Iibhodi zeesekethe ze-Automotive electronics eziprintiweyo (PCBs) zidlala indima ebalulekileyo ekusebenzeni kwezithuthi zanamhlanje eziphambili. Ukusuka kwiinkqubo ze-injini zokulawula kunye nemiboniso ye-infotainment ukuya kulawulo lweempawu zokhuseleko kunye nezakhono zokuqhuba ezizimeleyo, ezi PCB zifuna uyilo olucokisekileyo kunye neenkqubo zokuvelisa ukuqinisekisa ukusebenza kakuhle kunye nokuthembeka.Kweli nqaku, siza kungena kuhambo oluntsonkothileyo lweePCB ze-elektroniki zemoto, sijonge amanyathelo aphambili abandakanyekayo ukusuka kwinqanaba lokuqala loyilo ukuya kuthi ga kwimveliso.

1.Ukuqonda iPCB yemoto yombane:

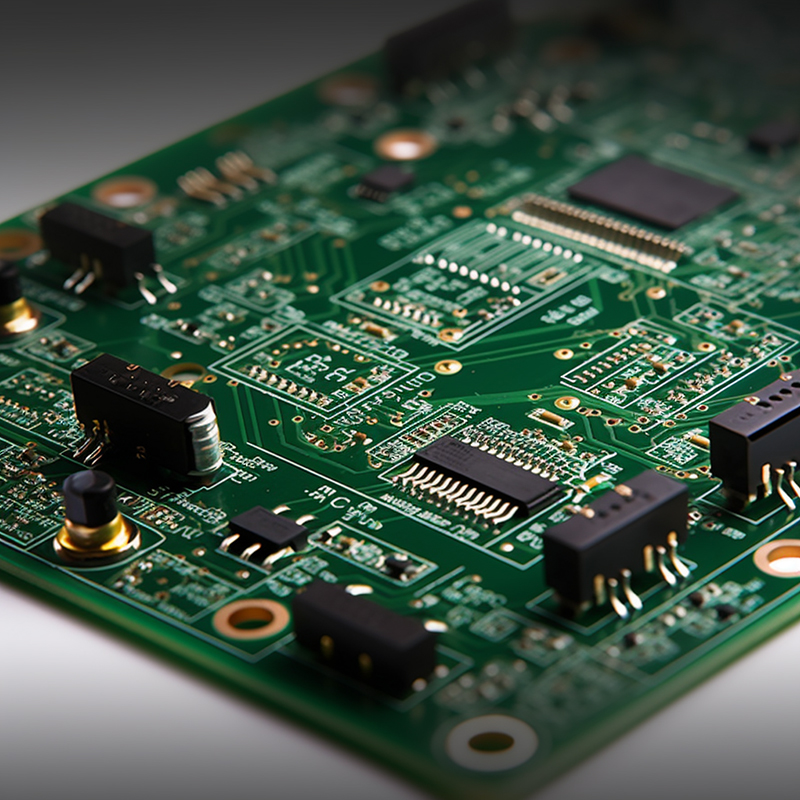

I-Automotive electronics PCB okanye ibhodi yesekethe eprintiweyo yinxalenye ebalulekileyo yeemoto zanamhlanje. Banoxanduva lokubonelela ngoqhagamshelo lombane kunye nenkxaso kwiinkqubo ezahlukeneyo zombane kwimoto, ezifana neeyunithi zokulawula iinjini, iisistim ze-infotainment, izinzwa, njl.njl.Into ephambili yeePCB ze-automotive electronics kukukwazi kwabo ukumelana nemekobume yemoto erhabaxa. Izithuthi ziphantsi kotshintsho olugqithisileyo lobushushu, ukungcangcazela kunye nengxolo yombane. Ngoko ke, ezi PCBs kufuneka ukuba ixesha elide kakhulu kwaye zithembeke ukuqinisekisa ukusebenza kakuhle kunye nokhuseleko. IiPCB ze-Automotive electronics zihlala ziyilwe kusetyenziswa isoftware ekhethekileyo evumela iinjineli ukuba zenze iiplani ezihlangabezana neemfuno ezithile zoshishino lweemoto. Ezi mfuno ziquka izinto ezifana nobukhulu, ubunzima, ukusetyenziswa kwamandla, kunye nokuhambelana kombane kunye namanye amacandelo. Inkqubo yokwenziwa kweePCB zombane wemoto ibandakanya amanyathelo amaninzi. Uyilo lwePCB luyilwe kuqala kwaye lulinganiswe ngokucokisekileyo kwaye luvavanyiwe ukuqinisekisa ukuba uyilo luyahlangabezana nemigaqo efunekayo. Uyilo luthi ke ludluliselwe kwi-PCB ebonakalayo kusetyenziswa ubuchule obunje ngokufaka okanye ukufaka imathiriyeli yokuqhuba kwi-PCB substrate. Ukunika ubunzima bee-PCB ze-elektroniki zemoto, amacandelo awongezelelweyo afana ne-resistors, i-capacitors, kunye neesekethe ezidibeneyo zihlala zixhonywe kwi-PCB ukugqiba i-electronic circuit. La macandelo aqhele ukuxhonywa phezulu kwi-PCB kusetyenziswa oomatshini bokubeka abazenzekelayo. Ingqwalasela ekhethekileyo ihlawulwa kwinkqubo ye-welding ukuqinisekisa uxhulumaniso olufanelekileyo kunye nokuqina. Ukunika ukubaluleka kweenkqubo zombane zemoto, ulawulo lomgangatho lubalulekile kushishino lweemoto. Ke ngoko, iiPCB ze-elektroniki zeemoto zivavanywa ngokungqongqo kwaye zihlolwe ukuqinisekisa ukuba ziyayifezekisa imigangatho efunekayo. Oku kubandakanya uvavanyo lombane, ukukhwela ibhayisekile eshushu, uvavanyo lokungcangcazela kunye novavanyo lokusingqongileyo ukuqinisekisa ukuthembeka kunye nokuqina kwePCB phantsi kweemeko ezahlukeneyo.

