Yazisa:

Kwimveliso yombane, indibano yePCB kunye novavanyo ngamanyathelo abalulekileyo ekuqinisekiseni ukusebenza kakuhle nokuthembeka kweebhodi zesekethe eziprintiweyo (PCBs). Ngeminyaka eyi-15 yamava okuvelisa ibhodi yesekethe, iCapel yinkampani eyaziwayo enika inkxaso yenkqubo ebanzi yendibano yePCB kunye novavanyo.Kule bhlog, siza kungena nzulu kubuchule bukaCapel kwezi ndawo, sijonge amandla abo kunye nendlela abancedisa ngayo ukwenza inkqubo yokwenziwa kwePCB engenamthungo.

Qonda inkqubo yendibano yePCB:

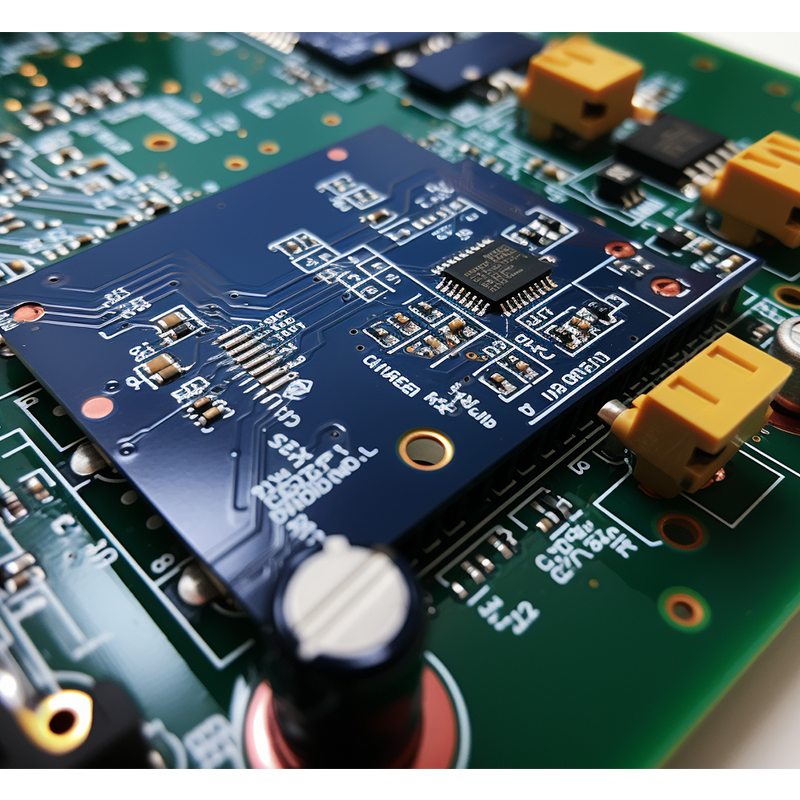

Indibano yePCB yinkqubo entsonkothileyo ebandakanya ukudibanisa amacandelo e-elektroniki kwibhodi yesekethe eprintiweyo ukwenza isixhobo esisebenzayo. I-Capel iyabuqonda ubunzima bale nkqubo kwaye inezakhono kunye nezixhobo ezifunekayo ukuyiphatha ngobuchule. Injongo yabo kukwandisa inkqubo yendibano kunye nokuhambisa umgangatho ophezulu kunye nokusebenza okungagungqiyo ngelixa bethobela imigangatho yoshishino kunye nezenzo ezilungileyo.

Ukuthengwa kwecandelo:

Omnye wemiba ephambili yendibano yePCB kukufumana amacandelo afanelekileyo. I-Capel iqinisekisa ukuba kuphela iindawo ezisemgangathweni kunye neziphezulu ezisetyenziselwa ukudibanisa. Uthungelwano lwabo olubanzi lwababoneleli lubavumela ukuba bafumane amacandelo avela kubavelisi abathembekileyo, ukunciphisa umngcipheko weenxalenye zomgunyathi okanye ezingekho mgangathweni. Ukufumana icandelo elisebenzayo akuqinisekisi ukuthembeka kuphela, kodwa kuphucula ukusebenza ngokubanzi kunye nobomi obude be-PCB.

INdibano ye-Surface Mount Technology (SMT):

ICapel igxile kakhulu kwindibano yeSurface Mount Technology (SMT), indlela esetyenziswa ngokubanzi nesebenzayo yokunyuswa kwezixhobo ze-elektroniki kwiiPCB. I-SMT ibonelela ngeenzuzo ezininzi, kubandakanywa ukuxinana kwecandelo eliphezulu, ukuthembeka okukhulu, kunye neendleko eziphantsi zemveliso. Izakhono zendibano ze-SMT zanamhlanje ze-SMT ezidityaniswe nabachwephesha abanezakhono ziqinisekisa ukubekwa okuchanekileyo, i-solder echanekileyo kunye nomgangatho ohlangeneyo ofanelekileyo, ophumela kwii-PCB ezithembekileyo neziphezulu.

