Ehlabathini lezixhobo zonyango, iteknoloji idlala indima ebalulekileyo ekuphuculeni ukuchaneka, ukusebenza kakuhle kunye nokuthembeka. Phakathi kwenkqubela phambili eyahlukeneyo, ukusetyenziswa kweesekethe eziphambili kunye neePCB eziguquguqukayo kulitshintshe kakhulu ishishini lezonyango.Apha siza kuphonononga ukuba iteknoloji ye-PCB ene-4-layer inokuxhasa njani izixhobo zonyango zoxinzelelo lwegazi.

Enye yeepropati eziphambili ze-PCB ye-4-layer yi-stiffness yayo, ngokukodwa kwimeko yeesekethe ezisekelwe kwi-steel sheet.Ukuqina kukuqwalaselwa okubalulekileyo kwizixhobo zonyango njengoko kuqinisekisa ukuzinza kwemveliso kunye nokuqina. Ukuchaneka kubalulekile xa kuziwa kwizixhobo zokujonga uxinzelelo lwegazi. Ukusetyenziswa kwamacwecwe ensimbi kwi-PCB kwandisa ukuqina kwesekethe, ukuthintela nayiphi na ukugoba okanye ukugoba okunokuchaphazela ukuchaneka kokufunda uxinzelelo lwegazi.