2.Inkqubo yoyilo lwePCB yombane yeemoto:

Inkqubo yoyilo lwePCB yeemoto zombane ibandakanya amanyathelo abalulekileyo okuqinisekisa ukuthembeka, ukusebenza, kunye nokusebenza kwemveliso yokugqibela.

2.1 Uyilo lweskim: Inyathelo lokuqala kwinkqubo yoyilo luyilo lweskim.Kweli nyathelo, iinjineli zichaza uqhagamshelo lombane phakathi kwezinto ezizimeleyo ngokusekwe kusetyenziso olufunekayo lwePCB. Oku kubandakanya ukwenza umzobo weskim omele isekethe ye-PCB, kubandakanywa uqhagamshelo, amacandelo, kunye nobudlelwane babo. Ngesi sigaba, iinjineli ziqwalasela izinto ezinje ngeemfuno zamandla, iindlela zomqondiso, kunye nokuhambelana nezinye iinkqubo kwisithuthi.

2.2 Uyilo loyilo lwePCB: Nje ukuba isicwangciso sigqityiwe, uyilo lungena kwisigaba soyilo loyilo lwePCB.Kweli nyathelo, iinjineli ziguqula iskimu sibe yimbonakalo yePCB. Oku kubandakanya ukugqiba ubungakanani, imilo, kunye nendawo yamacandelo kwibhodi yesekethe, kunye nokuhamba kweendlela zombane. Uyilo loyilo kufuneka luqwalasele izinto ezinje ngemfezeko yomqondiso, ulawulo lwe-thermal, ukuphazamiseka kwe-electromagnetic (EMI), kunye nokwenza. Ingqwalasela ekhethekileyo ihlawulwa ekubekweni kwecandelo ukuze kuphuculwe ukuhamba komqondiso kunye nokunciphisa ingxolo.

2.3 Ukukhethwa kwecandelo kunye nokubekwa: Emva kokuba uyilo lokuqala lwePCB lugqityiwe, iinjineli ziyaqhubeka nokukhethwa kwecandelo kunye nokubekwa.Oku kubandakanya ukukhetha amacandelo afanelekileyo ngokusekelwe kwiimfuno ezifana nokusebenza, ukusetyenziswa kwamandla, ukufumaneka kunye neendleko. Izinto ezinje ngezixhobo zebakala lemoto, uluhlu lobushushu kunye nokunyamezela ukungcangcazela zibalulekile kwinkqubo yokhetho. Amacandelo abekwe kwi-PCB ngokuhambelana neenyawo zawo kunye nezikhundla ezimiselwe ngexesha loyilo lwenqanaba loyilo. Ukubekwa ngokufanelekileyo kunye nokuqhelaniswa kwamacandelo kubalulekile ekuqinisekiseni ukudibanisa okufanelekileyo kunye nokuhamba komqondiso ofanelekileyo.

2.4 Uhlalutyo lwengqibelelo yomqondiso: Uhlalutyo lwengqibelelo yomqondiso linyathelo elibalulekileyo kwi-automotive electronics PCB design.Ibandakanya ukuvavanya umgangatho kunye nokuthembeka kweempawu njengoko zisasazeka ngePCB. Olu hlalutyo lunceda ekuchongeni iingxaki ezinokuthi zibekho ezinje ngokuncipha komqondiso, i-crosstalk, imbonakalo, kunye nokuphazamiseka kwengxolo. Iindidi ezahlukeneyo zokulinganisa kunye nezixhobo zokuhlalutya zisetyenziselwa ukuqinisekiswa koyilo kunye nokwandisa uyilo ukuze kuqinisekiswe imfezeko yomqondiso. Abaqulunqi bagxila kwizinto ezinjengobude bokulandela umkhondo, ukuhambelana kwe-impedance, ingqibelelo yamandla, kunye nokulawulwa kwendlela yokuthintela ukuthintela ukuhambisa umqondiso ngokuchanekileyo kunye nokungenangxolo.

Uhlalutyo lwemfezeko yoMqondiso lukwathathela ingqalelo imiqondiso enesantya esiphezulu kunye nonxibelelwano olubalulekileyo lwebhasi olukhoyo kwiinkqubo zombane zemoto. Njengoko ubuchwepheshe obuphambili obufana ne-Ethernet, i-CAN kunye ne-FlexRay isetyenziswa ngokunyukayo kwizithuthi, ukugcina ingqibelelo yesignali kuba ngumngeni kwaye kubalulekile.

