I-16-layer PCBs zibonelela ngobunzima kunye nokuguquguquka okufunwa zizixhobo zombane zanamhlanje. Uyilo lwezakhono kunye nokukhethwa kolandelelwano lokupakisha kunye neendlela zokudibanisa i-interlayer zibalulekile ekufezekiseni ukusebenza kwebhodi ngokufanelekileyo. Kweli nqaku, siza kuphonononga iingqwalasela, izikhokelo, kunye nezona ndlela zilungileyo zokunceda abayili kunye neenjineli benze iibhodi zesekethe ezisebenzayo nezithembekileyo.

1.Ukuqonda iZiseko ze-16 layer PCBs Stacking Sequence

1.1 Inkcazo kunye nenjongo yokupakishwa kocwangco

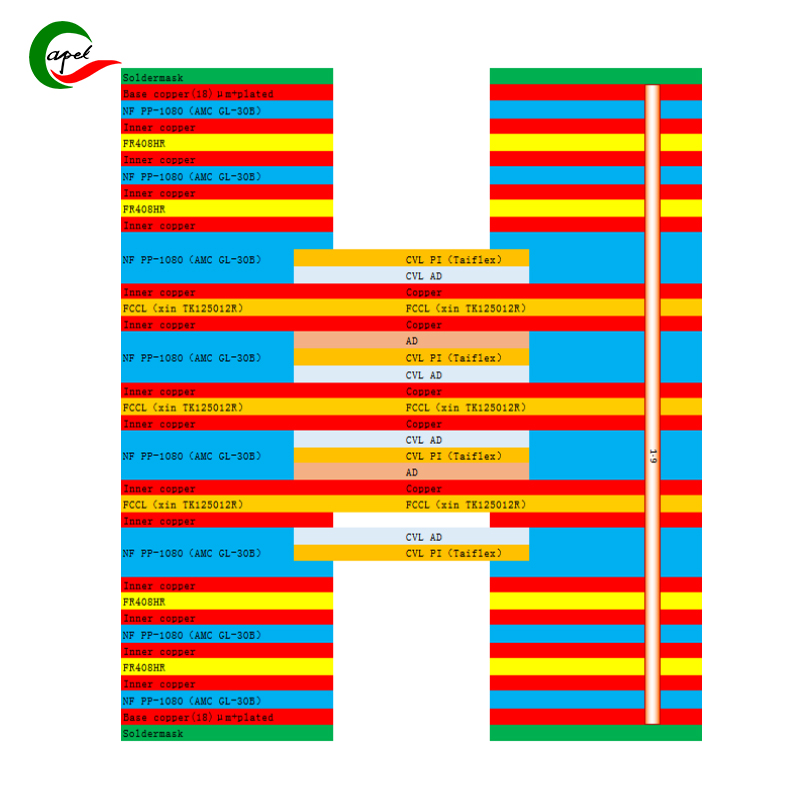

Ulandelelwano lwe-stacking lubhekiselele kulungiselelo kunye nolandelelwano apho izinto ezifana nobhedu kunye ne-insulating layers zihlanjululwe kunye ukuze zenze ibhodi yesekethe ye-multi-layer.Ulandelelwano lokupakisha lumisela ukubekwa kweempawu zeempawu, iileya zamandla, iileya zomhlaba, kunye namanye amacandelo abalulekileyo isitaki.

Injongo ephambili yokulandelelana kwe-stacking kukufezekisa iimpawu ezifunekayo zombane kunye nomatshini webhodi. Idlala indima ebalulekileyo ekumiseleni i-impedance yebhodi yesekethe, imfezeko yomqondiso, ukuhanjiswa kwamandla, ulawulo lwe-thermal, kunye nokwenziwa kwemveliso. Ulandelelwano lokupakisha lukwachaphazela ukusebenza ngokubanzi, ukuthembeka, kunye nokwenziwa kwebhodi.

1.2 Izinto ezichaphazela uyilo lolandelelwano lokupakisha: Kukho izinto ezininzi ekufuneka ziqwalaselwe xa uyila ulandelelwano lokupakisha

I-PCB enemigangatho eyi-16:

a) Iingqwalasela zombane:Uyilo lwesiginali, amandla, kunye neenqwelomoya zomhlaba kufuneka ziphuculwe ukuze kuqinisekiswe imfezeko yophawu olufanelekileyo, ulawulo lokungangeni, kunye nokunciphisa ukuphazamiseka kombane.

b) Iingqwalasela zobushushu:Ukubekwa kwamandla kunye neenqwelo zomhlaba kunye nokufakwa kwe-thermal vias kunceda ukukhupha ukushisa ngokufanelekileyo kunye nokugcina ubushushu obuphezulu bokusebenza kwecandelo.

c) Imiqobo yokwenziwa kwemveliso:Ulandelelwano lokupakisha olukhethiweyo kufuneka luthathele ingqalelo amandla kunye nemida yenkqubo yokwenziwa kwe-PCB, njengokufumaneka kwezinto, inani leeleya, i-drill aspect ratio,kunye nokuchaneka kolungelelwaniso.

d) Ukuphucula iindleko:Ukukhethwa kwezinto eziphathekayo, inani leeleya, kunye ne-stack-up complexity kufuneka ihambelane nebhajethi yeprojekthi ngelixa iqinisekisa ukusebenza okufunekayo kunye nokuthembeka.

1.3 Iindidi eziqhelekileyo zolandelelwano lokupakisha lwebhodi yesekethe ye-16: Kukho ulandelelwano oluqhelekileyo lokupakisha lwe-16-layer.

