Yazisa:

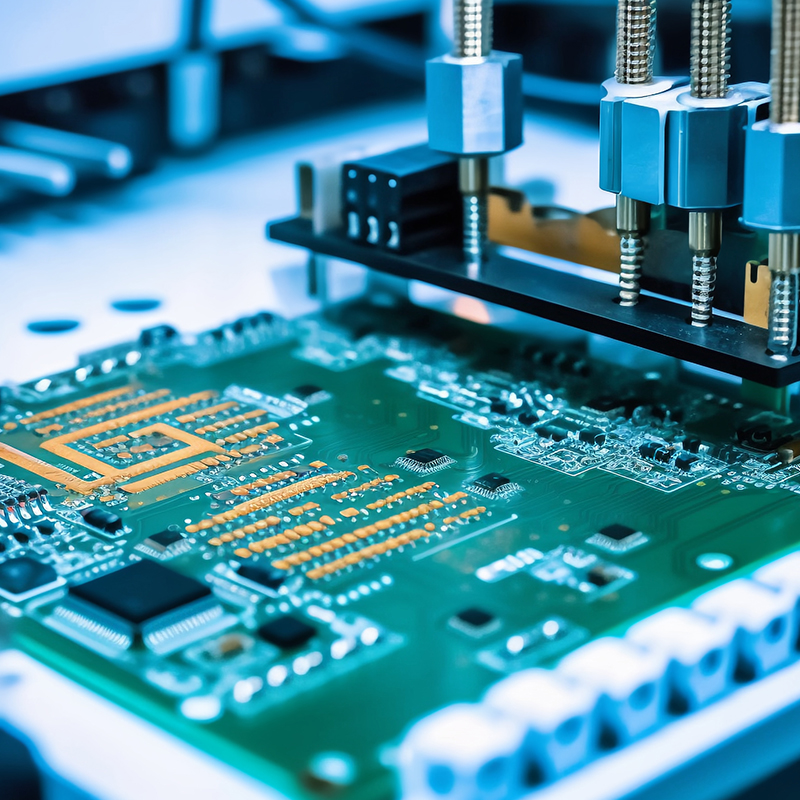

I-welding yebhodi yesekethe yinkqubo ephambili kwishishini lokuvelisa i-electronics, iqinisekisa ukusebenza ngokufanelekileyo kunye nokuthembeka kwezixhobo zombane. Nangona kunjalo, njengayo nayiphi na inkqubo yokuvelisa, ayikho ngaphandle kwemingeni yayo.Kule bhlog, siza kuntywila nzulu kwezona ngxaki zixhaphakileyo ezenzekayo xa kuthengiswa iibhodi zesekethe kwaye sijonge izisombululo ezisebenzayo zokuzoyisa.

1. PCB ibhodi yesekethe emfutshane:

Enye yeengxaki eziqhelekileyo kwi-soldering yebhodi yesekethe yimijikelezo emfutshane. Isiphaluka esifutshane senzeke xa i-current ithatha indlela engalindelekanga ngenxa yoxhumo oluphantsi lokumelana phakathi kwamanqaku amabini kwisekethe. Oku kunokubangelwa zizinto ezahlukeneyo, ezifana neebhulorho ze-solder, i-debris conductive elahlekileyo, okanye iziphene zoyilo.

isisombululo:

Ukuze ugweme iisekethe ezimfutshane, kubalulekile ukuhlola ngokucokisekileyo kunye nokuvavanya ibhodi emva kwenkqubo ye-soldering. Ukuphumeza itekhnoloji yokuhlola i-automated optical inspection (AOI) inganceda kakhulu ekuchongeni imiba enokubakho yesekethe emfutshane. Ukongezelela, ukusebenzisa izixhobo ezichanekileyo zokubethelela, ezifana nentsimbi ye-soldering kunye nokulawula ukushisa, kunokunceda ukukhusela i-solder engaphezulu ekwenzeni uxhulumaniso olungeyonjongo.