Ngokudibanisa umngxuma:

Ngelixa i-SMT iyeyona ndlela ikhethwayo yokudityaniswa kwe-PCB, amanye amacandelo kunye nezicelo zifuna ukudityaniswa komngxuma womngxuma. I-Capel ihlangabezana nezo mfuno ngokunikezela ngeenkonzo zokudityaniswa komngxuma. Ubuchule bubandakanya ukufaka iintambo zecandelo le-elektroniki kumngxuma ogrunjiweyo kwi-PCB uze uwathengise kwelinye icala. Ubuchwephesha beCapel kwindibano ye- through-hole assembly iqinisekisa ukuba inkqubo ayinasiphako, nto leyo ekhokelela kuqhagamshelo olukhuselekileyo nakwizicelo ezifuna kakhulu.

Iinkqubo zovavanyo olungqongqo:

Kwi-Capel, indibano yePCB ayipheli ngokubekwa kwecandelo kunye nokuthengisa. Bayakuqonda ukubaluleka kovavanyo olucokisekileyo ukuze bachonge naziphi na iimpazamo okanye iziphene ezinokubakho. Iinkqubo zokuvavanya iCapel zibandakanya uluhlu lweendlela, kubandakanywa uvavanyo olusebenzayo, uvavanyo lwe-in-circuit (ICT) kunye novavanyo lokutshisa. Ezi nkqubo zovavanyo zingqongqo ziyilelwe ukuqinisekisa intembeko yePCB edityanisiweyo, iqinisekisa ukuba icandelo ngalinye lisebenza njengoko kulindelekile kwaye yonke inkqubo ihlangabezana nemigaqo efunekayo.

Uvavanyo olusebenzayo kunye nokuqinisekiswa komgangatho:

Ukuzinikela kukaCapel kumgangatho kudlulela ngaphaya kovavanyo lwecandelo lomntu ngamnye. Baqhuba uvavanyo olusebenzayo olubanzi ukuvavanya ukusebenza ngokubanzi kwePCB edibeneyo. Ngokufanisa iimeko zobomi bokwenene, iCapel inokuchonga nakuphi na ukungahambelani okanye imiba, iququzelele ukulungiswa ngexesha elifanelekileyo kunye nokunciphisa ukungaphumeleli kwexesha elizayo. Ugxininiso lwabo kuqinisekiso lomgangatho luqinisekisa ukuba kuphela ii-PCBs ezanelisayo eziziswa kubathengi, ngaloo ndlela kwandisa ukwaneliseka kwabathengi kunye nokunciphisa umngcipheko wokungaphumeleli kwemveliso kade.

Uphuculo oluqhubekayo kunye nophando kunye nophuhliso:

Amava kaCapel ekuveliseni ibhodi yesekethe akhuthaza inkcubeko yophuculo oluqhubekayo kunye nophando kunye nophuhliso (R&D). Basoloko bezama ukuphucula indibano ye-PCB kunye neenkqubo zovavanyo kwaye bahambisane neteknoloji evelayo kunye neendlela zoshishino. Oku kuzinikezela kwizinto ezintsha kuqinisekisa ukuba uCapel uhlala ehamba phambili kwishishini, ukubonelela abathengi ngezisombululo ezibukhali kunye nokuhlala phambili kukhuphiswano.

Ukuququmbela:

Amava amaninzi kaCapel ekuveliseni ibhodi yesekethe, kunye nobuchule babo kwindibano yePCB kunye neenkqubo zokuvavanya, kubenza babe liqabane elithembekileyo kubenzi bezinto zombane kwihlabathi jikelele. Ngokubeka phambili ukufunwa kwecandelo, ukusebenzisa iindlela eziphambili zokuhlanganisa, ukuqhuba uvavanyo olungqongqo, kunye nokuhlakulela inkcubeko yokuphucula okuqhubekayo, iCapel ibeke ibhenchmark entsha kwi-PCB yokuvelisa. Ngokuzibophezela okungagungqiyo kumgangatho kunye nokwaneliseka kwabathengi, iCapel ibonakalise ukuba yinto ehamba phambili kwinkxaso yenkqubo ebanzi ehambelana nendibano yePCB kunye novavanyo.

Ixesha lokuposa: Nov-01-2023

Emva