PCB, ngokuxhomekeke kwintsebenzo efunekayo kunye neemfuno. Eminye imizekelo eqhelekileyo iquka:

a) Ulandelelwano lokupakishwa kweSymmetric:Olu landelelwano lubandakanya ukubeka iileya zesignali ngokulinganayo phakathi kwamandla kunye neengqimba zomhlaba ukufezekisa imfezeko yesignali elungileyo, i-crosstalk encinci, kunye nokuchithwa kobushushu okulinganayo.

b) Ulandelelwano lokupakisha:Kolu landelelwano, iileya zesignali zilandelelana ngokulandelelana phakathi kwamandla kunye nemigangatho yomhlaba. Ibonelela ngolawulo olukhulu kulungiselelo lomaleko kwaye iluncedo ekuhlangabezaneni neemfuno ezithile zophawu lwemfezeko.

c) Ulandelelwano lokupakisha oluxutyiweyo:Oku kubandakanya indibaniselwano ye-symmetric kunye nee-odolo zokupakisha ezilandelelanayo. Ivumela ukulungelelaniswa kunye nokulungelelaniswa kwesakhiwo kwiindawo ezithile zebhodi.

d) Ulandelelwano lokupakisha olunovakalelo lomqondiso:Olu landelelwano lubeka umaleko weempawu ezibuthathaka kufutshane nenqwelomoya ephantsi ukuze ikhuseleke ngcono kwingxolo kunye nokwahlukaniswa.

2.Iingqwalasela eziPhambili zoKhetho lwe-16 ye-PCB yokuGqama ngokuNgxunyekwa:

2.1 Umqondiso wemfezeko kunye nokuqwalaselwa kwemfezeko yamandla:

Ukulandelelana kwe-stacking kunempembelelo ebalulekileyo kwingqibelelo yomqondiso kunye nokunyaniseka kwamandla ebhodi. Ukubekwa ngokufanelekileyo komqondiso kunye neenqwelomoya zamandla / ezisemhlabeni zibalulekile ekunciphiseni umngcipheko wokuphazamiseka komqondiso, ingxolo, kunye nokuphazamiseka kwe-electromagnetic. Iingqwalasela eziphambili ziquka:

a) Ukubekwa ko maleko womqondiso:Iingqimba zeempawu zesantya esiphezulu kufuneka zibekwe kufuphi nenqwelomoya ephantsi ukuze unikeze indlela yokubuya ye-inductance ephantsi kunye nokunciphisa ukudibanisa ingxolo. Izaleko zemiqondiso nazo kufuneka zibekwe ngononophelo ukunciphisa umqondiso we-skew kunye nobude obuhambelanayo.

b) Ukuhanjiswa kwenqwelomoya yombane:Ulandelelwano lokupakisha kufuneka luqinisekise ukuhanjiswa kwenqwelomoya yamandla okwaneleyo ukuxhasa imfezeko yamandla. Amandla aneleyo kunye neenqwelomoya ezisemhlabeni kufuneka zibekwe ngobuchule ukunciphisa ukuhla kwamandla ombane, ukungaqhubeki kwe-impedance, kunye nokudibanisa ingxolo.

c) Ukuqhawula iiCapacitors:Ukubekwa ngokufanelekileyo kwe-decoupling capacitors kubalulekile ukuqinisekisa ukuhanjiswa kwamandla okwaneleyo kunye nokunciphisa ingxolo yokunikezelwa kwamandla. Ukulandelelana kwe-stacking kufuneka kunikeze ukusondela kunye nokusondela kwe-decoupling capacitors kumandla kunye neenqwelo-moya zomhlaba.

2.2 Ulawulo lobushushu kunye nokuchithwa kobushushu:

Ulawulo olufanelekileyo lwe-thermal lubalulekile ekuqinisekiseni ukuthembeka kwebhodi yesekethe kunye nokusebenza. Ulandelelwano lokupakisha kufuneka luthathele ingqalelo ukubekwa ngokufanelekileyo kwamandla kunye neenqwelomoya zomhlaba, i-thermal vias, kunye nezinye iindlela zokupholisa. Iingqwalasela ezibalulekileyo ziquka:

a) Ukuhanjiswa kwenqwelomoya yombane:Ukusasazwa okwaneleyo kwamandla kunye neenqwelomoya zomhlaba kulo lonke i-stack kunceda ubushushu ngqo kude nezinto ezibuthathaka kunye nokuqinisekisa ukuhanjiswa okufanayo kobushushu kwibhodi.

b) I-Thermal vias:Ulandelelwano lokupakisha kufuneka luvumele i-thermal esebenzayo ngokubeka ukuququzelela ukutshatyalaliswa kobushushu ukusuka kumaleko angaphakathi ukuya kumaleko angaphandle okanye isinki yobushushu. Oku kunceda ukukhusela iindawo ezishushu zendawo kunye nokuqinisekisa ukuchithwa kobushushu okusebenzayo.

c) Ukubekwa kwelungu:Ukulandelelana kwe-stacking kufuneka kuthathelwe ingqalelo ilungiselelo kunye nokusondela kwamacandelo okufudumeza ukuphepha ukufudumala. Ulungelelwaniso olululo lwamacandelo aneendlela zokupholisa ezifana neesinki zobushushu okanye iifeni kufuneka ziqwalaselwe.

2.3 Imiqobo yokwenziwa kwemveliso kunye nokwandisa iindleko:

Ulandelelwano lokupakisha kufuneka luthathele ingqalelo imiqobo yokuvelisa kunye nokwandisa iindleko, njengoko zidlala indima ebalulekileyo ekufikeleleni nasekufikeleleni kwebhodi. Iingqwalasela ziquka:

a) Ukufumaneka kwezinto:Ulandelelwano lokupakisha olukhethiweyo kufuneka luhambelane nokufumaneka kwezinto kunye nokuhambelana kwazo kunye nenkqubo yokuvelisa i-PCB ekhethiweyo.

b) Inani leeleya kunye nokuntsokotha:Ulandelelwano lokupakisha kufuneka luyilwe ngaphakathi kwemiqobo yenkqubo yokwenziwa kwePCB ekhethiweyo, kuthathelwa ingqalelo izinto ezifana nenani leeleya, i-drill aspect ratio, kunye nokuchaneka kolungelelwaniso.

c) Ukuphucula iindleko:Ukulandelelana kwe-stacking kufuneka kuphuculwe ukusetyenziswa kwezinto kunye nokunciphisa ubunzima bokuvelisa ngaphandle kokuphazamisa ukusebenza okufunekayo kunye nokuthembeka. Kufuneka ijolise ekunciphiseni iindleko ezinxulumene nenkunkuma yezinto eziphathekayo, inkqubo yobunzima kunye nokudibanisa.

