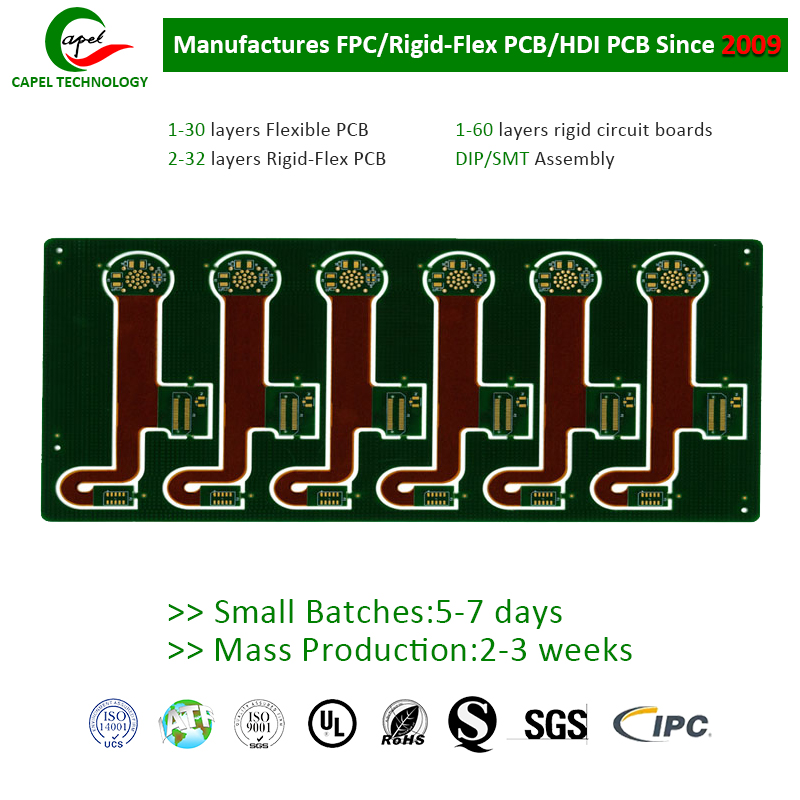

Xa uyila i-PCB eqinileyo (ibhodi yesekethe eprintiweyo), kukho izikhokelo ezininzi ezisisiseko ekufuneka zilandelwe. Ezi zikhokelo ziqinisekisa ukuba iiPCB zomelele, ziyasebenza kwaye zithembekile.Kule post yebhlog, siza kujonga ngakumbi izikhokelo zoyilo eziqhelekileyo zeePCBs eziguquguqukayo kwaye siqonde ukubaluleka kwazo ekufezekiseni ukusebenza kakuhle. Ngoko, masiqalise!

1. Cwangcisa uyilo lwebhodi yakho:

Ukucwangciswa ngononophelo koyilo lwebhodi kubalulekile kwiiPCB eziguquguqukayo eziqinileyo. Ukumisela indawo yamacandelo aqinileyo kunye aguquguqukayo, ukubekwa kwecandelo kunye neendlela zokuhamba kubalulekile. Uyilo kufuneka luphuculwe ukunciphisa uxinzelelo kunye noxinzelelo kwiindawo eziguquguqukayo ngexesha lokudibanisa kunye nokusebenza.

2. Kuphephe ukugoba okubukhali kunye noxinzelelo:

Enye yeendlela eziphambili zoyilo kukuphepha ukugoba okubukhali kunye noxinzelelo olugqithisileyo kwiindawo eziguquguqukayo. Ukugoba okubukhali kunokubangela umonakalo kwizinto eziguquguqukayo, okukhokelela ekunciphiseni ubomi benkonzo kunye nokungaphumeleli okunokwenzeka. Abaqulunqi kufuneka baqinisekise ukugoba ngokuthe ngcembe kwaye basebenzise imikhondo egobileyo ukuthintela uxinzelelo.

3. Nciphisa inani leenguqu eziguquguqukayo ukuya eziqinileyo:

Iinguqu ezininzi phakathi kweendawo eziguquguqukayo kunye neziqinileyo kufuneka zigcinwe zincinci. Inqaku ngalinye lenguqu lidala uxinizelelo loxinzelelo lomatshini olwenza buthathaka ukunyaniseka okupheleleyo kwebhodi. Ukunciphisa olu tshintsho kunceda ukuphucula ukuthembeka kunye nokuqina.

