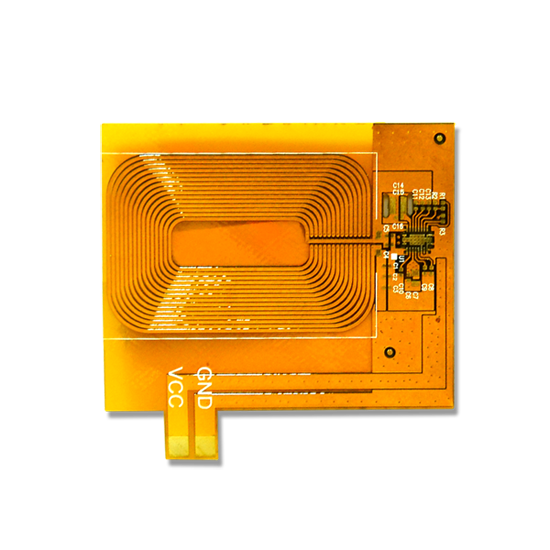

mobile phone rigid flex PCB | smartphone flex PCB ibhodi yesekethe

Zeziphi ezona ngxaki zinzima ekufuneka abathengi befowuni ye-antenna fpc iibhodi zesekethe eziguquguqukayo bazisombulule?

-UCapel uneminyaka eyi-15 yamava obugcisa obuchwephesha-

Ukuhanjiswa kwesignali ye-high-frequency: Qinisekisa ukuba ibhodi yesekethe inokudlulisa ngokufanelekileyo izibonakaliso ze-high-frequency ukuze ugweme ukuphazamiseka kunye nokuphazamiseka kwesignali.

Ikhono lokuchasana nokuphazamiseka: Qinisekisa ukuba ibhodi yesekethe ayichatshazelwa zezinye izixhobo zombane okanye ukuphazamiseka kwe-electromagnetic ngexesha lokusetyenziswa kwefowuni ephathwayo.

Ubungakanani kunye nobunzima: Ubungakanani kunye nobunzima bebhodi yeesekethe kufuneka ziqwalaselwe ukuqinisekisa ukuba zihambelana neemfuno zoyilo lwefowuni.

Ukuguquguquka kunye nokuqina: Qinisekisa ukuba ibhodi yesekethe eguquguqukayo ayinakwenzeka lula xa igobile okanye icinezelwe, kwaye inomsebenzi ozinzileyo wexesha elide.

Iindleko-Ukusebenza: Abathengi banokujamelana nemingeni efuna ukulingana phakathi kweendleko kunye nokusebenza.

Ukuvelisa: Kubandakanya ukuveliswa kwebhetshi esebenzayo kunye neenkqubo zendibano, kunye neteknoloji yokuqinisekisa umgangatho webhodi yesekethe kunye nokuhambelana.

Ukukhethwa kwezinto eziphathekayo: Ukuqwalaselwa kufuneka kunikwe izinto eziphezulu zokusebenza ezifanelekileyo kwiibhodi zeesekethe eziguquguqukayo kunye nokuqinisekisa ukuthembeka kwekhonkco lokubonelela. Ukukhuselwa kokusingqongileyo kunye nokuzinza: Qinisekisa ukuba inkqubo yokuveliswa kweebhodi zeesekethe ihlangabezana neemfuno zokusingqongileyo kunye nokuba ukulahlwa kweebhodi zeesekethe zenkunkuma kunokufikelela uzinzo.

Uvavanyo kunye nokuqinisekiswa: Kubandakanya uvavanyo olusebenzayo kunye nokuqinisekiswa kweebhodi zeesekethe eziguquguqukayo ukuqinisekisa ukuthotyelwa kwemigaqo kunye neemfuno zokusebenza.

Inkxaso yobuGcisa: Abathengi banokudinga ukubonelela ngenkxaso yobugcisa kunye nezisombululo zokujongana nemingeni kunye neengxaki kwizicelo ezisebenzayo.

