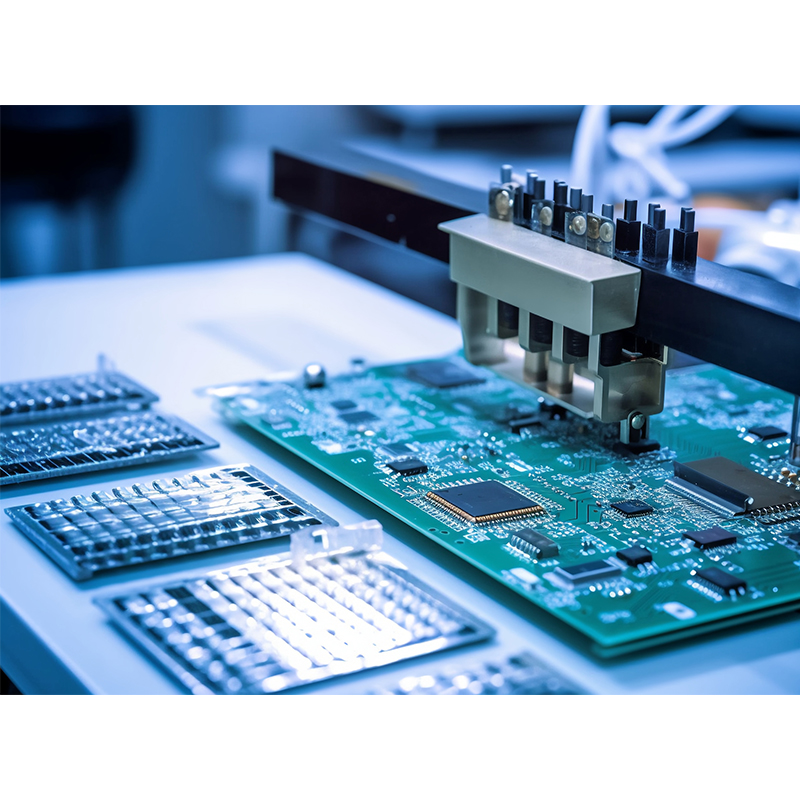

Ukujongwa koLawulo loMgangatho:

Ngexesha lenkqubo yokuvelisa, kubalulekile ukwenza iitshekhi zokulawula umgangatho ukuqinisekisa ukuba i-ENIG PCB ihlangabezana nemigaqo efunekayo. Olu hlolo lungabandakanya ukuhlolwa okubonakalayo, uvavanyo lombane kunye nohlalutyo oludibeneyo lwe-solder. Ukuhlolwa kokulawulwa komgangatho kunceda ukuchonga nayiphi na imiba ngexesha lenkqubo yokuvelisa kunye nokuqinisekisa ukuba i-PCB egqityiweyo ihlangabezana nemigangatho efunekayo.

Ukuhambelana kweNdibano:

Kubalulekile ukuqwalasela ukuhambelana kokugqitywa komphezulu we-ENIG kunye neenkqubo ezahlukeneyo zokuhlanganisa. I-solderability kunye neempawu zokubuyisela kwakhona ze-ENIG kufuneka zihambelane nenkqubo yendibano ethile esetyenzisiweyo. Oku kubandakanya ukuqwalaselwa okunjengokukhethwa kwe-solder paste, ukulungiswa kweprofayili ye-reflow, kunye nokuhambelana neenkqubo ze-lead-free soldering (ukuba ziyasebenza).

Ngokulandela ezi zikhokelo zoyilo kunye neenkqubo zemveliso ye-ENIG PCBs, abavelisi banokuqinisekisa ukuba imveliso yokugqibela ihlangabezana nemigangatho yokusebenza efunekayo kunye nokuthembeka. Kubalulekile ukusebenzisana ngokusondeleyo nabavelisi be-PCB kunye namaqabane endibano ukuhlangabezana neemfuno ezithile kunye nokuqinisekisa impumelelo yenkqubo yokuvelisa kunye nendibano.

6.ENIG PCB FAQ

Yintoni i-ENIG PCB? Imele ntoni?