3.Inkqubo yokwenziwa kwePCB yombane yeemoto:

3.1 Ukukhethwa kwezinto: I-Automotive electronics Ukukhethwa kwezinto zePCB kubalulekile ekuqinisekiseni ukuqina, ukuthembeka kunye nokusebenza.Izinto ezisetyenzisiweyo kufuneka zikwazi ukumelana neemeko ezinzima zokusingqongileyo ezidibana nazo kwizicelo zeemoto, kubandakanywa utshintsho lobushushu, ukungcangcazela, ukufuma kunye nokuvezwa kweekhemikhali. Izinto ezisetyenziswa ngokuqhelekileyo kwii-PCB ze-elektroniki zemoto ziquka i-FR-4 (i-Flame Retardant-4) e-epoxy-based laminate, ene-insulation efanelekileyo yombane, amandla omatshini kunye nokumelana nobushushu obugqwesileyo. I-laminates ezinobushushu obuphezulu obufana ne-polyimide nazo zisetyenziswa kwizicelo ezifuna ukuguquguquka okukhulu kobushushu. Ukukhethwa kwezinto eziphathekayo kufuneka kwakhona kuqwalaselwe iimfuno zesekethe yesicelo, njengezibonakaliso zesantya esiphezulu okanye i-electronics powers.

3.2 Itekhnoloji yokuvelisa iPCB: Iteknoloji yokuvelisa iPCB ibandakanya iinkqubo ezininzi eziguqula uyilo lube ziibhodi zesekethe eziprintiweyo.Inkqubo yokuvelisa ibandakanya la manyathelo alandelayo:

a) Utshintshelo loyilo:Uyilo lwePCB lukhutshelwa kwisoftware ezinikeleyo eyenza iifayile zomzobo ezifunekayo ekuveliseni.

b) Iphaneli:Ukudibanisa uyilo lwePCB ezininzi kwiphaneli enye ukuze kuphuculwe ukusebenza kakuhle kwemveliso.

c) Ukwenza umfanekiso:Gcoba umaleko wezinto ezibonisa ifoto kwiphaneli, kwaye usebenzise ifayile yomsebenzi wobugcisa ukuveza ipateni yesekethe efunekayo kwiphaneli eqatywe.

d) Ukurhweba:Ukufakwa kweekhemikhali iindawo eziveziweyo zephaneli ukususa ubhedu olungafunekiyo, ukushiya imikhondo yesekethe efunwayo.

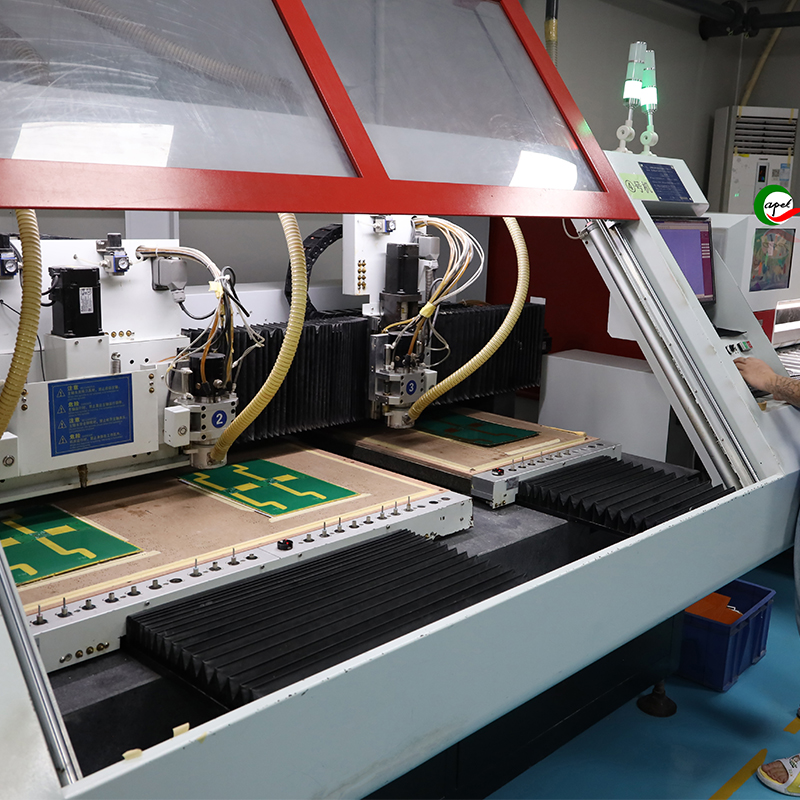

e) Ukugrumba:Imingxuma yokwemba kwindawo yolawulo ukulungiselela icandelo elikhokelayo kunye ne-vias yoqhagamshelo phakathi kwamaleko ahlukeneyo ePCB.

f) Electroplating:Uluhlu oluncinci lobhedu lufakwe kwi-electroplated kwipaneli ukuze kuphuculwe i-conductivity ye-trace trace kunye nokubonelela nge-smooth surface kwiinkqubo ezilandelayo.

g) Isicelo seMaski yeSolder:Faka umaleko we-solder mask ukukhusela imikhondo yobhedu kwi-oxidation kwaye unikeze ukugquma phakathi kweetrayisi ezikufutshane. Imaski yeSolder ikwanceda ukunika umahluko ocacileyo wokubonwayo phakathi kwamacandelo ahlukeneyo kunye nomkhondo.

h) Ushicilelo lwesikrini:Sebenzisa inkqubo yoshicilelo lwesikrini ukuprinta amagama amacandelo, iilogo kunye nolunye ulwazi oluyimfuneko kwi-PCB.