Ukuhanjiswa komqondiso we-high-frequency: Xa kuyilwa ii-eriyali ze-PCB eziguquguqukayo ze-PCB, iinjineli ziya kusebenzisa imigaqo yoyilo lwakudala lwemigca yothumelo oluhamba rhoqo, njengemigca ye-microstrip. Ngokuhambelana ne-impedance yeempawu ezifanelekileyo kunye noyilo lwe-wiring, qinisekisa ukuba imiqondiso ephezulu-frequency inokuhanjiswa kwibhodi yesekethe ngokuthomalalisa okuncinci. Iinjineli ziya kusebenzisa isoftware yokulinganisa ukwenza i-domain frequency kunye nohlalutyo lwesizinda sexesha ukuqinisekisa ukusebenza kokuhanjiswa komqondiso. Ngokomzekelo, xa iinjineli ziyila iibhodi zesekethe eziguquguqukayo, zandisa ububanzi bomgca, ukuphakama kwe-dielectric, kunye neempawu eziphathekayo ngokuhlalutya ukulinganisa ukuqinisekisa ukuba ukusebenza kokuhanjiswa kwifrikhwensi ethile kuhlangabezana neemfuno.

Ubuchule bokuchasana nokuphazamiseka: Xa usombulula ingxaki yokuchasana nokuphazamiseka, iinjineli ziya kusebenzisa itekhnoloji efana noyilo lokukhusela kunye nokucubungula ucingo lomhlaba. Ngokudibanisa iileya ezifanelekileyo zokukhusela kunye neengcingo zomhlaba kwi-eriyali ye-eriyali flex PCB, ukuphazamiseka kwezinye iimpawu ze-electromagnetic kwisignali ye-eriyali yeselula kunokwehliswa ngokufanelekileyo. Iinjineli zingasebenzisa ukulinganisa kunye nokulinganisa kwangempela ukuqinisekisa ukusebenza okuchasene nokuphazamiseka kwebhodi yesiphaluka ukuqinisekisa ukuzinza nokuthembeka kwayo. Umzekelo, kwiiprojekthi zokwenyani, iinjineli zinokuqhuba iimvavanyo zokuhambelana kwe-electromagnetic kwiibhodi zesekethe eziguquguqukayo zefowuni ukuze ziqinisekise amandla azo okuchasa uphazamiseko kwindawo eyiyo.

Ubungakanani kunye nobunzima: Xa uyila i-PCB eguquguqukayo ye-eriyali yefowuni ephathwayo, iinjineli kufuneka zithathele ingqalelo iimfuno zoyilo lwefowuni ephathwayo kwaye ziqwalasele ubungakanani kunye nezithintelo zobunzima. Ngokusebenzisa ubuchwepheshe obufana ne-substrates eguquguqukayo kunye ne-wiring emihle, ubukhulu kunye nobunzima beebhodi zeesekethe zinokuncitshiswa ngokufanelekileyo. Umzekelo, iinjineli zinokukhetha i-substrate eguquguqukayo enobunzima obuncinci kwaye ibeke ngokulula iisekethe ngokweemfuno zoyilo oluthile lwee-eriyali zeselfowuni ukunciphisa ubungakanani kunye nobunzima bebhodi yesekethe.

Ukuguquguquka kunye nokuqina: Ukuphucula ukuguquguquka kunye nokuqina kweebhodi zeesekethe eziguquguqukayo, iinjineli ziya kusebenzisa i-substrates eziguquguqukayo eziphambili kunye neenkqubo zokudibanisa. Umzekelo, khetha izinto eziguquguqukayo ezineempawu ezintle zokugoba kwaye usebenzise uyilo olufanelekileyo lwesinxibelelanisi ukuqinisekisa ukuba ibhodi yesekethe ayonakaliswa lula phantsi kokugoba rhoqo okanye ukukhutshwa. Iinjineli zinokuvavanya ukuba bhetyebhetye kunye nokuqina kwebhodi ngovavanyo lovavanyo kunye nokuqinisekisa ukuthembeka.

Ukusebenza kweendleko: Iinjineli zandisa uyilo kunye nokukhethwa kwezinto eziphathekayo ukulinganisa iindleko kunye nokusebenza. Ngokomzekelo, khetha ii-substrates ezinentsebenzo egqwesileyo kunye neendleko ezilinganiselweyo, ukunciphisa ukusetyenziswa kwezinto eziphathekayo ngokuyila i-wiring ephuculweyo, kunye nokwamkela iinkqubo ezisebenzayo zokuvelisa kunye nezixhobo ezizenzekelayo zokuphucula ukusebenza kakuhle kwemveliso, ngokunciphisa iindleko ngelixa uqinisekisa ukusebenza. Kwiiprojekthi zangempela, iinjineli zingasebenzisa izixhobo zokuhlalutya iindleko, ezifana ne-DFM (i-Design for Manufacturing) software, ukuvavanya ukuphumelela kweendleko zezisombululo zoyilo kunye nokubonelela abathengi ngesisombululo esona sisombululo.