2.4 Ulungelelwaniso lomaleko kunye ne-signal crosstalk:

Ulandelelwano lokupakisha kufuneka lujongane nemiba yolungelelwaniso kunye nokunciphisa i-signal crosstalk enokuthi ibe nefuthe elibi kwimfezeko yomqondiso. Iingqwalasela ezibalulekileyo ziquka:

a) Ukupakishwa okulinganayo:I-Symmetrical stacking yeempawu zeempawu phakathi kwamandla kunye neengqimba zomhlaba kunceda ukunciphisa ukudibanisa kunye nokunciphisa i-crosstalk.

b) Iindlela ezimbini ezahlukeneyo:Ulandelelwano lokupakisha kufuneka luvumele iileya zesignali zilungelelaniswe ngokufanelekileyo kumzila osebenzayo weempawu zokwahluka kwesantya esiphezulu. Oku kunceda ukugcina ingqibelelo yomqondiso kunye nokunciphisa i-crosstalk.

c) Ukwahlulwa komqondiso:Ukulandelelana kwe-stacking kufuneka kuthathelwe ingqalelo ukwahlulwa kwe-analog ebuthathaka kunye neempawu zedijithali ukunciphisa i-crosstalk kunye nokuphazamiseka.

2.5 Ulawulo lwe-impedance kunye nodibaniso lwe-RF/microwave:

Kwizicelo zeRF/microwave, ulandelelwano lokupakisha lubalulekile ukufezekisa ulawulo olululo lwe-impedance kunye nokudibanisa. Iingqwalasela eziphambili ziquka:

a) Uthintelo olulawulwayo:Ulandelelwano lokupakisha kufuneka luvumele uyilo olulawulwayo lwe-impedance, kuthathelwa ingqalelo izinto ezifana nobubanzi bomkhondo, ubukhulu be-dielectric, kunye nolungiselelo lomaleko. Oku kuqinisekisa usasazo oluchanekileyo lwesignali kunye nokuthintela ukuhambelana kweempawu zeRF/microwave.

b) Ukubekwa komgangatho womqondiso:Iimpawu zeRF/microwave kufuneka zibekwe ngobuchule kufutshane nomaleko wangaphandle ukunciphisa uphazamiseko oluvela kwezinye iisignali kunye nokubonelela ngosasazo olungcono lwesignali.

c) RF Shielding:Ulandelelwano lokupakisha kufuneka lubandakanye ukubekwa ngokufanelekileyo komgangatho womhlaba kunye nokukhusela ukwahlula kunye nokukhusela iimpawu zeRF/microwave ekuphazamisekeni.

3.IiNdlela zoQhagamshelwano lwe-Interlayer

3.1 Kwimingxuma, imingxunya engaboniyo kunye nemingxuma engcwatyiweyo:

Vias zisetyenziswa ngokubanzi kwibhodi yesekethe eprintiweyo (PCB) uyilo njengendlela yokudibanisa umaleko ezahlukeneyo. Zigrunjwa imingxuma kuzo zonke iileya ze-PCB kwaye zibekwe ukubonelela ngokuqhubekeka kombane. Ngemingxuma ibonelela ngoqhagamshelo oluluqilima lombane kwaye kulula ukwenza nokulungisa. Nangona kunjalo, zifuna iisayizi ezinkulu ze-drill bit, ezithatha indawo exabisekileyo kwi-PCB kwaye zinciphise iinketho zomzila.

Iindlela ezimfamekileyo nezingcwatywayo zezinye iindlela zokudityaniswa kwe-interlayer ezibonelela ngoncedo ekusetyenzisweni kwendawo kunye nokuguquguquka kwendlela.

I-vias eyimfama yombiwa ukusuka kumphezulu we-PCB kwaye iphele kumaleko angaphakathi ngaphandle kokudlula kuzo zonke iileya. Bavumela udibaniso phakathi kweeleya ezimeleneyo ngelixa ushiya iileya ezinzulu zingachaphazeleki. Oku kuvumela ukusetyenziswa ngokufanelekileyo kwendawo yebhodi kunye nokunciphisa inani lemingxuma yokubhoboza. I-vias engcwatywayo, kwelinye icala, yimingxunya evaleleke ngokupheleleyo ngaphakathi kweemaleko zangaphakathi ze-PCB kwaye musa ukwandisa ukuya kumaleko angaphandle. Banikezela ukudibanisa phakathi kweeleya zangaphakathi ngaphandle kokuchaphazela iileya zangaphandle. Ii-vias ezingcwatywayo zineenzuzo ezinkulu zokonga isithuba kunemingxuma edlulayo neyimfama ngenxa yokuba azithathi nasiphi na isithuba kumaleko angaphandle.

Ukukhetha ngokusebenzisa imingxunya, vias imfama, kwaye wangcwatywa vias kuxhomekeke kwiimfuno ezithile kuyilo PCB. Ngemingxuma idla ngokusetyenziswa kuyilo olulula okanye apho ukomelela kunye nokulungiseka kuyinkxalabo ephambili. Kuyilo olunoxinaniso oluphezulu apho indawo iyinto ebaluleke kakhulu, njengezixhobo eziphathwa ngesandla, ii-smartphones, kunye neelaptops, ii-vias ezingaboniyo kunye nezingcwatywe zikhethwa.