3.3 Lungiselela umaleko wobhedu: Ngaphambi kokudala isekethe yesicelo, iileya zobhedu kwi-PCB kufuneka zilungiswe.Oku kubandakanya ukucoca ubuso bobhedu ukususa nayiphi na inkunkuma, i-oxides okanye i-contaminants. Inkqubo yokucoca iphucula ukunamathela kwezixhobo ze-photosensitive ezisetyenziswe kwinkqubo yokucinga. Iindlela ezahlukeneyo zokucoca zingasetyenziswa, kubandakanywa ukukhuhla ngoomatshini, ukucocwa kweekhemikhali kunye nokucoca iplasma.

3.4 Isekethe yesicelo: Nje ukuba iileya zobhedu zilungiswe, isekethe yesicelo inokwenziwa kwi-PCB.Oku kubandakanya ukusebenzisa inkqubo yomfanekiso ukudlulisela ipateni yesekethe efunekayo kwiPCB. Ifayile yobugcisa eveliswe luyilo lwePCB isetyenziswa njengesalathiso sokuveza imathiriyeli yefotosensitive kwi-PCB kwisibane se-UV. Le nkqubo yenza lukhuni iindawo eziveziweyo, zenze imikhondo efunekayo yeesekethe kunye neepads.

3.5 Ukufakwa kwe-PCB kunye nokugaya: Emva kokudala isekethe yesicelo, sebenzisa isisombululo sekhemikhali ukukhupha ubhedu olugqithisiweyo.Izinto eziphathekayo ze-photosensitive zisebenza njengemaski, zikhusela imikhondo yesiphaluka efunekayo kwi-etching. Okulandelayo kuza inkqubo yokomba yokwenza imingxunya kukhokelela icandelo kunye vias kwi PCB. Imingxuma igrunjwa kusetyenziswa izixhobo ezichanekileyo kunye neendawo zazo zimiselwe ngokusekelwe kuyilo lwePCB.

3.6 I-Plating kunye nesicelo semaski ye-solder: Emva kokuba inkqubo ye-etching kunye ne-drilling igqityiwe, i-PCB ifakwe kwi-plated ukuze kuphuculwe ukuqhutyelwa kweentambo zesekethe.Icwecwe elicwecwe lobhedu kwindawo yobhedu evelileyo. Le nkqubo yokucwenga inceda ukuqinisekisa uqhagamshelo lombane oluthembekileyo kunye nokwandisa ukuqina kwePCB. Emva kokucwenga, umaleko we-solder imaski isetyenziswa kwi-PCB. Imaski ye-solder ibonelela nge-insulation kwaye ikhusela imikhondo yobhedu kwi-oxidation. Ngokuqhelekileyo isetyenziswe ngokuprintwa kwesikrini, kwaye indawo apho amacandelo abekwe khona ashiywe evulekileyo ukuze athengise.

3.7 Uvavanyo lwe-PCB nokuhlolwa: Inyathelo lokugqibela kwinkqubo yokwenziwa kuvavanyo kunye nokuhlolwa kwe-PCB.Oku kubandakanya ukujonga ukusebenza kunye nomgangatho wePCB. Iimvavanyo ezahlukeneyo ezifana nokuqhubekeka kovavanyo, uvavanyo lokumelana nokugquma, kunye novavanyo lokusebenza kombane lwenziwa ukuze kuqinisekiswe ukuba iPCB iyahlangabezana nemigaqo efunekayo. Uhlolo olubonakalayo lwenziwa kwakhona ukujonga naziphi na iziphene ezifana nezifutshane, ukuvula, ukungahambi kakuhle, okanye iziphene zokubekwa kwecandelo.

Inkqubo yokwenziwa kwePCB yeemoto zombane ibandakanya uthotho lwamanyathelo ukusuka ekukhethweni kwezinto ukuya kuvavanyo kunye nokuhlolwa. Inyathelo ngalinye lidlala indima ebalulekileyo ekuqinisekiseni ukuthembeka, ukusebenza kunye nokusebenza kwePCB yokugqibela. Abavelisi kufuneka babambelele kwimigangatho yoshishino kunye nezona ndlela zilungileyo zokuqinisekisa ukuba ii-PCBs ziyahlangabezana neemfuno ezingqongqo zezicelo zeemoto.

4. Iingqwalasela ezingqale ngqo kwimoto: kukho imiba ethile yemoto ekufuneka iqwalaselwe xa kuyilwa kwaye

ukuvelisa iiPCB zeemoto.

4.1 Ukutshatyalaliswa kobushushu kunye nokulawulwa kwe-thermal: Kwiimoto, ii-PCB zichaphazeleka kwiimeko eziphezulu zokushisa ngenxa yokushisa kwe-injini kunye nokusingqongileyo.Ke ngoko, ukuchithwa kobushushu kunye nolawulo lobushushu yingqwalasela ephambili kuyilo lwePCB yeemoto. Izinto ezivelisa ubushushu ezifana nombane wamandla, izilawuli ezincinci, kunye nezivamvo kufuneka zibekwe ngobuchule kwi-PCB ukunciphisa ubushushu. Iisinki zobushushu kunye neendawo zokuvula ziyafumaneka ukwenzela ukutshabalalisa ubushushu ngokufanelekileyo. Ukongeza, ukuhamba komoya okufanelekileyo kunye neendlela zokupholisa kufuneka zibandakanywe kuyilo lweemoto ukuthintela ukwakhiwa kobushushu obugqithisileyo kunye nokuqinisekisa ukuthembeka kwePCB kunye nokuphila ixesha elide.

