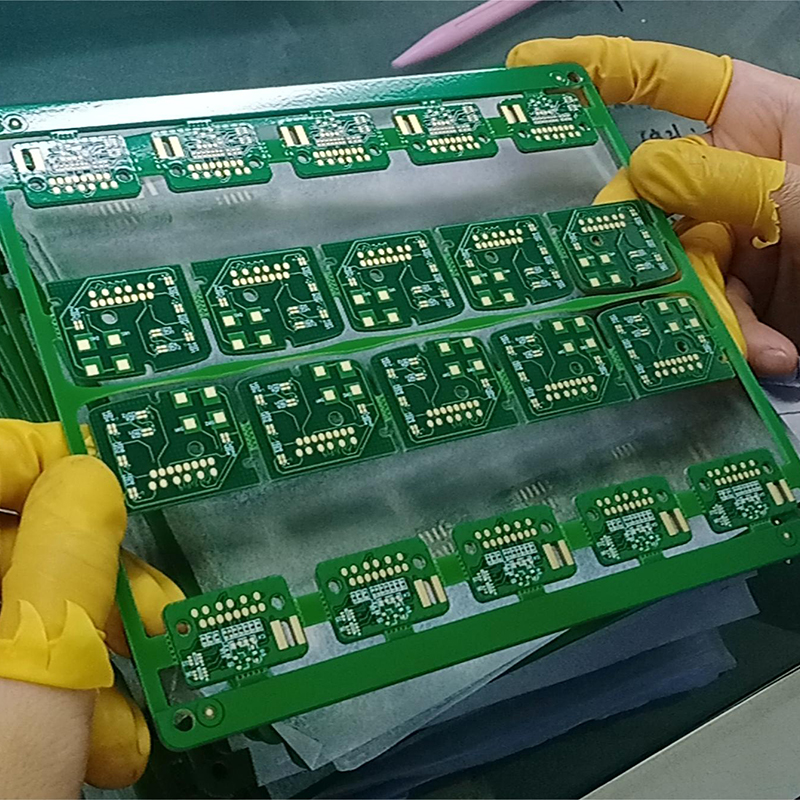

Iibhodi zesekethe eziprintiweyo (PCBs) zizinto ezibalulekileyo kwizixhobo ze-elektroniki, kwaye iibhodi zesekethe eziprintiweyo eziqinileyo zisetyenziselwa ukuqina kwazo kunye nokuguquguquka. Nangona kunjalo, ekuhambeni kwexesha, ezi PCBs zinokonakala kwaye zifuna ukulungiswa.Apha siza kungena kwisihloko sokulungisa ii-PCBs eziguquguqukayo ezonakalisiweyo, sihlolisise iintlobo eziqhelekileyo zomonakalo onokuthi zenzeke, sihlolisise iindlela ezahlukeneyo zokulungisa, kwaye sigxininise izinto ezibalulekileyo ekufuneka ziqwalaselwe xa ulungisa ngempumelelo i-PCB.Ngokuqonda izinto ezinokwenzeka kunye nobuchule obubandakanyekayo, unokucombulula ngempumelelo umonakalo wePCB kwaye ubuyisele ukusebenza kwizixhobo zombane.

Ukuqonda iibhodi eziguquguqukayo:

Ngaphambi kokuntywila kwiindlela zokulungisa i-PCB eyonakeleyo eqinileyo, masiqonde ukuba ziyintoni na.Ibhodi engqongqo-flex luhlobo lwebhodi edibeneyo edibanisa i-PCB eguquguqukayo kunye ne-PCB eqinile. Ezi bhodi zibandakanya iileyile eziguquguqukayo ezidityanisiweyo kunye namacandelo aqinileyo, anikezela ukuguquguquka kunye nokuzinza. Iibhodi eziguquguqukayo ezingqongqo zihlala zisetyenziswa kwizicelo ezibandakanya imiqobo yendawo kunye noyilo oluntsonkothileyo.