3.2 Micropore kunyeItekhnoloji yeHDI:

IMicrovias yimingxunya emincinci edayamitha (idla ngokuba ngaphantsi kwe-150 microns) ebonelela ngokudityaniswa kwe-interlayer yoxinaniso oluphezulu kwiiPCB. Banikezela ngeenzuzo ezibalulekileyo kwi-miniaturization, imfezeko yomqondiso kunye nokuguquguquka kwendlela.

I-Microvias inokohlulwa ibe ziindidi ezimbini: i-microvias etyhutyha-tyhutyha kunye ne-microvias eyimfama. IiMicrovias zakhiwa ngokugrumba imingxunya ukusuka kumphezulu ongaphezulu wePCB kwaye zanda kuzo zonke iileya. I-microvias eyimfama, njengoko igama libonisa, yandisa kuphela kwiileya ezithile zangaphakathi kwaye ungangeni kuzo zonke iileya.

I-High-density interconnect (HDI) yitekhnoloji esebenzisa i-microvias kunye nobuchule obuphambili bokuvelisa ukuphumeza ubuninzi besiphaluka kunye nokusebenza. Itekhnoloji ye-HDI ivumela ukubekwa kwamacandelo amancinci kunye neendlela ezingqongqo, ezikhokelela kwiifom ezincinci kunye nokunyaniseka kwesignali ephezulu. Itekhnoloji ye-HDI ibonelela ngeengenelo ezininzi ngaphezulu kwetekhnoloji ye-PCB yemveli ngokwemigaqo yokwenziwa kweminiaturization, ukusasazwa komqondiso ophuculweyo, ukugqwethwa komqondiso okucuthiweyo, kunye nokusebenza okuphuculweyo. Ivumela uyilo lwe-multilayer kunye ne-microvias ezininzi, ngaloo ndlela inciphisa ubude boqhagamshelwano kunye nokunciphisa amandla e-parasitic kunye ne-inductance.

Itekhnoloji ye-HDI ikwavumela ukusetyenziswa kwemathiriyeli ephucukileyo efana ne-high-frequency laminates kunye ne-dielectric layers ezibhityileyo, ezibaluleke kakhulu kwi-RF/microwave applications. Inika ulawulo olungcono lwe-impedance, inciphisa ilahleko yesignali kwaye iqinisekisa ukuhanjiswa kwesignali ethembekileyo.

3.3 Iimathiriyeli zokudityaniswa kwe-Interlayer kunye neenkqubo:

Ukukhethwa kwezinto zokudibanisa i-interlayer kunye nobuchule kubalulekile ekuqinisekiseni ukusebenza kakuhle kombane, ukuthembeka komatshini kunye nokuveliswa kweePCB. Ezinye izinto ezisetyenziswa ngokuqhelekileyo zokudityaniswa kwe-interlayer kunye nobuchule zezi:

a) Ubhedu:Ubhedu lusetyenziswa ngokubanzi kumaleko okuqhuba kunye ne-vias yee-PCBs ngenxa yokuhanjiswa kwayo okugqwesileyo kunye nokuthengiswa kwayo. Ngokuqhelekileyo ifakwe emngxunyeni ukubonelela ngoqhagamshelwano oluthembekileyo lombane.

b) Ukusoda:Iindlela zokuthengisa, ezinje nge-wave soldering okanye i-reflow soldering, zihlala zisetyenziselwa ukwenza uqhagamshelo lombane phakathi kwemingxuma kwii-PCB kunye nezinye izinto. Faka i-solder paste kwi-via kwaye usebenzise ubushushu ukunyibilikisa i-solder kwaye wenze uqhagamshelwano oluthembekileyo.

c) Electroplating:Ubuchule be-Electroplating obufana ne-electroless copper plating okanye i-electrolytic copper isetyenziselwa ukwenza iplate vias ukunyusa umgangatho wokuqhuba kunye nokuqinisekisa uqhagamshelo olululo lombane.

d) Ukudibanisa:Ubuchule bokudibanisa, obufana ne-adhesive bonding okanye i-thermocompression bonding, isetyenziselwa ukudibanisa izakhiwo ezinomaleko kunye nokudala uqhagamshelwano oluthembekileyo.

e) Imathiriyeli yeDielectric:Ukhetho lwemathiriyeli yedielectric kwi-PCB stackup ibalulekile kunxibelelwano lwe-interlayer. I-laminates ephezulu ye-frequency efana ne-FR-4 okanye i-Rogers laminates isoloko isetyenziselwa ukuqinisekisa ingqibelelo yesignali elungileyo kunye nokunciphisa ilahleko yesignali.

3.4 Uyilo kunye nentsingiselo yamacandelo:

Uyilo olunqamlezileyo lwe-PCB egciniweyo lumisela iimpawu zombane nezomatshini zoqhagamshelo phakathi kweeleya. Iingqwalasela ezingundoqo kuyilo lwamacandelo ahlukeneyo ziquka:

a) Ulungelelwaniso lomaleko:Ukulungelelaniswa komqondiso, amandla, kunye neenqwelomoya zomhlaba ngaphakathi kwe-PCB stackup ichaphazela imfezeko yesignali, imfezeko yamandla, kunye nokuphazamiseka kwe-electromagnetic (EMI). Ukubekwa ngokufanelekileyo kunye nokulungelelaniswa kweengqimba zesignali ngamandla kunye neenqwelo-moya zomhlaba zinceda ukunciphisa ukudibanisa ingxolo kunye nokuqinisekisa iindlela eziphantsi zokubuya kwe-inductance.

b) Ulawulo lokuphazamiseka:Uyilo olunqamlezileyo kufuneka luthathele ingqalelo iimfuno ezilawulwayo zokuthintela, ngakumbi kwisantya esiphezulu sedijithali okanye iisiginali zeRF/microwave. Oku kubandakanya ukhetho olufanelekileyo lwemathiriyeli ye-dielectric kunye nobukhulu ukufezekisa i-impedance yeempawu ezifunekayo.