4.2 Ukungcangcazela kunye nokumelana nokothuka: Iimoto zisebenza phantsi kweemeko ezahlukeneyo zendlela kwaye ziphantsi kokungcangcazela kunye nokothuka okubangelwa ngamaqhuma, imingxuma kunye neendawo ezimbi.Ezi vibrations kunye nokothuka kunokuchaphazela PCB ukuqina kunye nokuthembeka. Ukuqinisekisa ukuxhathisa ukungcangcazela kunye nokothuka, iiPCB ezisetyenziswa kwiimoto kufuneka zomelele ngoomatshini kwaye zixhonywe ngokukhuselekileyo. Ubuchule bokuyila obunjengokusebenzisa amakhonkco e-solder eyongezelelweyo, ukuqinisa i-PCB nge-epoxy okanye imathiriyeli yokuqinisa, kunye nokukhetha ngononophelo amacandelo amelana ne-vibration kunye nezihlanganisi kunokunceda ukunciphisa iziphumo ezibi zokungcangcazela kunye nokothuka.

4.3 Ukuhambelana kwe-Electromagnetic (EMC): Ukuphazamiseka kwe-Electromagnetic (EMI) kunye nokuphazamiseka kwerediyo yerediyo (RFI) kunokuchaphazela kakubi ukusebenza kwezixhobo zombane zemoto.Uqhagamshelwano olusondeleyo lwamacandelo ahlukeneyo emotweni luya kuvelisa iindawo ze-electromagnetic eziphazamisana. Ukuqinisekisa i-EMC, uyilo lwePCB kufuneka lubandakanye iindlela ezifanelekileyo zokukhusela, ukubeka phantsi komhlaba, kunye neendlela zokucoca ukunciphisa ukukhutshwa kunye nokuba sesichengeni kwimiqondiso yombane. Iitoti ezikhuselayo, izikhewu eziqhubayo, kunye nobuchule obufanelekileyo be-PCB (njengokwahlula i-analog enovakalelo kunye ne-digital traces) kunokunceda ukunciphisa imiphumo ye-EMI kunye ne-RFI kunye nokuqinisekisa ukusebenza ngokufanelekileyo kwe-automotive electronics.

4.4 Imigangatho yokhuseleko kunye nokuthembeka: Izixhobo ze-elektroniki zezemoto kufuneka zihambelane nokhuseleko olungqongqo kunye nemigangatho yokuthembeka ukuqinisekisa ukhuseleko lwabakhweli kunye nokusebenza ngokubanzi kwesithuthi.Le migangatho ibandakanya i-ISO 26262 yokhuseleko olusebenzayo, echaza iimfuno zokhuseleko kwizithuthi ezindleleni, kunye nemigangatho eyahlukeneyo yelizwe kunye neyamazwe ngamazwe yokhuseleko lombane kunye nokuqwalaselwa kokusingqongileyo (njenge-IEC 60068 yovavanyo lokusingqongileyo). Abavelisi bePCB kufuneka baqonde kwaye babambelele kule migangatho xa beyila kwaye besenza iiPCB zeemoto. Ukongeza, uvavanyo lokuthembeka olufana nokuhamba ngebhayisikile lobushushu, uvavanyo lokungcangcazela, kunye nokuguga okukhawulezileyo kufuneka lwenziwe ukuze kuqinisekiswe ukuba i-PCB ihlangabezana namanqanaba afunekayo okuthembeka kwizicelo zeemoto.

Ngenxa yeemeko eziphezulu zokushisa kwendawo yeemoto, ukutshatyalaliswa kobushushu kunye nokulawulwa kwe-thermal kubalulekile. Ukungcangcazela kunye nokuxhathisa ukothuka kubalulekile ukuqinisekisa ukuba iPCB inokumelana neemeko zendlela ezinzima. Ukuhambelana kwe-electromagnetic kubalulekile ekunciphiseni ukuphazamiseka phakathi kwezixhobo ezahlukeneyo zombane zemoto. Ukongeza, ukuthobela imigangatho yokhuseleko kunye nokuthembeka kubalulekile ekuqinisekiseni ukhuseleko kunye nokusebenza kakuhle kwesithuthi sakho. Ngokusombulula ezi ngxaki, abavelisi bePCB banokuvelisa iiPCB ezikumgangatho ophezulu ezihlangabezana neemfuno ezithile zoshishino lweemoto.

5.Iautomotive electronic PCB assembly kunye nokuhlanganiswa:

I-Automotive electronics PCB assembly and integration ibandakanya izigaba ezahlukeneyo ezibandakanya ukuthengwa kwecandelo, indibano yeteknoloji yokunyuswa komhlaba, iindlela zokudityaniswa okuzenzekelayo kunye nezandla, kunye nolawulo lomgangatho kunye novavanyo. Inqanaba ngalinye linceda ukuvelisa iiPCB ezikumgangatho ophezulu, ezithembekileyo ezihlangabezana neemfuno ezingqongqo zezicelo zeemoto. Abavelisi kufuneka balandele iinkqubo ezingqongqo kunye nemigangatho yomgangatho wokuqinisekisa ukusebenza kunye nokuphila ixesha elide kwezi zixhobo ze-elektroniki kwizithuthi.