Ukuvelisa: Iinjineli kufuneka zenze ukuveliswa kobuninzi obufanelekileyo kunye neenkqubo zokuhlanganisa ukuqinisekisa umgangatho kunye nokuhambelana kweebhodi zeesekethe. Ngokomzekelo, ngexesha lenkqubo yokuvelisa, iinjineli zingasebenzisa i-SMT (i-Surface Mount Technology) kunye nezixhobo zokuhlanganisana ezizenzekelayo ukuqinisekisa ukuveliswa kwebhodi yesekethe ephezulu. Iinjineli zinokuthi ziyile iinkqubo zovavanyo ezihambelanayo kunye nokuhlola ukujonga ngokufanelekileyo umgangatho weebhodi zeesekethe kunye nokuqinisekisa ukuba ziyahlangabezana neenkcukacha.

Ukukhetha izinto eziphathekayo: Iinjineli kufuneka zikhethe izinto eziphezulu zokusebenza ezifanelekileyo kwiibhodi zesekethe ze-antenna eziguquguqukayo zefowuni kunye nokuqinisekisa ukuthembeka kwekhonkco lokubonelela. Ngokomzekelo, xa ukhetha izinto eziphathekayo, iinjineli zinokuqwalasela izinto ezifana ne-dielectric constant, ilahleko ye-dielectric, kunye neempawu zokugoba ze-substrates eziguquguqukayo, kwaye zixoxisane nabathengisi ukuqinisekisa ukufumaneka kunye nokuzinza kwezinto. Iinjineli zinokuqhuba uvavanyo lwezinto kunye nokuthelekisa ukukhetha esona sisombululo sifanelekileyo.

Ukukhuselwa kokusingqongileyo kunye nozinzo: Iinjineli ziya kwamkela iinkqubo zokwenza izinto ezihambelana nokusingqongileyo kunye nokukhethwa kwezinto ezizinzileyo ukuze kuqinisekiswe ukuba inkqubo yokuvelisa i-FPC antenna flex PCB ihlangabezana neemfuno zokusingqongileyo. Ngokomzekelo, qwalasela ukusebenza kokusingqongileyo kwezixhobo ngexesha loyilo, khetha izinto ezihambelana nemiyalelo ye-RoHS, kunye noyilo lweenkqubo zokuvelisa ezinokuphinda zisetyenziswe. Iinjineli zinokusebenza kunye nababoneleli ukuseka iinkqubo zekhonkco lokubonelela ezihlangabezana neenjongo zozinzo.

Uvavanyo kunye nokuqinisekiswa: Iinjineli ziya kuqhuba iimvavanyo ezahlukeneyo kunye nokuqinisekiswa kwi-eriyali yefowuni ye-Fpc ukuqinisekisa ukuba bayahlangabezana neenkcukacha kunye neemfuno zokusebenza. Umzekelo, izixhobo zovavanyo ezikwi-high-frequency test zisetyenziselwa uvavanyo lwentsebenzo yokuhanjiswa komqondiso, kwaye izixhobo zokuvavanya ukuhambelana kwe-electromagnetic zisetyenziselwa ukuvavanywa kokusebenza okuchasene nokuphazamiseka ukuqinisekisa ukusebenza kwebhodi yesekethe. Iinjineli zinokusebenzisa izixhobo zokuvavanya ukuthembeka ukuqinisekisa ukuqina kunye nokuzinza kweebhodi zesekethe.

Inkxaso yobugcisa: Iinjineli ziya kubonelela ngenkxaso yobuchwephesha kunye nezisombululo xa abathengi bejongene nemingeni yesicelo esisebenzayo. Ngokomzekelo, ukuba umthengi uhlangabezana nengxaki yokusebenza kwisicelo sebhodi yesekethe ye-antenna yefowuni eguquguqukayo, injineli inokuqhuba uhlalutyo olunzulu lwesizathu sengxaki, icebo lokuphucula, kwaye inike inkxaso kunye noncedo olusebenzayo. izicelo. Iinjineli zinokubonelela abathengi ngezisombululo ezijolise kubo ngeendlela ezahlukeneyo, ezinje ngenkxaso yevidiyo ekude, isikhokelo sobugcisa kwindawo, njl.

