Iinjineli ezininzi kunye nabayili bahlala bejongana nemiceli mngeni yolawulo lwe-impedance kuyilo oluguquguqukayo lwePCB. Lo mbandela obalulekileyo uqinisekisa ingqibelelo yesignali kunye nokusebenza kakuhle kwesekethe. Kule post yebhlog, siza kuxoxa ngeendlela ezahlukeneyo kunye neendlela zokukunceda ukuba uqinisekise ulawulo olululo lwe-impedance kuyilo lwe-PCB eguquguqukayo.

1. Qonda iziseko zolawulo lwe-impedance

I-Impedance kukuxhathisa kwesekethe ekuhambeni kwe-alternating current (AC). Kuyilo lwe-PCB, ulawulo lwe-impedance lubhekiselele ekugcineni ixabiso elithile le-impedance yokulandelela umqondiso ukuqinisekisa ukusebenza kakuhle komqondiso. Ilinganiswa ngee-ohms kwaye ihlala ifuna ulawulo oluchanekileyo ukunqanda ukuthotywa komqondiso kunye neminye imiba yokusebenza.

2. Qwalasela ukupakishwa kwePCB

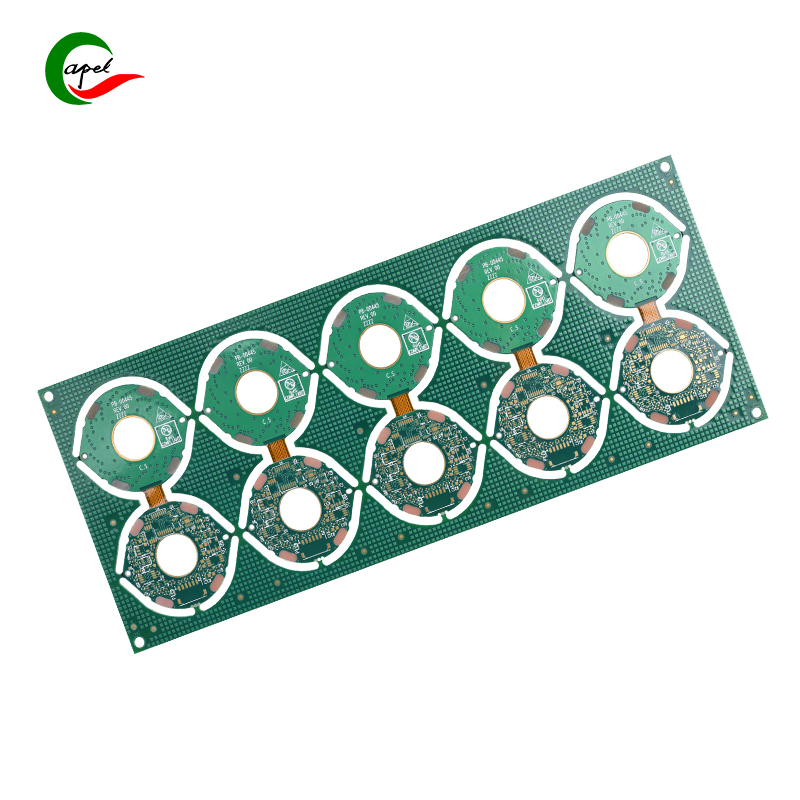

Ukupakishwa kweebhodi ze-rigid-flex kunempembelelo ebalulekileyo kulawulo lwe-impedance. Ukupakishwa okucwangcisiweyo ngokucokisekileyo kuqinisekisa ukuba isiphaluka sonke sifikelela kwinqanaba elifunekayo le-impedance. Ukufezekisa oku, kubalulekile ukuba ukhethe ngokucophelela inani kunye nohlobo lwemigangatho, izinto ze-dielectric, kunye nobukhulu bazo. Izixhobo ezifana nesoftware yengqibelelo yesiginali inokunceda ukumisela iiparamitha ezifunekayo kulawulo olululo lwe-impedance.