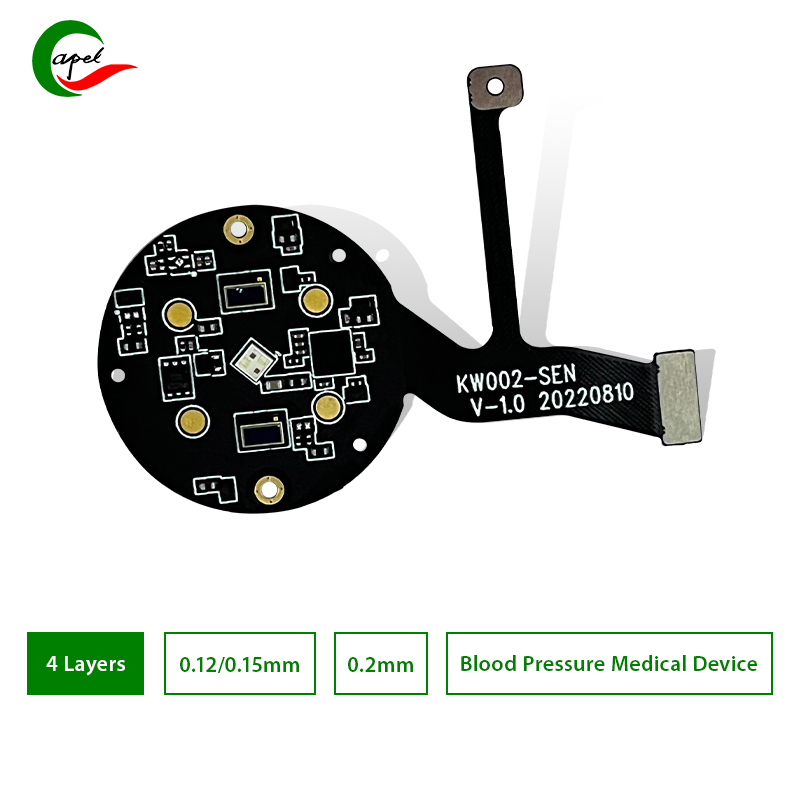

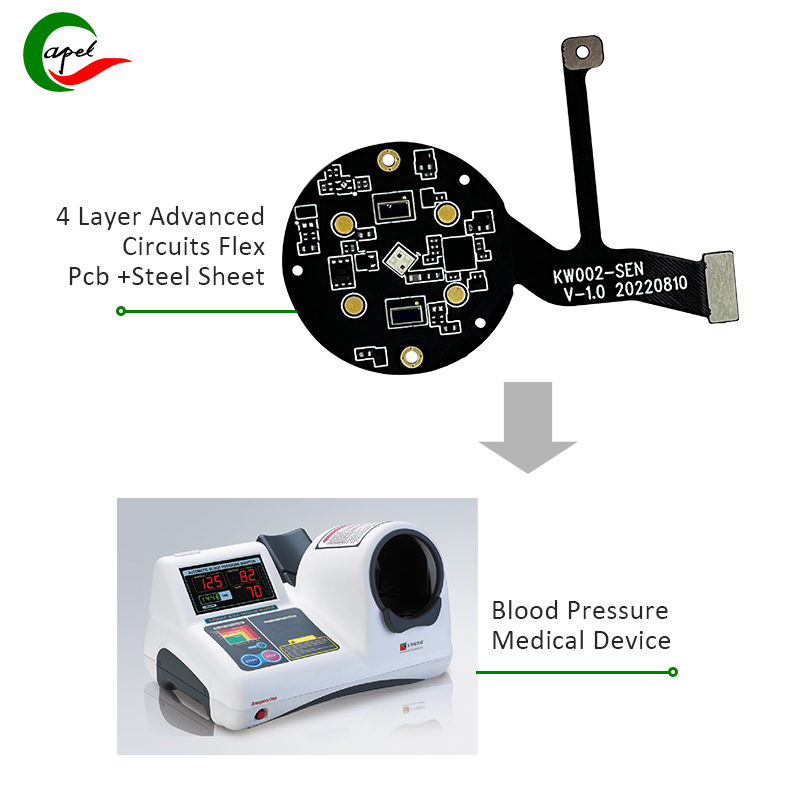

I-Advanced Circuits Flex PCB yi-4-layer PCB ebonelela ngeenzuzo ezininzi kwizixhobo zonyango, ngakumbi ukujonga uxinzelelo lwegazi. Makhe sijonge ngakumbi kwiimpawu zolu hlobo lwePCB:

1. Inani leeleya: Ukucwangciswa kwe-PCB ye-4-layer ibonelela ngenqanaba eliphezulu lokuhlanganiswa kwezixhobo zokujonga uxinzelelo lwegazi. Iingqimba ezongezelelweyo zibonelela ngesithuba esingakumbi sokuhamba kunye nokubeka amacandelo, okuvumela ukuhlanganiswa kweenzwa ezininzi kunye nemisebenzi yokucubungula idatha ebhodini. Oku kuvumela isixhobo ukuba siqokelele idatha kwii-sensors ezahlukeneyo ezifana ne-pressure sensors kunye ne-sensors yezinga lentliziyo, kunye nokucubungula ngokuchanekileyo idatha ukufumana ukufundwa okuchanekileyo kwegazi. Ukucwangciswa kwe-4-layer kunceda ukunciphisa ukuphazamiseka komqondiso, ukuphucula ukusebenza ngokubanzi kunye nokuthembeka kwesixhobo sokuhlola uxinzelelo lwegazi.

2. Ububanzi bomgca kunye nesithuba somgca:Ububanzi bomgca kunye nezithuba kwi-PCB zidlala indima ebalulekileyo ekuqinisekiseni ukuhanjiswa kwesignali echanekileyo kunye nokunciphisa umngcipheko wokuphazamiseka. Ububanzi bomgca we-0.12mm kunye ne-0.15mm yomgca we-pitch ibonelela ngesisombululo esilungileyo somzila ochanekileyo weempawu zomqondiso kwi-PCB. Kwizixhobo zonyango ezifana nabahloli bexinzelelo lwegazi, ukuhanjiswa komqondiso ngokuchanekileyo kubalulekile ekufumaneni imilinganiselo echanekileyo kunye nethembekileyo. Naluphi na utshintsho oluncinci okanye ukuphazamiseka kwisignali kunokukhokelela ekufundweni kwengcinezelo yegazi engafanelekanga, enokuba nemiphumo emibi kwimpilo yesigulane. Ngokusebenzisa ububanzi bemigca ecolekileyo kunye neepayithi, imiqondiso yombane inokuhanjiswa ngokuchanekileyo nangempumelelo. Oku kunceda ukunciphisa ukuthomalalisa umqondiso, i-crosstalk, kunye nokuphazamiseka kwe-electromagnetic, iqinisekisa intembeko yemilinganiselo yoxinzelelo lwegazi.

