Yazisa:

Kwihlabathi lanamhlanje eliqhutywa bubuchwephesha, imfuno yeebhodi zesekethe ezintsonkothileyo neziguquguqukayo (PCBs) ikhula ngokukhawuleza. Ukusuka kwiinkqubo zekhompyuter ezisebenza kakhulu ukuya kwizinto ezinxitywayo kunye nezixhobo zonyango, ezi PCBs ezihambele phambili ziye zaba yinxalenye yezixhobo zombane zanamhlanje. Nangona kunjalo, njengoko iimfuno ezintsonkothileyo kunye nokuguquguquka zisanda, kunjalo nesidingo sobugcisa bemveliso obunokufikelela ezi mfuno zikhethekileyo.Kule bhlog, siza kuphonononga ubume obuguqukayo bemveliso yePCB kwaye sixoxe ukuba iyakwazi na ukuhlangabezana neemfuno zeePCB ezinzima neziguquguqukayo.

Funda malunga neePCB ezintsonkothileyo neziguquguqukayo:

IiPCB ezintsonkothileyo ziphawulwa ngoyilo oluntsonkothileyo oludibanisa imisebenzi emininzi ngaphakathi kwendawo encinci. Ezi ziquka ii-PCBs ze-multilayer, iibhodi ze-high-density interconnect (HDI), kunye nee-PCB ezine-vias ezingaboniyo nezingcwatywayo. IiPCB eziguquguqukayo, kwelinye icala, ziyilelwe ukuba zigobe okanye zijije ngaphandle kokonakalisa ukujikeleza, zizenza zilungele usetyenziso apho ukuguquguquka kunye nokulungiswa kwendawo kubalulekile. Ezi PCBs zikholisa ukusebenzisa substrates bhetyebhetye ezifana polyimide okanye polyester.

Ukunyuka kwetekhnoloji yemveliso ephezulu:

Iindlela zemveli zemveliso yePCB, ezinje nge-etching, lamination, etc., azanelanga ukuhlangabezana neemfuno ze-PCB ezintsonkothileyo, eziguquguqukayo. Oku kuye kwakhokelela ekuphuhlisweni kobuchwephesha obuphezulu bemveliso obubonelela ngokuchaneka okukhulu, ukuguquguquka kunye nokusebenza kakuhle.

1. I-Laser Direct Imaging (LDI):Itekhnoloji ye-LDI isebenzisa iilaser ukuveza ngokuthe ngqo ii-substrates ze-PCB, ukuphelisa imfuneko yeefotomaski ezithatha ixesha kunye neempazamo. Itekhnoloji ivumela ukuveliswa kweesekethe ze-ultra-fine, iitrayisi ezincinci kunye ne-vias ezincinci, ezibaluleke kakhulu kwii-PCB ezinzima.