c) Ulawulo lobushushu:Uyilo olunqamlezileyo kufuneka luqwalasele ukutshatyalaliswa kobushushu obusebenzayo kunye nolawulo lwe-thermal. Ukubekwa ngokufanelekileyo kwamandla kunye neenqwelo-moya zomhlaba, i-vias ye-thermal, kunye namacandelo aneendlela zokupholisa (ezifana ne-heat sinks) zinceda ukutshabalalisa ubushushu kunye nokugcina amaqondo okushisa asebenzayo.

d) Ukuthembeka koomatshini:Uyilo lwecandelo kufuneka luthathele ingqalelo ukuthembeka koomatshini, ngakumbi kwizicelo ezinokuthi zibe phantsi kwebhayisekile eshushu okanye uxinzelelo lomatshini. Ukukhethwa ngokufanelekileyo kwezinto, ubuchule bokudibanisa, kunye nokucwangciswa kwe-stackup kunceda ukuqinisekisa ukuthembeka kwesakhiwo kunye nokuqina kwe-PCB.

4.Izikhokelo zoYilo lwe-16-Layer PCB

4.1 Ulwabiwo kunye nolwaleko:

Xa uyila ibhodi yesekethe ye-16, kubalulekile ukwaba ngokucokisekileyo kwaye usasaze iileyile zokuphucula ukusebenza kunye nokunyaniseka komqondiso. Nazi ezinye izikhokelo zolwabiwo lwamanqanaba

kunye nokuhanjiswa:

Qwalasela inani leempawu zomaleko ezifunekayo:

Cinga ubunzima boyilo lwesekethe kunye nenani leempawu ezifuna ukuhanjiswa. Yabela imiqondiso eyaneleyo ukuze ikwazi ukumelana nayo yonke imiqondiso efunekayo, uqinisekisa indawo eyaneleyo yomzila kwaye uthintele ukugqithisa.ukuxinana. Yabela umhlaba kunye neenqwelomoya zamandla:

Yabela ubuncinci imigangatho emibini yangaphakathi kumhlaba kunye neenqwelomoya zamandla. Inqwelomoya ephantsi komhlaba inceda ukubonelela ngereferensi ezinzileyo yemiqondiso kunye nokunciphisa ukuphazamiseka kwe-electromagnetic (EMI). Inqwelomoya yamandla ibonelela ngenethiwekhi yokuhambisa amandla ephantsi-impedance enceda ukunciphisa ukuhla kwamandla ombane.

Yahlula iileya zeempawu ezibuthathaka:

Ngokuxhomekeke kwisicelo, kunokuba yimfuneko ukwahlula izingqinisiso ezibukhali okanye ezinesantya esiphezulu kwizaleko ezinomsindo okanye eziphezulu zamandla okuthintela ukuphazamiseka kunye ne-crosstalk. Oku kunokwenziwa ngokubeka umhlaba ozinikeleyo okanye iinqwelomoya zamandla phakathi kwazo okanye ngokusebenzisa iileya zodwa.

Ukusasaza ngokulinganayo umaleko wemiqondiso:

Ukusasaza iileya zesignali ngokulinganayo kuyo yonke ibhodi ukupakisha ukunciphisa ukudibanisa phakathi kweempawu ezimeleneyo kunye nokugcina imfezeko yomqondiso. Kuphephe ukubeka iileya zesignali ecaleni kwenye kwindawo enye yokupakisha ukunciphisa i-interlayer crosstalk.

Qwalasela imiqondiso yezandi eziphezulu:

Ukuba uyilo lwakho luqulathe imiqondiso yefrikhwensi ephezulu, cinga ngokubeka izaleko zezandi zesantya esiphezulu kufutshane nezaleko zangaphandle ukunciphisa iziphumo zemigca yothumelo kunye nokunciphisa ulibaziseko losasazo.

4.2 Indlela kunye nendlela yomqondiso:

Uyilo lwendlela kunye nophawu lomkhondo lubalulekile ukuze kuqinisekiswe imfezeko yophawu olufanelekileyo kunye nokunciphisa ukuphazamiseka. Nazi ezinye izikhokelo zoyilo kunye nendlela yomqondiso kwiibhodi zesekethe ezinomaleko ali-16:

Sebenzisa ulandelelwano olubanzi lwemiqondiso yangoku ephezulu:

Kwimiqondiso ephethe umsinga ophakamileyo, njengamandla kunye noqhagamshelo lomhlaba, sebenzisa imikhondo ebanzi yokunciphisa ukuxhathisa kunye nokuhla kwamandla ombane.

Ukuthelekisa i-impedance yeempawu zesantya esiphezulu:

Kwimiqondiso enesantya esiphezulu, qinisekisa ukuba i-impedance yokulandelela ihambelana neempawu zokuthintela umgca wothumelo ukuthintela ukubonakaliswa kunye nokunciphisa umqondiso. Sebenzisa ubuchule obulawulwayo boyilo lweimpedance kunye nokubalwa kobubanzi bomkhondo ochanekileyo.

Nciphisa ubude bomkhondo kunye neendawo zokuwela:

Gcina ubude bomkhondo bufutshane ngokusemandleni kwaye unciphise inani lamanqaku e-crossover ukunciphisa i-parasitic capacitance, inductance, kunye nokuphazamiseka. Lungiselela ukubekwa kwecandelo kwaye usebenzise iileya ezizinikeleyo zendlela ukunqanda imikhondo emide, entsokothileyo.

Ukwahlula imiqondiso enesantya esiphezulu kunye nesantya esisezantsi:

Ukwahlula imiqondiso enesantya esiphezulu kunye nesantya esisezantsi ukunciphisa impembelelo yengxolo kwimiqondiso enesantya esiphezulu. Beka imiqondiso enesantya esiphezulu kwiileya zesignali ezinikezelweyo kwaye uzigcine zikude kumandla aphezulu okanye izinto ezinengxolo.