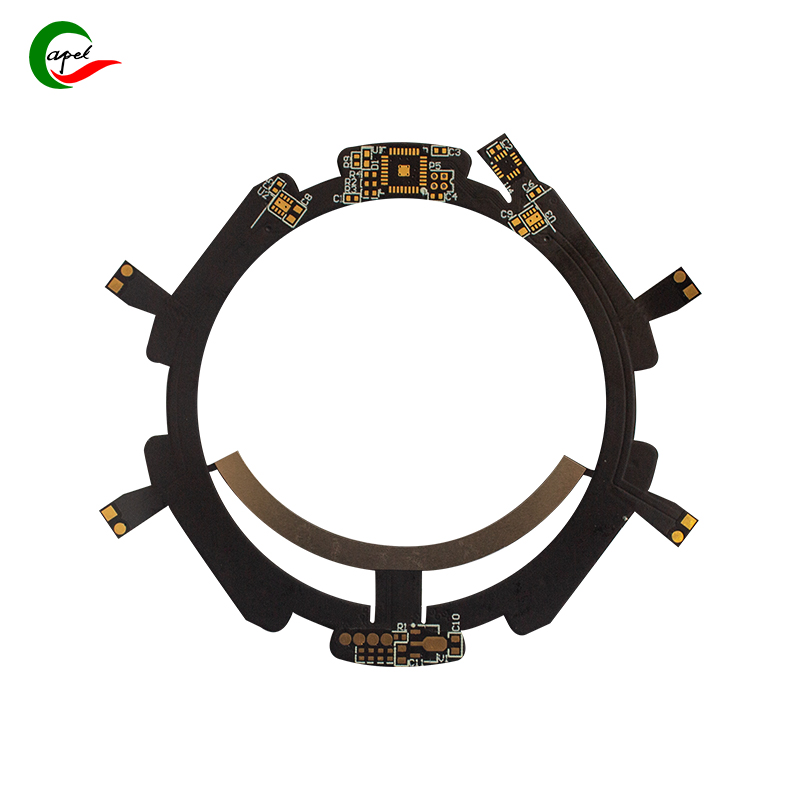

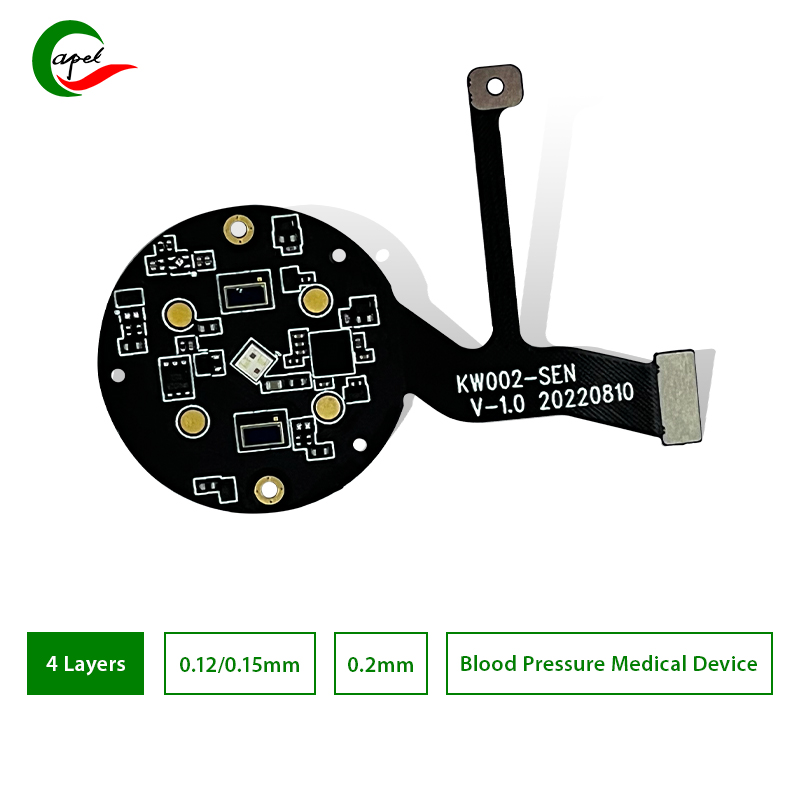

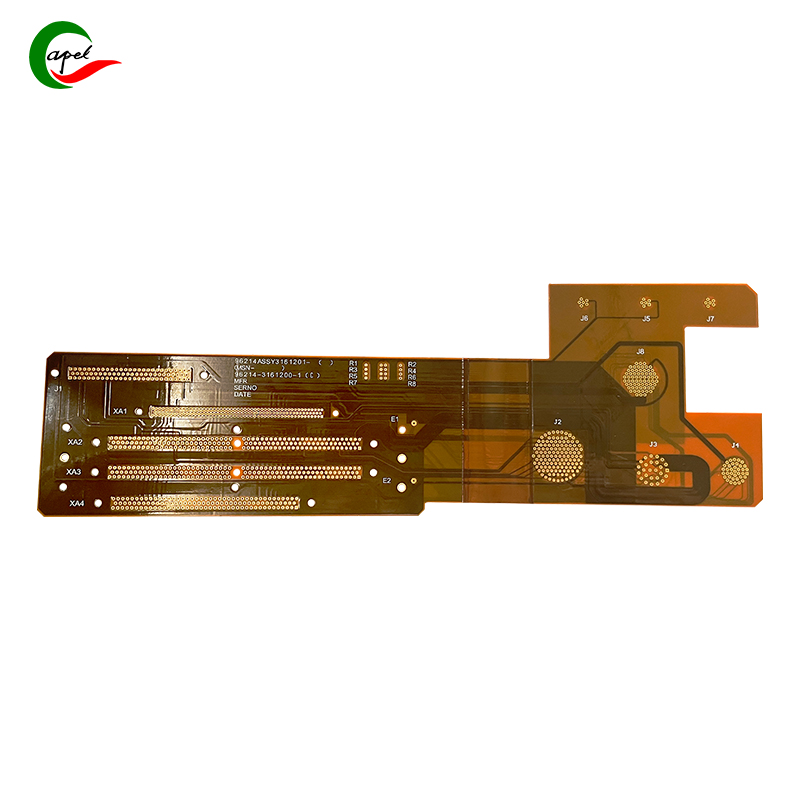

I-Capel Flexible PCB kunye neRigid-Flex PCB yeNkqubo yokukwazi

| Udidi | Inkqubo Yamandla | Udidi | Inkqubo Yamandla |

| Uhlobo lweMveliso | Umaleko omnye FPC / Umaleko kabini FPC Ii-Multi-layer FPC / Aluminium PCBs I-Rigid-Flex PCB | ILayers Number | 1-30FPC 2-32umaleko Rigid-FlexPCB1-60iileya ezingqongqo PCB HDIIibhodi |

| Ubungakanani obukhulu bokuVeliswa | Umaleko omnye FPC 4000mm Imigangatho ephindwe kabini FPC 1200mm Imigangatho emininzi yeFPC 750mm I-Rigid-Flex PCB 750mm | I-Insulating Layer Ukutyeba | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um/150um |

| Ukutyeba kweBhodi | I-FPC 0.06mm - 0.4mm I-Rigid-Flex PCB 0.25 - 6.0mm | Ukunyamezela kwe-PTH Ubungakanani | ±0.075mm |

| Umphezulu Gqiba | Ukuntywiliselwa kweGolide / ukuntywiliselwa ISilivere/uKutyalwa ngeGolide/uKutyathwa kweTin/OSP | Stiffener | FR4 / PI / PET / SUS / PSA / Alu |

| Ubungakanani beSemicircle Orifice | Ubuncinci 0.4mm | Min Line Isithuba/ ububanzi | 0.045mm/0.045mm |

| Ukutyeba Ukunyamezela | ±0.03mm | Impedance | 50Ω-120Ω |

| Ukutyeba kweFoil yobhedu | 9um/12um/18um/35um/70um/100um | Impedance Iyalawulwa Ukunyamezelana | ±10% |

| Ukunyamezela kwe-NPTH Ubungakanani | ±0.05mm | Ububanzi beMin Flush | 0.80mm |

| Min Via Hole | 0.1mm | Phumeza Umgangatho | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

I-Capel yenza ibhodi yeSekethe echanekileyo echanekileyo echanekileyo / eFlexible PCB / HDI PCB kunye neminyaka eyi-15 yamava ngobungcali bethu.