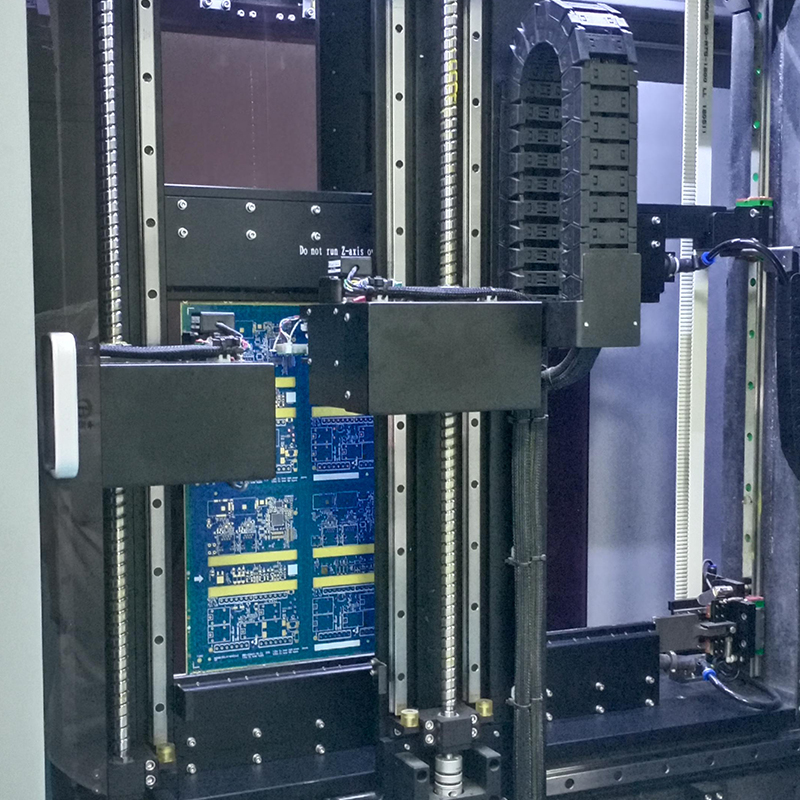

2. Imveliso eyoNgezelelweyo:Imveliso eyongeziweyo okanye ushicilelo lwe-3D luguqule ukuveliswa kweePCB ezintsonkothileyo neziguquguqukayo. Yenza kube lula ukwenza uyilo olunzima, ngakumbi kwiiprototypes kunye nokuveliswa kwevolumu ephantsi. Imveliso eyongeziweyo yenza ukuba kuphindaphindwe ngokukhawuleza kunye nokwenza ngokwezifiso, ukunceda abaqulunqi kunye nabavelisi bahlangabezane neemfuno ezizodwa zeePCB ezinzima kunye neziguquguqukayo.

3. Ukuphathwa kwesubstrate ethambileyo:Ngokwemveli, ii-PCB eziqinileyo zaziqhelekile, zinciphisa amathuba oyilo kunye nokunciphisa ukuguquguquka kweenkqubo zombane. Nangona kunjalo, ukuqhubela phambili kwezixhobo ze-substrate kunye neteknoloji yokucubungula kuye kwavula iindlela ezintsha zokuvelisa iibhodi zesekethe eziguquguqukayo. Ngoku abavelisi baxhotyiswe ngoomatshini abakhethekileyo abaqinisekisa ukuphathwa ngokufanelekileyo kunye nokulungelelaniswa kwe-substrates eguquguqukayo, ukunciphisa umngcipheko womonakalo ngexesha lokuvelisa.

Imingeni kunye nezisombululo:

Nangona iteknoloji yemveliso ephucukileyo iqhubela phambili, imingeni isafuna ukoyiswa ukuze kuhlangatyezwane ngokupheleleyo neemfuno zemveliso yeePCB ezintsonkothileyo, ezibhetyebhetye.

1. Iindleko:Ukuphumeza ubugcisa bemveliso ephucukileyo ngokuqhelekileyo kufuna iindleko eziphezulu. Oku kunokubalelwa kutyalo-mali lokuqala olufunekayo kwizixhobo, uqeqesho kunye nemathiriyeli yeengcali. Nangona kunjalo, njengoko obu bugcisa busiya buxhaphaka kwaye imfuno isanda, uqoqosho lwesikali kulindeleke ukuba lunciphise iindleko.

2. Izakhono noqeqesho:Ukwamkela ubugcisa obutsha bemveliso kufuna amagcisa anobuchule bokusebenza nokugcina oomatshini abakwizinga eliphezulu. Iinkampani kufuneka zenze utyalo-mali kwiinkqubo zoqeqesho eziqhubekayo kwaye zitsale italente ukuqinisekisa inguqu engenamagingxi-gingxi kobu buchwepheshe buvelisa izinto ezintsha.

3. Imigangatho kunye nolawulo lomgangatho:Njengoko iteknoloji ye-PCB iqhubeka nokuphuhlisa, kuye kwabaluleka ukuseka imigangatho yoshishino kunye nokuphumeza amanyathelo okulawula umgangatho ongqongqo. Abavelisi, abalawuli kunye nemibutho yoshishino kufuneka basebenzisane ukuqinisekisa ukuthembeka kunye nokhuseleko lweePCB ezinzima kunye neziguquguqukayo.

Isishwankathelo:

Iqhutywa ziimfuno ezikhulayo zeenkqubo zombane zanamhlanje, iimfuno zemveliso yeePCB ezintsonkothileyo neziguquguqukayo zihlala zitshintsha.Ngelixa ubugcisa bemveliso obuphambili obunje nge-laser yokucinga ngokuthe ngqo kunye nokuveliswa okongeziweyo kuye kwaphucula kakhulu amandla okwenza i-PCB, kusekho imingeni ekufuneka yoyiswe ngokweendleko, izakhono kunye nolawulo lomgangatho. Nangona kunjalo, ngeenzame eziqhubekayo kunye namanyathelo entsebenziswano, indawo yemveliso ikulungele ukuhlangabezana kunye nokugqithisa iimfuno ze-PCB ezinzima neziguquguqukayo. Njengoko itekhnoloji iqhubeka nokuhambela phambili, sinokulindela ukuvela ngokutsha kwiinkqubo zemveliso zokuqinisekisa ukudityaniswa komthungo kwee-PCBs kwezona zicelo ziphambili ze-elektroniki.

Ixesha lokuposa: Oct-30-2023

Emva