Sebenzisa izibini ezahlukeneyo kwimiqondiso enesantya esiphezulu:

Ukunciphisa ingxolo kunye nokugcina imfezeko yomqondiso weempawu ezikhawulezayo zokwahluka, sebenzisa iindlela zobuchule bokuhamba ngababini. Gcina i-impedance kunye nobude bezibini ezihlukeneyo ezihambelanayo ukukhusela i-skew yesignali kunye ne-crosstalk.

4.3 Umaleko ophantsi kunye nosasazo lweleya yamandla:

Ukusasazwa ngokufanelekileyo komhlaba kunye neenqwelomoya zamandla kubalulekile ekufezekiseni ingqibelelo yamandla kunye nokunciphisa ukuphazamiseka kwe-electromagnetic. Nazi ezinye izikhokelo zezabelo zenqwelomoya ezisemhlabeni kunye namandla kwiibhodi zesekethe ezinomaleko ali-16:

Yabela umhlaba ozinikeleyo kunye neenqwelomoya zombane:

Yabela ubuncinci imigangatho emibini yangaphakathi kumhlaba ozinikeleyo kunye neenqwelomoya zamandla. Oku kunceda ukunciphisa i-loops yomhlaba, ukunciphisa i-EMI, kunye nokubonelela nge-low-impedance indlela yokubuyela kwiimpawu eziphezulu ze-frequency.

Ukwahlula iinqwelomoya zedijithali kunye ne-analog emhlabeni:

Ukuba idizayini inamacandelo edijithali kunye ne-analog, kuyacetyiswa ukuba ube neenqwelo zomhlaba ezihlukeneyo kwicandelo ngalinye. Oku kunceda ukunciphisa ukudibanisa ingxolo phakathi kwamacandelo edijithali kunye ne-analog kunye nokuphucula imfezeko yomqondiso.

Beka umhlaba kunye neenqwelomoya zamandla kufutshane neenqwelomoya zomqondiso:

Beka umhlaba kunye neenqwelomoya zamandla kufutshane neenqwelomoya zomqondiso ezizondlayo ukunciphisa indawo ye-loop kunye nokunciphisa i-pickup yengxolo.

Sebenzisa ii-pass ezininzi kwiinqwelomoya zamandla:

Sebenzisa ii-vias ezininzi ukudibanisa iinqwelomoya zombane ukuze usasaze ngokulinganayo amandla kunye nokunciphisa i-impedance yendiza yamandla. Oku kunceda ukunciphisa ukuhla kwamandla ombane kunye nokuphucula imfezeko yamandla.

Ziphephe iintamo ezimxinwa kwiinqwelomoya zamandla:

Kuphephe iintamo ezimxinwa kwiinqwelomoya njengoko zinokubangela ukuxinana kwangoku kunye nokwandisa ukuxhathisa, okukhokelela ekuhlalweni kombane kunye nokungasebenzi kakuhle kwenqwelomoya. Sebenzisa uqhagamshelwano oluqinileyo phakathi kweendawo ezahlukeneyo zeenqwelomoya zamandla.

4.4 Iphedi ye-thermal kunye nokubekwa:

Ukubekwa ngokufanelekileyo kweepads ze-thermal kunye ne-vias kubalulekile ekukhupheni ubushushu ngokufanelekileyo kunye nokuthintela amacandelo ekugqithiseni. Nazi ezinye izikhokelo ze-thermal pad kunye nokubekwa kwiibhodi zesekethe ezine-16:

Beka iphedi ye-thermal phantsi kwezinto ezivelisa ubushushu:

Chonga icandelo elivelisa ukushisa (elifana ne-amplifier yamandla okanye i-IC yamandla aphezulu) kwaye ubeke i-thermal pad ngqo phantsi kwayo. Ezi pads ezishushu zibonelela ngendlela yokushisa ngokuthe ngqo ukuhambisa ubushushu kwi-thermal layer yangaphakathi.

Sebenzisa iindlela ezininzi zokushisa ubushushu:

Sebenzisa ii-vias ezininzi ze-thermal ukudibanisa umaleko we-thermal kunye nomgangatho wangaphandle ukubonelela ngokutshabalalisa ubushushu obusebenzayo. Ezi vias zinokubekwa kwipatheni egxadazayo malunga nephedi ye-thermal ukufikelela nokusasazwa kobushushu.

Qwalasela i-impedans ye-thermal kunye ne-stackup yomaleko:

Xa uyila i-vias thermal, qwalasela i-thermal impedance yezinto zebhodi kunye ne-stackup.

4.5 Ukubekwa kweCandelo kunye neMfezeko yoMqondiso:

Ukubekwa kwecandelo ngokufanelekileyo kubalulekile ekugcineni imfezeko yomqondiso kunye nokunciphisa ukuphazamiseka. Nazi ezinye izikhokelo zokubeka amacandelo kwibhodi yesekethe ene-16:

Amalungu anxulumene neqela:

Amalungu anxulumene neqela ayinxalenye yesistim engaphantsi enye okanye anonxibelelwano olomeleleyo lombane. Oku kunciphisa ubude bomkhondo kwaye kunciphisa ukuncipha komqondiso.

Gcina amacandelo anesantya esiphezulu ekufutshane:

Beka amacandelo anesantya esiphezulu, njenge-oscillator ephezulu-frequency okanye i-microcontrollers, kufuphi omnye komnye ukunciphisa ubude bomkhondo kunye nokuqinisekisa ukunyaniseka kwesignali efanelekileyo.

Nciphisa ubude bomkhondo wemiqondiso ebalulekileyo:

Ukunciphisa ubude bomkhondo wemiqondiso ebalulekileyo ukunciphisa ukulibaziseka kokusasazwa kunye nokunciphisa umqondiso. Beka la malungu ngokusondeleyo kangangoko.

Yahlula amalungu abuthathaka:

Ukwahlula amacandelo okuva ingxolo, njengamacandelo e-analog okanye i-low-level sensors, ukusuka kumandla aphezulu okanye amacandelo anomsindo ukunciphisa ukuphazamiseka kunye nokugcina imfezeko yesignali.