3. Ubukhulu bebhodi:Ukukhetha ubukhulu bebhodi obuyi-0.2mm kuneengenelo ezininzi xa udibanisa iPCB ebhetyebhetye kwisixhobo sonyango esinxitywayo soxinzelelo lwegazi. Okokuqala, ukutyeba kwebhodi encinci kwenza iPCB ibe khaphukhaphu. Oku kubalulekile kwizinto ezinxitywayo njengoko kuqinisekisa ukuba aziziva zinkulu okanye zinzima xa zinxitywe. I-PCB ekhaphukhaphu kwaye ebhetyebhetye inegalelo ekuthuthuzelekeni komsebenzisi, ivumela abantu ukuba banxibe ngokulula isixhobo ixesha elide ngaphandle kokuphatheka kakubi. Ukongeza, ukuguquguquka kwePCB kuyivumela ukuba igobe kwaye ihambelane nokumila kwesixhobo esinxitywayo. Oku kuqinisekisa ukufaneleka okungcono kunye nokuphucula ukuthuthuzela komsebenzisi njengoko isixhobo silungelelanisa ngokungenamthungo kwiikhonto zomzimba. Oku kuguquguquka kwakhona kunciphisa umngcipheko wokuphulwa kwe-PCB okanye ukonakala ngenxa yokugoba ngokuphindaphindiweyo okanye ukunyakaza. Iprofayile ephantsi yePCB yongeza ngakumbi ukonwaba komsebenzisi. Ngokugcina i-PCB ibhityile, inciphisa isambuku esinokuba nomsindo okanye siphazamise lowo uyinxibileyo. Uyilo oluphantsi luqinisekisa ukuba isixhobo sihlala silumkile, sisenza singabonakali kwabanye.

4. Ubunzima bobhedu:Ukukhetha ukutyeba kobhedu kwi-PCB kudlala indima ebalulekileyo ekuqinisekiseni ukuhanjiswa kombane okusebenzayo kunye nokuhanjiswa komqondiso ofanelekileyo, obaluleke kakhulu kumlinganiselo ochanekileyo nothembekileyo woxinzelelo lwegazi. Kule meko, ubukhulu bobhedu be-35um (micrometers) bufanelekile ukugcina ibhalansi elungileyo phakathi kwe-conductivity kunye nokuguquguquka. Ubhedu yinto eqhuba kakhulu enobunzima obuyi-35um, eyenza ukuhamba kakuhle kwemiqondiso yombane kuyo yonke imikhondo yePCB. I-conductivity yombane esebenzayo ebonelelwa ngobhedu iqinisekisa ukuba uphawu loxinzelelo lwegazi luhanjiswa ngokuchanekileyo ukusuka kwinzwa ukuya kumacandelo okucubungula isixhobo. Nakuphi na ukulahleka komqondiso okanye ukuphazamiseka okunokuthi kwenzeke ngokungahambi kakuhle kunokubangela ukufundwa kobuxoki kunye nokunciphisa ukuchaneka kunye nokuthembeka kwemilinganiselo yoxinzelelo lwegazi. Ukongeza, ubukhulu bobhedu obufanelekileyo bunceda ukunciphisa ukuxhathisa, i-impedance, kunye nokunciphisa umqondiso. Oku kubaluleke kakhulu kwizicelo ezinovakalelo ezifana nokulinganisa uxinzelelo lwegazi, apho ukuphazamiseka komqondiso okuncinci kunokuchaphazela kakhulu ukuchaneka kokufunda.

5. Ubuncinane bokungena: Ubuncinci besayizi yokuvula i-0.2mm ivumela ukubekwa okuchanekileyo kunye nokuhlanganiswa kwamacandelo kwi-PCB eguquguqukayo. Oku kuqinisekisa i-sensor efanelekileyo kunye nokulungelelaniswa kokudibanisa ukuze kubanjwe idatha echanekileyo kunye nokuhanjiswa.Nantsi indlela eqinisekisa ngayo ukuba abenzi boluvo kunye nezihlanganisi zilungelelaniswe ngokufanelekileyo ukuze kuthathwe idatha echanekileyo kunye nokuhanjiswa:

Ukubekwa kwecandelo:

Ubungakanani bomngxunya obuncinci buvumela ukubekwa okuchanekileyo kwamacandelo kwiiPCB eziguqukayo. Oku kubaluleke kakhulu kwiinzwa ezibuthathaka kunye nezihlanganisi, njengoko ulungelelwaniso oluchanekileyo luqinisekisa uqhagamshelwano olufanelekileyo kunye nomsebenzi.

Ulungelelwaniso lweSeva:

Ukulungelelaniswa kwenzwa engachanekanga kunokukhokelela ekufumaneni idatha engachanekanga. I-sensor inobungakanani obuncinci be-aperture ye-0.2mm kwaye inokulungelelaniswa ngokuchanekileyo ukuqinisekisa uqhagamshelwano olufanelekileyo kunye nokujoliswe kuyo kunye nokulinganisa kwedatha echanekileyo.

Umdibaniso wokudibanisa:

Izixhumi zidlala indima ephambili ekudluliseleni idatha phakathi kwamacandelo ahlukeneyo. Isayizi encinci yokuvula ivumela ukubekwa okuchanekileyo kunye nokulungelelaniswa kwekhonkco kwi-flexible PCB. Oku kuqinisekisa uqhagamshelwano oluchanekileyo lombane kunye nokuhanjiswa kwesignali ngokufanelekileyo ngaphandle kokulahlekelwa okanye ukuphazamiseka.