I-ENIG PCB imele i-Electroless Nickel Immersion Gold Printed Circuit Board. Lunyango lomphezulu olusetyenziswa ngokuqhelekileyo kwii-PCB kwaye lubonelela ngokumelana nomhlwa, ukuba tyaba kunye nokuthengiseka okulungileyo.

Ziziphi iingenelo zokusebenzisa i-ENIG PCB?

I-ENIG PCBs zibonelela ngezibonelelo ezininzi, kubandakanya ukuthengiseka okugqwesileyo, ukuhanjiswa kombane okuphezulu kunye nokumelana nomhlwa. Ukugqitywa kwegolide kunika umaleko wokukhusela, okwenza kube yinto efanelekileyo kwizicelo apho ukuthembeka kubaluleke kakhulu.

Ngaba i-ENIG PCB iyabiza?

I-ENIG PCBs ithande ukuba kubiza kancinci xa kuthelekiswa nolunye unyango olungaphezulu. Iindleko ezongezelelweyo zibangelwa yigolide esetyenziswe kwinkqubo yokufunxa. Nangona kunjalo, izibonelelo kunye nokuthembeka okubonelelwa yi-ENIG kuyenza ibe lukhetho lokuqala kwizicelo ezininzi, ithethelela iindleko zayo eziphezulu kancinci.

Ngaba kukho naziphi na izithintelo ekusebenziseni i-ENIG PCB?

Ngelixa ii-ENIG PCB zineengenelo ezininzi, zikwanazo nemida ethile. Umzekelo, umphezulu wegolide unokunxiba lula ukuba uphantsi koxinzelelo olugqithisileyo lomatshini okanye ukuguga. Ukongeza, i-ENIG ayinakulungela izicelo ezineemfuno zobushushu obuphezulu okanye apho kusetyenziswa imichiza ethile eqatha.

Ngaba i-ENIG PCB kulula ukuyithenga?

Ewe, iiPCB ze-ENIG zifumaneka ngokubanzi kubavelisi bePCB abahlukeneyo kunye nababoneleli. Ziinketho eziqhelekileyo zokugqiba kwaye zinokufumaneka ngokulula ukuze zihambelane neemfuno zeeprojekthi ezahlukeneyo. Kuyacetyiswa ukuba kujongwe ukufumaneka kunye namaxesha okuhanjiswa kunye nomenzi okanye umthengisi othile.

Ngaba ndingaphinda ndisebenze okanye ndilungise i-ENIG PCB?

Ewe, iiPCB ze-ENIG zinokuphinda zisetyenzwe okanye zilungiswe. Nangona kunjalo, inkqubo yokusebenza ngokutsha kunye nokulungiswa kwe-ENIG inokufuna ingqalelo ekhethekileyo kunye nobuchule xa kuthelekiswa nolunye unyango olungaphezulu. Kuyacetyiswa ukuba udibane nengcali enamava e-PCB esebenza ngokutsha ukuqinisekisa ukuphatha kakuhle kwaye uphephe ukubeka esichengeni isidima somphezulu wegolide.

Ngaba i-ENIG inokusetyenziselwa i-lead kunye ne-lead-free soldering?

Ewe, i-ENIG inokusetyenziswa nge-lead kunye ne-lead-free soldering process. Nangona kunjalo, kubalulekile ukuqinisekisa ukuhambelana ne-solder paste ethile kunye neprofayili yokuphinda isetyenziswe. Ukuze kuphunyezwe amajoyinti e-solder athembekileyo ngexesha lokudibanisa, iiparamitha ze-welding kufuneka zilungiswe ngokufanelekileyo.

Inkqubo ye-ENIG sisisombululo esithembekileyo nesisebenzayo kubenzi kunye nabathanda izinto zombane. Indibaniselwano yesithintelo esicekethekileyo, esifakwe ngokulinganayo senikeli kunye nomaleko ongaphezulu wegolide ubonelela ngowona mphezulu ugqityiweyo wokuqinisekisa ubomi obude kunye nokusebenza kwezixhobo zombane. Nokuba kunxibelelwano lomnxeba, i-aerospace okanye i-elektroniki yabathengi, iiPCB ze-ENIG ziyaqhubeka nokudlala indima ebalulekileyo ekuqhubeleni phambili itekhnoloji kunye nokubumba ikamva lezinto zombane.

Ixesha lokuposa: Sep-13-2023

Emva