Qwalasela i-decoupling capacitors:

Beka i-decoupling capacitors ngokusondeleyo kangangoko kunokwenzeka kwizikhonkwane zamandla zecandelo ngalinye ukunika amandla acocekileyo kunye nokunciphisa ukuguquguquka kwamandla ombane. Ezi capacitors zinceda ukuzinzisa ukunikezelwa kwamandla kunye nokunciphisa ukudibanisa ingxolo.

5.Ukulinganisa kunye noHlalutyo lweZixhobo zoYilo lwe-Stack-Up

5.1 Imodeli ye-3D kunye nesoftware yokulinganisa:

Imodeli ye-3D kunye nesoftware yokulinganisa sisixhobo esibalulekileyo soyilo lwe-stackup kuba ivumela abayili ukuba benze imiboniso ebonakalayo yee-PCB ezipakishiweyo. Isoftware inokubona iileya, amacandelo, kunye nokusebenzisana kwabo ngokomzimba. Ngokulinganisa i-stackup, abaqulunqi banokuchonga imiba enokubakho efana ne-signal crosstalk, i-EMI, kunye nemiqobo yoomatshini. Ikwanceda ukuqinisekisa ulungiselelo lwamacandelo kunye nokwandisa uyilo lwePCB ngokubanzi.

5.2 Izixhobo zokuhlalutya imfezeko yomqondiso:

Izixhobo zokuhlalutya imfezeko yomqondiso zibalulekile ekuhlalutyeni nasekuphuculeni ukusebenza kombane kwi-PCB stackups. Ezi zixhobo zisebenzisa i-algorithms yeemathematika ukulinganisa kunye nokuhlalutya ukuziphatha komqondiso, kubandakanywa nokulawulwa kwe-impedance, ukubonakalisa umqondiso, kunye nokudibanisa ingxolo. Ngokwenza ukulinganisa kunye nokuhlalutya, abaqulunqi banokuchonga imiba enokubakho yemfezeko yomqondiso kwangethuba kwinkqubo yoyilo kwaye benze uhlengahlengiso oluyimfuneko ukuze kuqinisekiswe ukuhanjiswa komqondiso okuthembekileyo.

5.3 Izixhobo zokuhlalutya i-Thermal:

Izixhobo zokuhlalutya i-thermal zidlala indima ebalulekileyo kuyilo lwe-stackup ngokuhlalutya kunye nokuphucula ulawulo lwe-thermal ye-PCBs. Ezi zixhobo zilinganisa ukutshatyalaliswa kobushushu kunye nokusabalalisa ubushushu ngaphakathi kwendawo nganye yesitaki. Ngokubonisa ngokuchanekileyo ukuchithwa kwamandla kunye neendlela zokuhambisa ubushushu, abaqulunqi banokuchonga iindawo ezishushu, balungise ukubekwa kweeleyile zobhedu kunye ne-thermal vias, kunye nokuqinisekisa ukupholisa okufanelekileyo kwamacandelo abalulekileyo.

5.4 Uyilo lokwenziwa kwezinto:

Uyilo lokwenziwa kokwenziwa ngumba obalulekileyo woyilo lwe-stackup. Kukho iintlobo ngeentlobo zezixhobo zesoftware ezikhoyo ezinokunceda ekuqinisekiseni ukuba i-stack-up ekhethiweyo inokuveliswa ngokufanelekileyo. Ezi zixhobo zibonelela ngengxelo malunga nokubanakho ukufezekiswa kogcino olunqwenelekayo, kuthathelwa ingqalelo izinto ezifana nokufumaneka kwezinto, ubukhulu bomaleko, inkqubo yokuvelisa, kunye neendleko zokuvelisa. Banceda abaqulunqi ukuba benze izigqibo ezinolwazi lokwandisa ukupakisha ukwenza lula ukwenziwa, ukunciphisa umngcipheko wokulibaziseka, kunye nokunyusa isivuno.

6.Inyathelo ngeNyathelo loYilo lweNkqubo ye-16-Layer PCBs

6.1 Ukuqokelelwa kweemfuno zokuqala:

Kweli nyathelo, qokelela zonke iimfuno eziyimfuneko kuyilo lwePCB yomaleko olu-16. Qonda ukusebenza kwePCB, ukusebenza kombane okufunekayo, imiqobo yoomatshini, kunye nazo naziphi na izikhokelo zoyilo okanye imigangatho ethile ekufuneka ilandelwe.

6.2 Ulwabiwo lwamacandelo kunye nolungiselelo:

Ngokweemfuno, yabela amacandelo kwi-PCB kwaye umisele amalungiselelo awo. Qwalasela izinto ezinje ngophawu lwemfezeko, ukuthathelwa ingqalelo kwe-thermal, kunye nemiqobo yomatshini. Amacandelo eqela asekelwe kwiimpawu zombane kwaye azibeke ngobuchule ebhodini ukunciphisa ukuphazamiseka kunye nokwandisa ukuhamba kwesignali.

6.3 Uyilo oluqokelelweyo kunye nokuhanjiswa kweeleyile:

Qinisekisa uyilo lwe-stack-up ye-16-layer PCB. Qwalasela izinto ezinje ngedielectric constant, thermal conductivity, kunye neendleko zokukhetha imathiriyeli efanelekileyo. Yabela umqondiso, amandla, kunye neenqwelomoya zomhlaba ngokweemfuno zombane. Beka umhlaba kunye neendiza zamandla ngokulinganayo ukuze uqinisekise isitaki esilungeleleneyo kunye nokuphucula imfezeko yomqondiso.