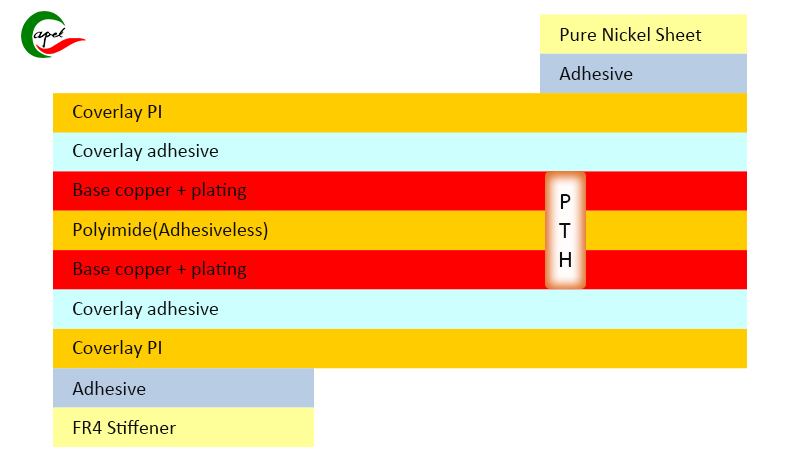

2 Layer Flexible PCB Boards Stackup

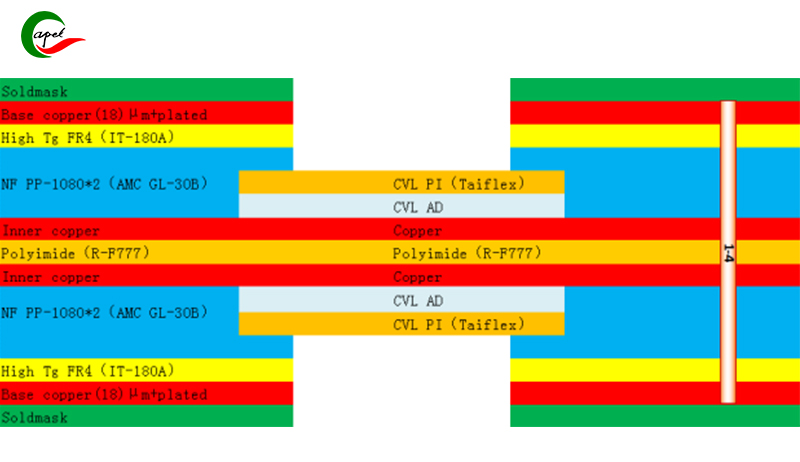

4 Layer Rigid-Flex PCB Stackup

8 umaleko HDI PCBs

Uvavanyo kunye nezixhobo zokuHlola

Uvavanyo lweMicroscope

Ukuhlolwa kwe-AOI

Uvavanyo lwe-2D

Uvavanyo lwe-Impedans

Uvavanyo lweRoHS

Flying Probe

Umvavanyi othe tye

Ukugoba iTeste

I-Capel ibonelela abathengi ngeNkonzo ye-PCB elungiselelwe iminyaka eyi-15 yamava

- Ukuba ngabanini 3iifektri zeFlexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Iinjineli zibonelela ngenkxaso yobugcisa kwiintengiso zangaphambili kunye nasemva kokuthengisa kwi-Intanethi;

- 1-30FPC,2-32iileya eziRigid-FlexPCB,1-60iileya ezingqongqo PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCB, Single-sided PCB, Iibhodi zeSekethe ezinamacala amabini, iibhodi eziHollow, Rogers PCB, rf PCB, Metal Core PCB, Iibhodi zeNkqubo eziZodwa, iCeramic PCB, iAluminium PCB , I-SMT & PTH Assembly, PCB Prototype Service.

- NikaIiyure ezingama-24Inkonzo ye-PCB yePrototyping, iiBatshi ezincinci zeebhodi zesekethe ziya kusiwa ngaphakathi5-7 iintsuku, Ukuveliswa kweMisa yeebhodi zePCB ziya kuhanjiswaIiveki ezi-2-3;

- Imizi-mveliso esiyinika inkonzo:Izixhobo zonyango, i-IOT, iTUT, i-UAV, i-Aviation, i-Automotive, i-Telecommunications, i-Electronics yabathengi, i-Military, i-Aerospace, i-Industrial Control, i-Artificial Intelligence, i-EV, njl.

- Isakhono sethu seMveliso:

I-FPC kunye neRigid-Flex PCBs umthamo wokuvelisa unokufikelela ngaphezu150000sqmngenyanga,

Umthamo wemveliso we-PCB unokufikelela80000sqmngenyanga,

PCB Ukuhlanganisa umthamo kwi150,000,000amacandelo ngenyanga.

- Amaqela ethu eenjineli kunye nabaphandi bazinikele ekufezekiseni iimfuno zakho ngokuchanekileyo nangobuchule.