Iintlobo zomonakalo oqhelekileyo kwiibhodi zepcb eziguquguqukayo:

Iibhodi ezi-Rigid-flex zinokubandezeleka kwiintlobo ezahlukeneyo zomonakalo kwaye zinokufuna ukulungiswa okanye ukutshintshwa. Ezinye iintlobo eziqhelekileyo zomonakalo ziquka:

a) Iingcingo ezaphukileyo:Umkhondo kwi-PCB eguquguqukayo inokwaphuka ngenxa yoxinzelelo lomatshini okanye uxinzelelo lwangaphandle. Oku kunokwenzeka ngexesha lokuphatha okanye ukudibanisa, okanye ngenxa yokuguquguquka okugqithisileyo okanye ukugoba kwebhodi. Intambo ephukileyo inokubangela ukuba uxhulumaniso lombane luphazamiseke, lubangele ukungasebenzi kakuhle okanye ukungasebenzi kakuhle kwesekethe.

b) Ukusilela kwelungu:Izixhobo ezithengiswa kwi-PCB eguquguqukayo eqinile, efana ne-resistors, i-capacitors, okanye iisekethe ezidibeneyo, zingonakala okanye zingaphumeleli ekuhambeni kwexesha. Oku kunokubangelwa zizinto ezinje ngokuguga, i-voltage spikes, ubushushu obugqithisileyo okanye uxinzelelo lomatshini. Xa icandelo lisilela, ukusebenza kwe-PCB kuthotywa, kubangele iingxaki nge-electronics ekuyo.

c) Ukucalula:I-Delamination yenzeka xa iileya ezingaphakathi kwePCB zahlukana okanye zixobuka. Oku kunokubangelwa yimibandela eyahlukeneyo, kubandakanywa ukuvezwa kwamaqondo okushisa agqithisileyo ngexesha lokuvelisa okanye ukuphatha, ukugoba ngokugqithiseleyo okanye ukugoba kwebhodi, okanye ukuphatha ngokungafanelekanga ngexesha lokudibanisa. I-Delamination yenza buthathaka isidima se-PCB, ekhokelela ekusebenzeni kombane okuphantsi kunye nokusilela kwesekethe.

d) Iziqhagamshelo ezonakeleyo:Iziqhagamshelo, ezinjengeesokethi okanye iiplagi, zisetyenziselwa ukuseka unxibelelwano lombane phakathi kwamacandelo ahlukeneyo ebhodi eqinileyo okanye phakathi kwePCB kunye nezixhobo zangaphandle. Ezi ziqhagamshelo zingonakaliswa kukothuka komzimba, ukufakwa okanye ukususwa ngokungafanelekanga, okanye ukunxitywa kunye nokukrazula ngokuhamba kwexesha. Iziqhagamshelo ezonakalisiweyo zinokubangela ukuqhagamshelwa kombane okungazinzanga, ukungaphumeleli kwangethuba, okanye ukulahleka okupheleleyo konxibelelwano phakathi kwamacandelo.

Iindlela ezinokwenzeka zokulungisa iibhodi zesekethe eziguquguqukayo ezinokwenzeka:

Ukulungisa kwakhona kuyindlela esebenzayo kwezinye iimeko, nangona ukutshintshwa kweephaneli eziguquguqukayo ezonakalisiweyo kunokuba yimfuneko kwezinye iimeko ezinzima. Nazi iindlela eziqhelekileyo zokulungisa umonakalo kwiibhodi eziguquguqukayo eziqinileyo:

a) Ukulungisa umkhondo:Xa umkhondo kwibhodi ye-rigid-flex ibonakaliswe okanye iphukile, inokulungiswa ngokuphinda udibanise umbane. Enye indlela kukusebenzisa ipeyinti eqhubayo, esetyenziswa ngokuthe ngqo kwindawo eyonakeleyo ukuvala umsantsa. Enye inketho kukusebenzisa i-adhesive conductive, esetyenziswe kwindawo eyonakalisiweyo kwaye iphiliswe ukwenza indlela yokuhambisa. I-tape ye-adhesive-backed copper ingasetyenziselwa ukulungisa umkhondo ngokuyibeka phezu kwendawo eyonakalisiweyo kunye nokuqinisekisa uqhagamshelwano olufanelekileyo lombane.