2. Uqhagamshelwano olumnyama kunye nolunenkozo:

Uqhagamshelwano olumnyama kunye nolunenkozo kumphezulu we-PCB lunokubonisa uxhulumaniso olubi lwe-solder. Le ngxaki idla ngokubangelwa kukungadluliswa kobushushu okwaneleyo ngexesha lenkqubo ye-solder, okubangela ukumanzisa okungaphelelanga kwe-solder joint.

isisombululo:

Ukufezekisa ukumanzisa okufanelekileyo kunye nokuthintela ukudibanisa okumnyama, i-grainy, i-welding parameters kufuneka iphuculwe. Qinisekisa ukuba incam yentsimbi yokujongisisa icocekile, ifakwe kwitoti, kwaye ikwiqondo lobushushu elichanekileyo. Ukongeza, ukusebenzisa i-flux ngexesha le-soldering kunokuphucula ukuhamba kwe-solder kunye nokuphucula ukuhlangana. I-Flux inceda ukususa ii-oksidi kunye nezingcoliso ezivela kumphezulu wesinyithi, ukukhuthaza ukumanzisa okungcono kunye nokuqina kwamalungu e-solder.

3. Amalungu e-solder e-PCB ajika abe bugolide tyheli:

Xa amalungu e-solder kumphezulu we-PCB ajika atyheli egolide, oko kubonisa ukuba kukho iingxaki ezifana nokwakheka kwe-alloy ye-solder engachanekanga okanye iteknoloji ye-solder engalunganga. Lo mbandela unokuchaphazela ingqibelelo nokuthembeka kwebhodi yesekethe.

isisombululo:

Ukusebenzisa i-alloy ye-solder echanekileyo kubalulekile ekuqinisekiseni ubude bebhodi yesekethe yakho. Ngalo lonke ixesha unamathela kwimigangatho yealloyi ye-solder kwaye ugweme ukusebenzisa izinto ezikumgangatho ophantsi okanye ezingangqinisiswanga. Ukongezelela, ukugcina amaqondo okushisa afanelekileyo kunye nokusetyenziswa kobuchule obufanelekileyo be-solder, kubandakanywa ukutshisa i-PCB kunye nokusebenzisa umlinganiselo ofanelekileyo we-solder, kunokunceda ukufikelela kwizinga eliphezulu le-solder yegolide.

4. Impembelelo yokusingqongileyo kwiziphene zebhodi yesekethe:

Imeko apho iibhodi zeesekethe zithengiswa nazo zinokuchaphazela kakhulu umgangatho wemveliso yokugqibela. Izinto ezifana nokufuma, ukuguquguquka kobushushu, kunye nongcoliseko lomoya kunokubangela iziphene ezahlukeneyo kwiibhodi zesekethe.

isisombululo:

Ukunciphisa impembelelo yokusingqongileyo kwiziphene zebhodi yesekethe, kubalulekile ukuseka indawo yokuvelisa elawulwayo. Umonakalo obangelwe ngumbane ongashukumiyo unokuthintelwa ngokumisela imiqathango efanelekileyo ye-ESD (i-electrostatic discharge), efana nokusebenzisa indawo yokusebenzela ekhuselekileyo ye-ESD kunye nokunxiba izixhobo zokukhusela. Ukongeza, ukugcina amaqondo afanelekileyo obushushu kunye nokufuma kwiindawo zemveliso kunceda ukuthintela iingxaki ezifana neziphene ze-welding kunye nokuthotywa kwezinto.

Ukuququmbela:

I-solder yebhodi yesekethe yinkqubo enzima efuna ukuchaneka kunye nengqalelo kwiinkcukacha.Ngokucombulula iingxaki eziqhelekileyo ezivame ukuvela ngexesha le nkqubo, abavelisi banokuqinisekisa ukuveliswa kwezixhobo zombane ezikumgangatho ophezulu, ezithembekileyo. Ukuphumeza izisombululo ezixutyushwa kule bhlog, njengeendlela zokuhlola ezisebenzayo, iiparamitha ze-soldering eziphuculweyo, kunye neemeko ezilawulwayo zokusingqongileyo, kunokuphucula kakhulu umgangatho webhodi yesiphaluka.

Ixesha lokuposa: Oct-23-2023

Emva