UkuNcitshiswa koMqondiso:

Ukubekwa okuchanekileyo kunye namacandelo adibeneyo ngokusebenzisa ubungakanani obuncinci be-aperture bunceda ukunciphisa ukuphazamiseka komqondiso. Oku kubaluleke kakhulu kwiiPCB eziguquguqukayo, apho ukugoba kunye nokunyakaza kunokuchaphazela ingqibelelo yomqondiso. Ukulungelelaniswa okuchanekileyo kunciphisa ithuba lokulahleka komqondiso okanye ukuthotywa ngexesha lokubanjwa kwedatha kunye nokuhanjiswa.

6. Ukubuyiswa komlilo:I-94V0 i-flame retardant material isetyenziselwa ukuqinisekisa ukhuseleko lwesixhobo sokuhlola uxinzelelo lwegazi. Kwimeko yonyango apho ukhuseleko lwesigulane lubaluleke kakhulu, ukuthembeka kunye nokuchasana nomlilo okunikezelwa yi-PCB kubalulekile.

Kwiimeko zonyango apho ukhuseleko lwesigulana lubaluleke kakhulu, ii-PCB ezineepropathi ezibuyiswa ngamadangatya zibonelela ngeengenelo ezininzi: Ukumelana nomlilo:

Izixhobo ze-94V0 ezibuyisela amadangatya zinamandla okuthintela ukusasazeka kwamadangatye, ukuthintela okanye ukucinezela umlilo. Oku kubaluleke kakhulu kwizicwangciso zonyango apho ubukho bezinto ezinokutsha okanye iziphene zombane zingabangela ingozi enkulu kwizigulane kunye nabaqeqeshi bezempilo. Ukusebenzisa ii-PCB ezineempawu zokubuyiswa komlilo kunceda ukunciphisa ukubakho kweengozi zomlilo.

Ukuthembeka:

Ii-PCB ezineempawu zokunqanda amadangatye zinokuthembeka okuphezulu ngenxa yokukwazi ukumelana nobushushu obuphezulu kunye nokumelana nomlilo. Kwimeko yonyango, izixhobo ezifana nezijongi zoxinzelelo lwegazi ziphantsi kweemeko ezahlukeneyo, kubandakanywa amaqondo obushushu aphezulu ukusuka kwinkqubo yokuvala inzala okanye ukuvezwa ngengozi kwimithombo yobushushu. Ngokusebenzisa ii-PCB ezithintela amadangatye, umngcipheko wokulimala okanye ukungaphumeleli ngenxa yobushushu okanye umlilo uyancipha kakhulu, ukuqinisekisa ukusebenza okuthembekileyo kwezixhobo.

Ukuthotyelwa kwemigangatho yokhuseleko:

Ii-arhente ezininzi ezilawulayo kunye nemigangatho yemibutho ifuna izixhobo zombane ezisetyenziswa kwiindawo zonyango ukuhlangabezana nemigangatho ethile yokunqanda umlilo. Ngokusebenzisa i-94V0 i-flame retardant materials kwi-PCB, abavelisi bezixhobo zonyango banokuqinisekisa ukuthotyelwa kwale migangatho yokhuseleko, ukuphucula ukhuseleko olupheleleyo kunye nokuthotyelwa kwezixhobo zokujonga uxinzelelo lwegazi.

Ukhuseleko lwamalungu e-elektroniki:

Ukongeza kukhuseleko lomlilo, ii-PCBs ezinqandwa ngumlilo zikwakhusela izixhobo ze-elektroniki ezifakwe kuzo. Izinto eziphathekayo ezinokumelana nomlilo zinceda ukuthintela umonakalo wecandelo kubushushu okanye emlilweni, ukugcina ingqibelelo kunye nokusebenza kwezixhobo zokujonga uxinzelelo lwegazi.

7. Unyango lomphezulu: Ukuntywiliselwa kunyango lomphezulu wegolide kubonelela ngokugqwesa ukuxhathisa umhlwa kunye nokuqina. Oku kuqinisekisa ubomi obude kunye nokuqina kwe-PCB, nakwiimeko zonyango ezinomngeni.