3. Yila iingqalelo zokulandelela ububanzi kunye nesithuba

Ukulandelela ububanzi kunye nezithuba kuchaphazela ngokuthe ngqo ulawulo lwe-impedance. Umkhondo obhityileyo une-impedance ephezulu, ngelixa umkhondo obanzi une-impedance ephantsi. Kubalulekile ukubala ububanzi obufunekayo bokulandelela ngokusekwe kwi-impedance efunekayo kwaye uqinisekise isithuba esaneleyo phakathi kweetrayisi ezikufutshane ukukhusela i-crosstalk kunye nokunye ukuphazamiseka kwesignali.

4. Izinto ezilawulwayo zedielectric

Ukhetho lwemathiriyeli ye-dielectric nayo idlala indima ebalulekileyo kulawulo lwe-impedance. Izinto ezahlukeneyo zinee-dielectric constants ezahlukeneyo, ezichaphazela i-impedance yeempawu zomkhondo. Ukukhetha izinto ezilawulwa yi-dielectric zivumela ulawulo oluchanekileyo lwe-impedance. Kucetyiswa ukuba udibane nomthengisi wezinto eziphathekayo kwaye usebenzise iinkcukacha zabo ukuqinisekisa ukubala okuchanekileyo kwe-impedance.

5. Ukubekwa ngokuchanekileyo kwamacandelo

Ukubekwa ngokufanelekileyo kwamacandelo kunokuchaphazela kakhulu ulawulo lwe-impedance. Ukubeka izinto ezinesantya esiphezulu kufutshane nobude bomkhondo wophawu kwaye kunciphisa ithuba lokungahambelani kwe-impedance. Oku akuphuculi nje ingqibelelo yomqondiso kodwa kunciphisa ubunzima obupheleleyo boyilo.

6. I-impedance controlled technology

Itekhnoloji ye-routing nayo idlala indima ebalulekileyo ekuphumezeni ulawulo lwe-impedance. Iindidi ezahlukeneyo zokulandela umkhondo, ezifana ne-microstrip okanye i-stripline, zineempawu ezithile zokuthintela. Sebenzisa izikhokelo zendlela ezibonelelwe ngumenzi kunye nesoftware yokulinganisa ngokuchanekileyo ukuhambisa imiqondiso enesantya esiphezulu ngelixa ugcina i-impedance efunekayo.

7. Qinisekisa kwaye ulinganise i-impedance

Ukuqinisekisa ulawulo olululo lwe-impedance, amaxabiso okubalwa kwe-impedance kufuneka aqinisekiswe kwaye afaniswe. Izixhobo zokulinganisa ingqibelelo yomqondiso zinokunceda ukuhlalutya indlela yokuziphatha kwemiqondiso kuyilo kunye nokuchonga imiba enokubakho enxulumene ne-impedance. Ngokulinganisa iimeko ezahlukeneyo, unokuqinisekisa uyilo lwakho kwaye wenze uhlengahlengiso oluyimfuneko kulawulo olululo lwe-impedance.

8. Sebenza neengcali zokwenziwa kwePCB

Ukusebenza kunye neqabane lokwenziwa kwe-PCB elinamava kunokubonelela ngemibono exabisekileyo ekuphumezeni ulawulo olululo lwe-impedance. Banokubonelela ngeengcebiso kubuchule bokuvelisa, ukukhetha izinto eziphathekayo, kunye nokunceda ngovavanyo lwe-impedance. Ubuchwephesha babo buqinisekisa ukuba imveliso yokugqibela idibana neenkcukacha ezifunekayo ze-impedance.

Isishwankathelo, ulawulo olululo lwe-impedance lubalulekile ekuqinisekiseni imfezeko yophawu olululo kunye nokusebenza kuyilo lwePCB oluguquguqukayo. Ngokuqonda izinto ezisisiseko, ukuqwalasela i-stackup, ukulandelela ububanzi kunye nesithuba, usebenzisa izinto ezilawulwayo ze-dielectric, ukulungelelanisa ukubekwa kwecandelo, ukusebenzisa iindlela ezichanekileyo zendlela, kunye noyilo lokulinganisa, unokuqinisekisa ukuba uyalufezekisa ulawulo olufunekayo lwe-impedance kuyilo lwakho oluguquguqukayo lwe-PCB. Ukusebenza nengcali yokwenziwa kwe-PCB kunokunyusa ngakumbi izinga lempumelelo yoyilo lwakho.

Ixesha lokuposa: Sep-19-2023

Emva