4. Sebenzisa ububanzi bomqhubi owaneleyo:

Ububanzi be-conductor budlala indima ebalulekileyo ekunciphiseni ukuxhathisa kunye nemiphumo yokushisa. Kucetyiswa ukuba kusetyenziswe imikhondo ebanzi kwiindawo eziqinileyo ukuthwala imisinga ephezulu kunye nemigca emincinci kwiindawo eziguquguqukayo zokunciphisa uxinzelelo. Ububanzi be-conductor obaneleyo bukwavumela ingqibelelo yesignali engcono kunye nolawulo lwe-impedance.

5. Gcina ubukhulu bobhedu olwaneleyo:

Ukuqinisekisa ukuhanjiswa kombane okulungileyo kunye nokuchithwa kobushushu, kubalulekile ukugcina ubuninzi bobhedu olwaneleyo kwiindawo zombini eziqinileyo kunye neziguquguqukayo. Umaleko wobhedu ongqindilili wonyusa amandla oomatshini kwaye unciphise ukuxhathisa kombane, ngaloo ndlela uphucula ukusebenza ngokubanzi kwePCB.

6. Idityaniswe ne-impedance elawulwayo:

Kwizicelo zesantya esiphezulu, i-impedance elawulwayo ibalulekile. Abaqulunqi kufuneka babale ngononophelo ububanzi bomkhondo kunye nobukhulu be-dielectric ukufezekisa i-impedance efunekayo. Ukuthelekisa okuchanekileyo kwe-impedance kunceda ukuthintela ukubonakaliswa kweempawu kunye nokuqinisekisa ukusebenza okuthembekileyo.

7. Landela izikhokelo zozinzo lwe-dimensional:

Ukwandiswa kwe-Thermal kunye nokunciphisa kunokuchaphazela kakhulu ukusebenza kwee-PCB eziguquguqukayo. Abaqulunqi kufuneka bahlawule ngokucokisekileyo ukuzinza kwe-dimensional yezinto ezisetyenzisiweyo. Ukukhetha izinto ezine-coefficients ezifanayo zokwandiswa kwe-thermal kunokunceda ukunciphisa umngcipheko wokungaphumeleli ngenxa yoxinzelelo olugqithisileyo.

8. Qinisekisa ukuba amacandelo abekwe ngokuchanekileyo:

Amacandelo abekwe ngobuchule abaluleke kakhulu kulawulo lwe-thermal kunye nokunciphisa umngcipheko woxinzelelo lomatshini. Kungcono ukubeka amacandelo anzima kufutshane neendawo eziqinileyo ukukhusela iindawo eziguquguqukayo ukusuka kwi-flexing over-flexing kunye noxinzelelo. Ukubekwa ngononophelo kukwanceda kumzila osebenzayo kunye nemfezeko yomqondiso.

9. Vavanya kwaye uqinisekise uyilo:

Uvavanyo olubanzi kunye nokuqinisekiswa koyilo lwePCB oluguquguqukayo lubalulekile ngaphambi kokungena kwimveliso. Iprototyping kunye novavanyo olucokisekileyo lunceda ekuchongeni naziphi na iimpazamo kuyilo olunokubakho, imiba yokusebenza, okanye imiba yokuvelisa. Ukuqinisekiswa okuphindaphindiweyo kuqinisekisa ukuba uyilo lokugqibela luhlangabezana nazo zonke iinkcukacha ezifunekayo.

10. Sebenza nabavelisi abanamava:

Ukusebenza kunye nomvelisi onamava we-PCB ogxile kwitekhnoloji ye-rigid-flex kubalulekile. Ubungcali kunye nolwazi lwabo lunokunceda kakhulu ekuphuculeni uyilo, ukuqinisekisa ukwenziwa okuchanekileyo kunye nokuhlangabezana nemigangatho yoshishino. Basenokukhokela abayili ekukhetheni izixhobo ezifanelekileyo kunye neenkqubo zendibano yePCB eyimpumelelo.

Ukuququmbela:

Kubalulekile ukubambelela kwezi zikhokelo zoyilo jikelele xa uyila iiPCBs eziguquguqukayo. Ukucwangcisa ngokucokisekileyo, ukuqwalaselwa kweempawu zezinto eziphathekayo, umzila olawulwayo, kunye novavanyo olufanelekileyo zizinto ezingundoqo ekufezekiseni ii-PCB ezithembekileyo, ezisebenza ngokungqongqo. Ngokulandela ezi zikhokelo kunye nokusebenza kunye nomvelisi onamava, abaqulunqi banokuqinisekisa impumelelo yeeprojekthi zabo ze-PCB eziguquguqukayo.

Ixesha lokuposa: Sep-18-2023

Emva