Nazi ezinye zezizathu zokuba kutheni ukuntywiliselwa kwegolide kugqityiwe kuluncedo, ngakumbi kwiindawo zonyango ezinomngeni:

Ukuchasa umhlwa:

Ukuntywiliselwa konyango lomphezulu wegolide kwenza umaleko okhuselayo wokukhusela amakhondo obhedu kwi-PCB kwi-oxidation kunye nokuhlwa. Kwiindawo zonyango, apho ukuvezwa kokufuma, iikhemikhali kunye neenkqubo zokuvala inzala zixhaphakile, ukuxhathisa ukubola kubaluleka. I-coating yegolide yokuntywiliselwa isebenza njengesithintelo kwezi zinto ziyingozi, iqinisekisa ixesha elide kunye nokuthembeka kwe-PCB.

I-Solderability:

Ubhedu, intsimbi engundoqo esetyenziswa kwii-PCB, i-oxidized ngokulula, inciphisa ukuthengiswa kwayo. Isiphelo segolide sokuntywiliselwa senza umaleko obhityileyo wegolide kwimikhondo yobhedu, ephucula ukuthengiswa kwePCB. Oku kuququzelela inkqubo ye-solder ngexesha lendibano ye-PCB, ekhokelela kwi-solder eqinile kwaye ethembekileyo. Ukuphucula ukuthengiselana kubaluleke kakhulu kwizixhobo zonyango kuba uqhagamshelo lwe-solder olungaguqukiyo noluhlala luhleli lubalulekile ekusebenzeni kwesixhobo.

Ubomi kunye nokuqina:

Ukumelana nomhlwa okubonelelwa kukuntywiliselwa ukugqiba kwegolide kunceda ukwandisa ubomi bePCB. Kwimeko yonyango, apho izixhobo zinokuba phantsi kweemeko ezinzima ezifana neenkqubo zokuvala inzala, ukuvezwa kweekhemikhali okanye uxinzelelo kumatshini, ukuqina kwePCB kubalulekile. Umaleko wegolide okhuselayo uqinisekisa ukuba i-PCB inokumelana nale mingeni kwaye igcine ukusebenza kwayo kunye nokusebenza ixesha elide.

Umqondiso weMfezeko:

Igolide yokuntywiliselwa igqibezela ineempawu ezibalaseleyo zombane, kubandakanywa ukuxhathisa okuphantsi kunye nesakhono esihle sokuhambisa umqondiso. Oku kubalulekile kwizixhobo zonyango ezifana nabahloli bexinzelelo lwegazi abaxhomekeke ekuhanjisweni komqondiso ochanekileyo nothembekileyo. Umaleko wegolide kwi-PCB unceda ukugcina imfezeko yomqondiso kunye nokunciphisa umngcipheko wokuthotywa komqondiso okanye ilahleko ngenxa ye-oxidation yomhlaba okanye i-solder joints.

Izixhobo zokujonga uxinzelelo lwegazi ezisebenzisa itekhnoloji ye-PCB ene-4-layer ibonelela ngeenzuzo ezininzi kwizigulana kunye neengcali zempilo.Ukuchaneka kunye nokuthembeka kwemilinganiselo yoxinzelelo lwegazi kunegalelo ekuxilongweni okungcono kunye nezigqibo zonyango. Ubume obuguquguqukayo kunye nekhaphukhaphu yePCB yenza isixhobo silungele ukunxiba ixesha elide, ngaloo ndlela siphucula ukuthotyelwa kwesigulane.

Ukusetyenziswa kweteknoloji ye-PCB ye-4-layer kwizixhobo zokuhlola uxinzelelo lwegazi kubonisa amandla amakhulu eesekethe eziphambili kunye nee-PCB eziguquguqukayo kwishishini lezonyango.Ukudibanisa ukuqhubela phambili kwezobuchwepheshe kunye neempawu zemveliso zinikeze inkxaso enkulu yokuphucula ukuchaneka, ukusebenza kakuhle kunye nokuthembeka komlinganiselo wegazi.

Ukusetyenziswa kweteknoloji ye-PCB ye-4-layer, ngokukodwa ngokuqina kokwakheka kwepleyiti yensimbi, idlala indima ebalulekileyo ekuxhaseni izixhobo zonyango lwegazi.I-PCB yesekethe eguquguqukayo ibonelela ngeqonga elibalaseleyo lokuphuhlisa izixhobo ezichanekileyo nezithembekileyo zokujonga uxinzelelo lwegazi kunye neempawu zayo ezithile zemveliso. Njengoko itekhnoloji iqhubeka nokuvela, sinokulindela inkqubela phambili kwizixhobo zonyango eziqhutywa kukudityaniswa kobuchwephesha bePCB.

Ixesha lokuposa: Sep-06-2023

Emva