5.1 Ukuthengwa kwecandelo: Ukuthengwa kwamacandelo linyathelo elibalulekileyo kwinkqubo yokudityaniswa kwePCB ye-automotive electronics.Iqela lokuthenga lisebenza ngokusondeleyo nababoneleli ngeenkonzo ukufumana nokuthenga amacandelo afunekayo. Amacandelo akhethiweyo kufuneka ahlangabezane neemfuno ezichaziweyo zokusebenza, ukuthembeka, kunye nokuhambelana nezicelo zeemoto. Inkqubo yokuthenga ibandakanya ukuchonga abanikezeli abathembekileyo, ukuthelekisa amaxabiso kunye namaxesha okuhanjiswa, kunye nokuqinisekisa ukuba amacandelo ayinyaniso kwaye ayahlangabezana nemigangatho yomgangatho oyimfuneko. Amaqela okuthenga nawo aqwalasela izinto ezifana nolawulo oluphelelwe lixesha ukuqinisekisa ukufumaneka kwecandelo kumjikelo wobomi bemveliso.

5.2 I-Surface Mount Technology (SMT): I-Surface Mount technology (SMT) yindlela ekhethwayo yokuhlanganisa ii-PCB ze-automotive electronics ngenxa yokusebenza kwayo kakuhle, ukuchaneka kwayo, kunye nokuhambelana namacandelo amancinci. I-SMT ibandakanya ukubeka amacandelo ngokuthe ngqo kumphezulu we-PCB, ukuphelisa imfuno yokukhokela okanye izikhonkwane.Amacandelo e-SMT aquka izixhobo ezincinci, ezikhaphukhaphu ezifana nezixhasi, ii-capacitors, iisekethe ezidibeneyo, kunye ne-microcontrollers. La macandelo abekwe kwi-PCB kusetyenziswa umatshini wokubeka ozenzekelayo. Umatshini ubeka ngokuchanekileyo amacandelo kwi-solder paste kwi-PCB, eqinisekisa ulungelelwaniso oluchanekileyo kunye nokunciphisa ithuba leempazamo. Inkqubo ye-SMT ibonelela ngeenzuzo ezininzi, kubandakanywa ukwanda koxinaniso lwamacandelo, ukuphuculwa kokwenziwa kwemveliso, kunye nokusebenza kombane okwandisiweyo. Ukongezelela, i-SMT yenza ukuba kuhlolwe ngokuzenzekelayo kunye nokuvavanya, okwenza kube lula ukuveliswa ngokukhawuleza nokuthembekileyo.

I-5.3 I-automatic and manual assembly: Indibano ye-automotive electronics PCBs inokufezekiswa ngeendlela ezizenzekelayo kunye nezandla, kuxhomekeke kubunzima bebhodi kunye neemfuno ezithile zesicelo.Indibano ezenzekelayo ibandakanya ukusetyenziswa koomatshini abaphambili ukudibanisa ii-PCBs ngokukhawuleza nangokuchanekileyo. Oomatshini abazenzekelayo, abafana nezixhosi zetshiphu, izishicileli ze-solder paste, kunye nee-oveni zokugalela kwakhona, zisetyenziselwa ukubeka icandelo, usetyenziso lwencama ye-solder, kunye ne-reflow soldering. Indibano ezenzekelayo isebenza kakuhle kakhulu, inciphisa ixesha lokuvelisa kunye nokunciphisa iimpazamo. Ukudityaniswa ngesandla, kwelinye icala, ngokuqhelekileyo kusetyenziselwa ukuveliswa kwevolumu ephantsi okanye xa amacandelo athile engafanelanga ukuhlanganisana okuzenzekelayo. Amagcisa anezakhono asebenzisa izixhobo ezikhethekileyo kunye nezixhobo ukubeka ngononophelo amacandelo kwi-PCB. Ukudityaniswa ngesandla kuvumela ukuguquguquka okukhulu kunye nokwenza ngokwezifiso kunendibano ezenzekelayo, kodwa iyacotha kwaye ityekele kwimpazamo yomntu.

5.4 Ulawulo lomgangatho kunye noVavanyo: Ulawulo lomgangatho kunye novavanyo ngamanyathelo abalulekileyo kwi-automotive electronics PCB assembly kunye nokuhlanganiswa. Ezi nkqubo zinceda ekuqinisekiseni ukuba imveliso yokugqibela ihlangabezana nemigangatho yomgangatho ofunekayo kunye nokusebenza.Ulawulo lomgangatho luqala ngokuhlola amacandelo angenayo ukuqinisekisa ubunyani kunye nomgangatho wawo. Ngexesha lenkqubo yendibano, uhlolo lwenziwa kumanqanaba ahlukeneyo ukuchonga kunye nokulungisa naziphi na iziphene okanye imiba. Ukuhlolwa okubonakalayo, ukuhlolwa kwe-automated optical inspection (AOI) kunye nokuhlolwa kwe-X-reyi zihlala zisetyenziselwa ukukhangela iziphene ezinokuthi zifane neebhulorho ze-solder, ukulungelelaniswa kwecandelo okanye ukudibanisa okuvulekileyo.