6.4 Ukuhanjiswa kwendlela yoMqondiso kunye nokwenza ngcono indlela:

Kweli nyathelo, umkhondo wesiginali uhanjiswa phakathi kwamacandelo ukuqinisekisa ulawulo olululo lwe-impedance, imfezeko yesiginali, kunye nokunciphisa isignali ye-crosstalk. Lungiselela indlela yokunciphisa ubude beempawu ezibalulekileyo, uthintele ukuwela imikhondo ebuthathaka, kwaye ugcine ukwahlukana phakathi kweempawu zesantya esiphezulu kunye nesantya esisezantsi. Sebenzisa izibini ezihlukeneyo kunye neendlela ezilawulwayo ze-impedance xa zifuneka.

6.5 Ukudityaniswa kwe-Interlayer nangokubeka:

Cwangcisa ukubekwa kwe-vias yokudibanisa phakathi kweeleyile. Qinisekisa ngokufanelekileyo ngohlobo, olufana nomngxuma okanye umngxuma oyimfama, ngokusekwe kumaleko otshintsho kunye nemidibaniso yecandelo. Yandisa ngoyilo lokunciphisa ukubonakalisa umqondiso, ukungaqhubeki kokuphazamiseka, kunye nokugcina usasazo olulinganayo kwi-PCB.

6.6 Ukuqinisekiswa koyilo lokugqibela kunye nokulinganisa:

Ngaphambi kokuveliswa, ukuqinisekiswa koyilo lokugqibela kunye nokulinganisa kuyenziwa. Sebenzisa izixhobo zokulinganisa ukuhlalutya uyilo lwe-PCB lwemfezeko yomqondiso, imfezeko yamandla, indlela yokuziphatha eshushu, kunye nokwenziwayo. Qinisekisa uyilo ngokuchasene neemfuno zokuqala kwaye wenze uhlengahlengiso oluyimfuneko ukuze wenze ngcono ukusebenza kunye nokuqinisekisa ukwenziwa kwezinto.

Sebenzisana kunye nokunxibelelana nabanye abachaphazelekayo abanje ngeenjineli zombane, iinjineli zoomatshini, kunye namaqela okuvelisa kuyo yonke inkqubo yoyilo ukuqinisekisa ukuba zonke iimfuno ziyafezekiswa kwaye imiba enokubakho iyasonjululwa. Ukuphonononga rhoqo kwaye uphindaphinde uyilo ukubandakanya ingxelo kunye nophuculo.

7.Ezona Ziqhelo ezigqwesileyo kwiShishini kunye neZifundo zeMyelelo

7.1 Iimeko eziphumeleleyo zoyilo lwe-PCB ye-16:

Umzekelo 1:I-Shenzhen Capel Technology Co., Ltd. yenzelwe ngempumelelo i-PCB ene-16 yezixhobo zenethiwekhi ezikhawulezayo. Ngokuqwalasela ngononophelo imfezeko yomqondiso kunye nokuhanjiswa kwamandla, bafezekisa ukusebenza okuphezulu kwaye banciphise ukuphazamiseka kwe-electromagnetic. Isitshixo kwimpumelelo yabo luyilo olugcinwe ngokupheleleyo lwe-stack-up usebenzisa itekhnoloji yokulawula i-impedance.

Umzekelo 2:I-Shenzhen Capel Technology Co., Ltd. yenzelwe i-PCB ene-16 yesixhobo sonyango esinzima. Ngokusebenzisa indibaniselwano yokuphakama komphezulu kunye nezixhobo zokuphuma komngxuma, bazuze uyilo olubambeneyo kodwa olunamandla. Ukubekwa kwecandelo ngononophelo kunye nendlela esebenzayo iqinisekisa imfezeko yophawu olugqwesileyo kunye nokuthembeka.

7.2 Funda kwiintsilelo kwaye uphephe imigibe:

Umzekelo 1:Abanye abavelisi be-pcb badibana nemiba yengqibelelo yomqondiso kuyilo lwe-PCB ye-16 yezixhobo zonxibelelwano. Izizathu zokungaphumeleli kwakungaqwalaselwa ngokwaneleyo ulawulo lwe-impedance kunye nokungabikho kokusasazwa kwendiza yomhlaba. Isifundo esifundiweyo kukuhlalutya ngononophelo iimfuno zemfezeko yomqondiso kunye nokunyanzelisa izikhokelo zoyilo lolawulo lwe-impedance.

Umzekelo 2:Abanye abenzi pcb bajongana nemingeni yokuvelisa kunye PCB-layer yayo-16 ngenxa yoyilo nobunzima. Ukusetyenziswa ngokugqithisileyo kwee-vias ezingaboniyo kunye namalungu apakishwe ngokuxineneyo kukhokelela kubunzima bokuvelisa kunye nokudibanisa. Isifundo esifundiweyo kukwenza ulungelelwaniso phakathi koyilo oluntsokothileyo kunye nokwenziwa kobuchule bomenzi wePCB okhethiweyo.

Ukunqanda imigibe kunye nemigibe kuyilo lwe-PCB yomgangatho we-16, kubalulekile ukuba:

a. Ziqonde ngokupheleleyo iimfuno kunye nemiqobo yoyilo.

b.Ulungelelwaniso olucwangcisiweyo olwandisa imfezeko yomqondiso kunye nokuhanjiswa kwamandla. c.Sasaza ngononophelo kwaye ulungiselele amacandelo okuphucula ukusebenza kunye nokwenza lula ukwenziwa.

d.Qinisekisa iindlela ezifanelekileyo zokusebenzisa iindlela, ezinjengokulawula uthintelo kunye nokuphepha ukusetyenziswa ngokugqithisileyo kweendlela ezingaboniyo.

e. Ukusebenzisana kunye nokunxibelelana ngokufanelekileyo nabo bonke abachaphazelekayo ababandakanyekayo kwinkqubo yoyilo, kubandakanywa iinjineli zombane kunye nezomatshini kunye namaqela okuvelisa.

f.Yenza ukuqinisekiswa koyilo olubanzi kunye nokulinganisa ukuchonga kunye nokulungisa imiba enokubakho phambi kokuveliswa.

Ixesha lokuposa: Sep-26-2023

Emva