b) Ukutshintshwa kwelungu:Ukuba icandelo kwibhodi ye-rigid-flex ihluleka okanye yonakele, inokutshintshwa ngabanye. Oku kufuna ukuba kuchongwe amacandelo athile ekufuneka etshintshwe kwaye kuqinisekiswe ukuba zikhona ezinye ezihambelanayo. Icandelo eliphosakeleyo linokuchithwa kwi-PCB ngentsimbi ye-soldering okanye i-reflow station, kwaye inxalenye entsha inokuthengiswa kwindawo yayo.

c) Ukulungiswa kweDelamination:Ukulungisa iileya ezilahlisiweyo kwi-PCB eguquguqukayo kunokuba ngumngeni. Kwezinye iimeko, isisombululo sokubambelela singasetyenziselwa ukuphinda unamathisele i-delaminated layers. Faka ngokucophelela i-adhesive kwindawo echaphazelekayo, uqinisekise ukuba yenza uqhagamshelwano olufanelekileyo kunye nazo zonke iileya. Nangona kunjalo, ukuba i-delamination inzima okanye iileya zonakaliswe kakhulu, ungenelelo lobuchule okanye ukutshintshwa kwePCB kungafuneka.

d) Ukutshintsha isiqhagamshelo:Ukuba umdibaniso kwibhodi e-rigid-flex yonakalisiwe, inokutshintshwa ngokuchithwa kwekhonkco ephosakeleyo kunye ne-solder entsha. Oku kufuna ukususwa ngononophelo kwamacandelo anesiphene usebenzisa i-soldering iron okanye i-reflow station. Isidibanisi esitsha emva koko sithengiswa kwindawo enye, ukuqinisekisa ukulungelelaniswa okufanelekileyo kunye noqhagamshelwano lombane.

Iingqwalaselo ezibalulekileyo zokuLungisa iibhodi zepcb eziqinileyo eziyimpumelelo:

Xa uzama ukulungisa ibhodi eyonakeleyo, kubalulekile ukuqwalasela oku kulandelayo:

a) Isakhono kunye nobuNgcali:Ukulungiswa kwePCB kufuna ubungcali kunye nokuchaneka. Ukuba awunamava, kuyacetyiswa ukuba udibane neengcali okanye ufune isikhokelo kwingcali kwintsimi.

b) Izixhobo kunye neZixhobo:Ukulungisa ii-PCBs kufuna izixhobo ezikhethekileyo kunye nezixhobo, ezifana neentsimbi ze-soldering, i-multimeters, iiglasi zokukhulisa, njl.njl., Ukuqinisekisa ukulungiswa okuchanekileyo kunye nokusebenzayo.

c) Uxwebhu loYilo:Amaxwebhu oyilo achanekileyo, kubandakanywa i-schematics kunye nokuhlelwa kwebhodi, kubalulekile ukuqonda isakhiwo se-PCB kunye nokuchonga iindawo ezonakalisiweyo.

d) Uvavanyo kunye nokuqinisekiswa:Emva kokulungisa ibhodi ye-rigid-flex, inani elikhulu leemvavanyo kufuneka liqhutywe ukuze kuqinisekiswe ukusebenza kakuhle kokulungiswa. Oku kubandakanya ukujonga uqhagamshelo lombane olufanelekileyo, umsebenzi kunye nokumelana nombane.

e) Ukucoca nokuhlola:Kubalulekile ukucoca ibhodi e-rigid-flex kakuhle ngaphambi kokuqala inkqubo yokubuyisela. Uthuli, ukungcola kunye ne-debris kunokuthintela inkqubo yokulungisa kwaye kuchaphazele umsebenzi we-PCB elungisiweyo. Ukuhlolwa ngononophelo kwebhodi kunokunceda ekuboneni nawuphi na omnye umonakalo okanye imiba enokufuna ukulungiswa ngexesha lokulungiswa.

f) Amanyathelo okhuseleko:Ukulungiswa kwe-PCB kubandakanya amacandelo e-elektroniki kunye ne-soldering, enokuthi ibeke umngcipheko wokhuseleko. Kubalulekile ukulandela amanyathelo okhuseleko afanelekileyo, njengokunxiba izixhobo zokhuselo ezifana neeglavu kunye neendondo zokhuseleko. Kwakhona, ukuqinisekisa ukuba iPCB icinyiwe kwaye iqhawulwe kuwo nawuphi na umthombo wamandla kubalulekile ukunqanda ukothuka kombane okanye umonakalo wecandelo.