Emva kokuhlanganisana, iPCB kufuneka ivavanywe ngokusebenzayo ukuqinisekisa ukusebenza kwayo. Tiinkqubo esting ingabandakanya uvavanyo amandla-on, uvavanyo ukusebenza, uvavanyo-kwisekethe, kunye novavanyo lokusingqongileyo ukuqinisekisa ukusebenza, iimpawu zombane, kunye nokuthembeka PCB.

Ulawulo lomgangatho kunye novavanyo lukwabandakanya ukulandeleka, apho iPCB nganye ithegiwe okanye iphawulwe ngesichongi esisodwa ukulandelela imbali yayo yemveliso kunye nokuqinisekisa ukuphendula.Oku kuvumela abavelisi ukuba bachonge kwaye balungise nayiphi na imiba kwaye ibonelele ngedatha ebalulekileyo yokuphucula okuqhubekayo.

6.I-Automotive electronic PCB Iintsingiselo kunye nemingeni kwixesha elizayo:Ikamva leePCB ze-automotive electronics liya kuphenjelelwa

izinto ezifana ne-miniaturization, ukwanda kobunzima, ukudityaniswa kobuchwepheshe obuphambili, kunye nesidingo sokuphucula

iinkqubo zokuvelisa.

6.1 I-Miniaturization kunye nokunyuka kobunzima: Enye yeendlela ezibalulekileyo kwii-PCB ze-automotive electronics kukutyhala okuqhubekayo kwe-miniaturization kunye nobunzima.Njengoko izithuthi zihambela phambili ngakumbi kwaye zixhotyiswe ngeenkqubo ezahlukeneyo zombane, imfuno yeePCB ezincinci kunye nezixineneyo iyaqhubeka nokukhula. Le miniaturization ibeka imingeni ekubekweni kwecandelo, umzila, ukuchithwa kwe-thermal, kunye nokuthembeka. Abaqulunqi be-PCB kunye nabavelisi kufuneka bafumane izisombululo ezintsha zokujongana nemiba yefomu ecuthekayo ngelixa igcina ukusebenza kwe-PCB kunye nokuqina.

6.2 Ukudityaniswa kobuchwepheshe obuphambili: Ishishini leemoto libona inkqubela ekhawulezileyo kwezobuchwepheshe, kubandakanywa ukudityaniswa kobuchwepheshe obuphambili kwizithuthi.IiPCB zidlala indima ephambili ekwenzeni obu buchwepheshe busebenze, njengeenkqubo zokuncedisa umqhubi (ADAS), iinkqubo zezithuthi zombane, izisombululo zoqhagamshelwano kunye neempawu zokuqhuba ezizimeleyo. Ezi teknoloji ziphambili zifuna ii-PCB ezinokuxhasa isantya esiphezulu, ukuphatha idatha enzima, kunye nokuqinisekisa unxibelelwano oluthembekileyo phakathi kwamacandelo kunye neenkqubo ezahlukeneyo. Ukuyila kunye nokwenza iiPCBs ezihlangabezana nezi mfuno ngumngeni omkhulu kushishino.

6.3 Inkqubo yokwenziwa kwemveliso kufuneka iqiniswe: Njengoko imfuno yee-PCB ze-automotive electronics iqhubeka nokukhula, abavelisi bajongene nomceli mngeni wokuphucula iinkqubo zokwenziwa kwemveliso ukuhlangabezana nomthamo ophezulu wemveliso ngelixa begcina imigangatho yomgangatho ophezulu.Ukulungelelanisa iinkqubo zemveliso, ukuphucula ukusebenza kakuhle, ukunciphisa amaxesha okujikeleza kunye nokunciphisa iziphene ziindawo apho abavelisi kufuneka bagxininise imizamo yabo. Ukusetyenziswa kobuchwephesha bokuvelisa obuphezulu, obufana nendibano ezenzekelayo, iirobhothi kunye neenkqubo zokuhlola eziphambili, kunceda ukuphucula ukusebenza kakuhle kunye nokuchaneka kwenkqubo yokuvelisa. Ukwamkela i-Industry 4.0 iikhonsepthi ezifana ne-Intanethi yeZinto (IoT) kunye nohlalutyo lwedatha lunokubonelela ngengqiqo ebalulekileyo ekuphuculeni inkqubo kunye nokugcinwa kwangaphambili, ngaloo ndlela ukwandisa imveliso kunye nemveliso.

7.Umvelisi owaziwayo webhodi yesekethe yeemoto:

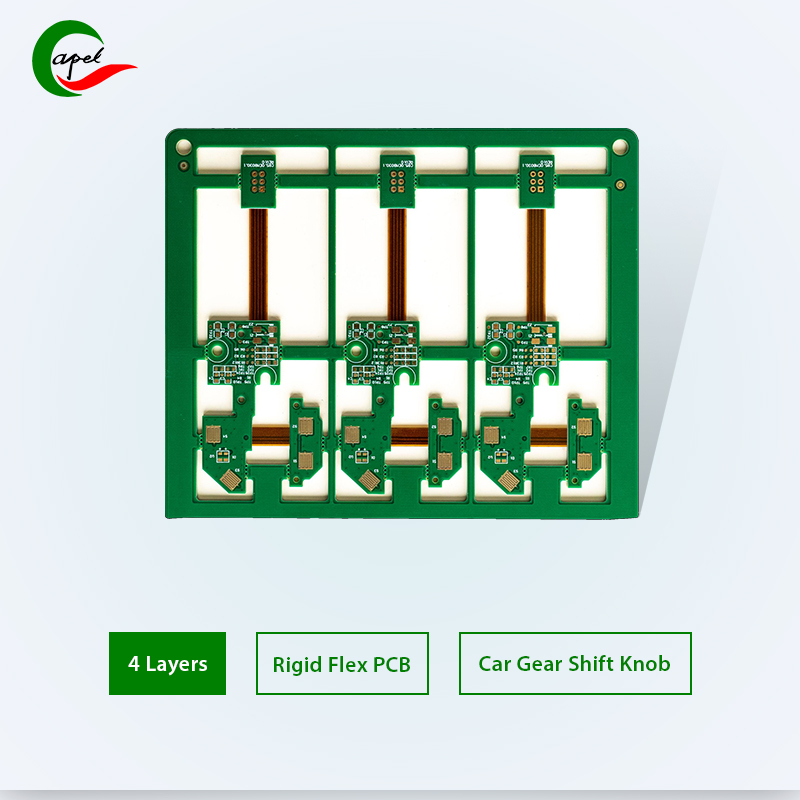

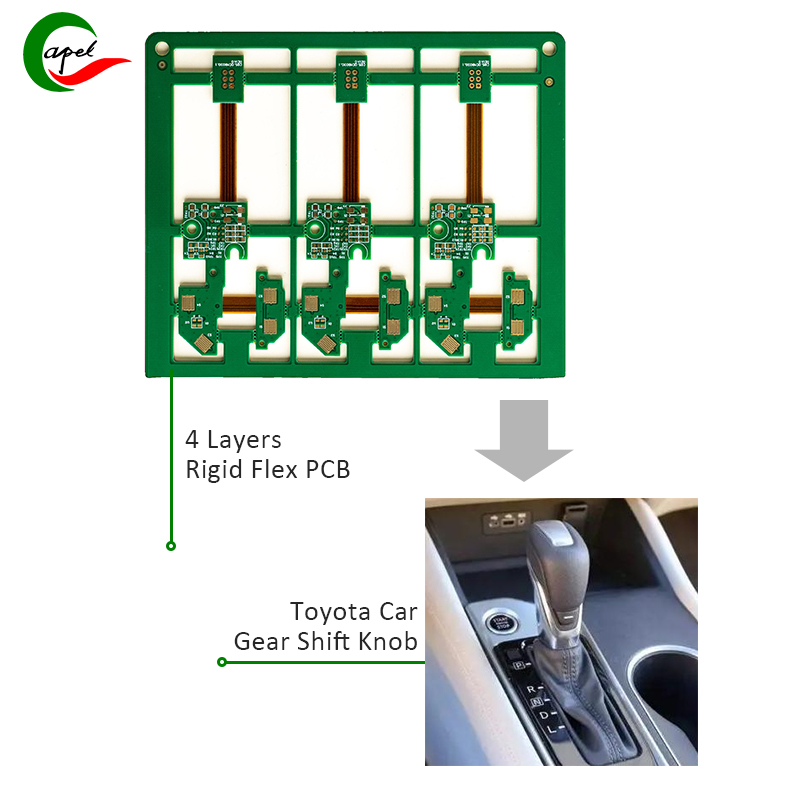

I-Shenzhen Capel Technology Co., Ltd. yaseka umzi-mveliso webhodi yesekethe ngo-2009 kwaye yaqala ukuphuhlisa nokwenza iibhodi zeesekethe eziguquguqukayo, iibhodi zemihlanganisela, kunye neebhodi eziqinileyo. Kule minyaka ili-15 idlulileyo, sigqibe ngempumelelo amashumi amawaka eeprojekthi zebhodi yesekethe yeemoto kubathengi, saqokelela amava atyebileyo kushishino lweemoto, saza sanika abathengi izisombululo ezikhuselekileyo nezithembekileyo. Ubunjineli obuchwephesha baseCapel kunye namaqela e-R&D ziingcali onokuzithemba!

Isishwankathelo,Inkqubo yokwenziwa kwePCB yeemoto zombane ngumsebenzi onzima nocokisekileyo ofuna intsebenziswano esondeleyo phakathi kweenjineli, abayili, kunye nabavelisi. Iimfuno ezingqongqo zeshishini leemoto zifuna umgangatho ophezulu, othembekileyo kunye neePCB ezikhuselekileyo. Njengoko itekhnoloji iqhubeka nokuhambela phambili, iiPCB ze-elektroniki zemoto ziya kufuna ukuhlangabezana nemfuno ekhulayo yemisebenzi entsonkothileyo kunye nentsonkothileyo. Ukuhlala uphambi kweli candelo livela ngokukhawuleza, abavelisi bePCB kufuneka bahambisane neendlela zamva nje. Kufuneka batyale imali kwiinkqubo zokuvelisa eziphambili kunye nezixhobo zokuqinisekisa ukuveliswa kweePCB eziphezulu. Ukusebenzisa izenzo ezikumgangatho ophezulu akuphuculi nje kuphela amava okuqhuba, kodwa kukwabeka phambili ukhuseleko nokuchaneka.

Ixesha lokuposa: Sep-11-2023

Emva