g) Umgangatho wezinto zokulungisa:Izixhobo, i-solders, i-adhesives kunye nezinye izinto zokulungisa ezisetyenziselwa inkqubo yokulungisa ziya kuba kumgangatho ophezulu. Ukusebenzisa izinto ezingafanelekanga kunokubangela ukulungiswa kakubi okanye umonakalo ongakumbi kwibhodi e-rigid-flex. Ukufumana izinto ezithembekileyo nezithembekileyo zokubuyisela kubaluleke kakhulu.

h) Ixesha kunye nomonde:PCB ukulungiswa kufuna ingqalelo iinkcukacha kunye nomonde. Ukukhawuleza kwinkqubo yokulungisa kunokubangela iimpazamo okanye ukulungiswa okwaneleyo. Thatha ixesha elifunekayo ukuhlalutya ngononophelo umonakalo, cwangcisa amanyathelo okulungisa kwaye uwenze ngokucokisekileyo.

i) Amaxwebhu kunye nokugcinwa kweerekhodi:Kuyacetyiswa ukuba kugcinwe amaxwebhu kunye neerekhodi zenkqubo yolondolozo. Oku kubandakanya ukubhalwa kwamanyathelo athathiweyo, izinto ezisetyenzisiweyo, kunye naluphi na utshintsho olwenziwe ngexesha lokubuyisela. Olu xwebhu luluncedo kwireferensi yexesha elizayo okanye nayiphi na imiba enokuthi ivele kamva.

j) Uncedo lobungcali:Ukuba ibhodi ye-rigid-flex eyonakalisiweyo iyinkimbinkimbi okanye umsebenzi wokulungisa ubonakala ungaphezu kwamandla akho, kuyacetyiswa ukuba ufune uncedo lwengcali. Amagcisa okulungisa iPCB anamava nanobuchule anokubonelela ngesikhokelo sobuchule kwaye aqinisekise ukulungiswa okuyimpumelelo.

Ukulungisa ezonakalisiweyo flex iibhodi zesekethe eprintiweyo kunokwenzeka kwezinye iimeko.Impumelelo yokubuyisela ixhomekeke kubungakanani kunye nohlobo lomonakalo kunye nokusetyenziswa ngokufanelekileyo kweendlela zokubuyisela. Nangona kunjalo, mayivunywe ukuba kwezinye iimeko umonakalo usenokungalungiseki kwaye kuya kufuneka ukutshintshwa ngokupheleleyo kwePCB. Ukuqinisekisa iziphumo ezilungileyo, kucetyiswa ukuba ufune uncedo lweengcali, ngakumbi ukulungiswa okuyinkimbinkimbi okanye iimeko zokungaqiniseki. Ukuthathela ingqalelo le miba kuya kunceda ukufezekisa iziphumo ezichanekileyo nezithembekileyo zokulungisa iipaneli eziqinileyo.I-Shenzhen Capel Technology Co., Ltd. yaseka umzi-mveliso wayo oqinileyo we-flex pcb ngo-2009 kwaye iyingcali yeFlex Rigid Pcb Manufacturer. Ngeminyaka eyi-15 yamava eprojekthi etyebileyo, ukuhamba kwenkqubo engqongqo, ubuchule obugqwesileyo bobugcisa, izixhobo ezizenzekelayo ezizenzekelayo, inkqubo yokulawula umgangatho obanzi, kwaye uCapel uneqela leengcali zeengcali ukubonelela abathengi behlabathi ngokuchaneka okuphezulu, umgangatho ophezulu we-1-32 layer rigid flex. ibhodi, hdi Rigid Flex Pcb, Rigid Flex Pcb Fabrication, rigid-flex pcb assembly, fast turn rigid flex pcb, quick turn pcb prototypes.Our responsive pre-intengiso kunye neenkonzo zobugcisa emva-intengiso kunye nonikezelo ngexesha zenza ukuba abathengi bethu babambe imarike ngokukhawuleza. amathuba kwiiprojekthi zabo.

Ixesha lokuposa: Aug-28-2023

Emva